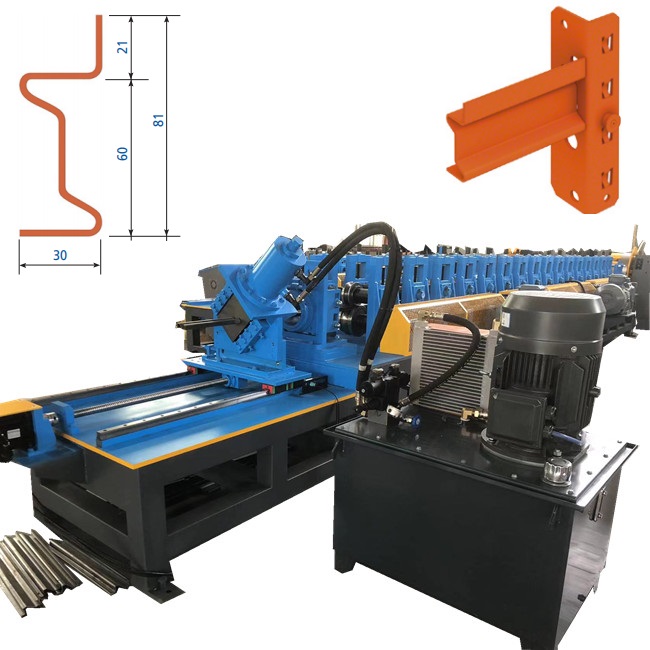

The P Beam Step Beam Roll Forming Machine is an innovative and efficient solution for manufacturing P beams with step beams. This state-of-the-art machine is specifically designed to produce high-quality P beams with precision and accuracy. With automated controls and precision engineering, it ensures seamless and accurate roll forming, resulting in consistent and precise P beams with step beams. The machine is versatile and can handle various materials like steel, aluminum, or other alloys, making it ideal for a wide range of structural applications. Experience superior P beam step beam production and elevate your construction projects with this reliable and high-performance P Beam Step Beam Roll Forming Machine.Heavy duty shelf P beam roll forming machine could be used to make heavy duty P beam in batch and fully automatically.

What is the P beam of shelf?

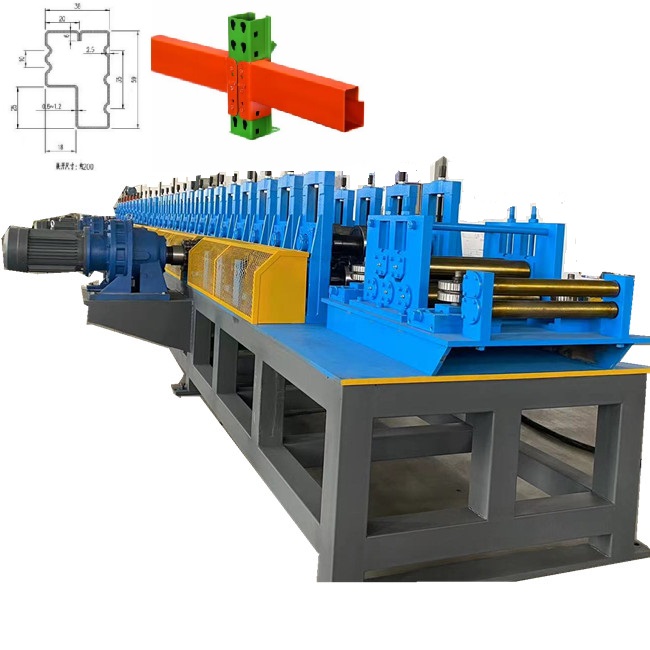

The goods shelf is made of the following elements: upright pillar, P beam, transverse braces, diagonal braces and self locking bolts. For the for the P beam, there are also two types, one is welding, the other is made by cold roll forming without pointing. Compared with point welding P beam, without welding type is not strong. So in the following part, I will take the point welding P beam for example. In the market, there are also some interlocked type P beam which the thickness should be within 1.2mm.

About this drawing, you can use welding either continuous or spot welding to make it strong. And for the above type, it uses the interlocked type.

Questions about the P beam rolling forming machine: Whether many sizes could be made by one machine and how to make, if Yes.

The answer is Yes, if those profiles have some principle to follow. If you know how to adjust spacer, you can change those profiles by spacer. Meanwhile you need to change the cutting blade. But if you do not know how to change, you can use the fast change type.

By a rolling forming and closed welding; welding beam and column and according to hold the pass of different specifications, different collocation column card; 4 surface treatment: shelf surface adopts electrostatic spraying epoxy resin, coating thickness 60~80 micron; spraying process: surface decreasing, pickling, washing, washing, washing, drying, photostatting, high-voltage electrostatic spraying and high temperature curing; 5 production process: automatic punch punching, automatic rolling line, computer fixed length shear folding, CO2 welding, electrostatic spraying (this step according to different customers the color needs to choose different spraying color).

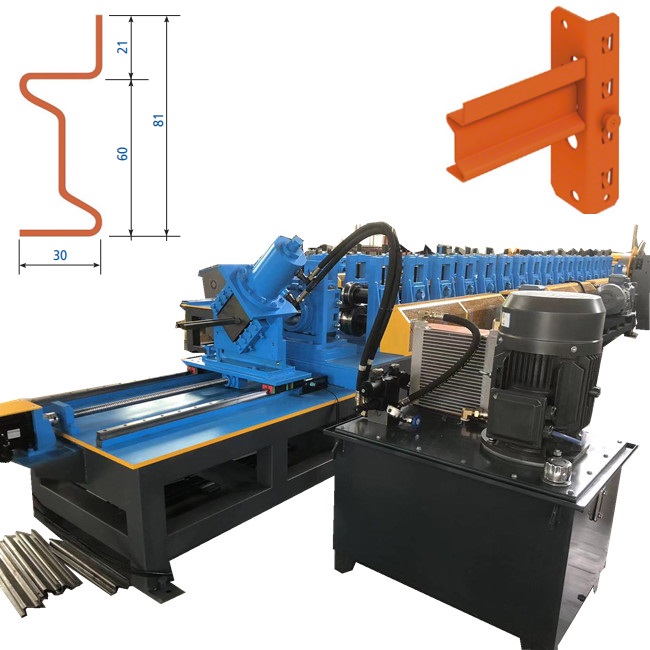

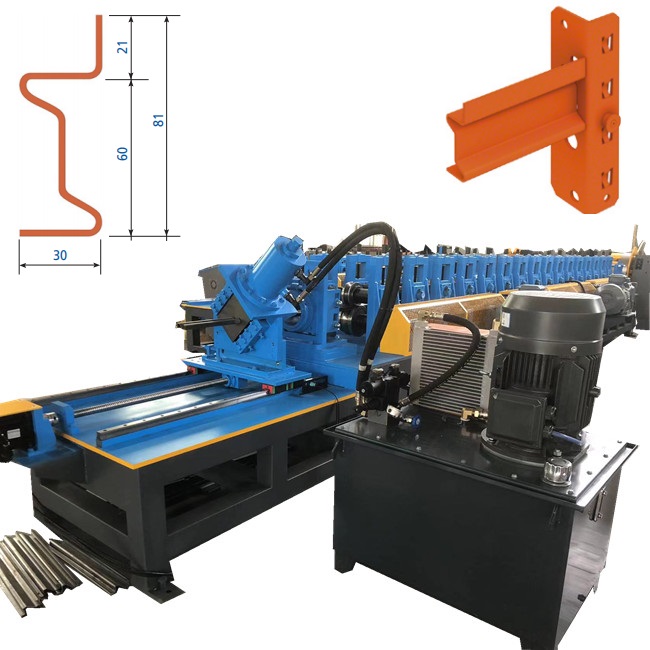

Features of this Point welding P beam roll forming machine:

- Working speed is around 5m/min including welding speed.

- Economic machine design plan but machine is quite strong.

- Dis shearing to make sure the P beam can keep perfect shape.

- Point welding can do at the same time of rolling forming.

P beam step beam roll forming machine for warehouse shelf

Machine base frame is made of U beam weld steel. In the main roll forming machine, there are 2 buttons for urgency stop in case any accident happens. Machine stations are made of iron cast to make machine stable and strong.

Main motor power (electric motor): 18.5 kw

Table frame: 460 U beam

Main roll forming

Roller station: 28 stations system

Roller material: Cr15 quench treatment precision machining,

hard chrome-plated ,HRC55-60

Shaft diameter:¢80mm

Shaft material: S45C, heat treatment HRC42

Pinching device: 2 Steps of pinching

Transmission: by chain

Roller stand: cast steel structure

Width adjust motors (electric motor): 1.5 kw*1 set, 0.75*2

sets

Voltage: 480V 60HZ 3Ph

Now checking where P beam is is used in our daily life: