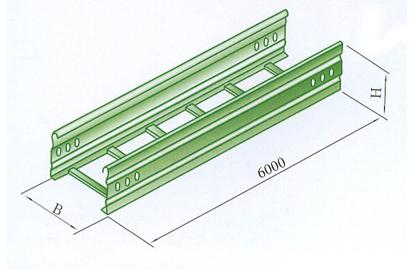

Cable tray is divided into trough type, tray type, ladder type, grid format and other structures, which is composed of support, bracket and installation accessories. The bridge in the building can be erected independently or attached to various buildings (structures) and pipe gallery supports. It should reflect the characteristics of simple structure, beautiful appearance, flexible configuration and convenient maintenance. All parts need galvanizing treatment and can be installed on the bridge in the open air outside the building.

The full name of the rigid structure system with closely connected supporting cables (hereinafter referred to as the bridge) composed of trough type, tray type or step type straight-line section, bend, tee, cross components, bracket (arm support), hanger, etc. The upwelling cable tray has been continuously recognized and accepted by the market, and the localization of the cable tray industry has been strengthened. The products are made of high-quality cold-rolled steel plate, which has attracted wide attention. The products are made of high-quality cold-rolled steel plate, and the surface processes include cold galvanizing, hot galvanizing, electrostatic spraying, fire-proof coating, baking paint, etc.

The V-type stepped cable tray is improved and designed according to relevant data at home and abroad. It has the advantages of light weight, low cost, unique shape, convenient installation, good heat dissipation and ventilation. It is suitable for the laying of general cables with larger diameter and for the laying of high and low voltage power cables.

Tray type cable tray is the most widely used in petroleum, chemical industry, light industry, telecommunications and other fields. It has the advantages of light weight, large load, beautiful appearance, simple structure, convenient installation and so on. It is not only suitable for the installation of power cables, but also suitable for the laying of control cables.

Trough type cable tray is a kind of fully enclosed cable tray. It is most suitable for laying computer cables, communication cables, thermocouple cables and control cables of other highly sensitive systems. It has a good effect on the shielding interference of control cables and the protection of cables in heavy corrosion environment.

Advantages and disadvantages of ladder type, tray type and trough type cable trays: the ladder type cable tray has good ventilation performance and is not dustproof and interference proof. Tray type and tray type anti-interference performance.

At present, long-span cable trays are generally assembled from pultruded FRP profiles, which are suitable for power cables, control cables, lighting cables and accessories. Compared with iron bridge, it has the advantages of long service life (the general design life is 20 years), convenient installation and low cost (the proportion is only 1 / 4 of carbon steel, there is no need for hot work in construction, and the length of a single bridge can be up to 8m or even longer), convenient cutting and no maintenance.

Combined cable tray is a new type of cable tray, which is the second generation of cable tray series. It is suitable for the laying of various projects, units and cables. It has the characteristics of simple structure, flexible configuration, convenient installation and novel form.

As long as the combined cable tray adopts three basic types with width of 100, 150 and 200mm, it can form the cable tray of the size you need. It does not need to produce bend, tee and other accessories, and can turn, widen, lead up and down arbitrarily according to the on-site installation. At any position, it can be led out by pipe without drilling and welding. It is not only convenient for engineering design, but also convenient for production and transportation, and more convenient for installation and construction. It is the most ideal product in cable tray at present

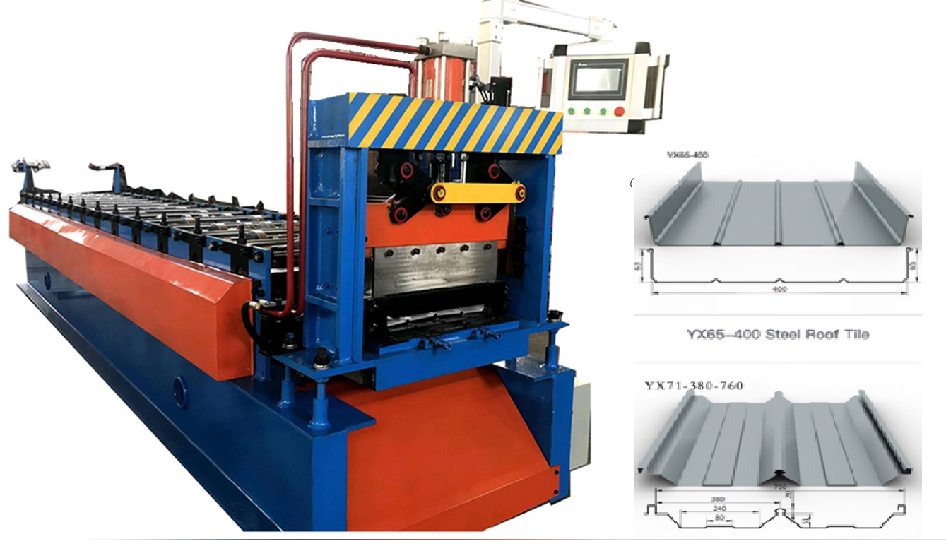

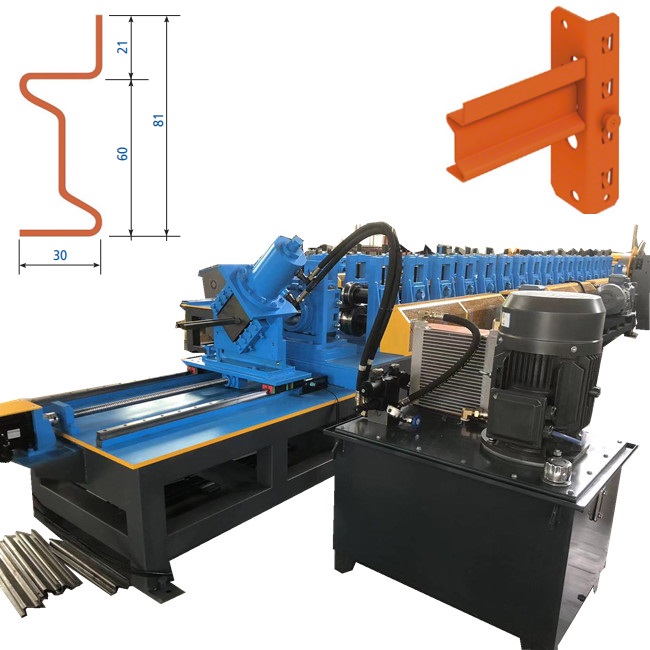

Normally the cable tray roll forming machine can produce so many sizes cable tray product in one machine, it can automatic changing sizes by PLC computer system.

It can achieve one machine for all the sizes which you need.