Guardrail safety barrierroll forming equipment

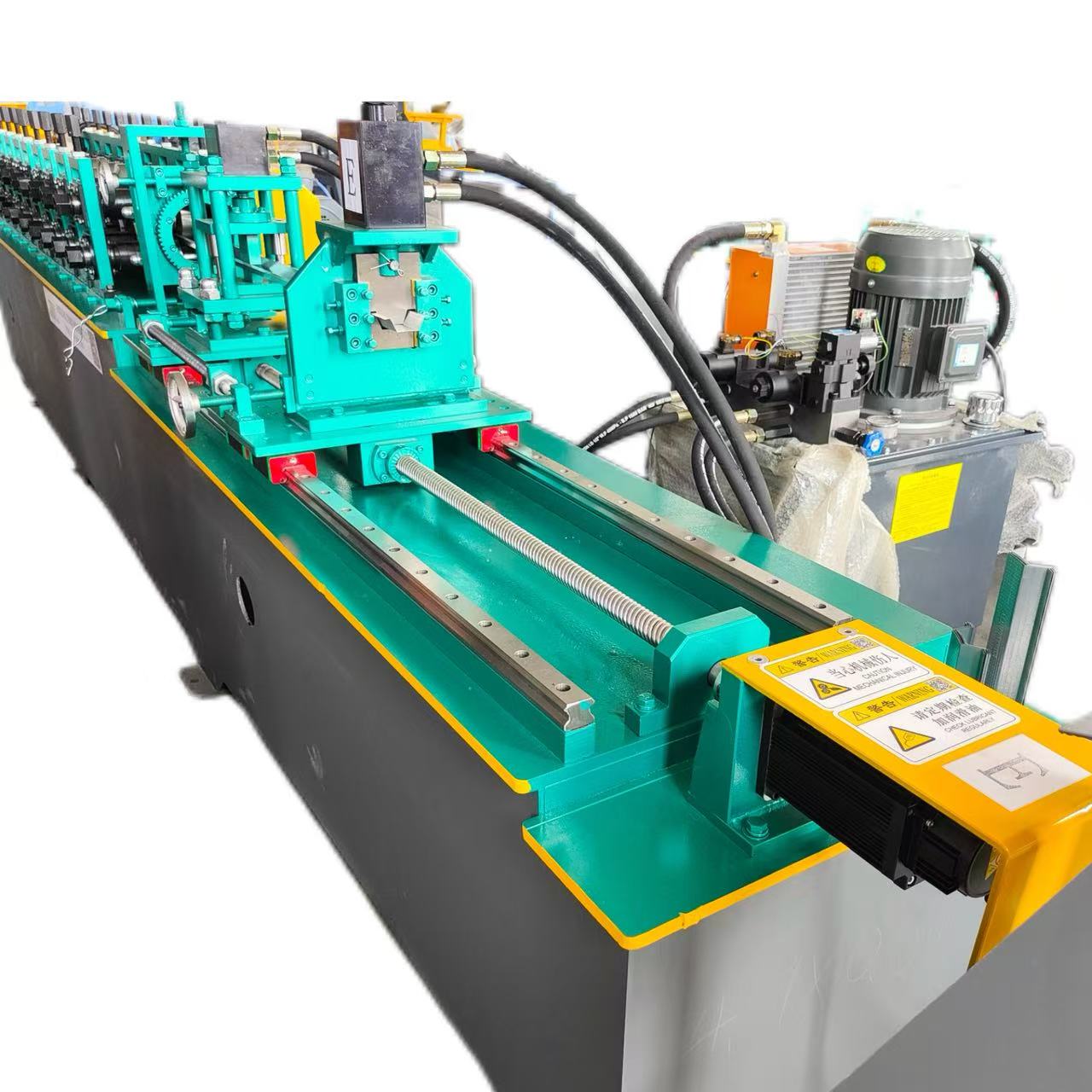

Equipment definition and core function

Guardrail safety barrierroll forming equipment(also known as highway guardrail) is a protective facility set up on both sides of the highway, in the central divider, and in dangerous sections. Its core function is to guide the trajectory of vehicles, buffer collision impact, prevent vehicles from rushing out of the road or entering the opposite lane, and enhance road recognition through eye-catching warning colors, fundamentally reducing traffic accident casualties and property losses. It is a core component of the highway traffic safety system.

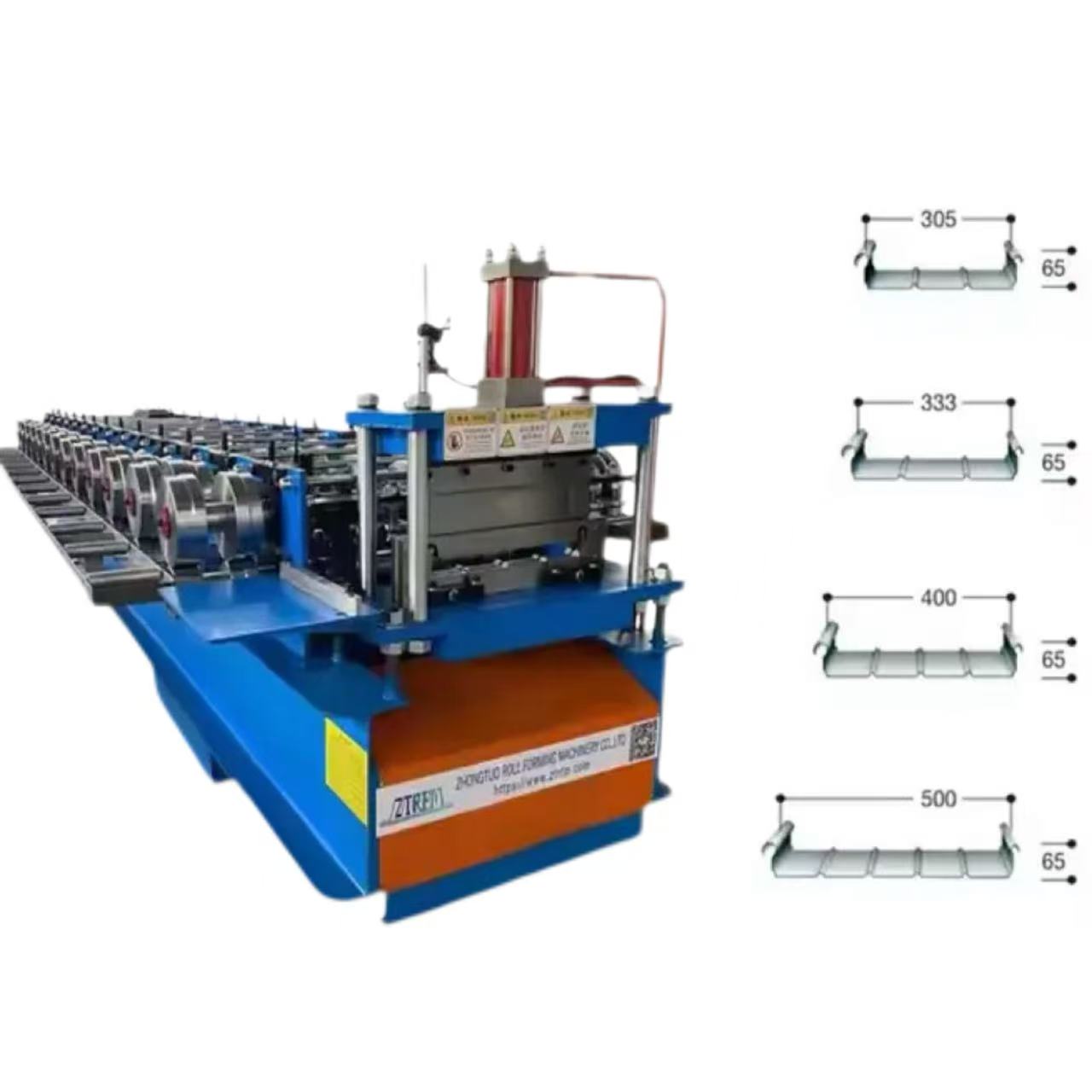

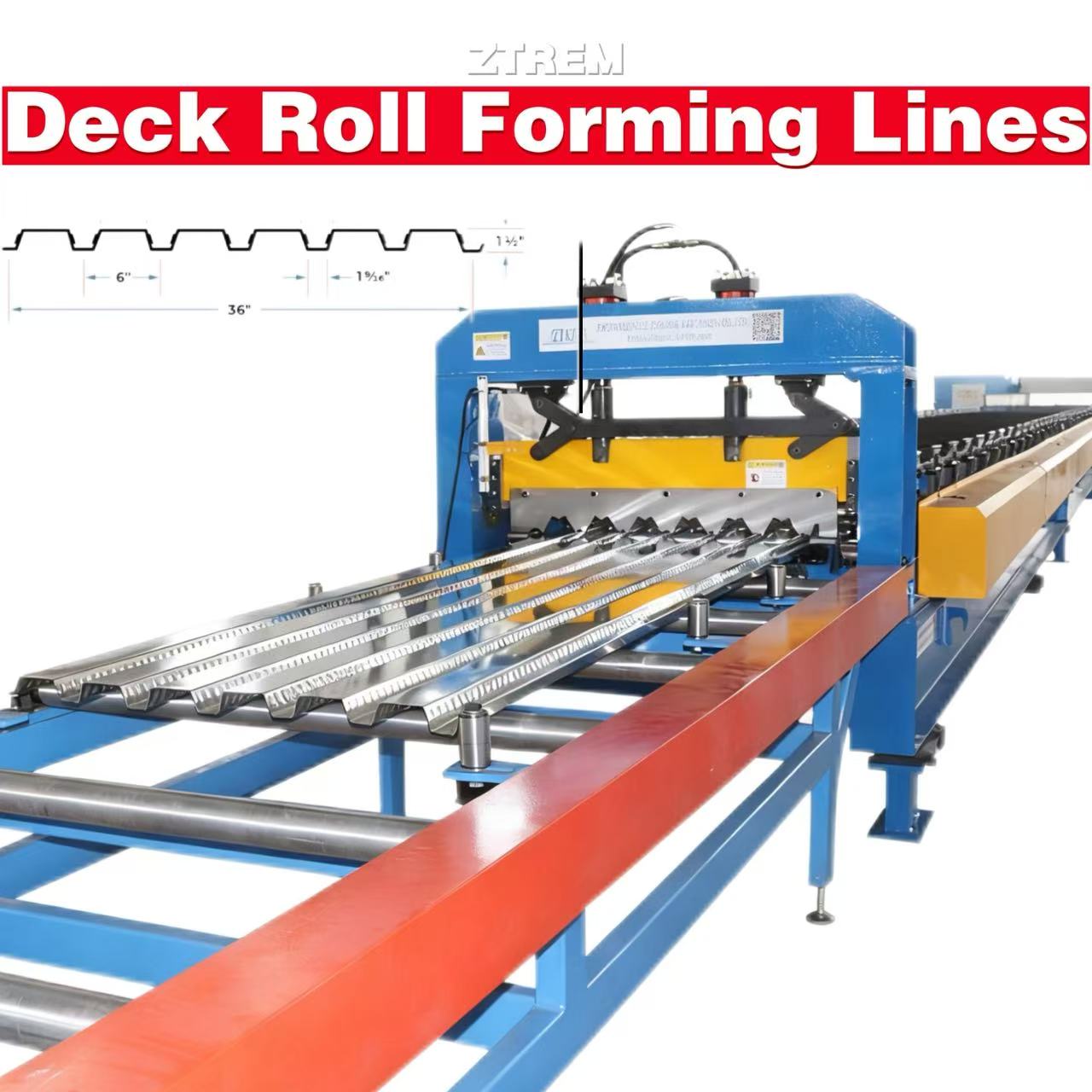

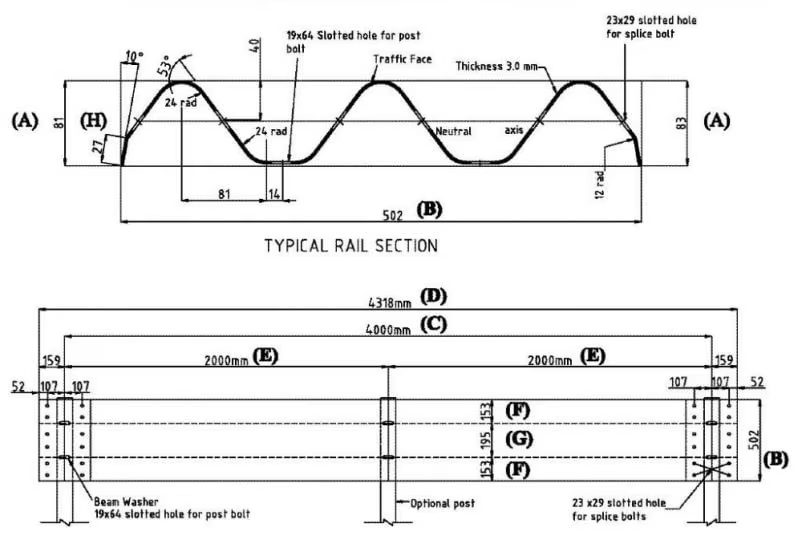

Profile drawing:

Product Attributes:

| Suitable material | Q235 color steel coils;0.3-0.7mm;1220&1450mm coil width |

| Forming speed | About 20- 25m/min |

| Power Requirement | Main motor power: 55 Kw(Depend on final design) |

| Hydraulic station power: 5Kw(Depend on final design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, with heat treatment.Roller grinder milling. |

| Shaft diameter | 82mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 11500KGS |

| Machine’s size | About 18m×2.2m× 1.5m (Depend on final design) |

| Shipping | 1x40GP container can load one machine |

According to the differences in material, structure, and protective performance, guardrail safety barrierroll forming equipmentis mainly divided into three categories, adapted to the needs of different road sections:

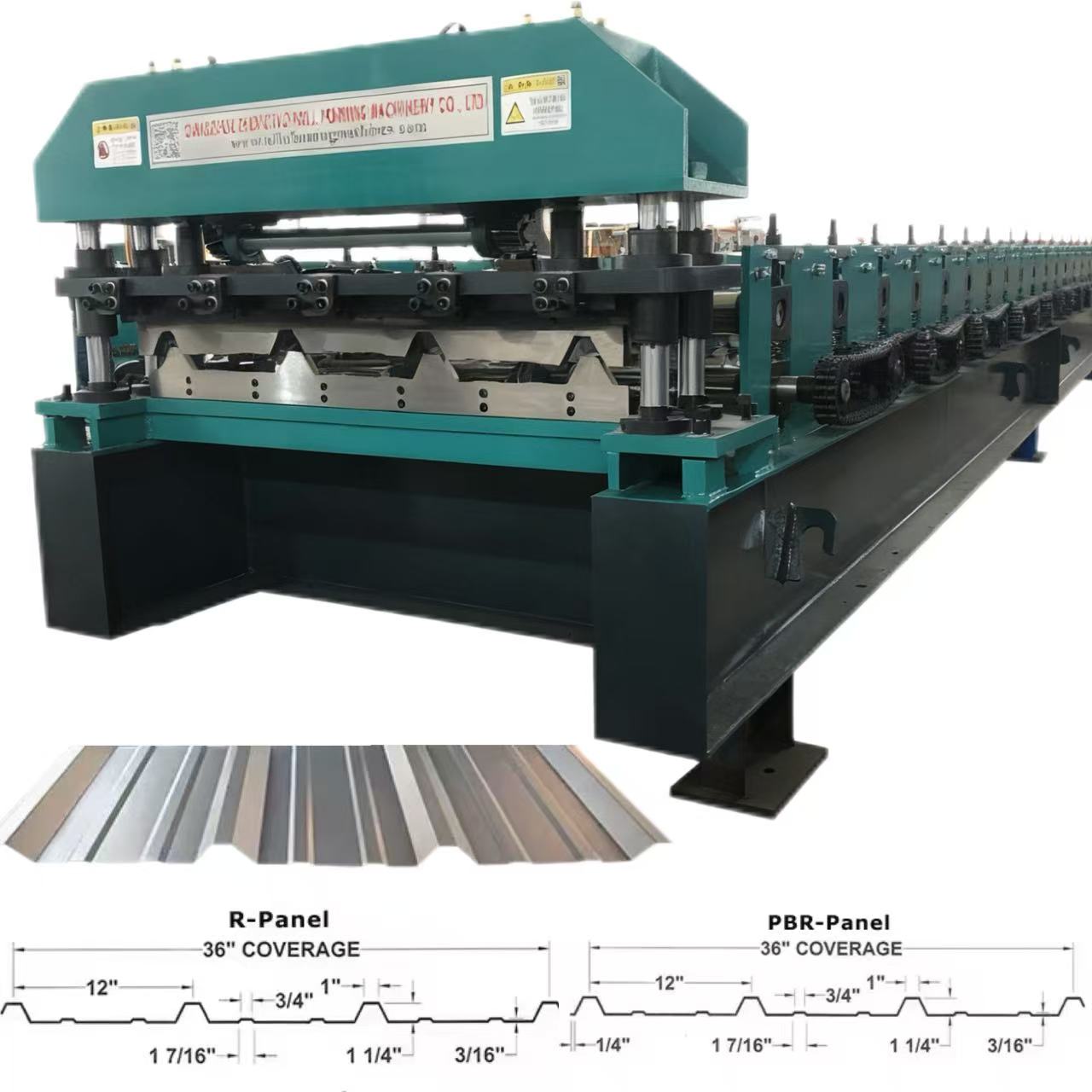

1. Corrugated beam steel guardrail (most widely used)

• Core features: Continuous waveform steel plate splicing, rigid elastic combination, waveform deformation energy absorption during collision, preventing vehicle rebound.

• Material specifications: Q235/Q345 low-carbon steel plate, standard type 4320mm × 310mm × 85mm, reinforced type 4320mm × 506mm × 85mm, plate thickness 2.5-4.0mm.

• Applicable scenarios: conventional sections such as highways, ramps, etc., suitable for speeds of 60-120km/h.

2. Concrete guardrail (representative of rigid protection)

• Core features: C30+concrete pouring, high rigidity, strong impact resistance, preventing vehicles from crossing the boundary.

• Structural form: F-type and single slope type are common, with a height of 800-1200mm, a bottom width of 500-800mm, and some parts including steel reinforcement skeleton.

• Applicable scenarios: High risk areas such as median strips and cliff sections, suitable for speeds of 80-120km/h.

3. Cable guardrail (special case of flexible protection)

• Core features: 3-5 high-strength galvanized steel cables (Φ 16-20mm) are connected to columns and brackets, and the steel cables stretch and absorb energy during collisions, reducing vehicle damage.

• Performance indicators: Steel cable breaking force ≥ 195kN, Q235 steel column, soil foundation burial depth ≥ 1.5m.

• Applicable scenarios: Long straight lines in mountainous areas, highways in tourist areas, suitable for speeds of 60-100km/h, balancing protection and landscape.