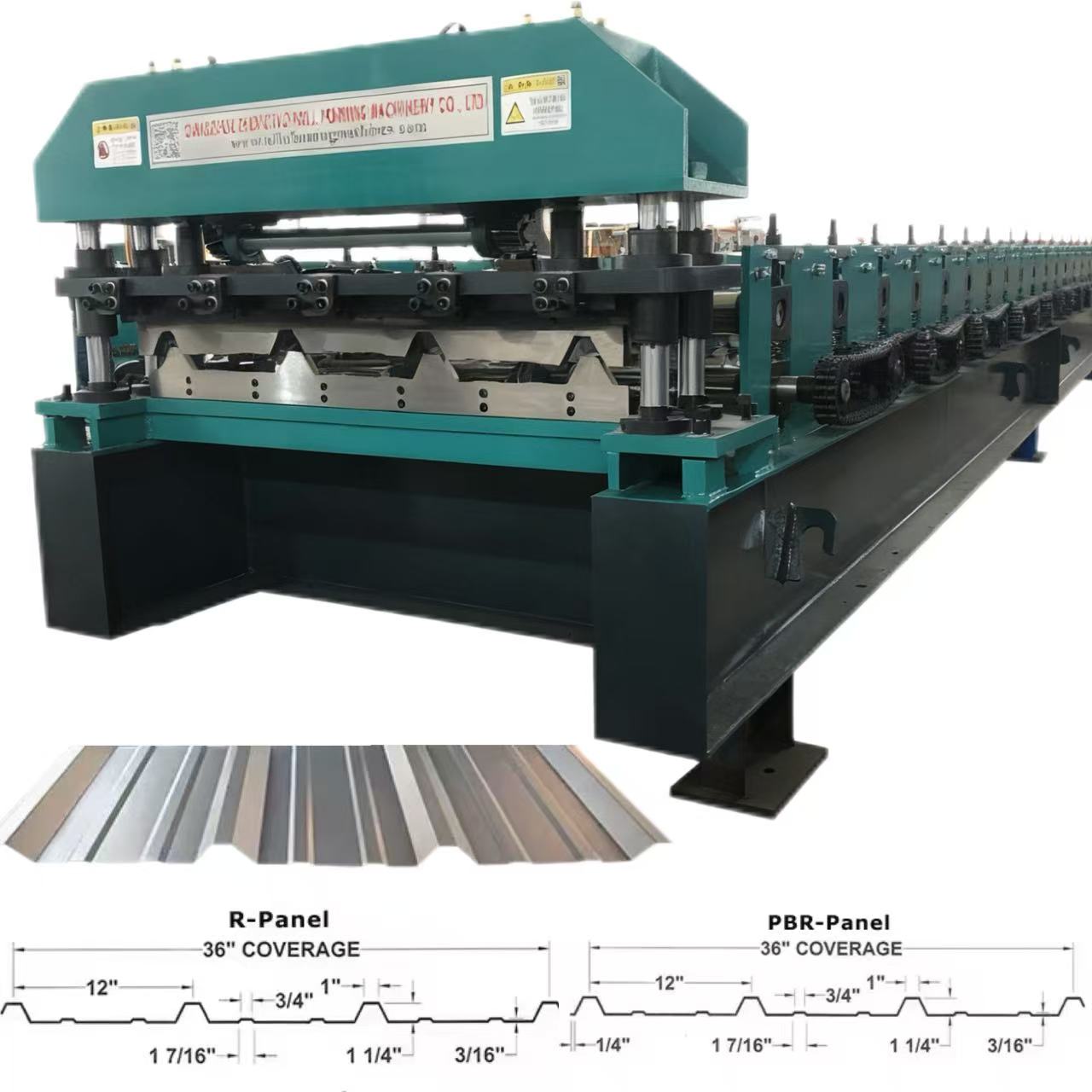

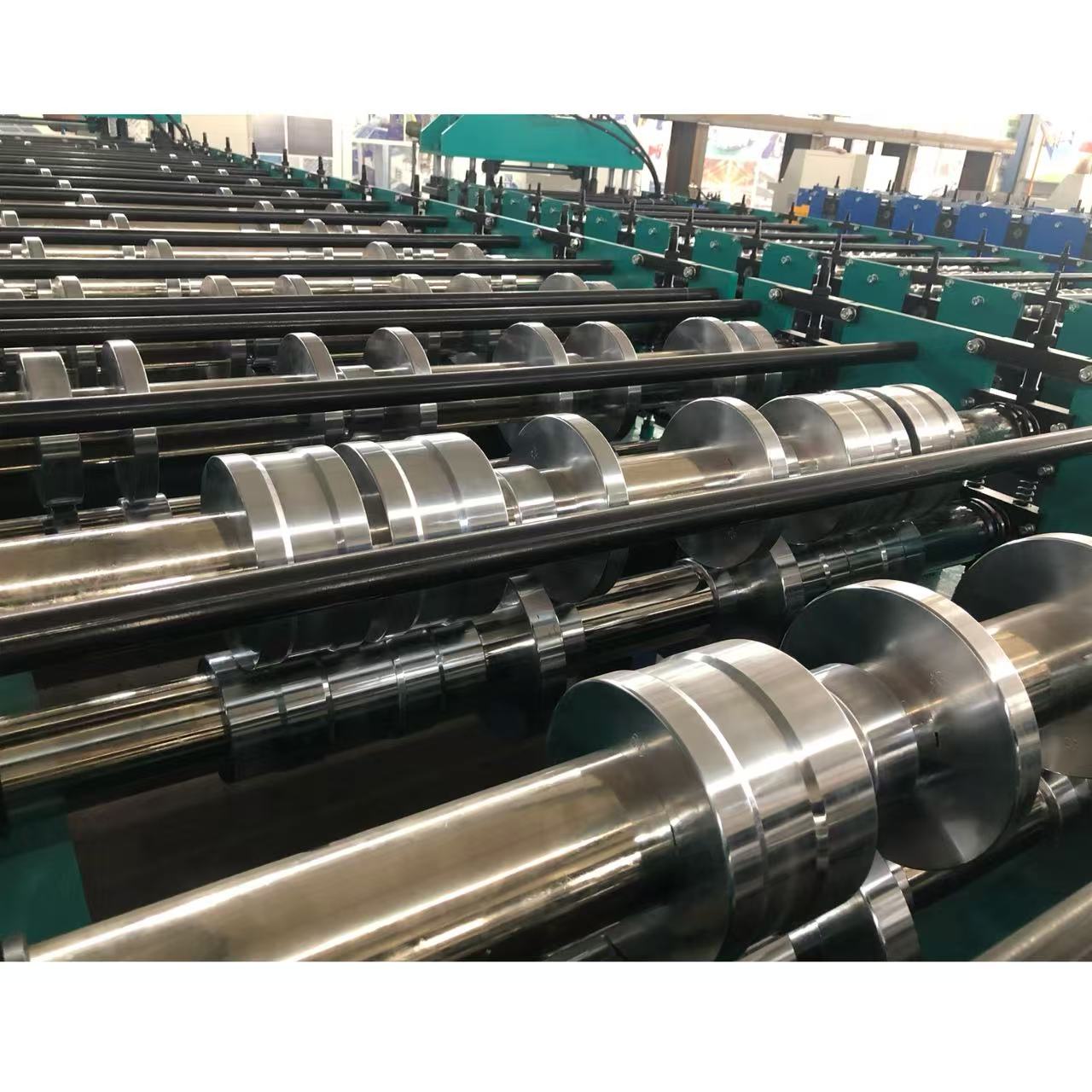

PBR R panel roll forming equipment with pre-cutter

Profile drawing that PBR R panel roll forming equipment makes:

The PBR R panel roll forming equipment is primarily used to process metal sheets such as color-coated steel plates and galvanized steel plates through continuous rolling and cutting processes to produce trapezoidal roof tiles. The tiles produced by this equipment are widely used in roof systems for industrial buildings and civil residences due to their stable load-bearing capacity, easy installation, and excellent waterproofing performance.

The features of this machine

1.One machine can produce for R panel and PBR panel(feeding different width coil)

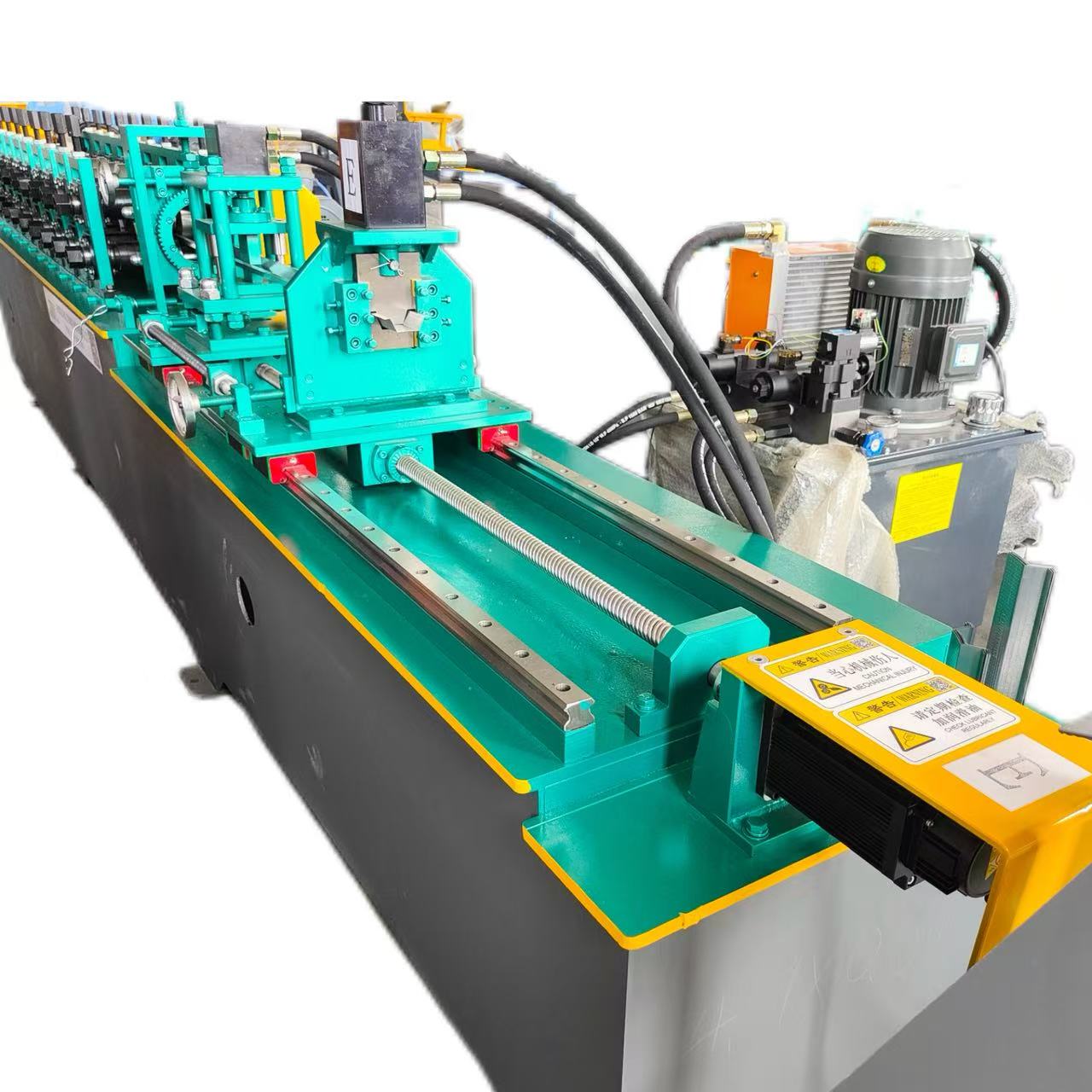

2. pre cutting design-to make full use of the left material inside the machine.

3.Our own Updated design-Easy installation and operation.

4.Full automatic-save labors.

5.Rollers with bearing inside which can eliminate linear velocity inconsistency,it can make the final product perfect.

6.High quality and high accuary for long time using.

Core application scenarios

• Industrial and Warehouse Buildings:

Such as steel structure factories, logistics warehouses, large workshops, etc., which require extensive roof coverage with waterproofing and wind resistance performance.

• Civil and Public Buildings:

Such as rural self-built houses, villas, schools, hospitals, etc., where there is a demand for roof aesthetics and durability.

• Special Environment Architecture:

Such as coastal area buildings (require corrosion resistance, suitable for galvanized/aluminum alloy panels), and rainy area buildings (require high waterproofing, suitable for concealed fastener trapezoidal tiles).

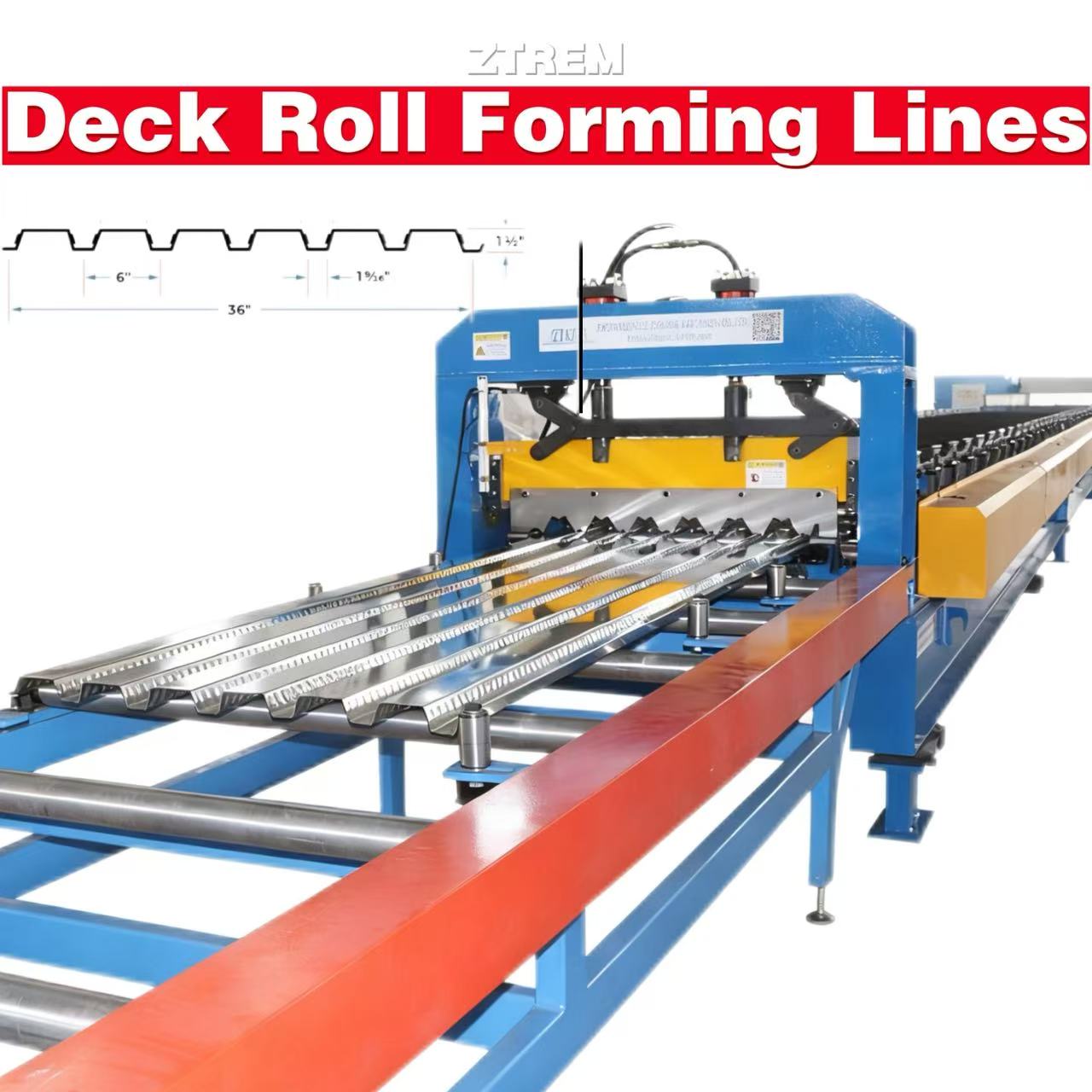

Product Attributes

|

1.Formed Material

|

Material Thickness

|

24-26 gauge |

||

|

2.Main body

|

Roller station

|

19 rows

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 20mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

3.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

4.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

5.Voltage

|

480V/440v/600v/240v 60Hz 3Phase

|

As your requirement

|

||

|

6.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

7.Forming Speed

|

0-15m/min

|

45ft/min

|

||