As with any industry, the metal forming sector is continuously evolving, driven by new technologies and trends that push the boundaries of efficiency, precision, and versatility. In this post, we will explore some of the most exciting innovations in wall angle rolling machines, taking a closer look at the latest technologies, features, and advancements that are shaping the future of metal bending.

CNC Technology: Enhancing Precision and Automation

One of the most significant innovations in wall angle rolling machines is the integration of CNC (Computer Numerical Control) technology. This advanced control system allows operators to program precise bend angles, roller positions, and other parameters directly into the machine’s software. The machine then executes the bending process automatically, ensuring optimal accuracy and repeatability.

Some benefits of CNC wall angle rolling machines include:

Improved precision: CNC technology enables tighter tolerances and more accurate bends, reducing the need for post-processing and rework.

Increased efficiency: The automation capabilities of CNC machines streamline the bending process, allowing for faster production times and higher throughput rates.

Enhanced versatility: CNC machines can store multiple bending programs, making it easy to switch between different projects or profiles without manual adjustments.

Reduced operator error: By automating the bending process, CNC machines minimize the risk of operator errors, ensuring consistent results across multiple pieces.

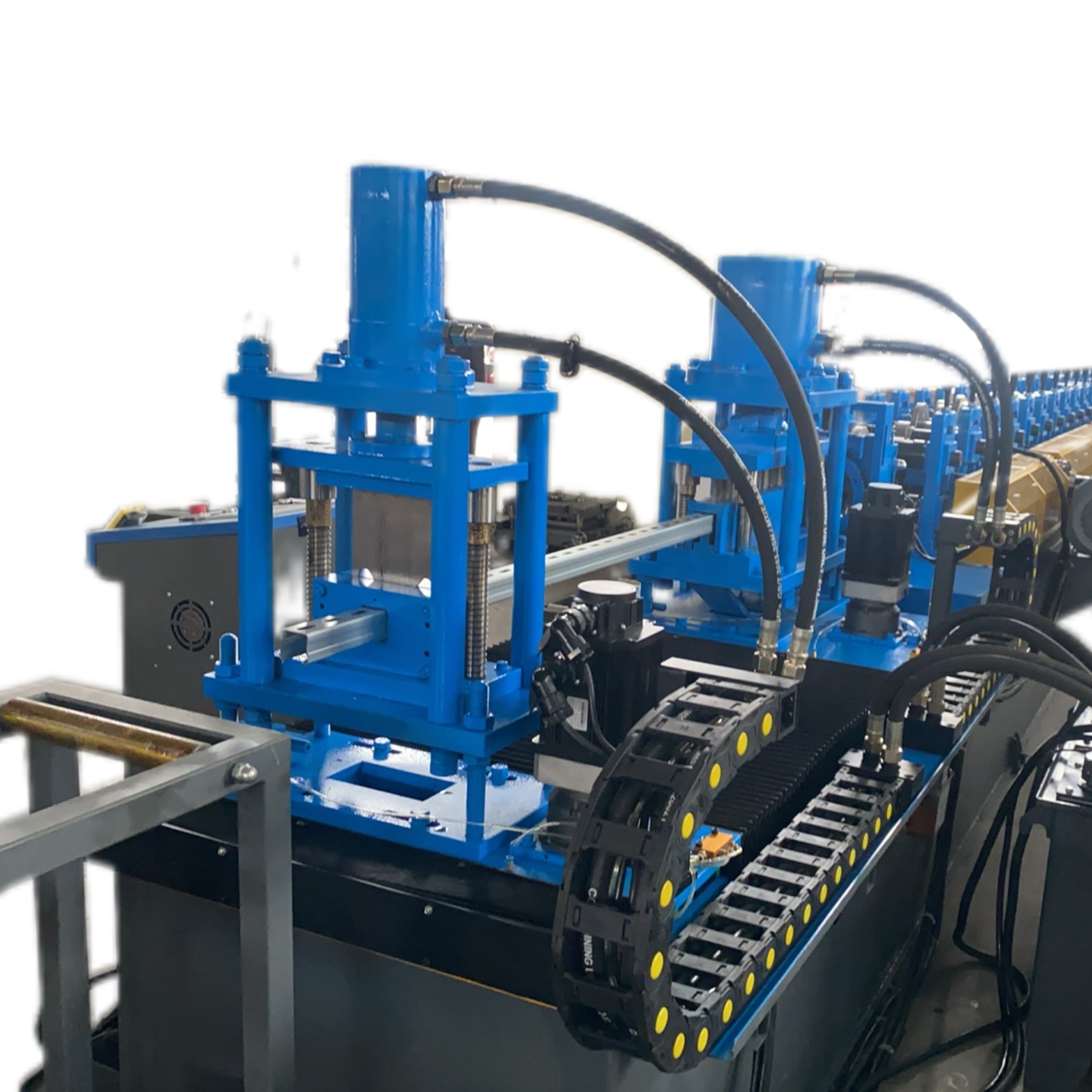

Advanced Drive Systems: Boosting Power and Control

Modern wall angle rolling machines often feature advanced drive systems, such as hydraulic, pneumatic, or servo-electric, which provide improved power and control during the bending process. These systems enable the machine to apply more force to the metal profile, allowing for tighter bends and the ability to work with thicker or more resilient materials.

Some advantages of advanced drive systems in wall angle rolling machines include:

Increased power: Hydraulic and pneumatic drive systems can generate more torque than traditional mechanical systems, enabling the machine to bend thicker materials or create more complex shapes.

Enhanced control: Servo-electric drive systems offer precise control over roller positioning and force, ensuring accurate and consistent bends.

Energy efficiency: Advanced drive systems often consume less energy than traditional mechanical systems, resulting in cost savings and reduced environmental impact.

IoT and Industry 4.0 Integration: Streamlining Production and Data Management

As the metal forming industry embraces the concepts of Industry 4.0 and the Internet of Things (IoT), wall angle rolling machines are becoming increasingly interconnected and intelligent. By integrating sensors, data analytics, and cloud-based platforms, these machines can provide real-time feedback and insights into the bending process, enabling operators to optimize production and improve overall efficiency.

Some of the benefits of IoT and Industry 4.0 integration in wall angle rolling machines include:

Real-time monitoring: Sensors and data analytics provide continuous feedback on machine performance and bending results, allowing operators to make informed decisions and adjustments as needed.

Predictive maintenance: By analyzing machine data and usage patterns, operators can identify potential maintenance issues before they become critical, minimizing downtime and ensuring optimal performance.

Remote access and control: Cloud-based platforms enable operators to access and control their wall angle rolling machines from anywhere, providing increased flexibility and convenience.

Enhanced collaboration: By sharing machine data and insights across teams and departments, companies can foster better collaboration and decision-making, leading to more efficient and effective operations.

[Image suggestion: A visual representation of IoT and Industry 4.0 integration in a wall angle rolling machine, highlighting the various connected components and data analytics capabilities.]

Modular and Customizable Designs: Tailoring Machines to Specific Needs

In response to the growing demand for flexibility and customization, wall angle rolling machine manufacturers are increasingly offering modular and customizable designs. These machines can be easily adapted to suit specific production needs or material requirements, providing an efficient and cost-effective solution for a wide range of applications.

Some advantages of modular and customizable wall angle rolling machines include:

Scalability: Modular designs enable companies to scale their production capabilities as needed, adding or removing components to match changing requirements.

Custom tooling: Customizable machines can be equipped with specialized tooling designed for specific materials or bending processes, ensuring the best possible results.

Reduced setup times: Modular and customizable machines can be quickly reconfigured for different projects or profiles, minimizing setup times and boosting overall efficiency.

Future-proofing: As new technologies and innovations emerge, modular and customizable machines can be easily upgraded or adapted to stay current and competitive.

Conclusion

The future of wall angle rolling machines is bright, driven by a range of exciting innovations and technologies that are transforming the way metal is bent and shaped. From CNC technology and advanced drive systems to IoT integration and modular designs, these advancements are making metal bending more precise, efficient, and versatile than ever before. By staying informed about the latest trends and incorporating these innovations into your operations, you can ensure your metal forming processes remain at the cutting edge and continue to meet the evolving needs of your customers.