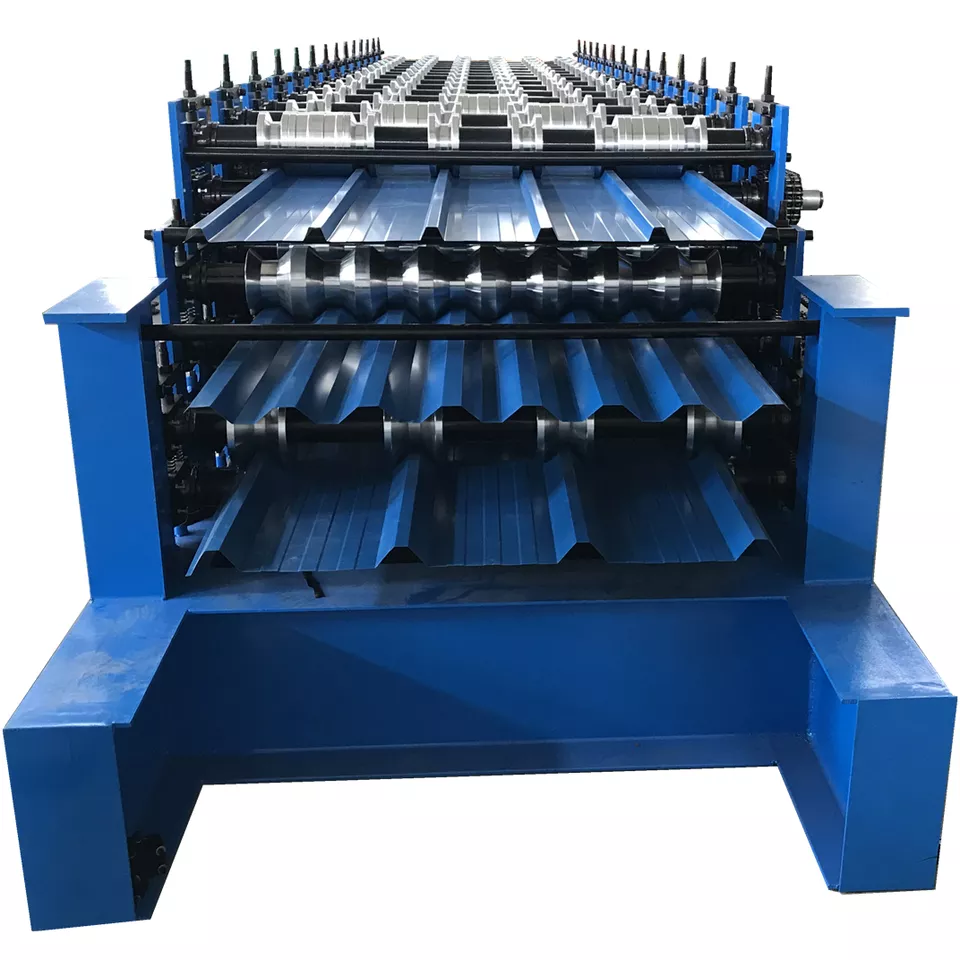

The Double Layer Roofing Sheet Making Machine is an advanced and versatile solution for producing high-quality roofing sheets. This cutting-edge machine is designed to form two layers of roofing sheets simultaneously, enhancing production efficiency. With precision engineering and automated controls, it ensures consistent and accurate sheet formation. The Double Layer Roofing Sheet Making Machine is capable of handling various materials, such as steel, aluminum, or other alloys, making it suitable for a wide range of roofing applications. Experience increased productivity and top-notch roofing sheet quality with this reliable and efficient roll forming machine for your roofing projects.

Full Automatic Double Layer Roofing Sheet Making Machine with Automatic decoiler and Auto stacker is the full automatic production line which is used to produce the Metal Roofing panel or wall panel.

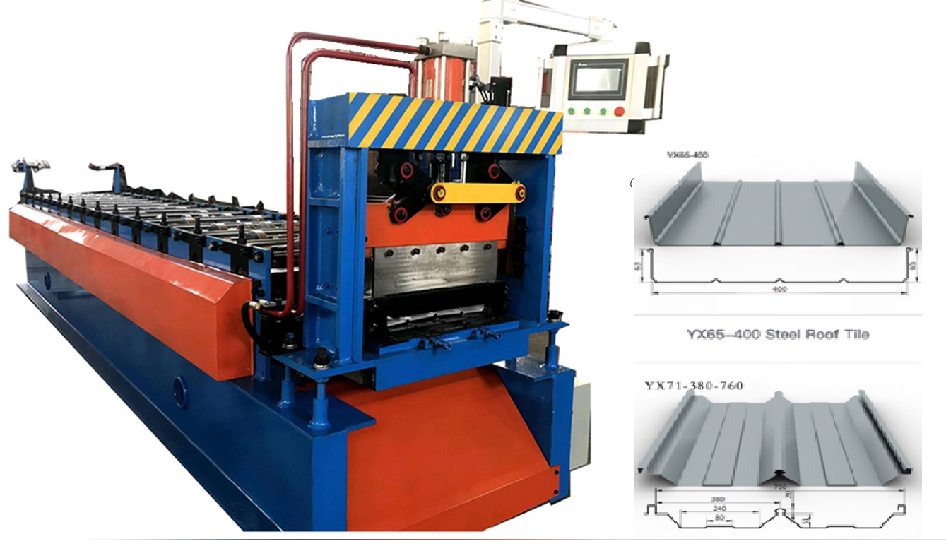

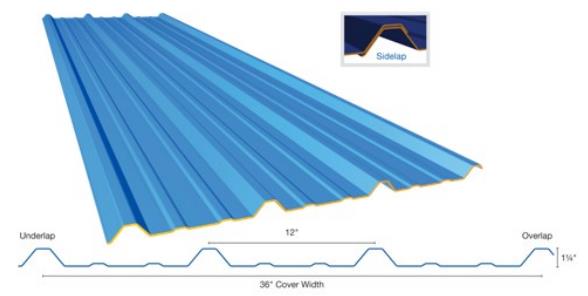

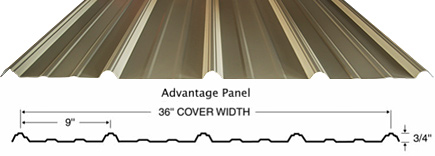

The finished product it produces:

R Panel AG Panel

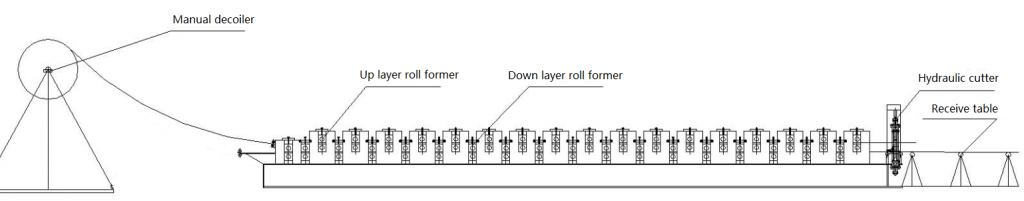

The whole production line layout:

The introduction of the whole production line:

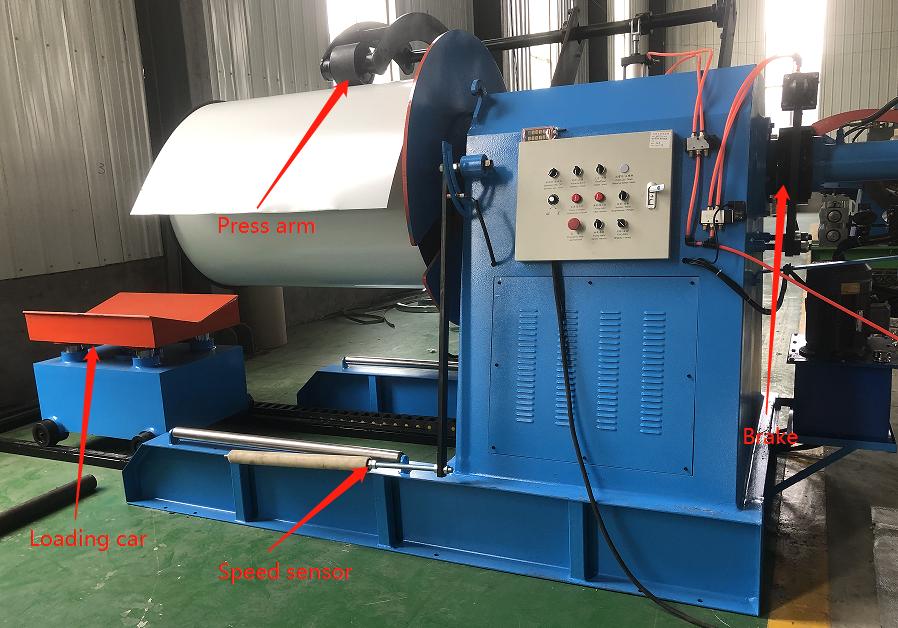

1.Decoiler:We have manual decoiler and hydraulic decoiler for optional,the manual decoiler is for free.

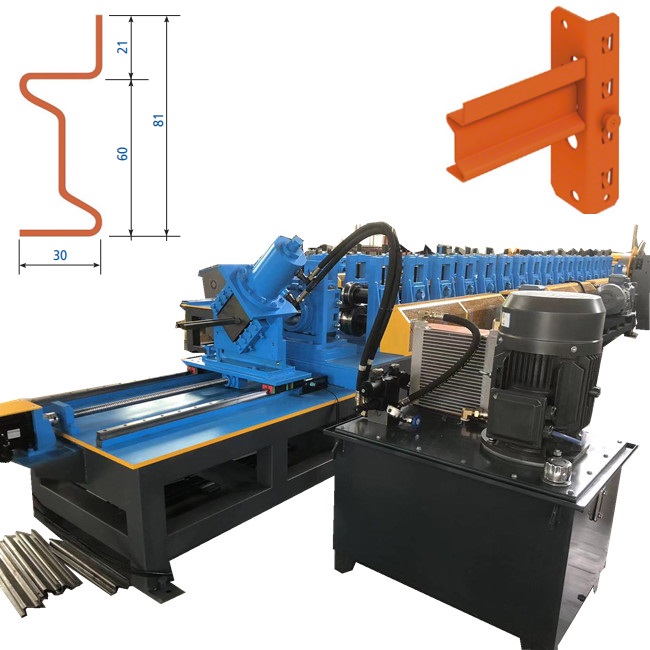

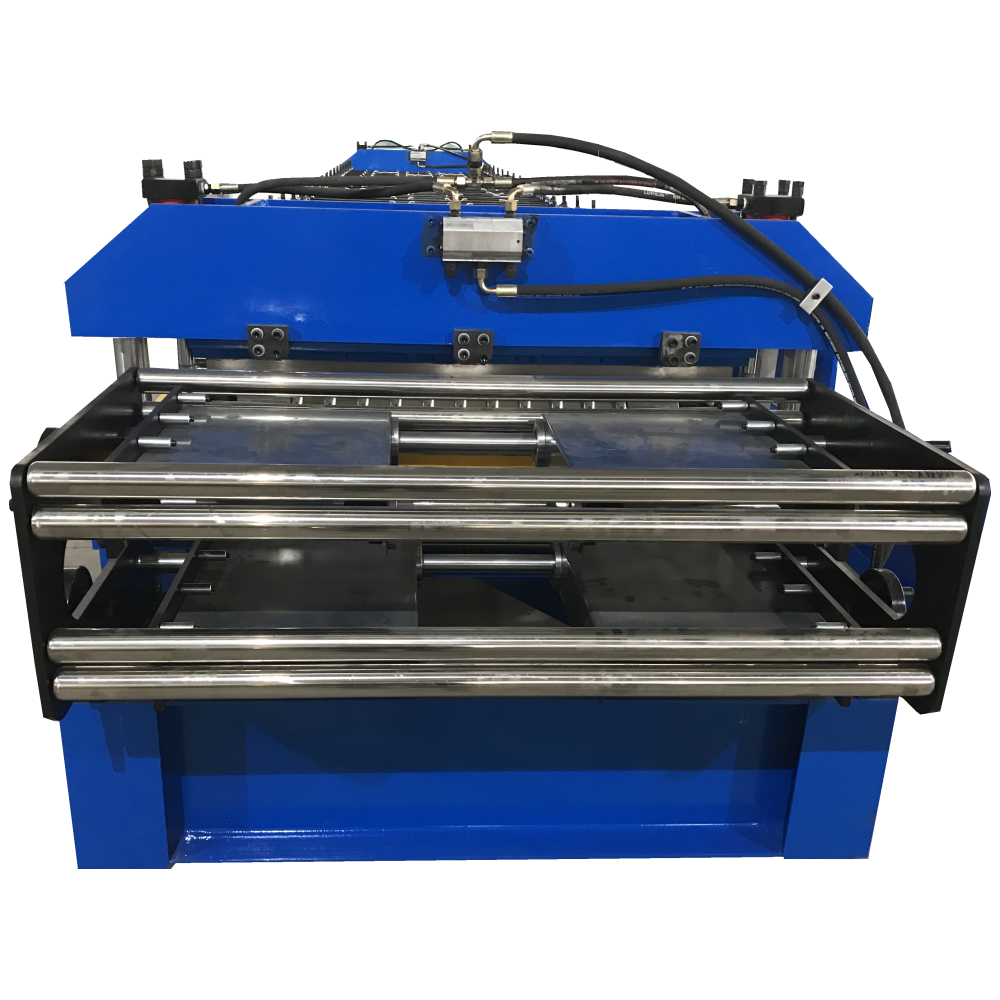

2.Main roll former:It include the hydraulic pre-cutting device,roll former,hydraulic post-cutting device

Description 1: Hydraulic pre-cutter,it can cut the material automatically before roll forming.It has the function of counter,so it can reduce the waste material for customer.

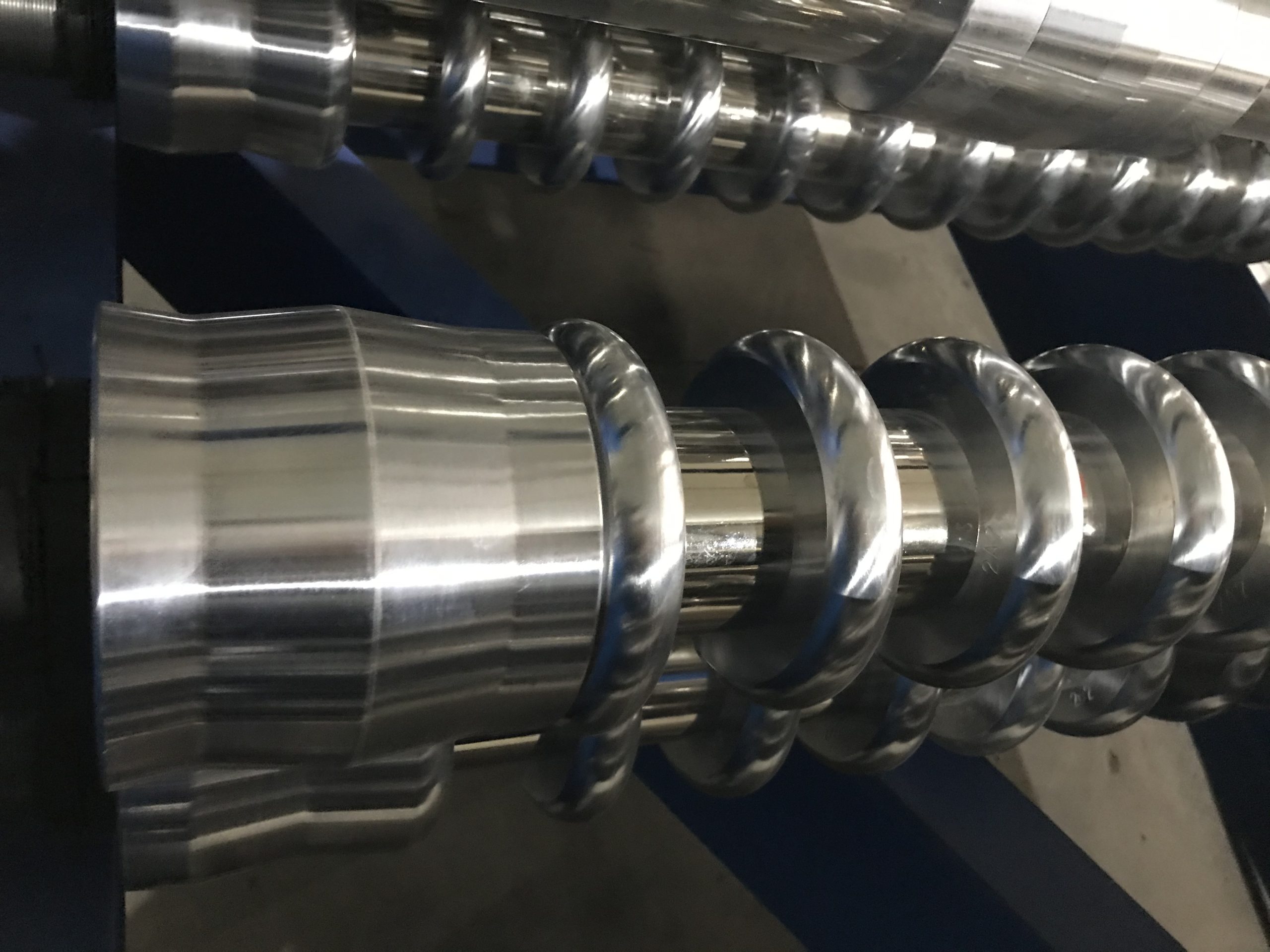

Description 2: Main roll former.

Roller:The material of the roller is 45# steel and the surface is hard chromed which can improve the life-time of the roller.

Shaft:The shaft diameter is 80mm,and it is tempered treatment.We guarantee the roller is solid.

Machine frame:350# H steel,with the 18mm middle plate welded.

Description 3: Braking system for up and down layer,the up and down layer will not work at the same time to reduce the wear out.

3.Control system

Our electric parts are all international famous brand,such as Siemens,Schneider,Delta,Panasonic,and we also support appointed brand from customer.

4.Hydraulic system

We use big electric valve and famous brand to guarantee the quality,and we also add the fan cooling system for cooling down the temperature of the oil during the long time working or in hot weather.

5.Run-out table

We have manual table and automatic table to meet different customer’s demand.

Manual run-out table Auto stacker