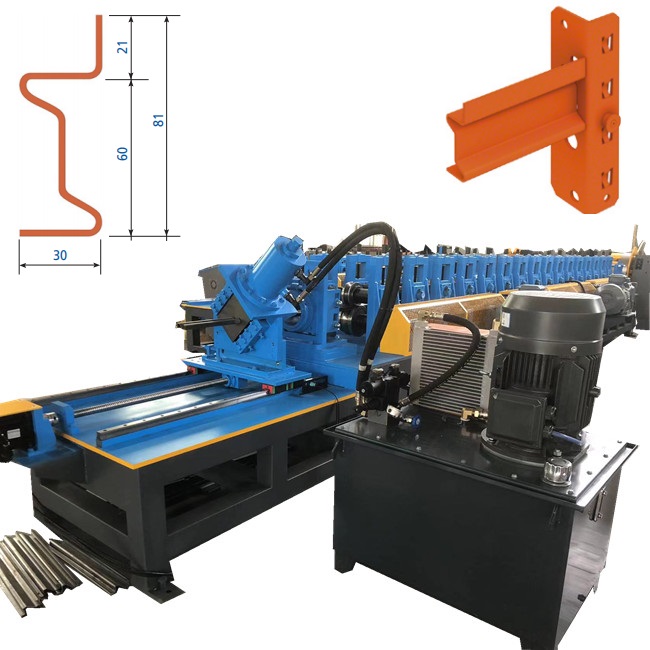

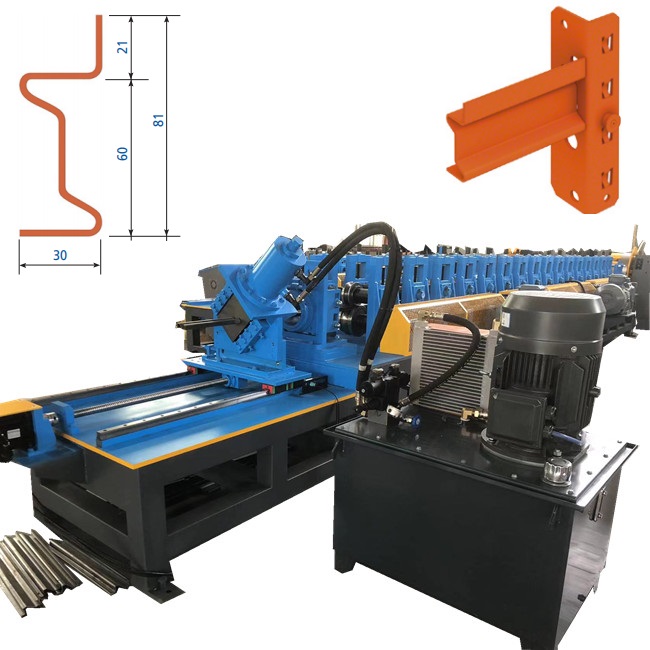

The Pallet Rack Roll Forming Machine is a state-of-the-art and versatile solution for manufacturing high-quality pallet racks. This cutting-edge machine is specifically designed to produce durable and reliable pallet rack components with precision and efficiency. With automated controls and precision engineering, it ensures seamless and accurate roll forming, resulting in consistent and precise pallet rack sections. The machine is compatible with various materials like steel, aluminum, or other alloys, making it ideal for a wide range of industrial storage applications. Experience superior pallet rack production and maximize your storage space with this reliable and high-performance Pallet Rack Roll Forming Machine, the perfect choice for efficient and organized storage systems.

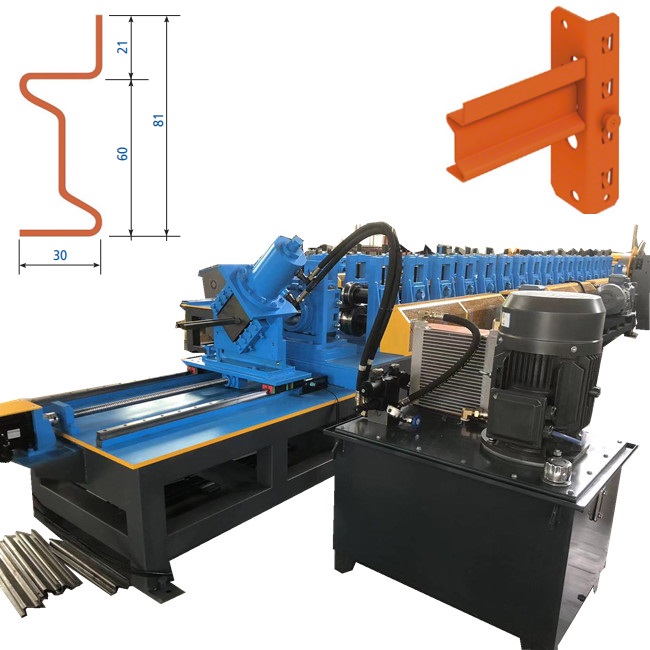

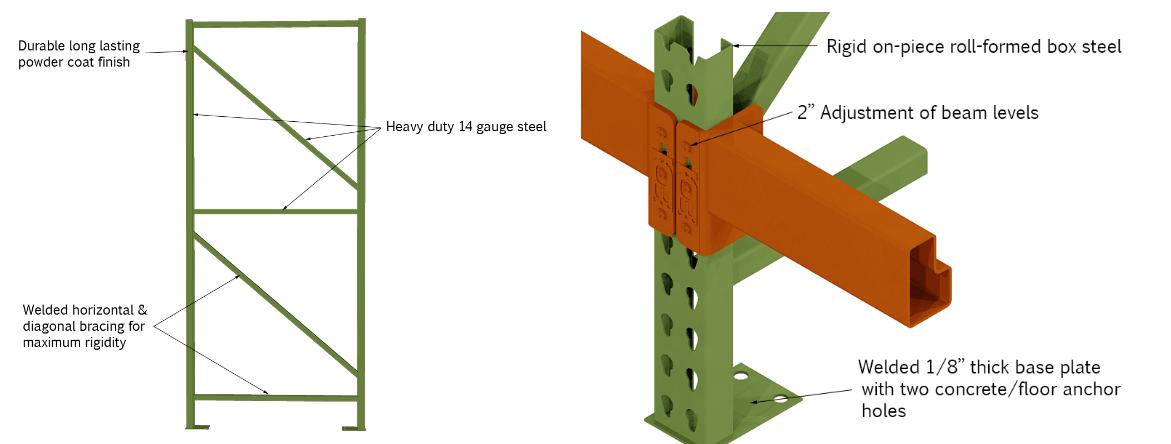

Pallet Rack Uprights/Upright Rack Roll Forming Machine is designed to make the upright in batch fully automatically. Featuring a 3″x 3″ standard column design and 5″ x 8″ base plate. Regular duty uprights are constructed of 16 gauge steel with a 16,100 lbs. capacity. Heavy duty uprights feature 14 gauge steel construction with a capacity of 23,300 lbs. (regular and heavy duty capacities based on 36″ maximum shelf spacing). Uprights utilize a bolt together design for easy component replacement. Beams can be adjusted every 2″.

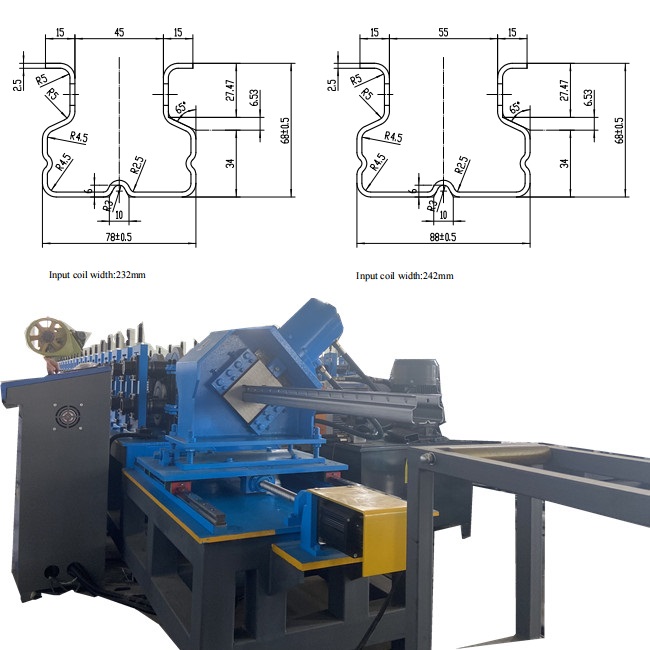

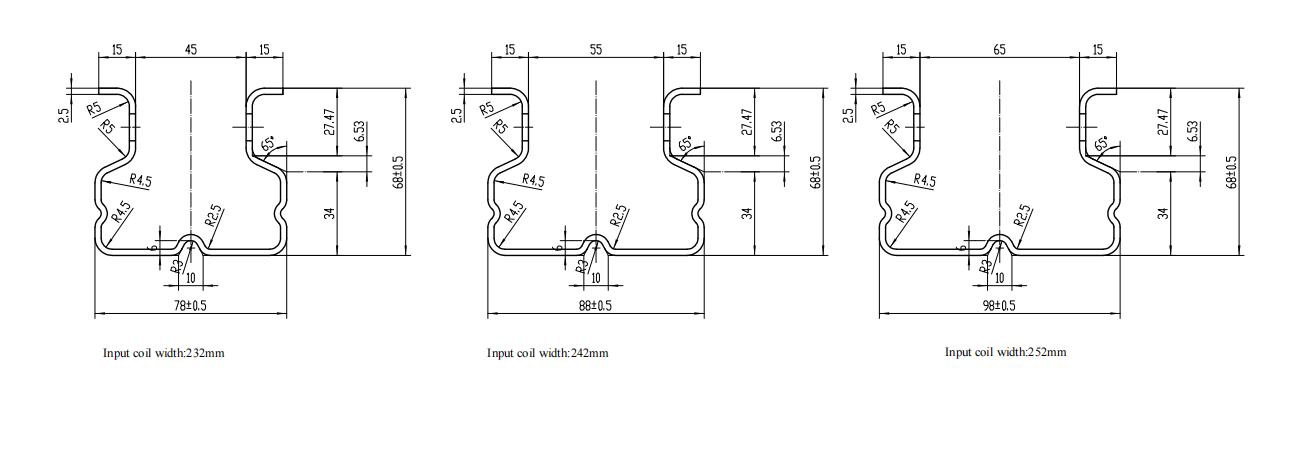

Upright Rack(also called Uprights or Upright Columns) vary in size and design depend on the load capacity and styles. Such as L Shape ( Light Capacity), C Shape (Medium Capacity), Special C Type for heavy Capacity. Holes(Tear Drop Design) and slots are punched during producing so that the load beams can be mounted into the Upright Racks. The heavy Upright Racks thickness up to 2.5mm. Here are some drawing profile for your reference:

More in details with sizes:

Pallet Rack Uprights/Upright Rack Roll Forming Machine

Upright Roll Forming Machine is suitable to form galvanized and CS Stainless steel and copper and so on. Mostly customers place orders for galvanized and carbon steel that for business construction is more popular.

Pallet racking is usually comprised of beams, wire decks, and uprights.

Most common types of pallet racking systems:

Cantilever Racking

Selective Racking

Push Back Racking

Drive-In Racking

Pallet Flow Racking

Carton Flow Racking

They are different in the drawing profiles, we can customize the racks according to the customer drawing profiles.

This production line consists of de-coiler, servo feeder, hole press, main roll forming machine and hydraulic shear units. And each elements could be designed according to the customer budget like hydraulic decoiler or manual one, gearbox transmission or chain, flying tracking shearing or stop shearing. All those are optional.

Zhongtuo Upright Rack Roll Forming Machine advantages:

- Three profiles could be made by one machine by adjusting spacers or fully automatic type.

- Gcr12mov rollers are durable and long time to use.

- Molding frame of thickness 45mm, for more stronger when working.

- YangLi punching station, for fast and accurate punching.

- One button control for whole production line.

- High accuracy when punching and shearing.

- No need to cut half holes.

- Automatic decoiler with the leveling system, take up small space and more accurate.

- Molding frame with the protection cover, beautiful and safety.

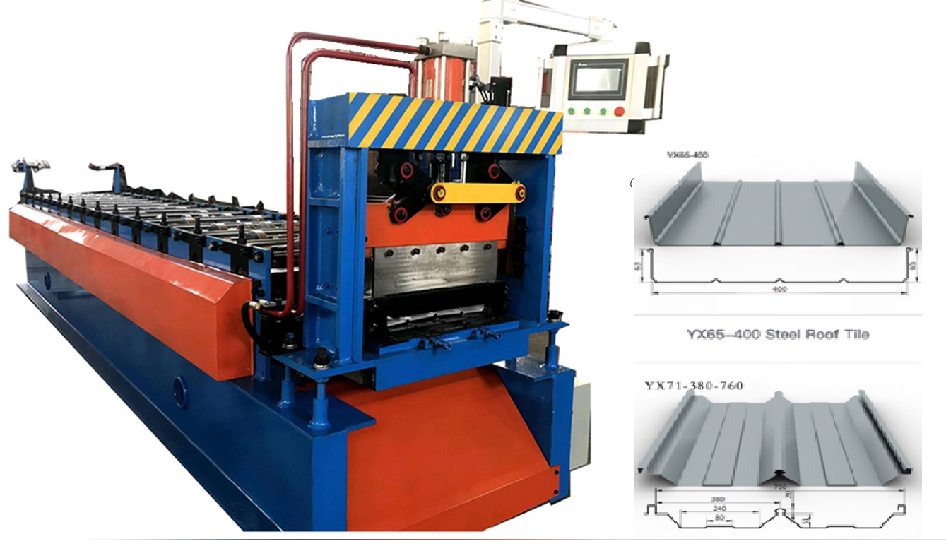

We also make the related elements rolling forming machines like:

C bracing rolling forming machine

Box beam rolling forming machine

P beam rolling forming machine

Shelf panel rolling forming machine

Pallet Rack Uprights/Upright Rack Roll Forming Machine working working video for your reference: