Steel profile roll forming machine is designed to make the metal steel profile in batch fully automatically. Metal cold rolling forming is a kind of metal processing process in which metal plates and strips such as coils and strips are continuously bent laterally through sequentially configured multi-pass forming rollers to produce specific cross-section profiles. Cold bending forming is a new process and technology for metal sheet forming that is material saving, energy saving, and efficient. Using this process can not only produce high-quality section steel products, but also shorten the product development cycle, improve production efficiency, and improve the market competitiveness of enterprises. By this kind of technology, we could use rolling forming machines to design lots of types steel profiles.Here are some special steep profiles for your reference:

Steel profile roll forming machine has many types for example:

- Metal roofing sheet machines.

- Wall cladding sheet machines.

- Drywall elements making machine

- Shutter profile rolling forming machines.

- Some special shape profiles rolling forming machine.

Steel profile roll forming machine–> How to get an accurate quotation?

There are following elements effecting the price of the machine.

- Roller stations.

- Motor power.

- Machine working speed and automatic degree.

In this case when you ask accurate quotation, please supply the following information.

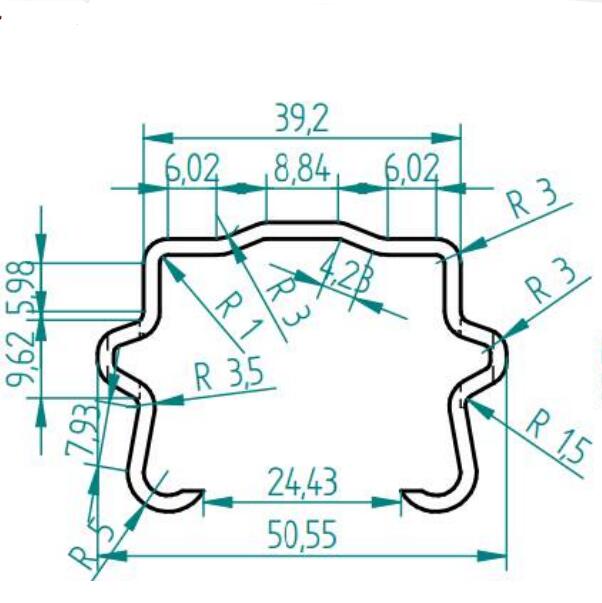

- If you have an accurate drawing profile with sizes and thickness, please supply.

- If you have the clear production rate and speed requirement, please supply.

- If you have the clear automatic degree requirements like which kind of decoiler and which kind of stacker, please tell us.

Here is one drawing profile for your reference:

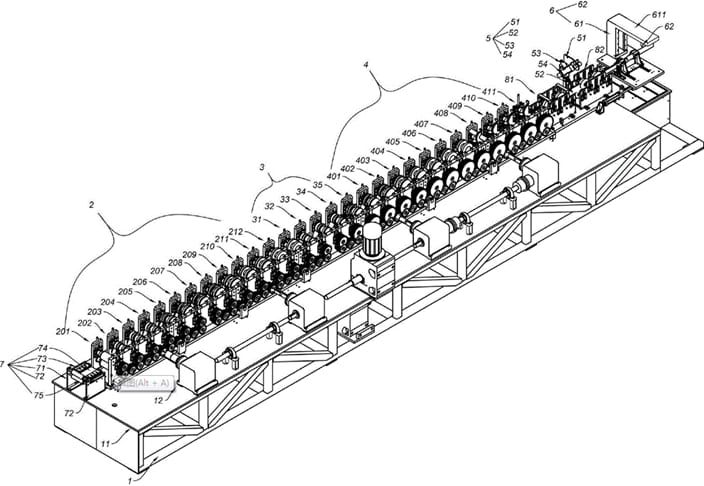

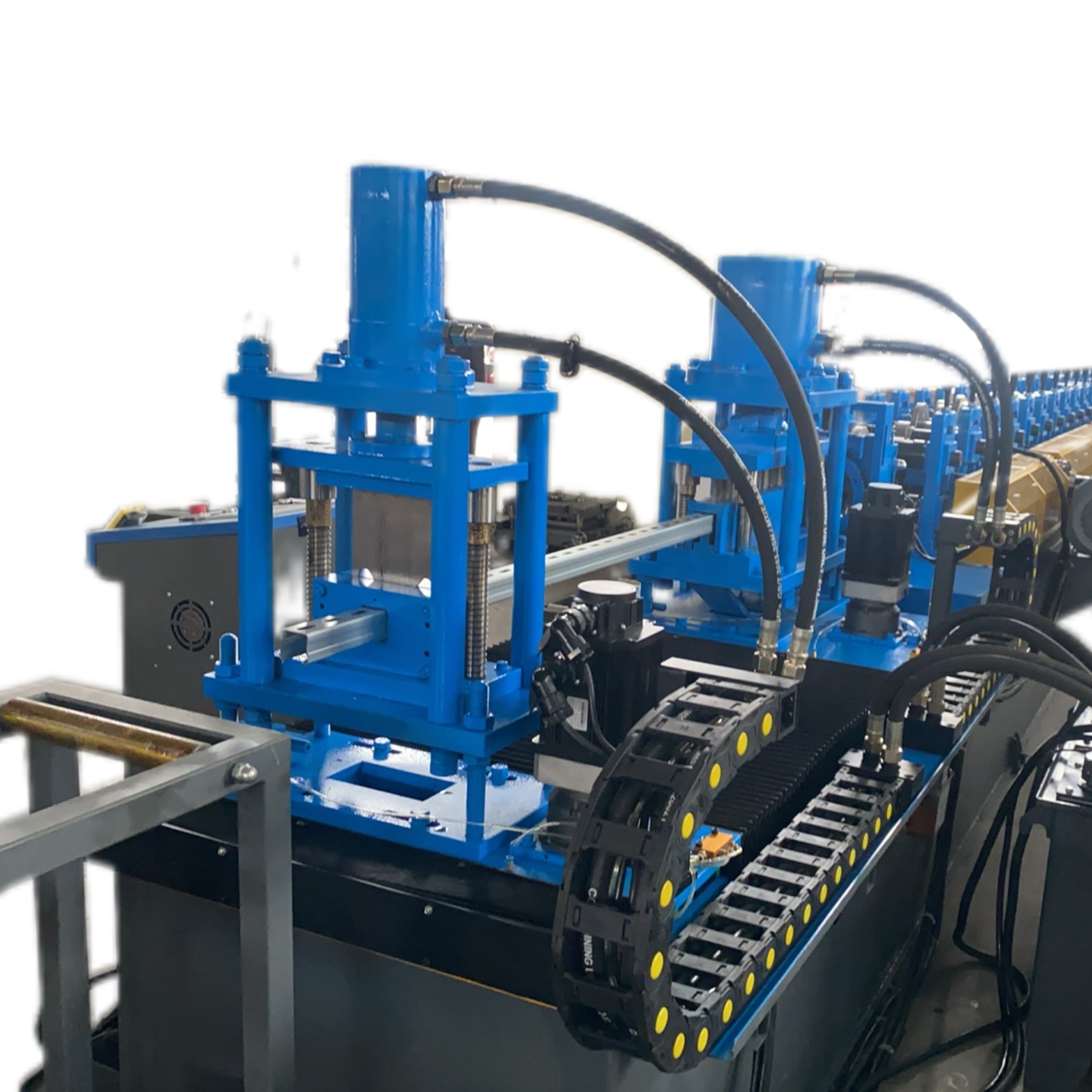

Steel profile roll forming machine design something like this:

Here are some parameters of metal steel profile rolling forming machines for your reference:

2.Main Forming machine Forming speed 10-18m/min

individual structure : Open style

Main motor :15.0kw Siemens

Hydraulic cutting:7.5kw

Gcr15 forming rollers:19 stations

HRB bearing or ZWZ bearing Optional

Control cabinet PLC Siemens

Hydraulic punching before forming 2 groups

3.Gear box driven system

Gear boxes ×19 pcs

Universal joint coupling with cardan axis×19 pcs

Support table ×1 Speed up to 30m/min

- Servo feeding system

Servo feeding device for precision feeding 270mm

Leveling device:9 rollers

Pinching device:2 rollers

Individual control system

So when you have needs about the steel profile roll forming machines, please contact us at any time.