Machine video

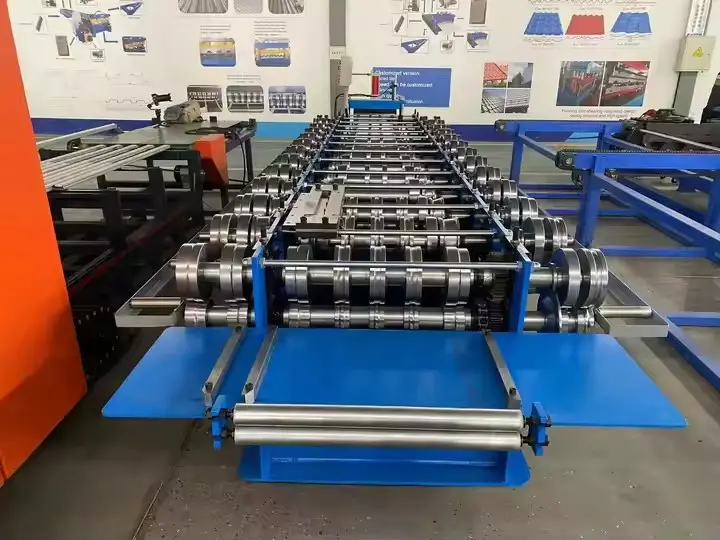

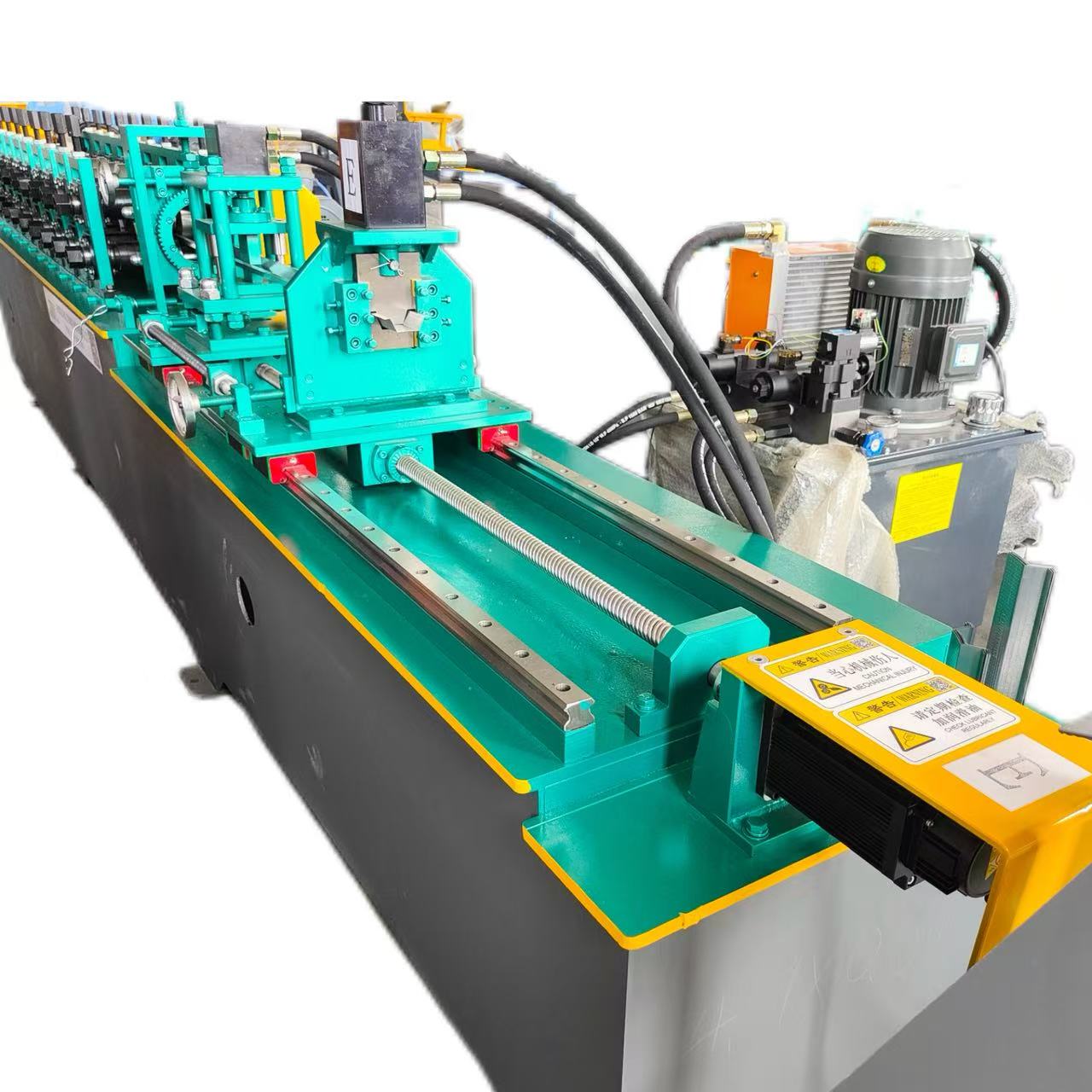

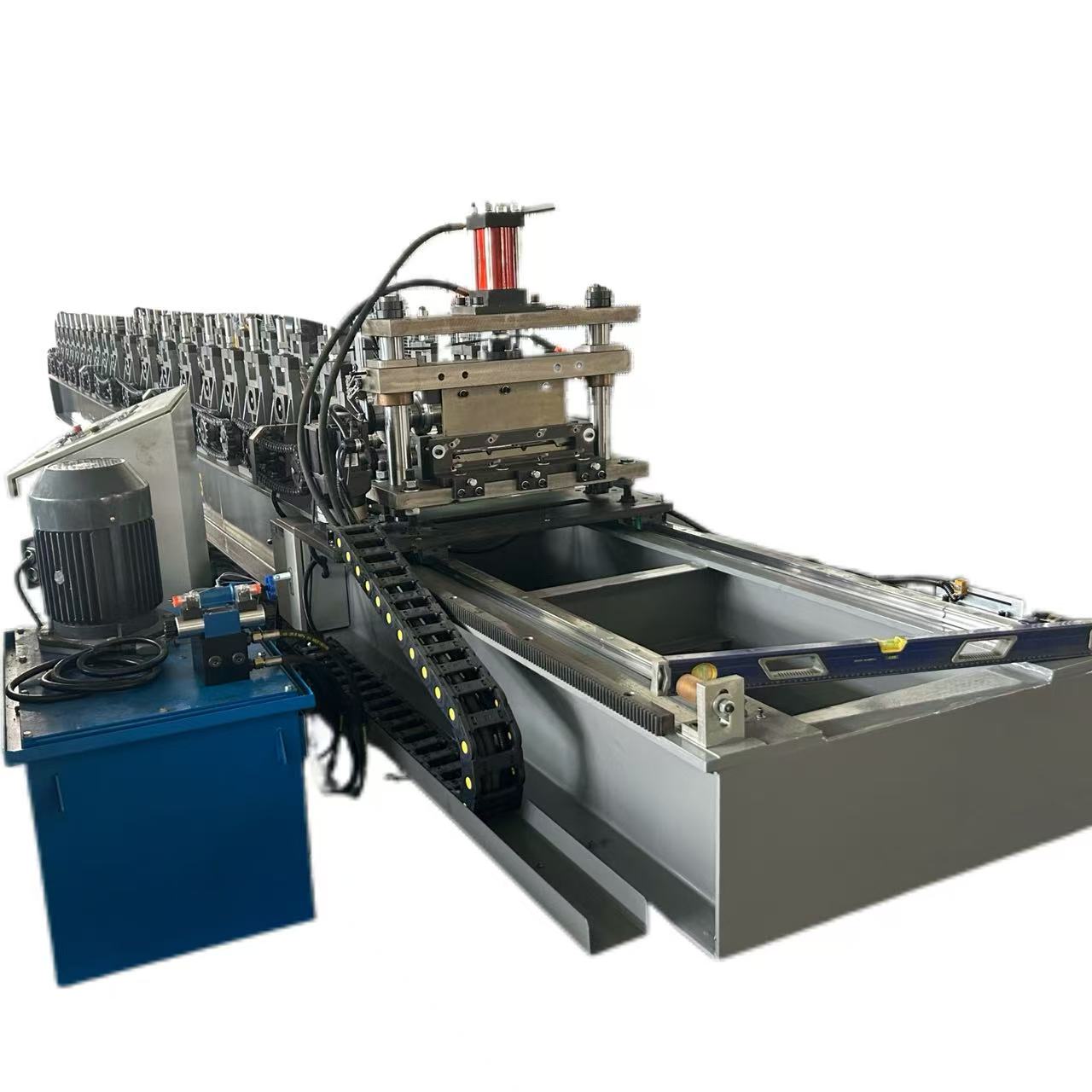

Standing seam roll forming line

The Standing seam roll forming line stands out with its three core advantages of precise molding, efficient production, and flexible adaptation, becoming a tool for the transformation of the construction industry from “factory prefabrication” to “on-site intelligent manufacturing”. From large steel structure factories to rural self built houses, this equipment can achieve integrated production and construction of vertical seam roof panels, breaking through the constraints of traditional models and bringing significant benefits to customers in cost reduction, speed increase, and quality improvement.

Product Attributes

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.3-1.0mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

Due to your requirement profile

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

gear and Double Chain transmission/gearbox transmission optional

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-15m/min

|

Provide customized

|

||

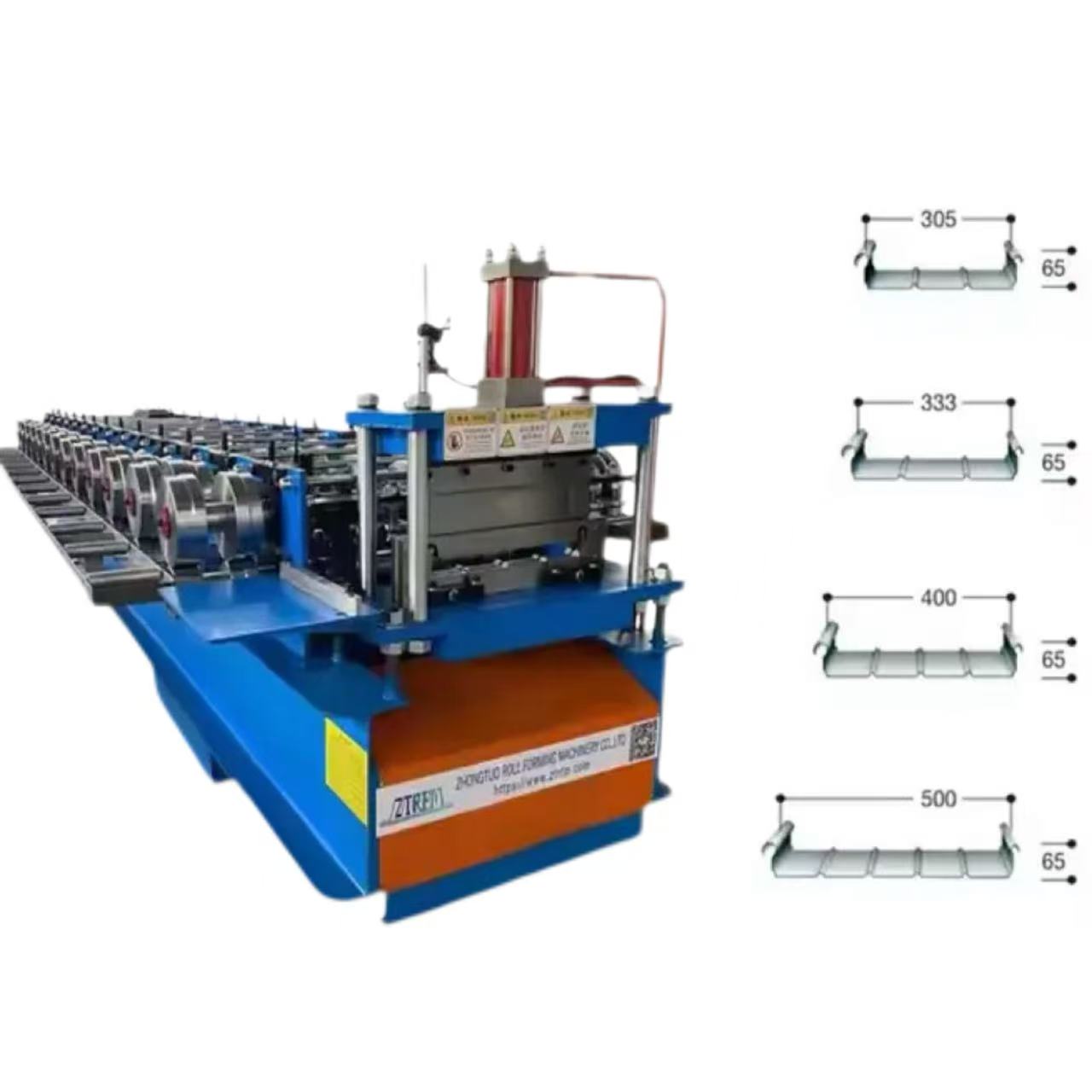

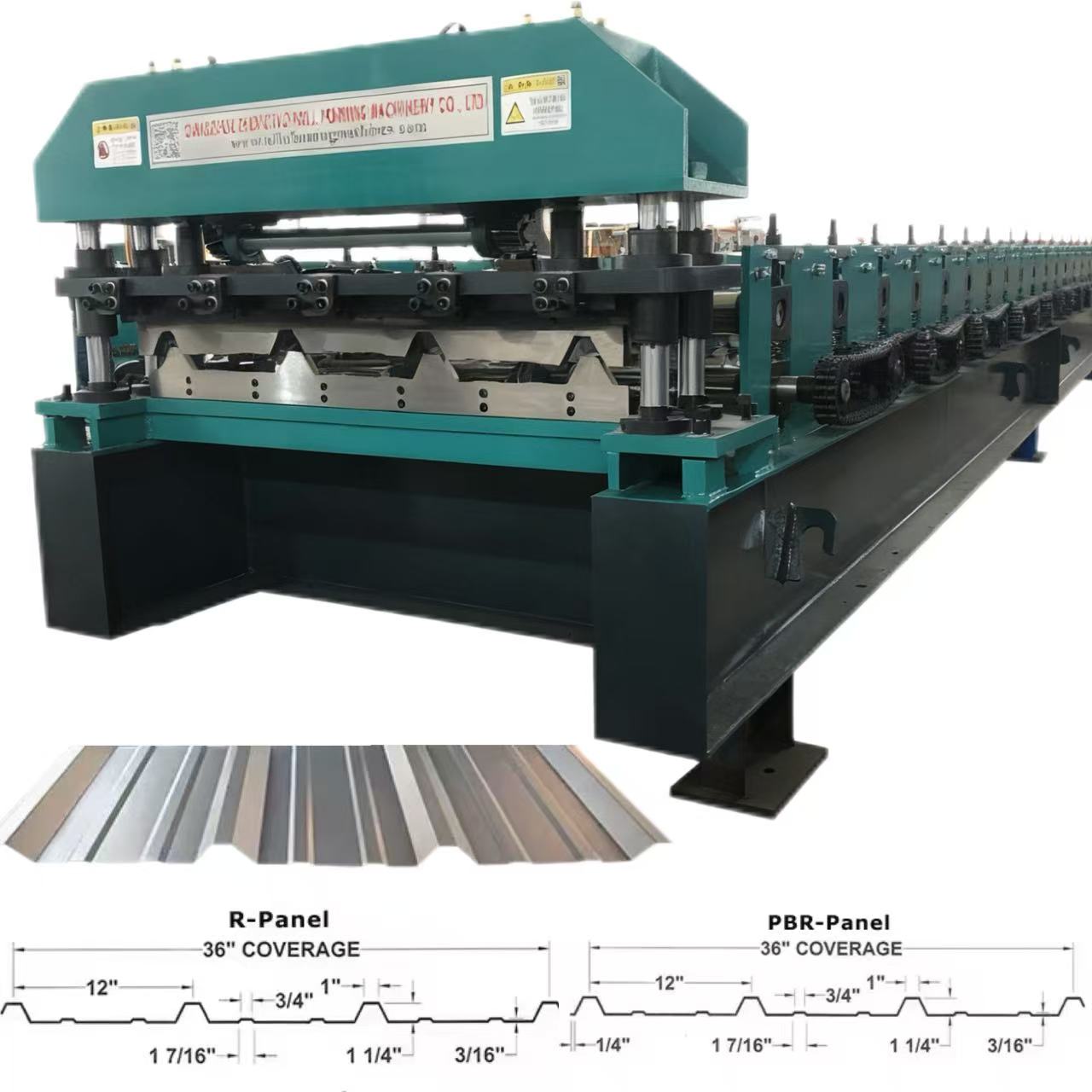

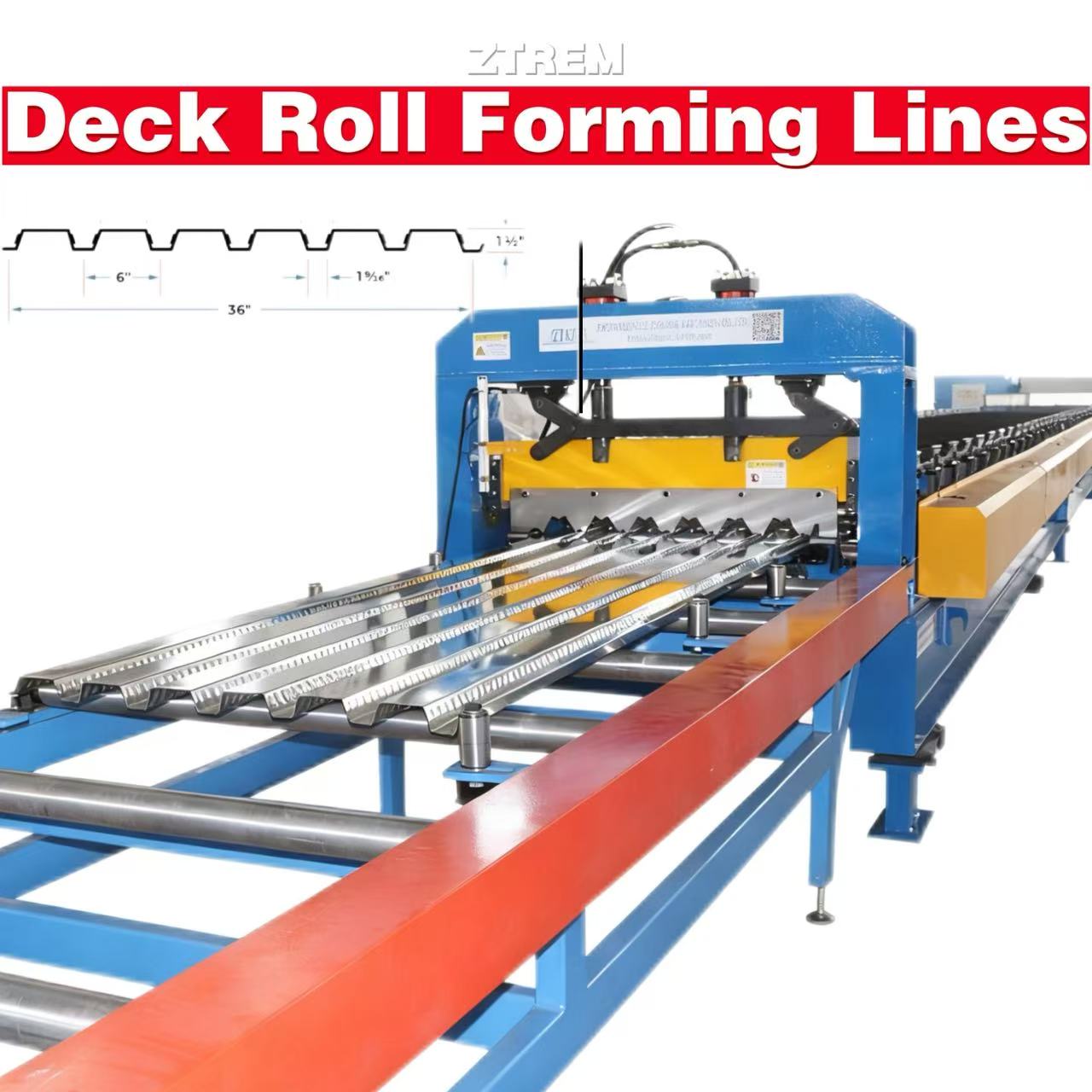

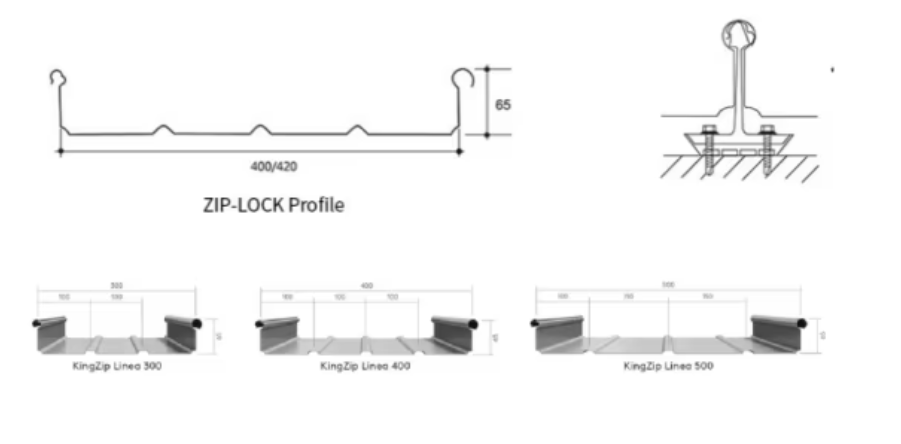

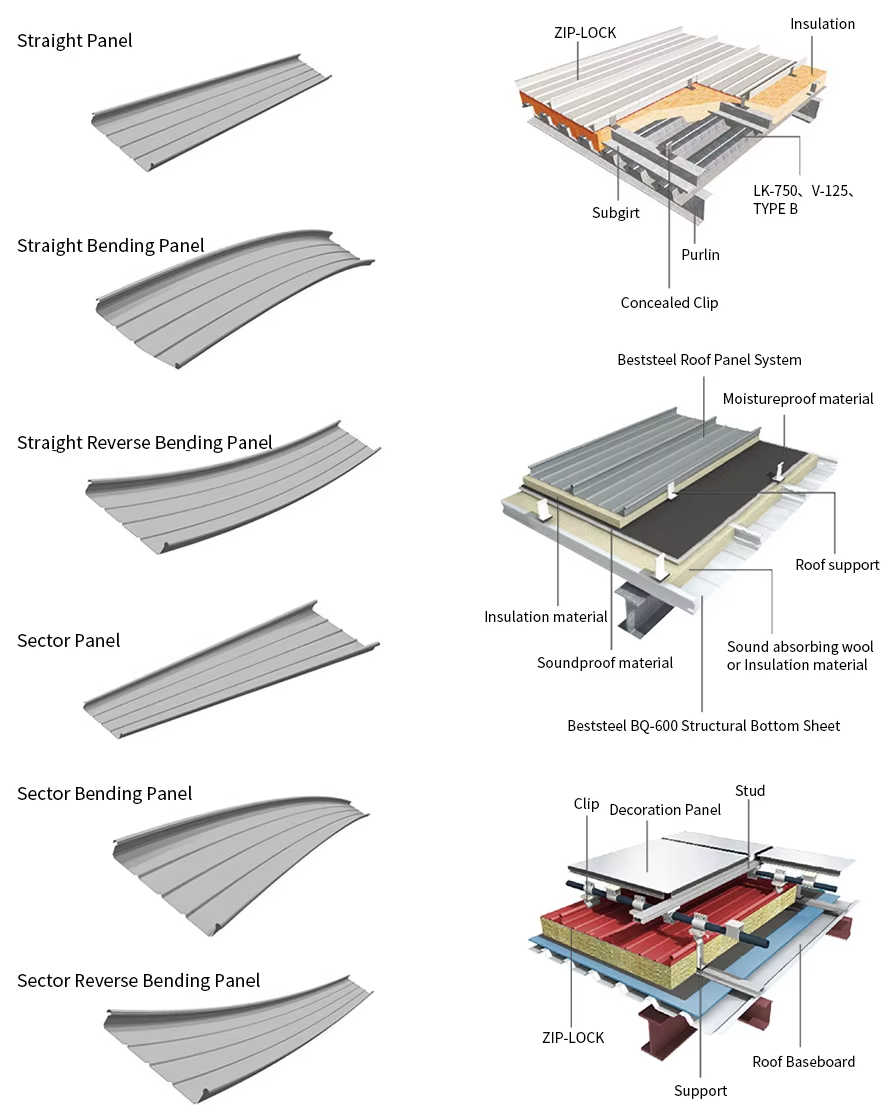

Profile drawing

What can you get by choosing us? ——Not just one device, but a complete solution

We are well aware that what our customers need is not only a ‘production capable equipment’, but also a ‘profitable solution’. Therefore, in addition to high-quality vertical seam roof panel equipment, we also provide comprehensive service support, allowing you to buy with confidence and use with ease:

1. Tailored selection plan

Our professional team will recommend the most suitable equipment model for you based on your construction scenario (remote construction site/urban project), production capacity demand (500 ㎡/1500 ㎡ per day), and raw material type (color coated board/aluminum board), to avoid the problem of “buying big wastes, buying small is not enough”; Provide personalized process adjustment suggestions for special projects such as curved roofs and large-span factories.

2. Cost optimization suggestions

Based on years of industry experience, we provide you with suggestions for raw material procurement and production process optimization, such as how to reasonably set panel length according to roof dimensions and reduce corner materials; How to adjust the molding speed and cutting frequency to increase daily production capacity; Help you reduce overall production costs by 15% -20% and recover equipment investment faster.