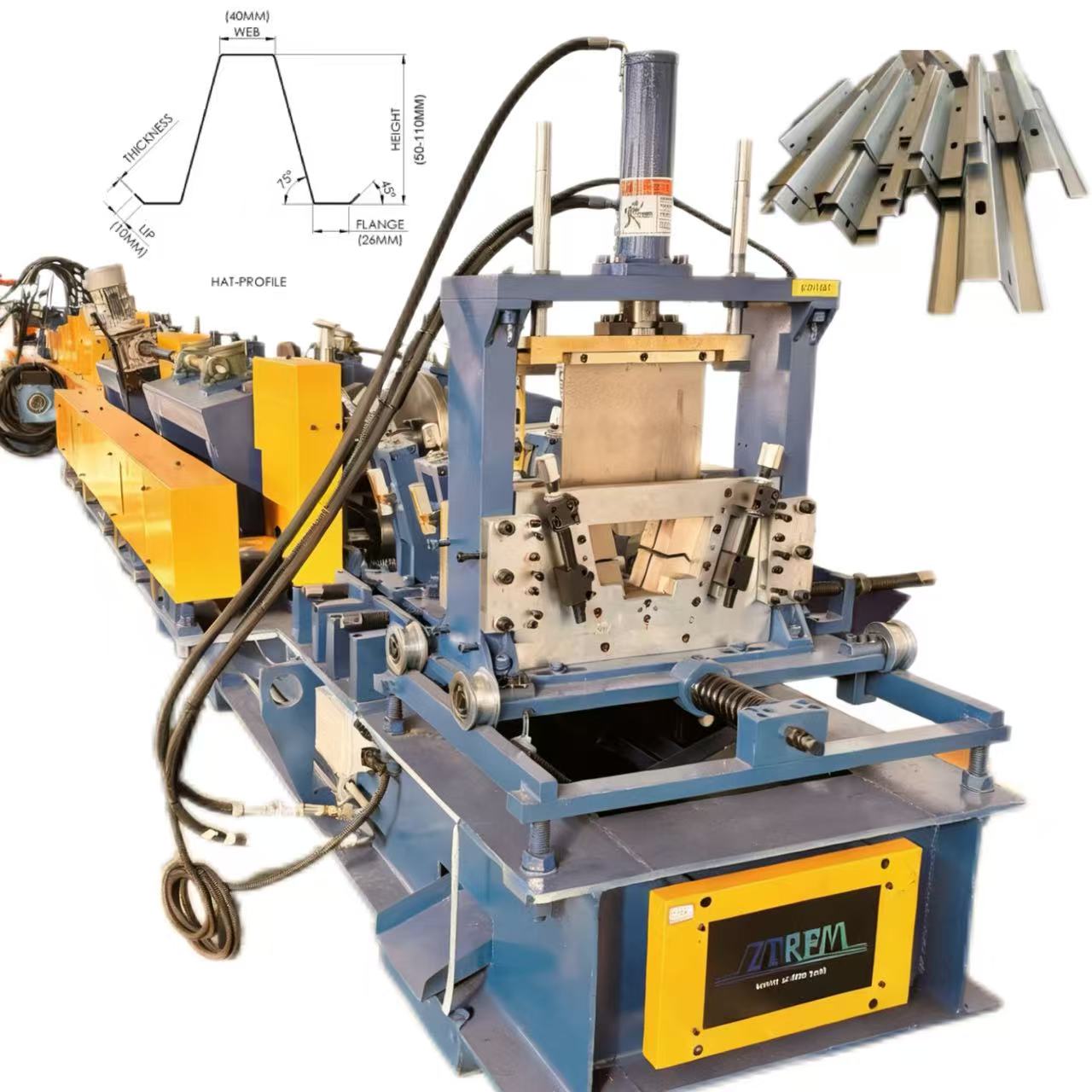

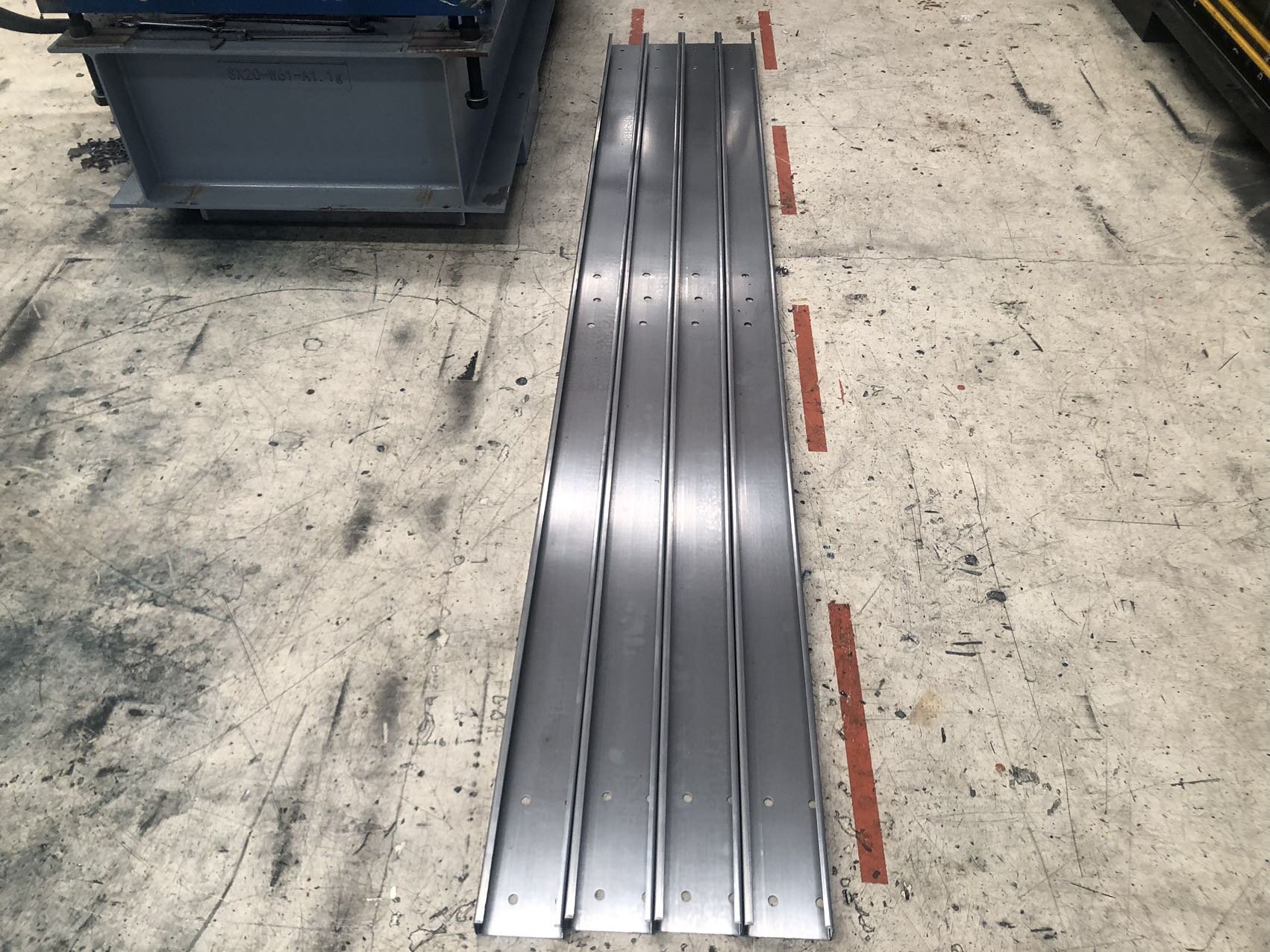

In the construction sector, C purlin roll forming machines are employed to manufacture top-notch purlins that play a key role in supporting the roofs and walls of buildings. These machines are engineered in a way that enables them to create purlins with diverse sizes and shapes, which are customized according to the specific demands of different building projects.

The purlin roll forming machines possess high productivity. They can turn out a substantial quantity of purlins within a brief time span. Besides, they are simple to operate and don’t need much maintenance. As a result, they are a budget-friendly choice for all construction projects.

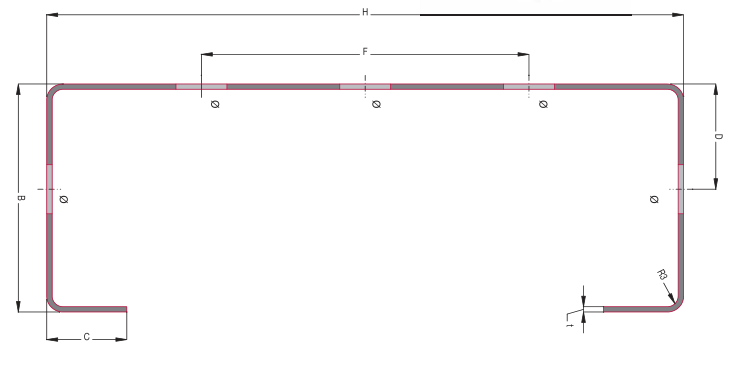

Customer request profile drawing and punching hole arrangement:

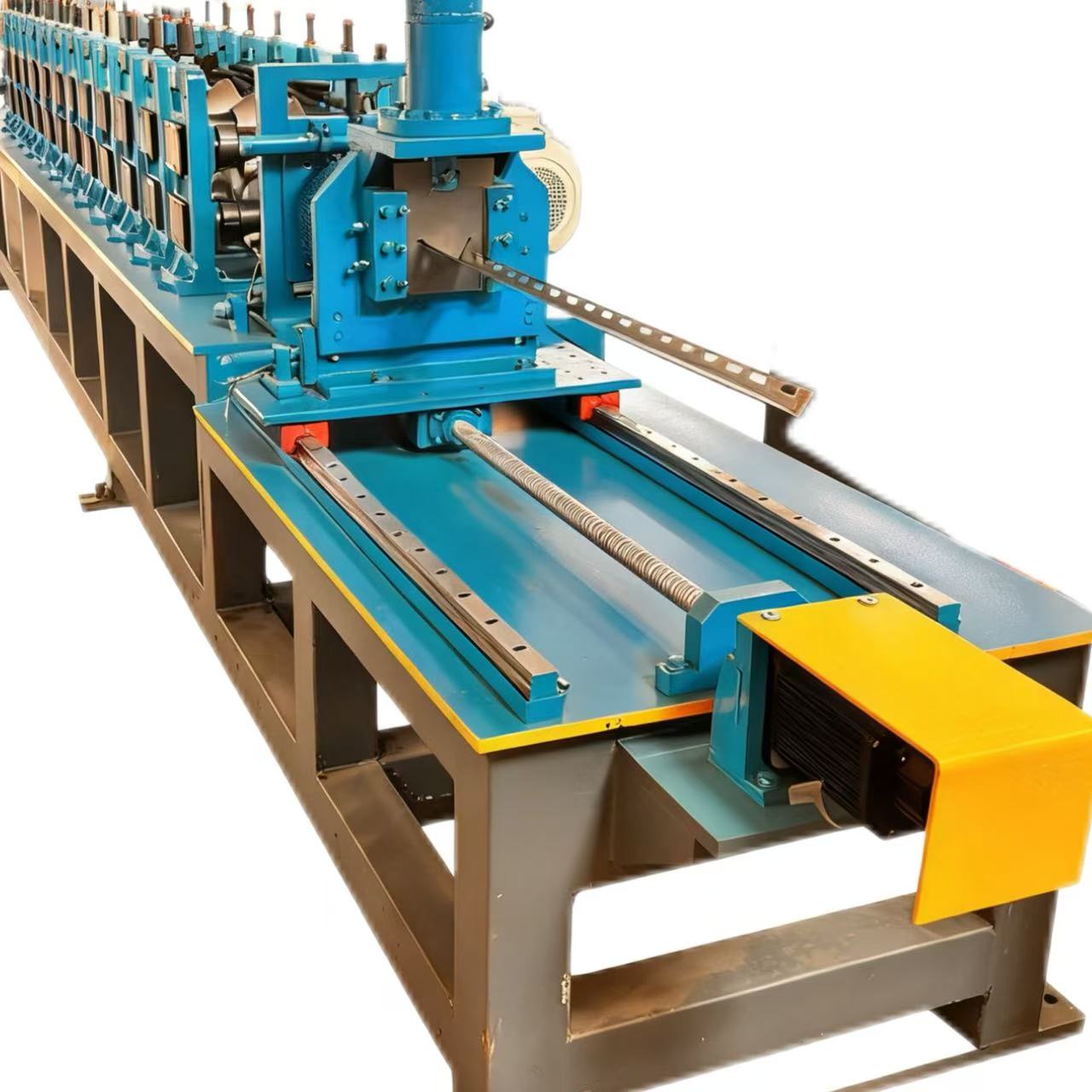

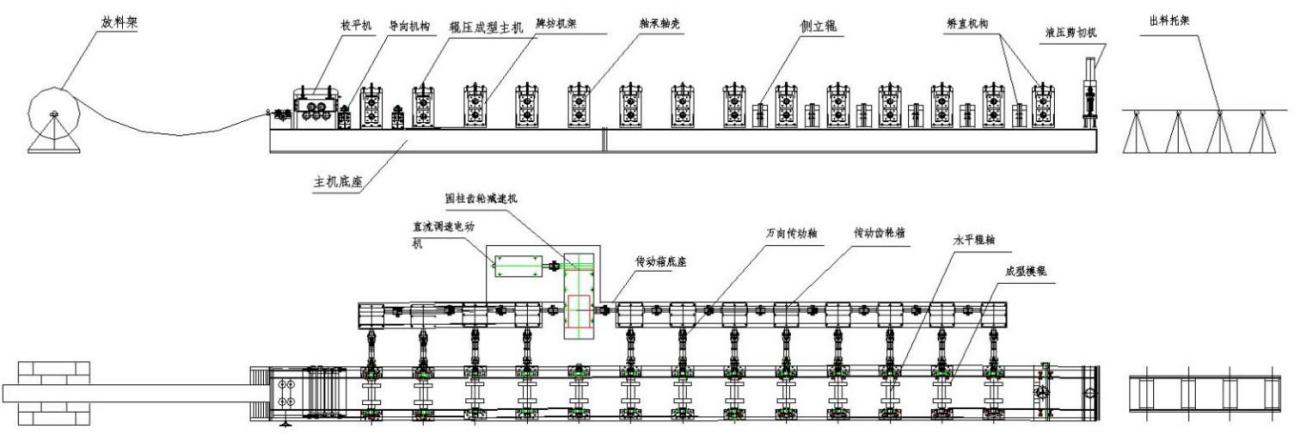

Working Process of C Purlin Roll Forming Machine:

Technical parameters of the machine:

1.5 tons manual decoiler

| Loading capacity | 5T |

| Uncoiling width | 450mm |

| Inner diameter | 450-550mm |

| Power | Manual |

2.Main roll forming machine

| Rolling shaft material | 40Cr |

| Shaft diameter | 70 mm |

| Roller material | GCr15 with heat treatment, polishing and galvanizing |

| Rolling station | 18 stations |

| Work speed | 0-12 m/min |

| Size adjustment | Automatically by PLC control |

| Motor power for sliding | 3kw |

| Machine frame | Iron casting vertical structure (stronger structure match with 70mm diameter shaft) |

| Work power | 15 kw |

| Transmission | Gear |

3.Punching device

| Punching type | Hydraulic stop punching |

| Punching unit quantity | 2 sets with cylinder driving |

| Mold adjustment | Adjust the screw Manually |

| Mold material | Cr12 |

4.cutting system

| Material of cutter | Cr12MOV, quenching |

| Universal cutters | 75-200mm |

| Cutting length tolerance | ±2mm |

- PLC control system