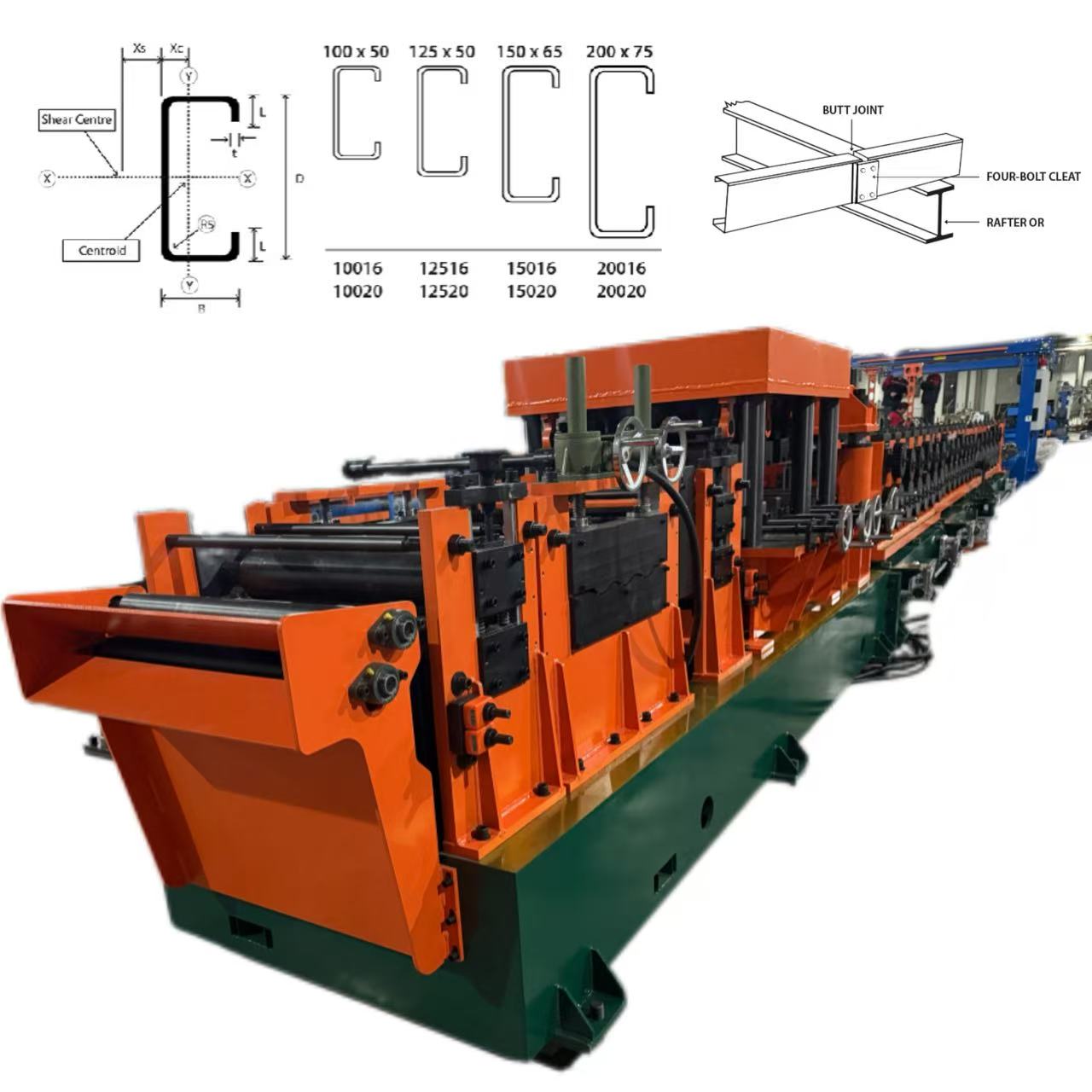

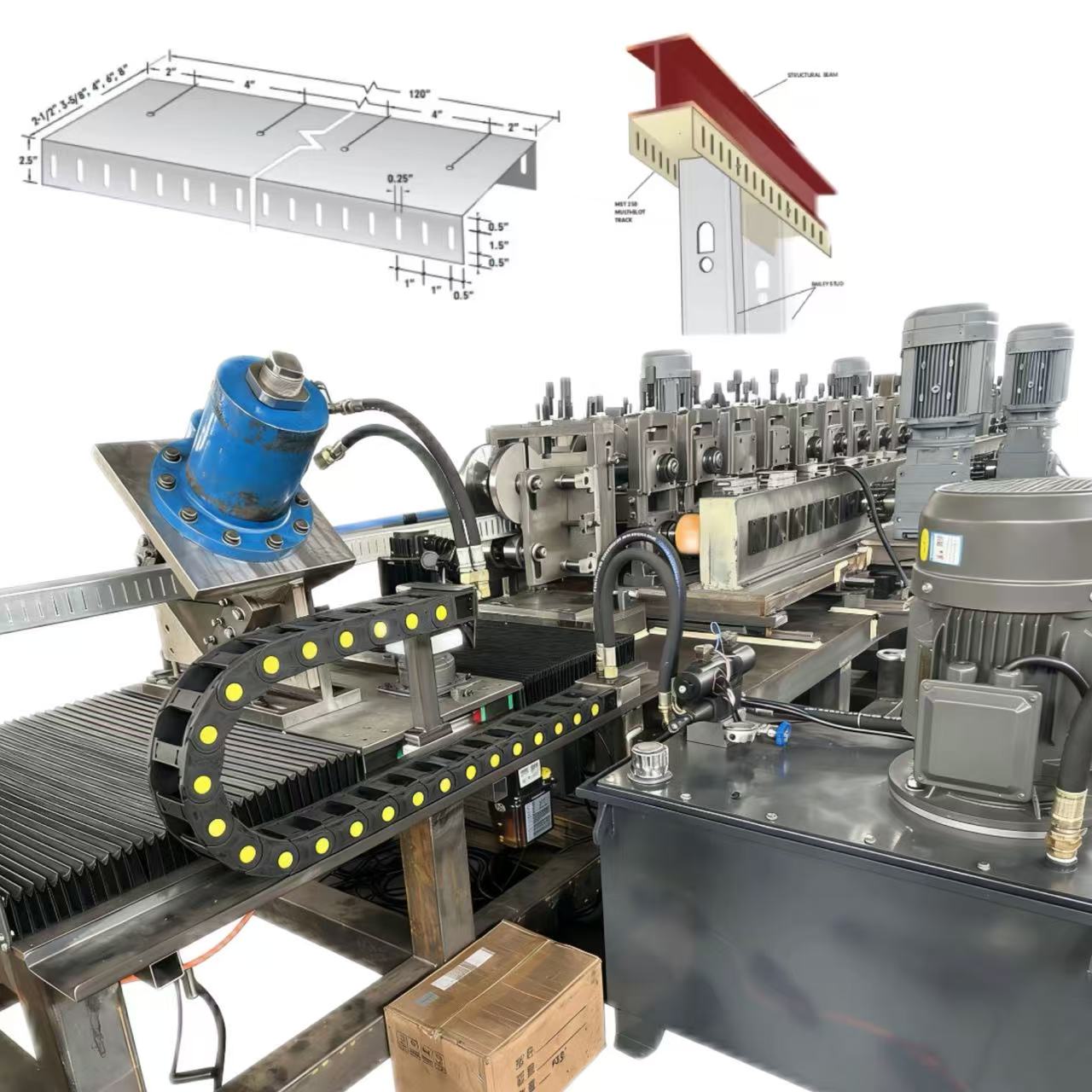

Under the wave of architectural industrialization, C-shaped keels serve as the core load-bearing components of suspended ceilings, partition walls, and support systems, and their production quality and efficiency directly determine project progress and engineering quality. The professional C Channel Stud and Track Roll Forming Machine was born in response to the trend, with precise cold bending forming technology as the core, integrating automation and intelligent production modules, and easily achieving efficient mass production and quality control of C-type keels. It has become a core tool for building materials enterprises to reduce costs, increase efficiency, and seize the market!

Application scenario: Multi adaptability, covering the entire construction field

1. Civil building scene

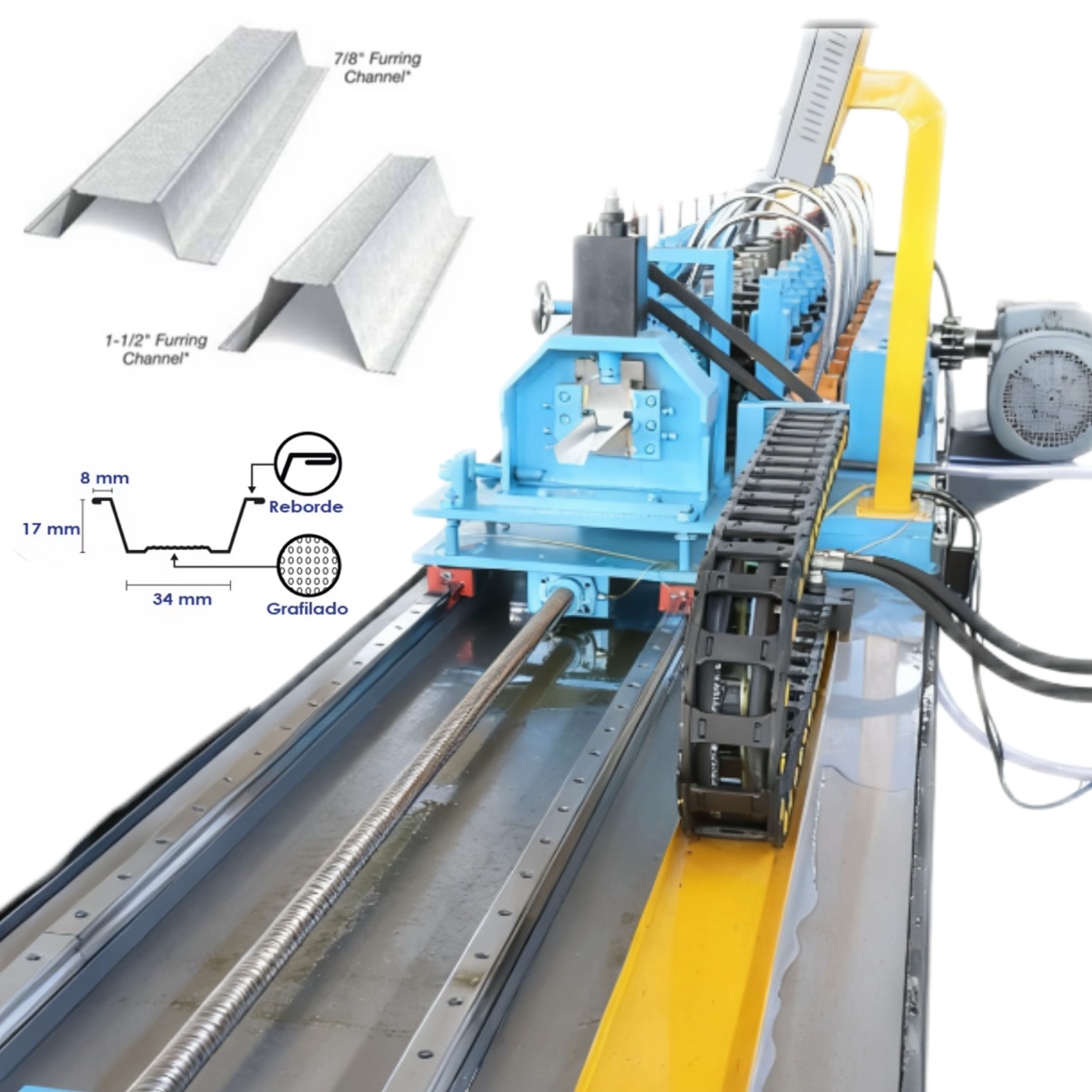

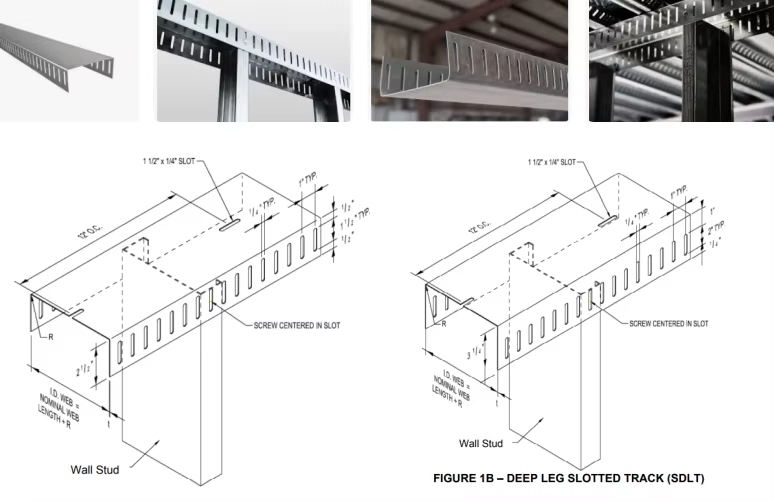

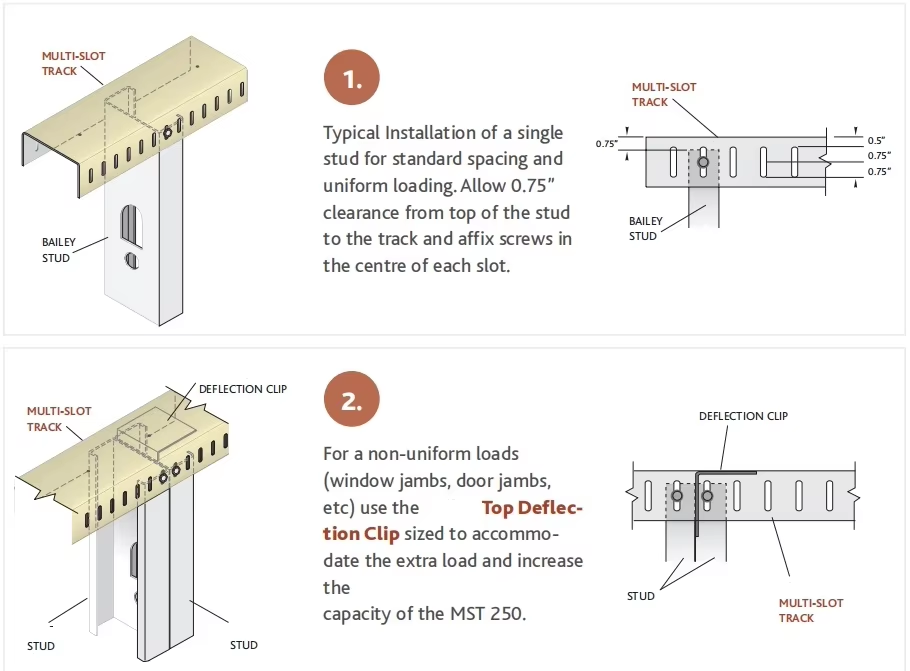

In residential, apartment, villa and other civil buildings, C-shaped keel can be used for indoor ceiling frame construction and lightweight partition wall support. With the advantages of lightweight and easy installation, it effectively improves the efficiency of decoration construction, while ensuring spatial aesthetics and structural stability, and is suitable for household decoration, bulk construction of high-end houses and other needs.

2. Commercial building scene

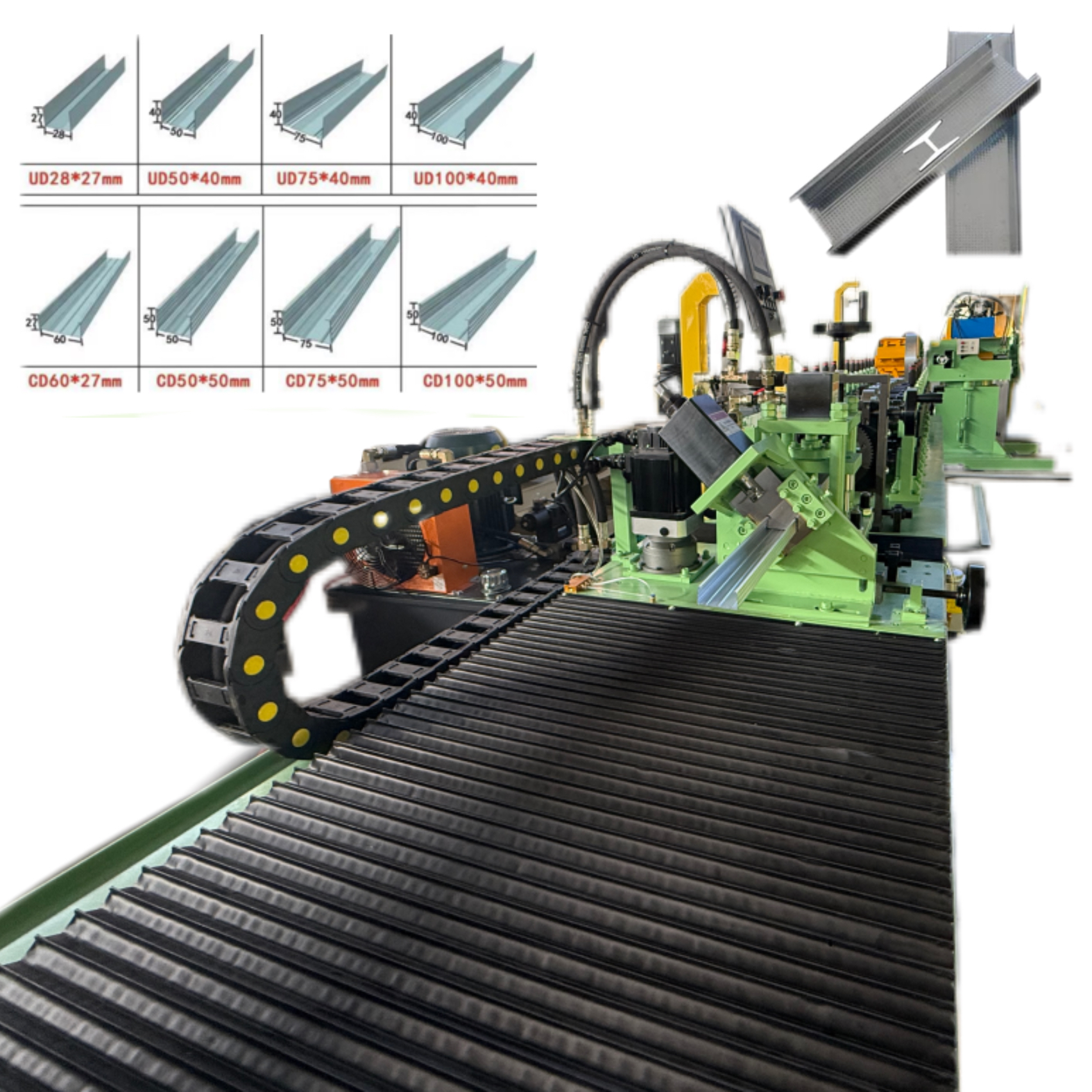

Commercial buildings such as office buildings, shopping centers, hotels, and chain supermarkets have a high demand for keel in bulk and high quality requirements. The profiles produced by the C-type keel machine can be accurately adapted to applications such as large-area ceilings, shop partitions, equipment brackets, etc. They can meet the load-bearing needs of commercial spaces and ensure construction uniformity through standardized production, helping projects to be delivered quickly.

3. Industrial and public building scenes

The equipment brackets and wall supports of industrial plants, warehouses, logistics centers, as well as the ceiling and partition systems of hospitals, schools, airport terminals, and sports venues, all rely on the support of high-strength C-shaped keels. This machine can produce high-strength, thick walled C-shaped keels, suitable for the use of large-span and heavy loads, while meeting the special requirements of public buildings for fire prevention, moisture resistance, and corrosion resistance.

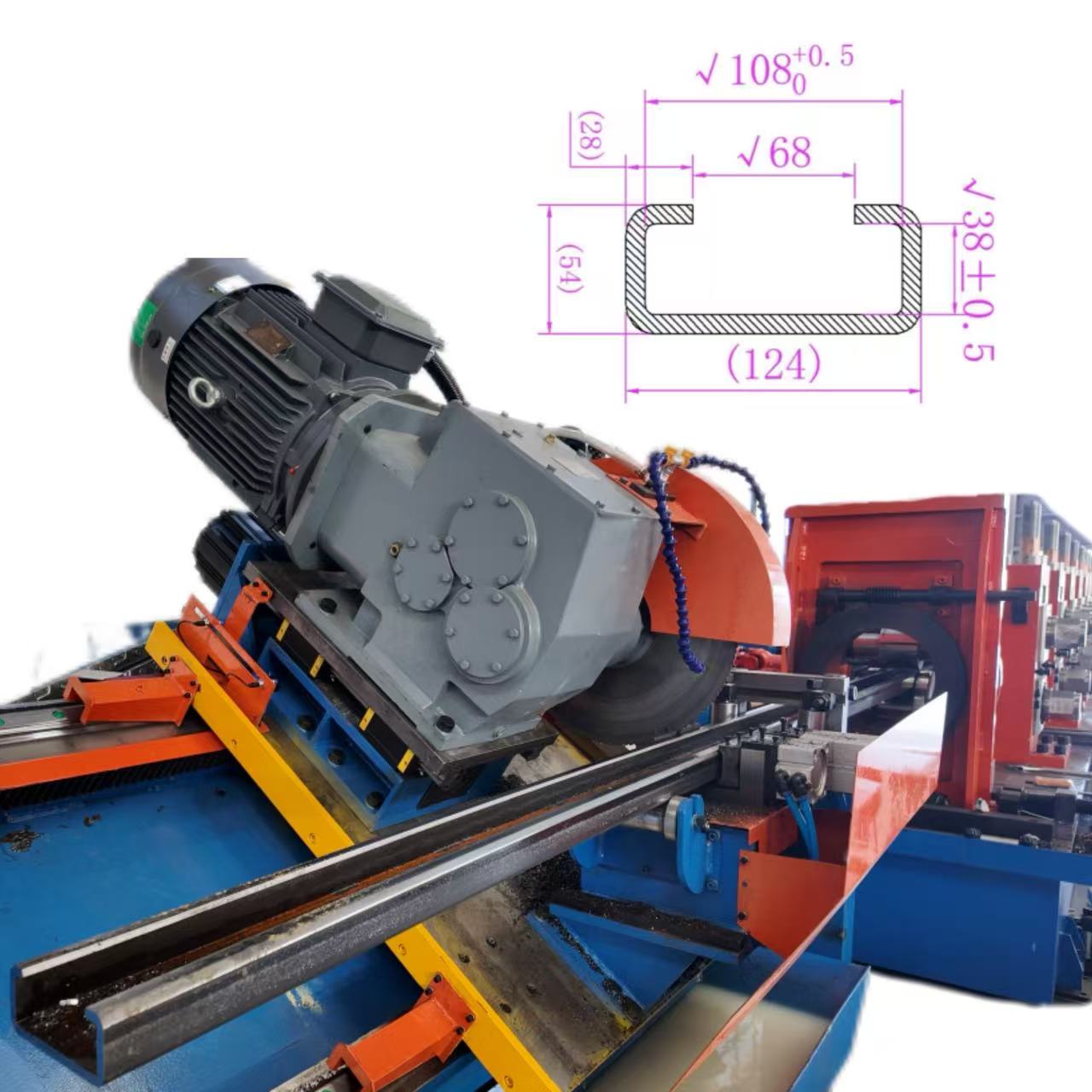

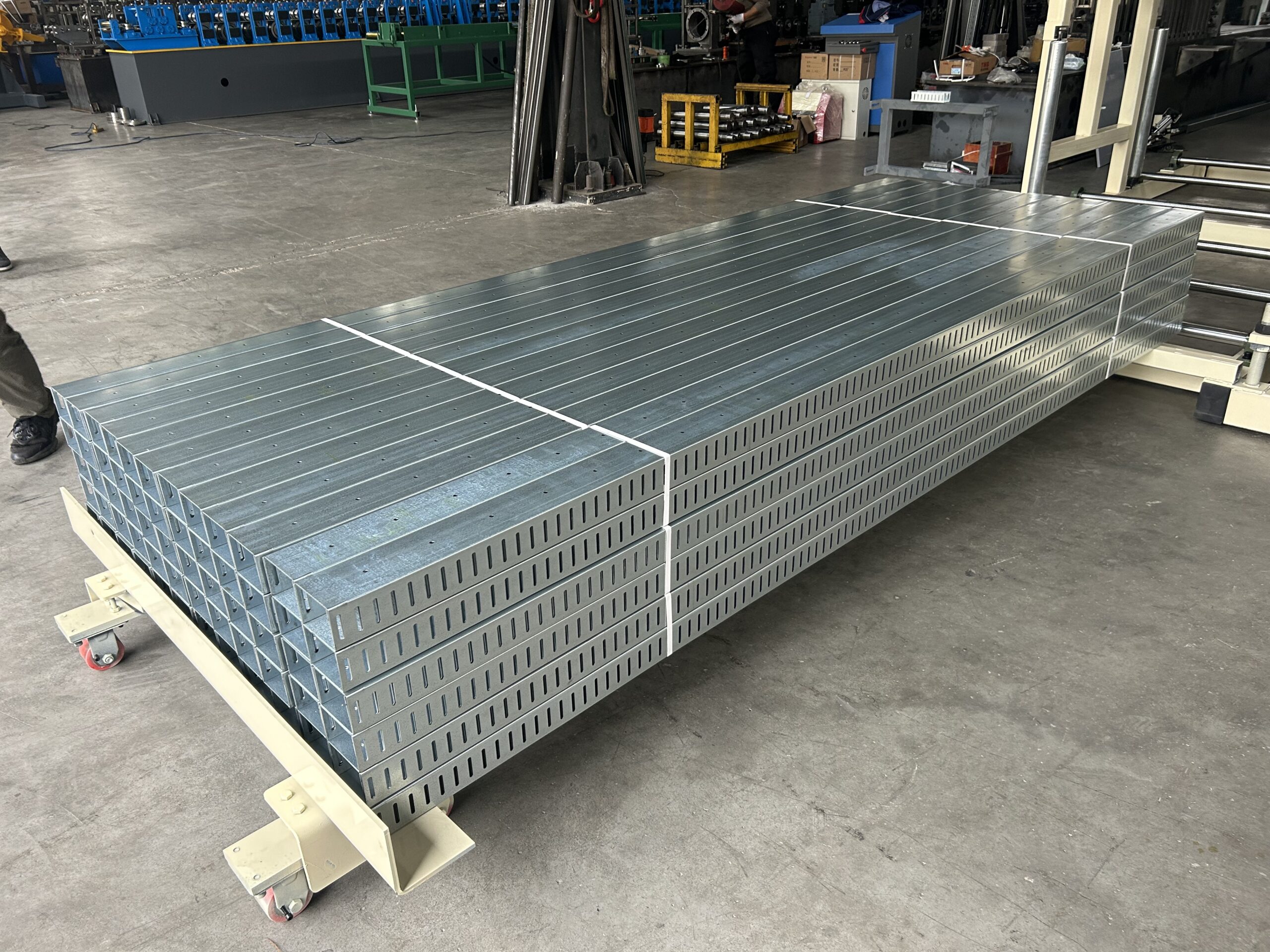

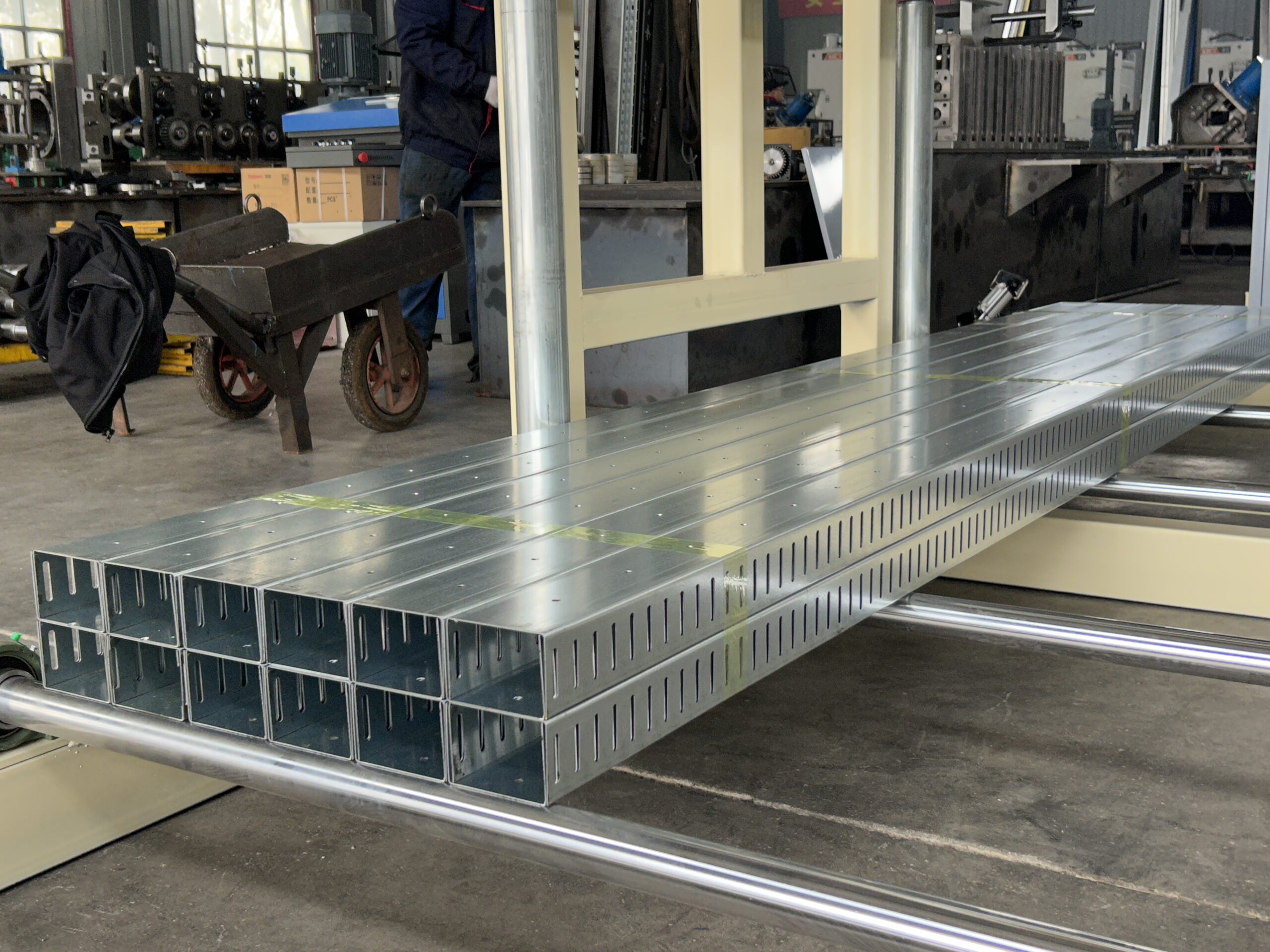

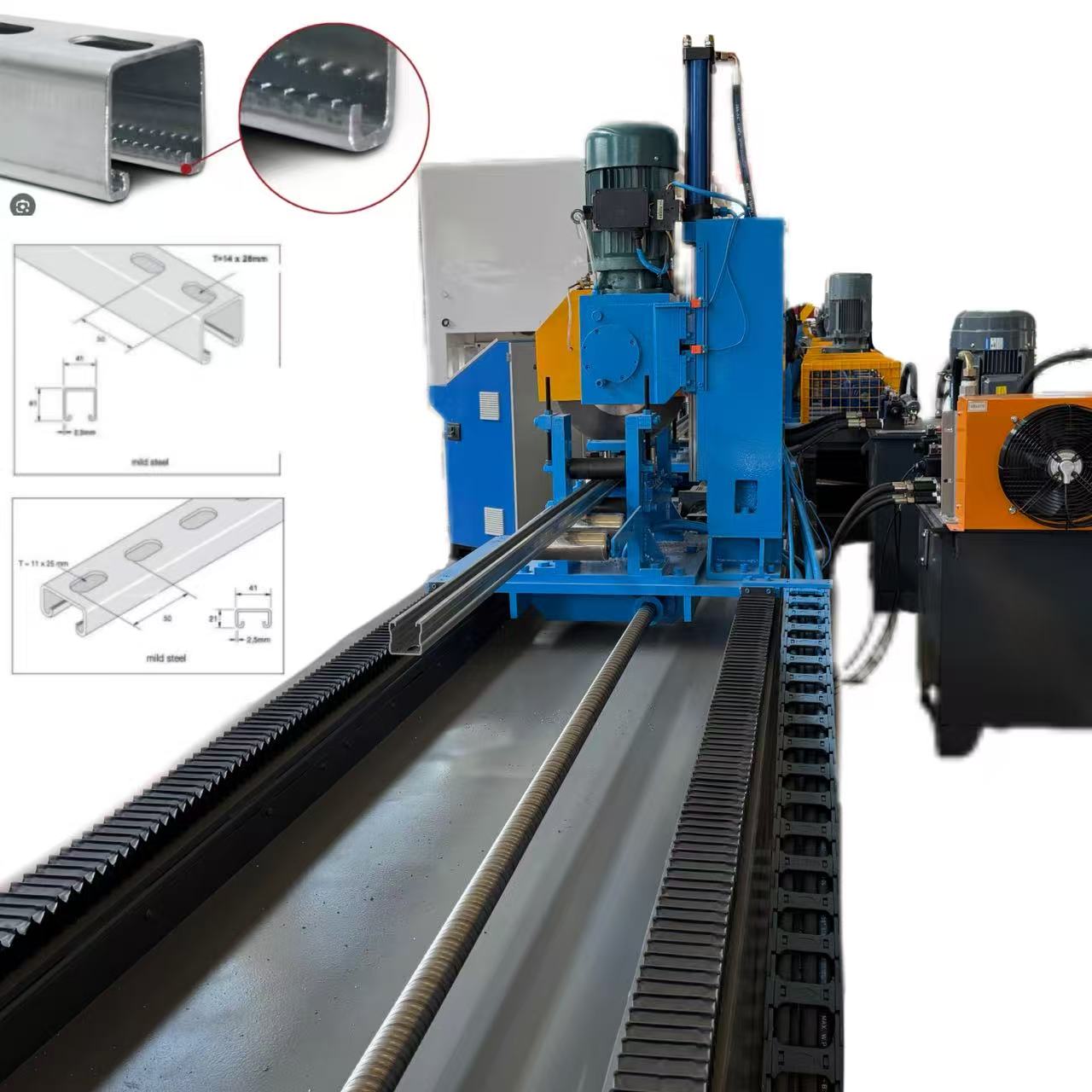

Finished product image:

Core advantage: Multi dimensional empowerment, cost reduction and efficiency improvement, more worry free

• Precise molding, quality builds a solid foundation

• Efficient mass production, worry free handling of large orders

• Flexible adaptation, expanding the market track

• Intelligent and convenient, with lower operation and maintenance costs

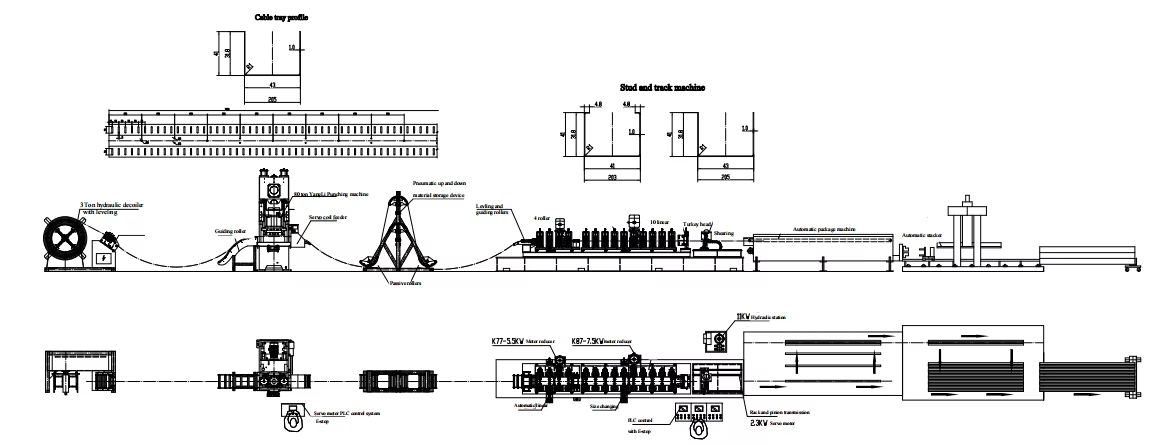

Working flow:

Product Attributes:

| 1.Formed Material | GI | Thickness:0.7-1.2mm | ||

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler | ||

| 3.Main body | Roller station | As your requirement | ||

| Diameter of shaft | 50mm solid shaft | |||

| Material of rollers | 45# steel, hard chrome plated on the surface | |||

| Machine body frame | Metal steel welded | |||

| Drive | will give you as free | |||

| Dimension(L*W*H) | 5500*800*1200(customize) | |||

| Weight | About 3T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 7.5KW | ||

| Hydraulic system power | 3KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 45m/min(customized) | Speed is adjustable according to customer’s request | ||