The High Speed Corrugated Roofing Roll Forming Machine offers several key advantages. First, its precision engineering ensures the production of high-quality corrugated roofing sheets with consistent accuracy. Second, its high-speed capabilities enable faster production rates, optimizing efficiency and reducing production time. Third, the machine’s automated operations minimize labor requirements, saving costs and enhancing productivity. Lastly, the versatility of the machine allows for various corrugated roofing sheet designs and sizes, meeting diverse construction needs. Overall, the High Speed Corrugated Roofing Roll Forming Machine provides an efficient and cost-effective solution for producing top-notch roofing materials.

High Speed Corrugated Roofing Roll Forming Machine is for making the corrugated roofing sheet in batch fully automatically, the speed can reach 50 to 60 meter per minute. The speed increased up by Invert and double hydraulic system. All Rollers are made of high quality material and gone under Taiwan vacuum heat treatment which makes them stronger and have long lifespan.

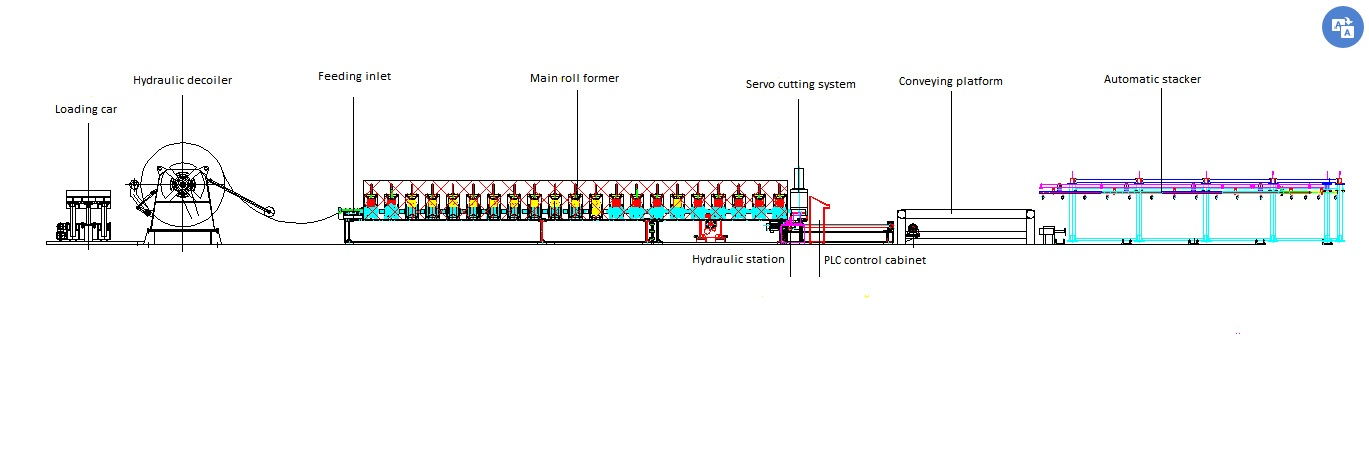

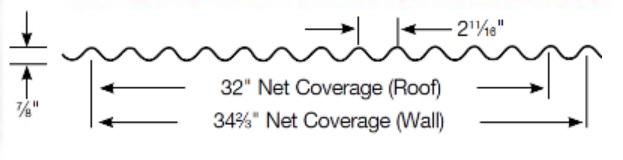

Take the following drawing profiles to show how the machine is designed:

The High Speed Corrugated Roofing Roll Forming Machine is designed like the following pictures:

High Speed Corrugated Roofing Roll Forming Machine features:

1.To make sure of the accuracy, all rollers are custom designed and machined precisely by state-of-the-art CNC machines placed inside the factory. Rollers are hardened through vacuum heat treatment (Taiwan technology) and chrome plating.

2.For the machine, all we use the the molding frame thickness of 45mm. Frame are made by hardened steel and connected by bolts which make machinery sturdy, easy to maintain, and avoid deformation while operating.

3.As to the shearing part, we do the cutting from down to top and then it will not damage the surface of raw material. Shearing (Cutting) made by S50C or SKD, gone through vacuum heat treatment to have a longer lifespan.

4.For the Control system with intelligent PLC and HMI touch-screen helps to operate machine simply and to create identical rollformed steel sheets which present your exact specifications.

There are more details pictures of High Speed Corrugated Roofing Roll Forming Machine for your reference:

High Speed Corrugated Roofing Roll Forming Machine parameters for your reference:

| SPECIFICATION FOR HIGH SPEED CORRUGATED ROOFING FORMING MACHINE | |||

| Machine specification | Electric power | KW | 11-15 |

| Machine weight | tons | 9.0-11.0 | |

| Machine dimension | m | 20*1.8*2.5 | |

| Rolling step | station | 18-24 | |

| Raw material | Material thickness | mm | 0.2-0.6 |

| Coil width | mm | 914-1250 | |

| Production specification | Forming speed | M/min | 40-60 |

| Control system | PLC, touch screen | ||

| Cutting blade | Cr12MoV | ||

| Tolerance | mm | ±0.5 | |

In order to ensure high production efficiency, in addition to the above configuration, you also need to equip the following equipment

Hydraulic decoiler with loading car

Time-saving and labor-saving, with good uncoiling effect and easy to operate.

Operation Controls with Push buttons. (No need to start de-coiler by pulling by the operators).

The car can move levelly and vertically, which is convenient for putting the steel coils into the de-coiler.

When the coils on decoiler, the car will return back to the start position. It can also carry back the unfinished coils from decoiler.

Feed rate to be adjustable.

Automatic Stacker

The formed roof deck are collected automatically and stacked neatly.Then moved out of the stacker by the transverse conveyor belt, so that the forklift can move it to the designed position.

Time-saving and labor-saving.

High efficiency.

Why our Hi-Speed Corrugated Galvanized Iron Roofing Roll Forming Machine differ from others:

1) Easy in installation and maintenance.

2) Hardened structural steel and components provide long life and safe operational stability.

3) Adopting advanced world famous brand components in controlling parts, electric parts and operation parts.

4) Running in an automation, high durability and stability.

5) Compact design, meet custom demands.

For this machine, if you want to know more information, please contact us at any time.

Edward Huang

Mobile/Whatsapp: 0086 18631755835

E-mail: cnzt018@zhongtuocn.com