Machine video

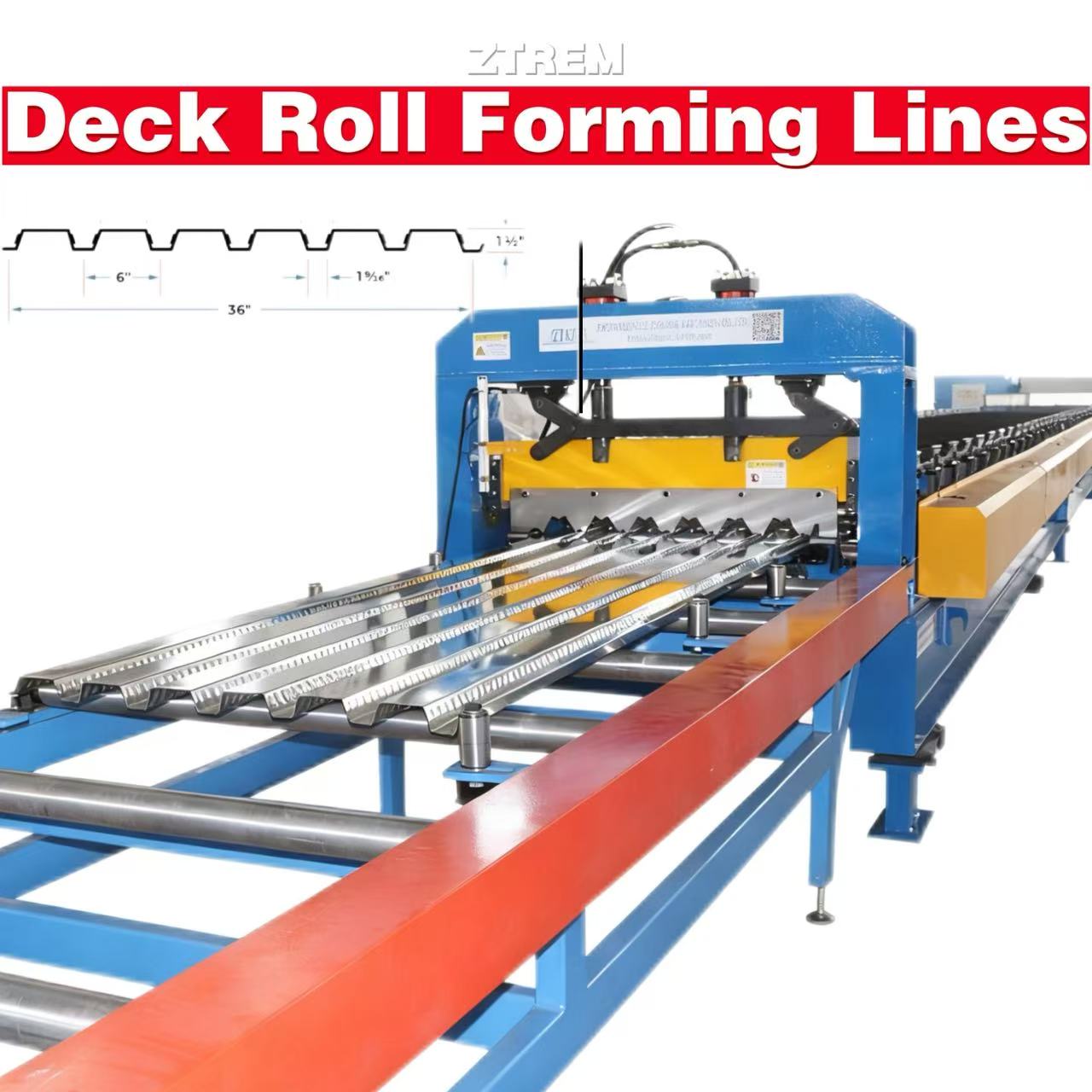

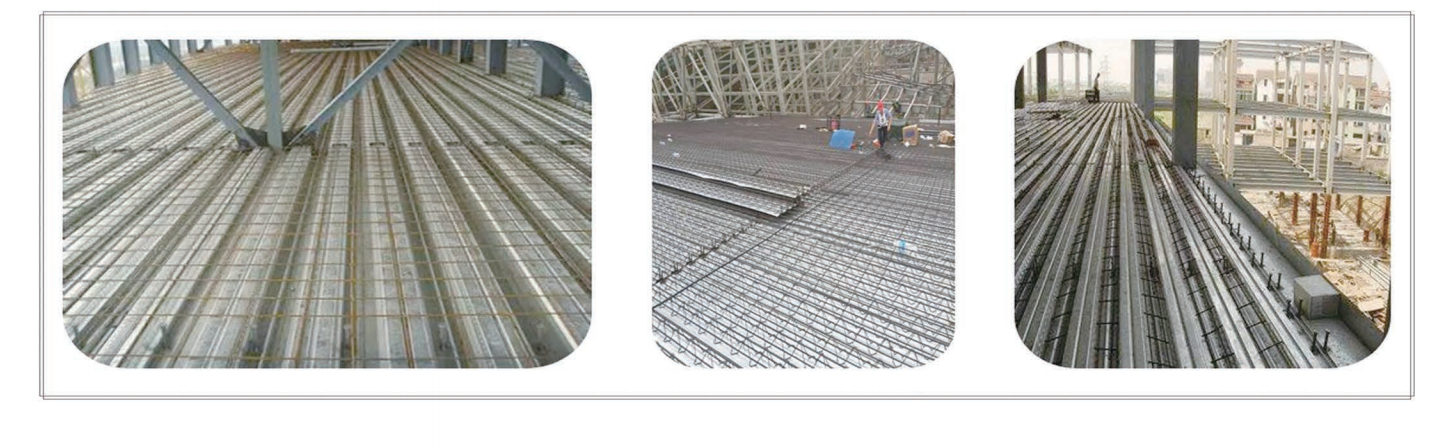

Deck Roll Forming Lines are built for flexibility and high quality

The advent of the Deck Roll Forming Lines has completely transformed the industry’s production landscape, becoming a “production powerhouse” for steel structure enterprises and construction engineering companies.

Core advantage: Using technology to solve production problems

• Ultra high efficiency, helping to speed up projects

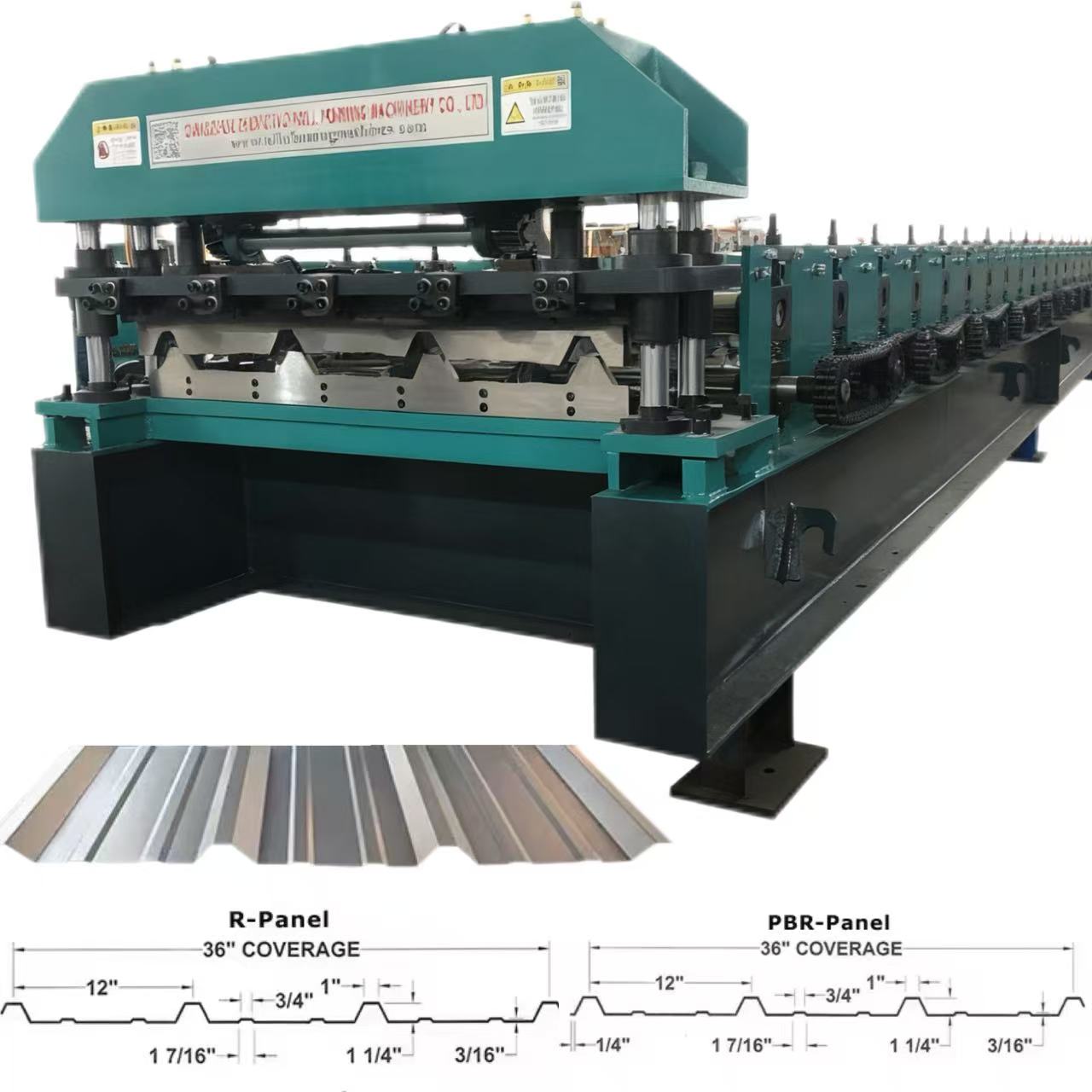

• Precise molding, strict control of product quality

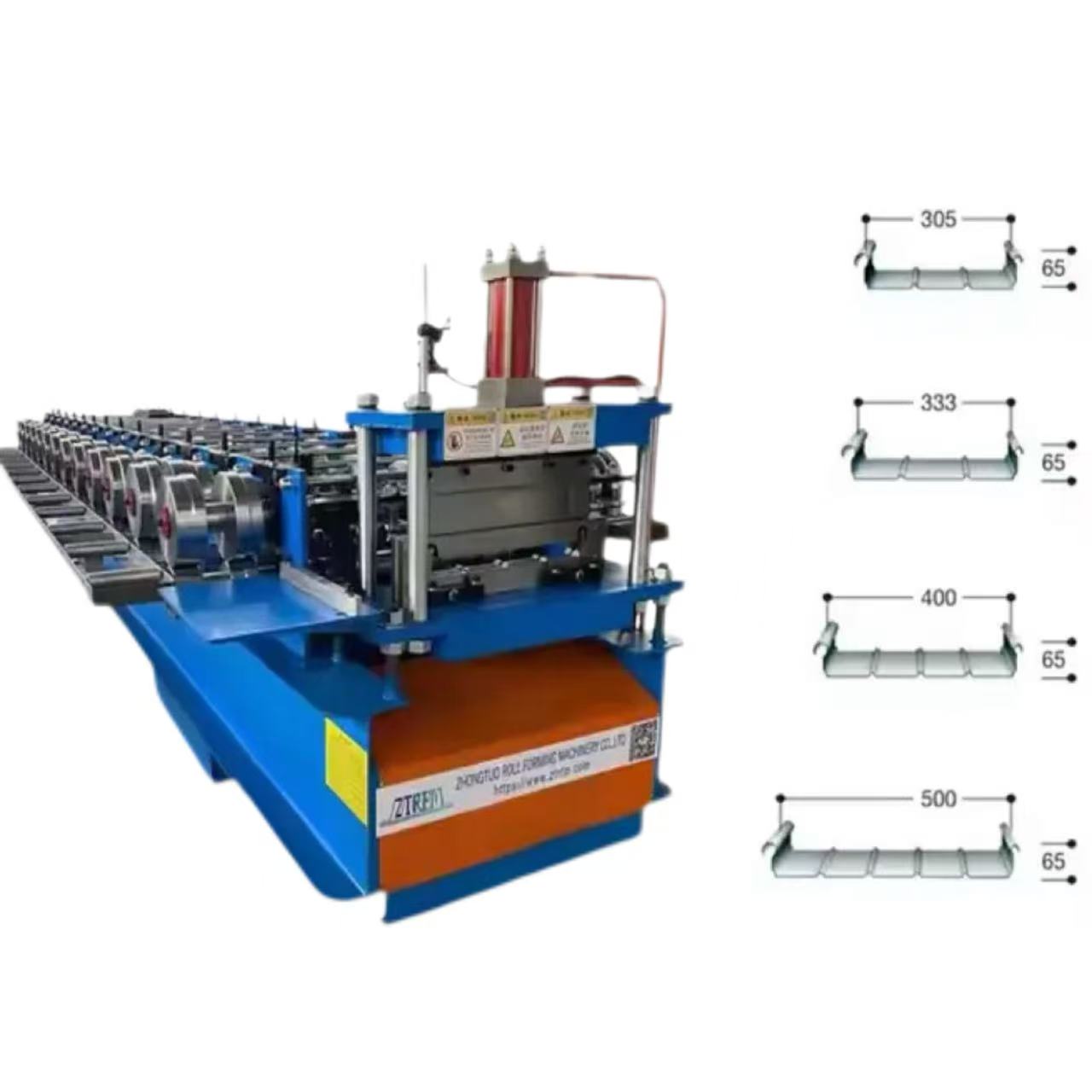

• Flexible adaptation to meet diverse needs

• Intelligent energy saving, reducing operating costs

Joining Hands for Win win: Embarking on a New Chapter of Intelligent Building Manufacturing Together

This Deck Roll Forming Lines has served over 200 enterprises nationwide, and has won wide market recognition with its core advantages of “efficiency, precision, intelligence, and energy conservation”.

If you are troubled by low production efficiency, unstable quality, and high costs of floor decks, you may choose this intelligent floor deck machine – it is not only a device, but also a strategic partner for you to enhance competitiveness and seize market opportunities!

Product Attributes

|

1.Formed Material

|

GI

|

Thickness:0.7-1.2mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Capacity:12T With loading car

|

||

|

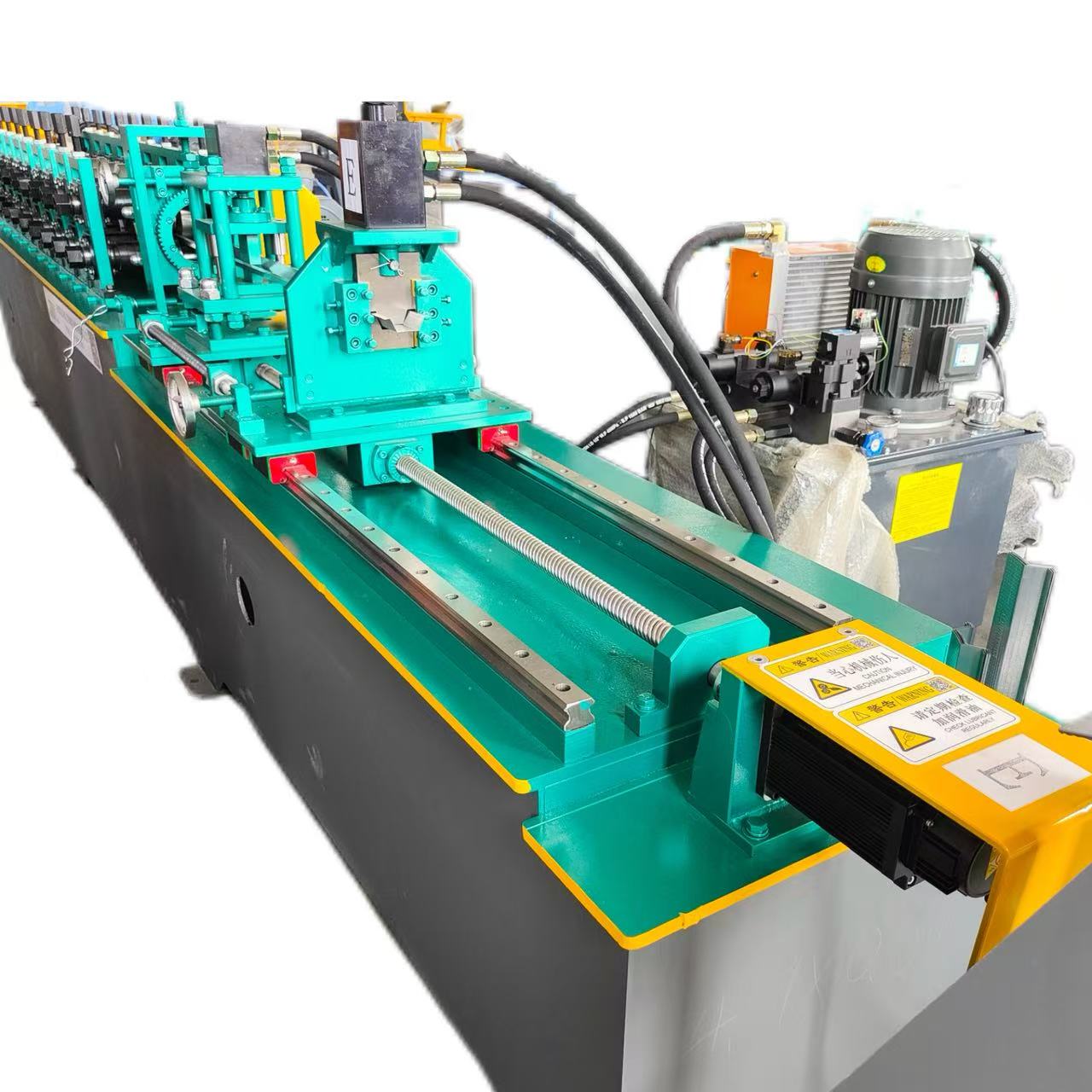

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

Diameter of shaft

|

95mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Double chain transmission

|

|||

|

Dimension(L*W*H)

|

About 14500*1700*1600(customize)

|

|||

|

Weight

|

About 13T

|

|||

|

4.Cutter

|

Hydraulic

|

Cutting blade material:Cr12 with quenched treatment

|

||

|

5.Power

|

Motor Power

|

15kw*2 sets

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

220V 50Hz 3Phase

|

As requirement

|

||

|

7.Control system

|

PLC and touch screen

|

Delta brand

|

||

|

Low pressure apparatus

|

Schneider

|

|||

|

Language

|

Chinese and English

|

|||

|

8.Forming Speed

|

8-15m/min

|

The speed is adjustable

|

||