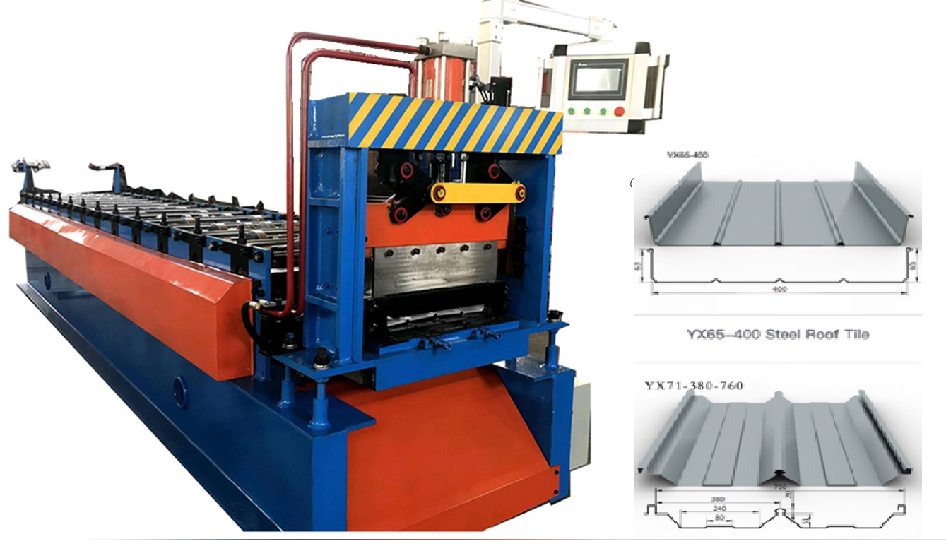

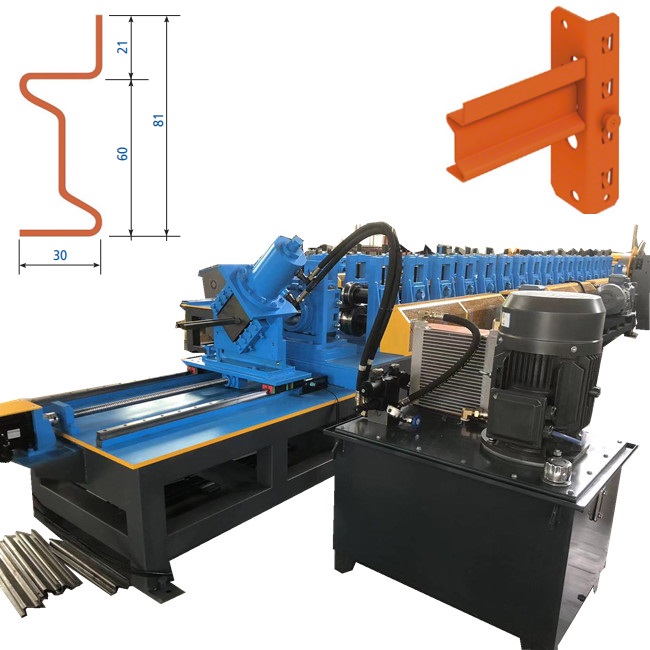

The Trapezoidal Profile Sheet Roll Forming Machine is a cutting-edge solution for producing high-quality trapezoidal profile sheets. Its key advantages lie in its efficiency and versatility. This machine is engineered with precision to create trapezoidal profiles with consistent dimensions and smooth finishes. It offers flexibility in sheet thickness and length, accommodating various construction needs. The machine’s automated operation ensures a streamlined production process, reducing labor costs and enhancing productivity. Its durable construction guarantees long-term reliability and low maintenance. With the Trapezoidal Profile Sheet Making Machine, you can meet the demands of diverse roofing and cladding projects, offering excellent weather resistance, structural integrity, and aesthetic appeal.

Material type:Color coated Steel, Galvanized Steel, Aluminum sheet, Stainless steel

Thickness: 0.3-0.8 mm

Yield Strength: 230-300/350/550-675 MPa

Input material width: According to profile drawing

Effective width after forming: According to profile drawing

Sheet cutting length: Adjustable

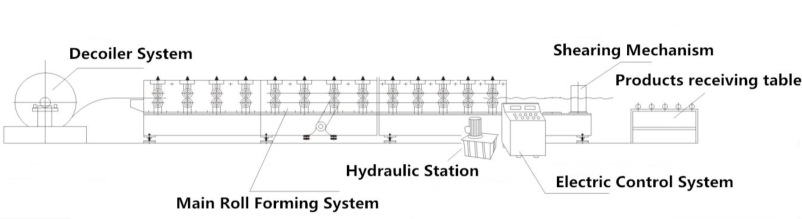

Working Flow of Trapezoidal Profile Roofing Sheet Making Machine

Normally, the working of the trapezoidal profile roofing sheet making machine will go through the following processes.

Coil Charging Car (optional)-Decoiler System(manual/auto)-Front Shear (optional)- Feeding and Guiding Table -Main Roll Forming System-Shearing Mechanism-Product Receiving

Production line Components and Parameters of Trapezoidal Profile Sheet Roll Forming Machine

| Decoiler | 5t/8t/10t/15t (manual or hydraulic) |

| Filming covering | optional |

| Front shear | optional |

| Roll forming system | 15/20/30/40/50/60 m/min as requested |

| Safety cover | optional |

| Shearing Mechanism | hydraulic |

| Output System | manual or automatic |

| Hydraulic Station | equipped with fan on the tank |

| Electric Control System | PLC Touch screen Transducer-Delta or as requested |