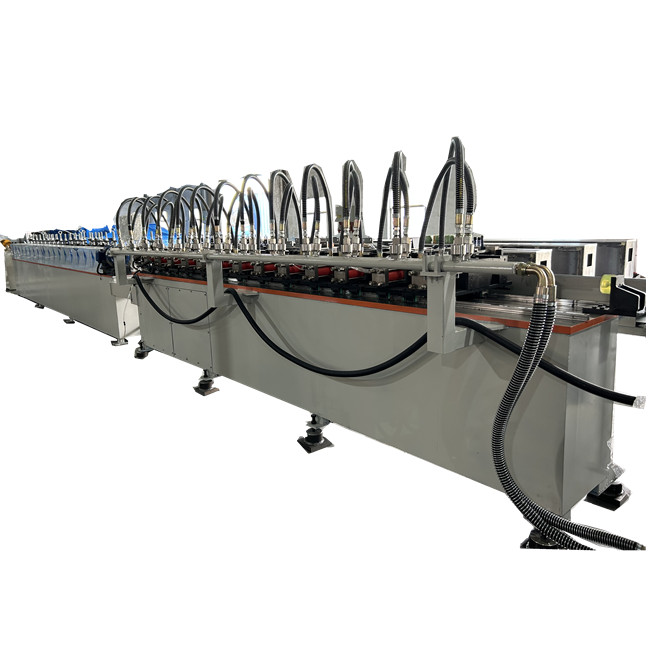

The Ceiling T Grid Roll Forming Machine is an advanced industrial device designed specifically for the efficient production of ceiling T grids. With cutting-edge roll forming technology, this machine effortlessly shapes metal strips into precise and high-quality T grid profiles. It offers versatility in creating different sizes and designs of T grids, meeting diverse construction requirements. The machine’s automated operations and customizable settings ensure consistent results, reducing labor costs and improving productivity. The Ceiling T Grid Roll Forming Machine is an essential tool for manufacturers aiming to optimize production and deliver reliable and durable T grids for suspended ceiling systems in residential, commercial, and industrial buildings.

T bar suspended ceiling T grid roll forming machine for main T and cross T bar is designed to making the ceiling T bar in batch fully automatically. Those days the main T and cross T bar are quite popular as the following reasons:

Main Characteristic of T bar

- High grade galvanized steel as main material, non-deforming, fadeless,moisture proof and anti-corrosive.

Strong close fitting, high symmetry

3. High load capacity

4. Easy and fast installation, save installing time and labor cost

5.Large production line and strict product inspection, larger quantity and better quality are available.

Zhongtuo high speed fully automatic ceiling T grid roll forming machine allows you to do the followings.

1.Fully automatic with punching holes, fire holes and end.

- Speed is around 25 to 35 meter per minute.

- High accuracy and 0 error in length.

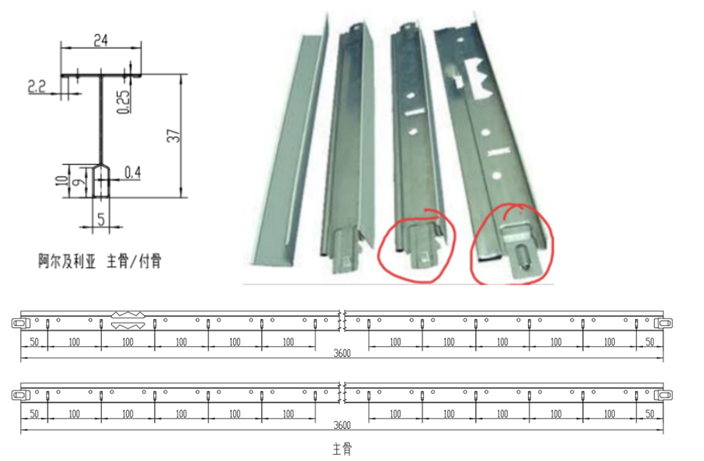

Now we take the following drawing profile as an example to show you how our machine design is. Different with other T bar, this type main T and cross T sizes are same, just they are different in the punching ends.

For the cross T, we make the sizes of following: 1200mm, 600mm, and 300mm. For the cross T300mm is not easy to make. If you need, the cost of the machine will be more expensive and the machine needs more punching stations.

T bar suspended ceiling T grid roll forming machine

More details parameters for your reference:

- Roller station 18 with 1 set of correction for main T.

- Machine frame processed in high accuracy: base frame 20MM thick, and the sides 6MM thick welded as a whole then polished with a gantry grinder to make the surface flat and smooth. 45 # trump steel is adopted.

- Roller material: CR12MOV die steel. The vacuum heat treatment makes the hardness uniform, the average hardness is HRC55, and the surface is smooth without scratching the product.

- The shaft material: 40CR and processed by grinding machine with a diameter of 45.

- Main motor 5.5KW Siemens copper wire motor, and each roller drive is an independent 1:15 gearbox, with stable transmission and low noise.

- The two material racks are single-head vertical and can bear 500KG, and are manually tensioned.

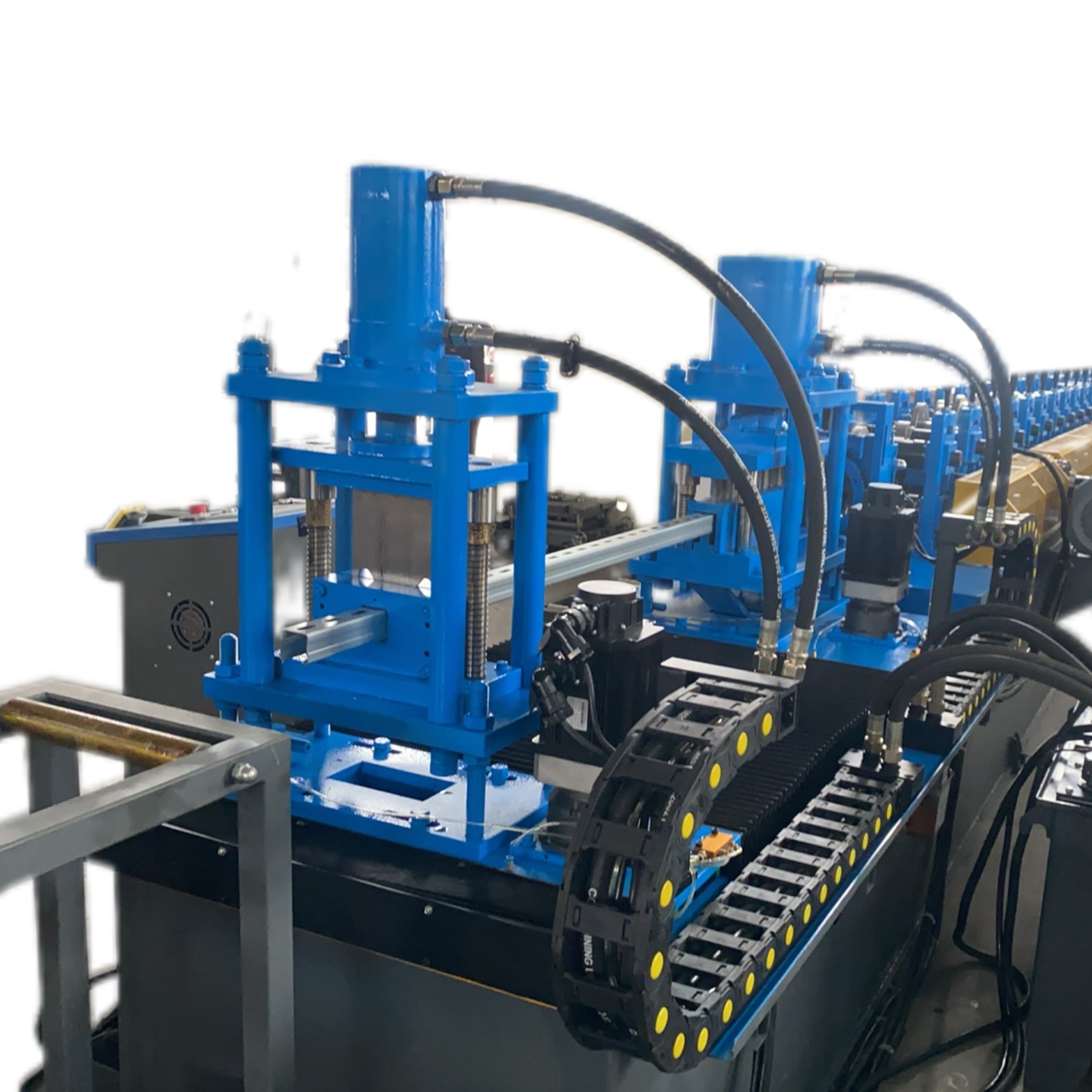

- Guide pillar type high-precision frame, frame thickness is 38, each group has 8 Japanese NSK6206 bearings, and all frame surfaces are blackened to make them rust-proof and knock-resistant.

- The mold frame is made of 45 # trump steel, all of which are finished and the surface is blackened. The form of inserts used in the mold can be changed quickly, and the material is made of Japanese SKD11 and vacuum heat treatment. The die steel plate is 50 # trump steel, which is finished. The stamping worktable is an integral type, with the worktable 20MM thick and the side 6MM thick, and the surface is finely polished. Side anti-corrosion treatment.

- The hydraulic pump adopts the Taiwan Kaijia brand, the oil valve adopts the Taiwan oilfield brand, the oil pipes are all wired, the motor is 7.5KW all-copper wire temperature-resistant motor, and the oil circuit block is finely ground.

- Energy-storage rapid stamping can complete punching and punching at one time without stopping the machine (note: at present, the only manufacturer in China and Taiwan can complete punching and punching at one time without stopping the machine).

- The 70P oil cooler is used for hydraulic pressure to control the oil temperature.

- The stamping part of the linear track moves back and forth. Taiwan Dongyuan servo controller and motor, PLC is Delta, and touch frequency is Veyron. Low-voltage electrical appliances are famous brands of Siemens.

T bar suspended ceiling T grid roll forming machine working video for your reference: