The integrated machine of C-shaped steel and Z-shaped steel has a wide range of applications in the fields of construction and engineering, mainly used in the main load-bearing structures of large and medium-sized industrial and civil buildings. For example, they can be used for roof load-bearing and wall support in factories, warehouses, locomotive depots, aircraft hangars, exhibition halls, theaters, sports venues, and market flower sheds.

Application scenarios:

1.Factory buildings and warehouses:

The steel produced by the integrated machine of C-shaped steel and Z-shaped steel is commonly used to construct large steel structure factories and warehouses. Due to its lightweight and high-strength characteristics, it can withstand large loads, and is easy to construct, which can shorten the construction period.

2.Airports and stations:

In large transportation facilities such as airports and stations, the steel produced by the integrated production of C-shaped steel and Z-shaped steel is used to construct roof and wall structures, providing stable support and load-bearing capacity.

3.Sports venues:

In the construction of sports venues, the steel produced by the integrated machine of C-shaped steel and Z-shaped steel is used to construct structures such as roofs and stands, ensuring the stability and safety of the venues.

4.Exhibition halls and cinemas:

These places have high requirements for the aesthetics and stability of the structure, and the steel produced by the integrated machine of C-shaped steel and Z-shaped steel can meet these needs, providing a sturdy and beautiful structure.

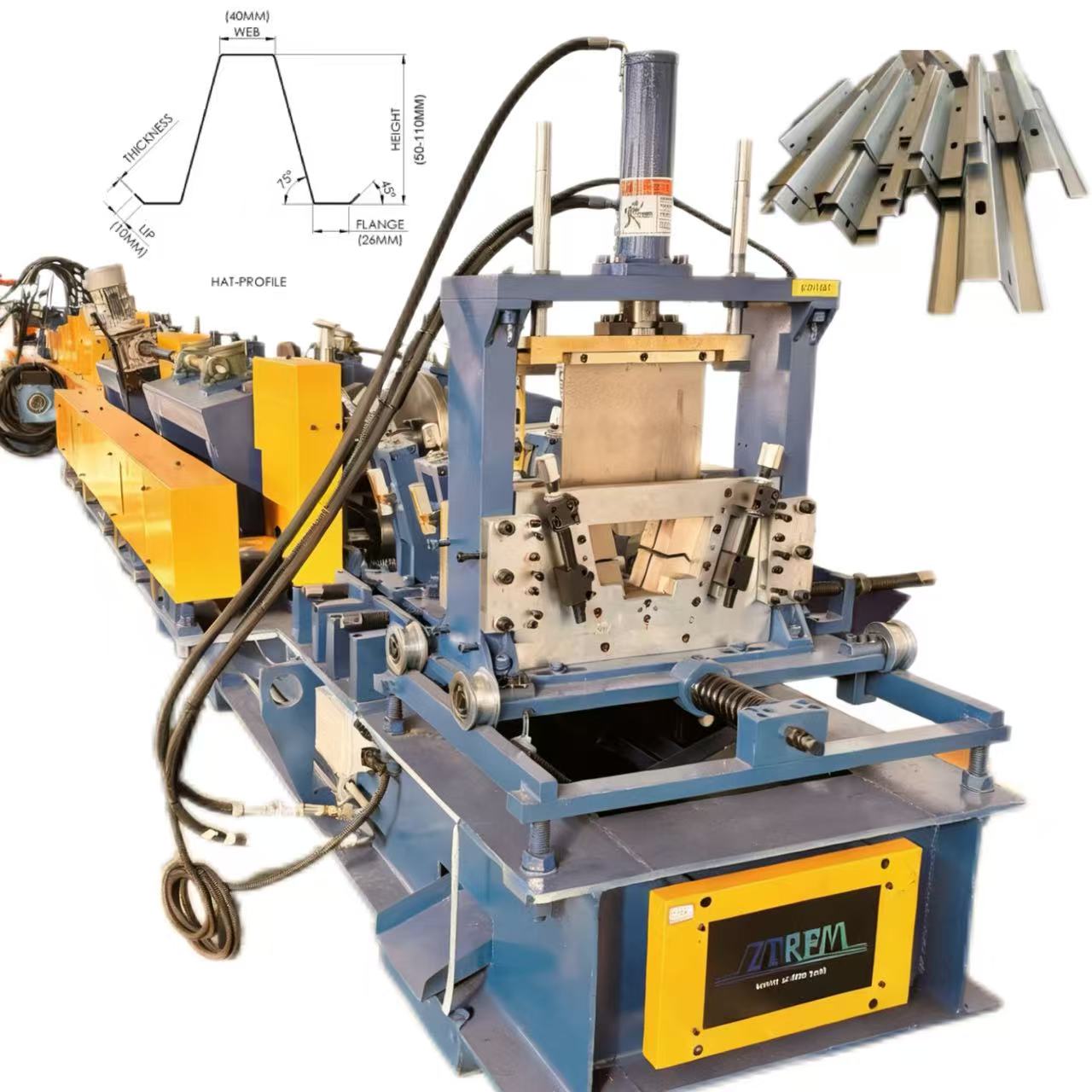

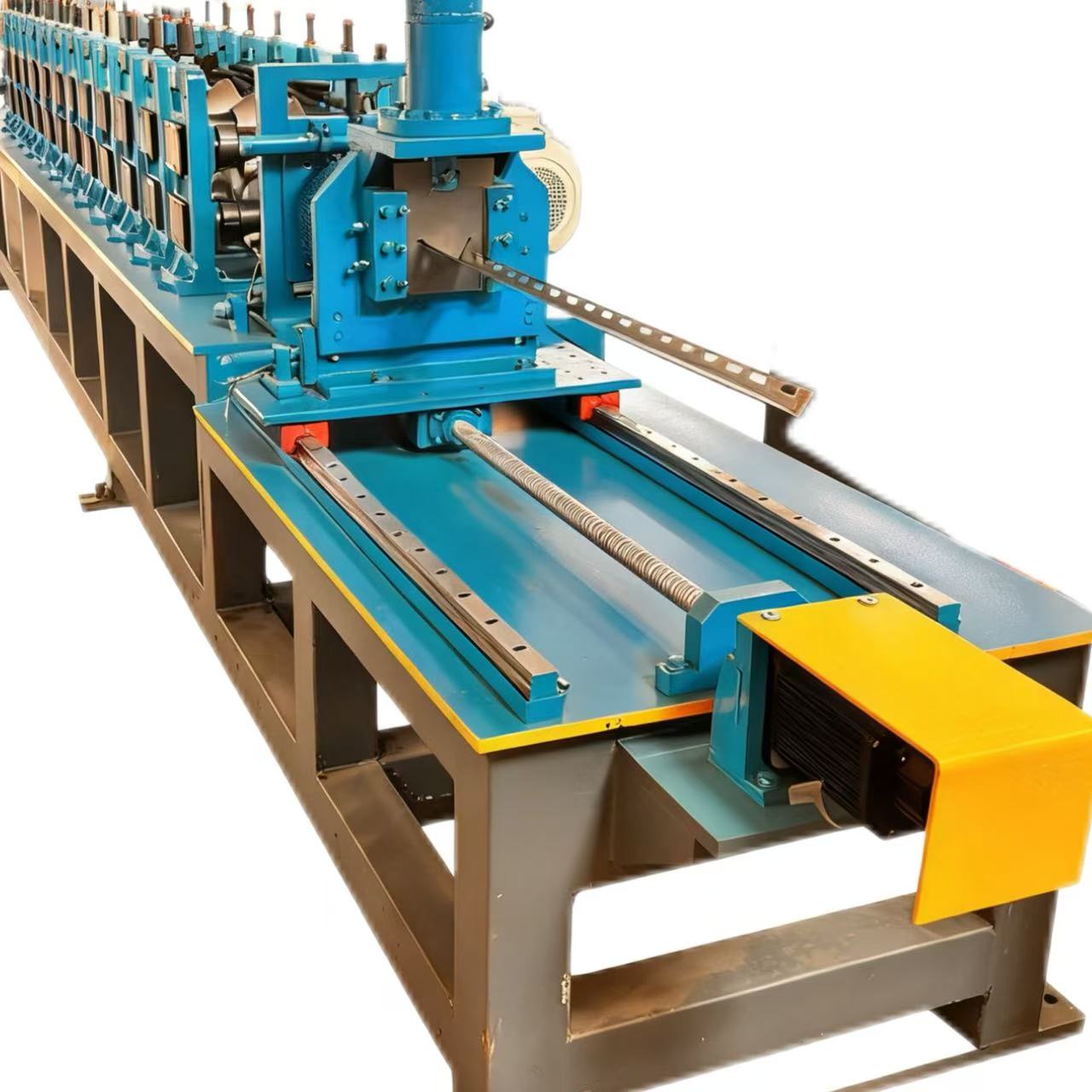

Technical features:

- Infinite transformation system:

capable of infinite transformation and infinite cutting, cutting can be completed without changing the blade, with high production efficiency. - High productivity:

capable of producing 8-10 meters of steel per minute, suitable for large-scale production needs. - Multifunctionality:

capable of producing standard and non-standard board shapes to meet diverse needs.

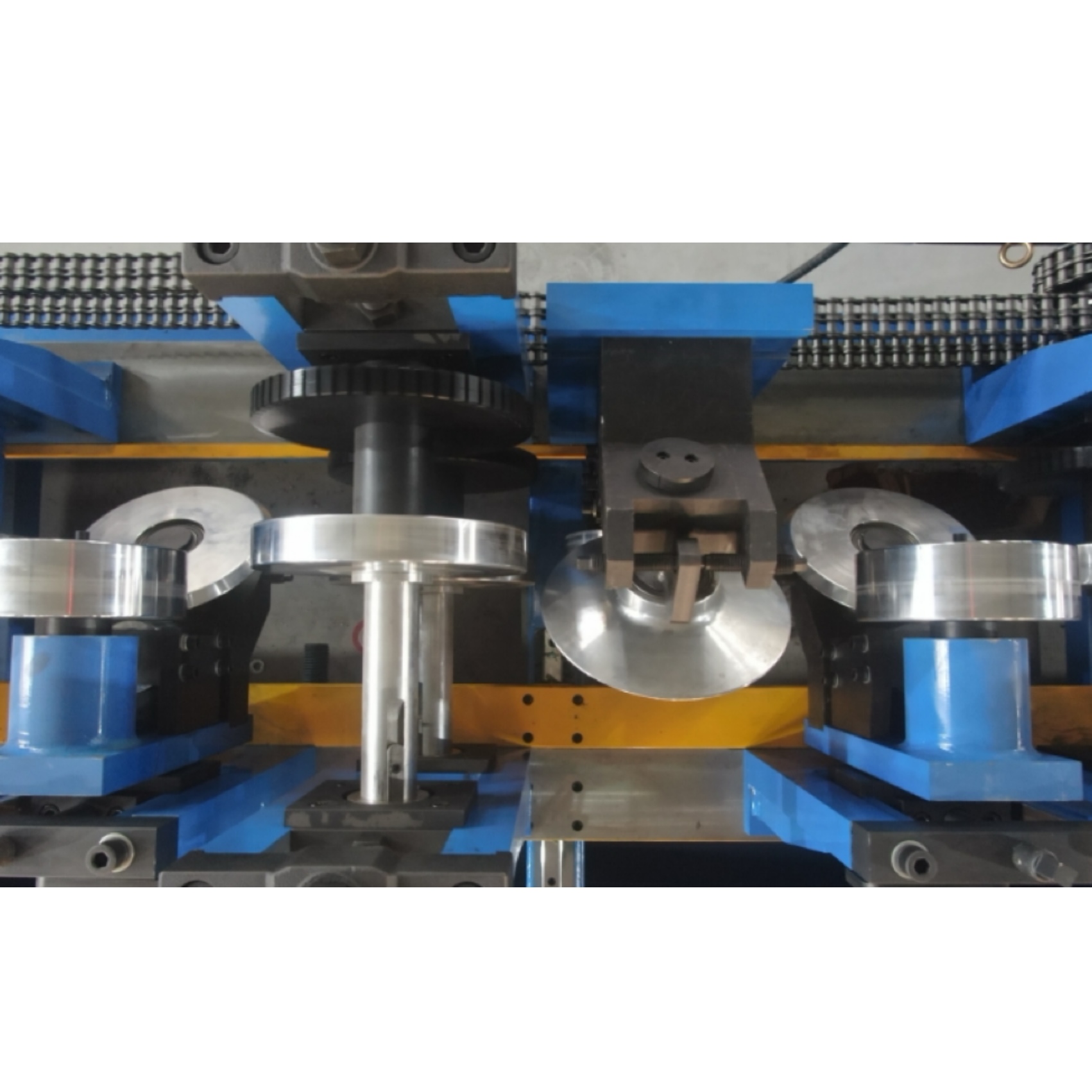

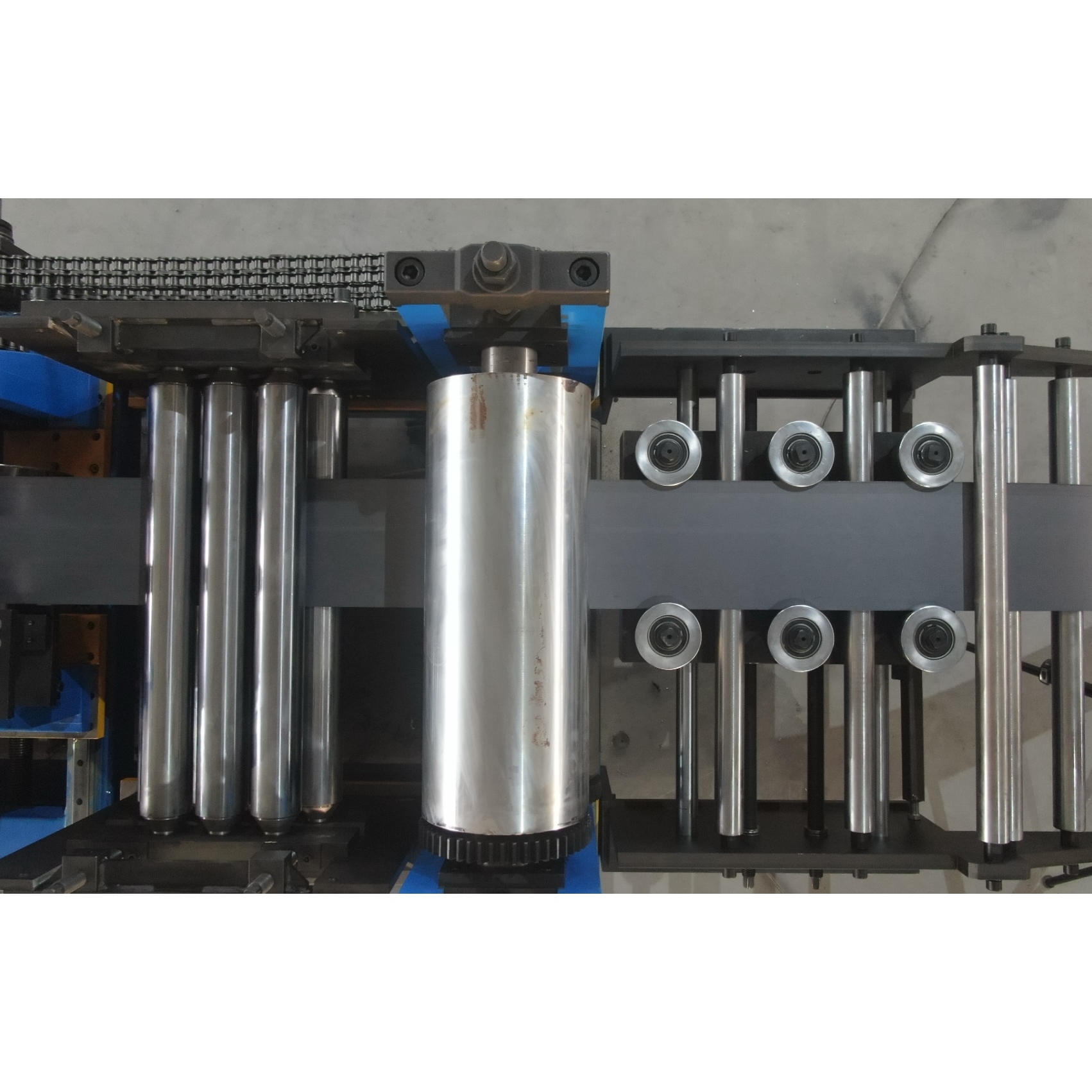

Product Attributes :

1.Formed MaterialPPGI,GI,AIThickness:1.5-3mm2.DecoilerHydraulic automatic decoilerManual decoiler(will give you as free)3.Main bodyRoller station12 rows(As your requirement)Diameter of shaft80mm solid shaftMaterial of rollersGcr 15 with quenched teeatmentMachine body frameMetal steel weldedDriveChain transmissionDimension(L*W*H)9500*800*1200(customize)WeightAbout 7T4.CutterAutomaticcr12mov material, no scratches, no deformation5.PowerMotor Power15KWHydraulic system power5.5KW6.Voltage380V 50Hz 3PhaseAs your requirement7.Control systemElectric BoxCustomized(famous brand)LanguageEnglish(Support multiple languages)PLCAutomatic production of the whole machine. Can set batch, length, quantity, etc.18.Forming Speed60-70m/min(customized)The speed depends on the shape of the tile and the thickness of the material.Products Display:

Here is the working video of this machine for everyone to watch: