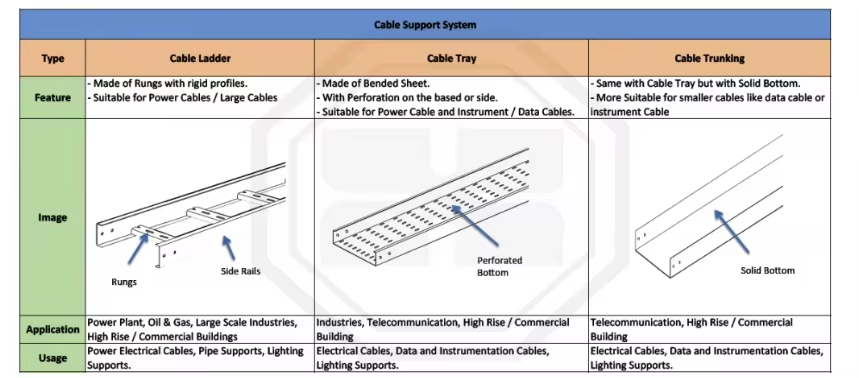

Against the backdrop of rapid construction of new infrastructure such as 5G base stations, data centers, and smart factories, cable trays, as the “vascular network” of the power system, are experiencing explosive growth in market demand. The traditional handmade methods can no longer meet the requirements of modern engineering for accuracy, efficiency, and reliability. The emergence of professional Cable Tray Roll Forming Machine is reshaping the construction standards of power cabling systems.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:200-1130 mm

|

||

|

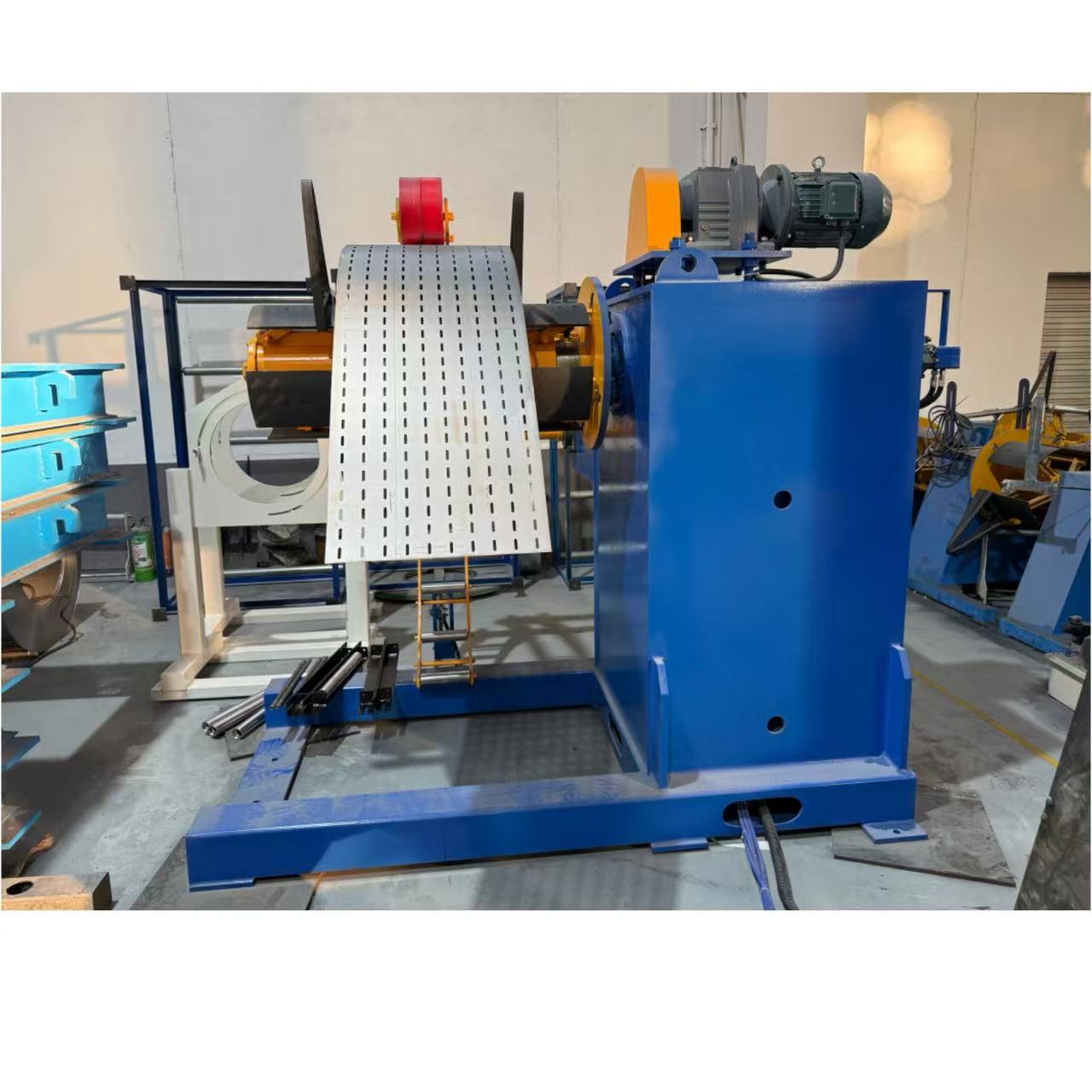

2.Decoiler

|

Hydraulic automatic decoiler

|

7T

|

||

|

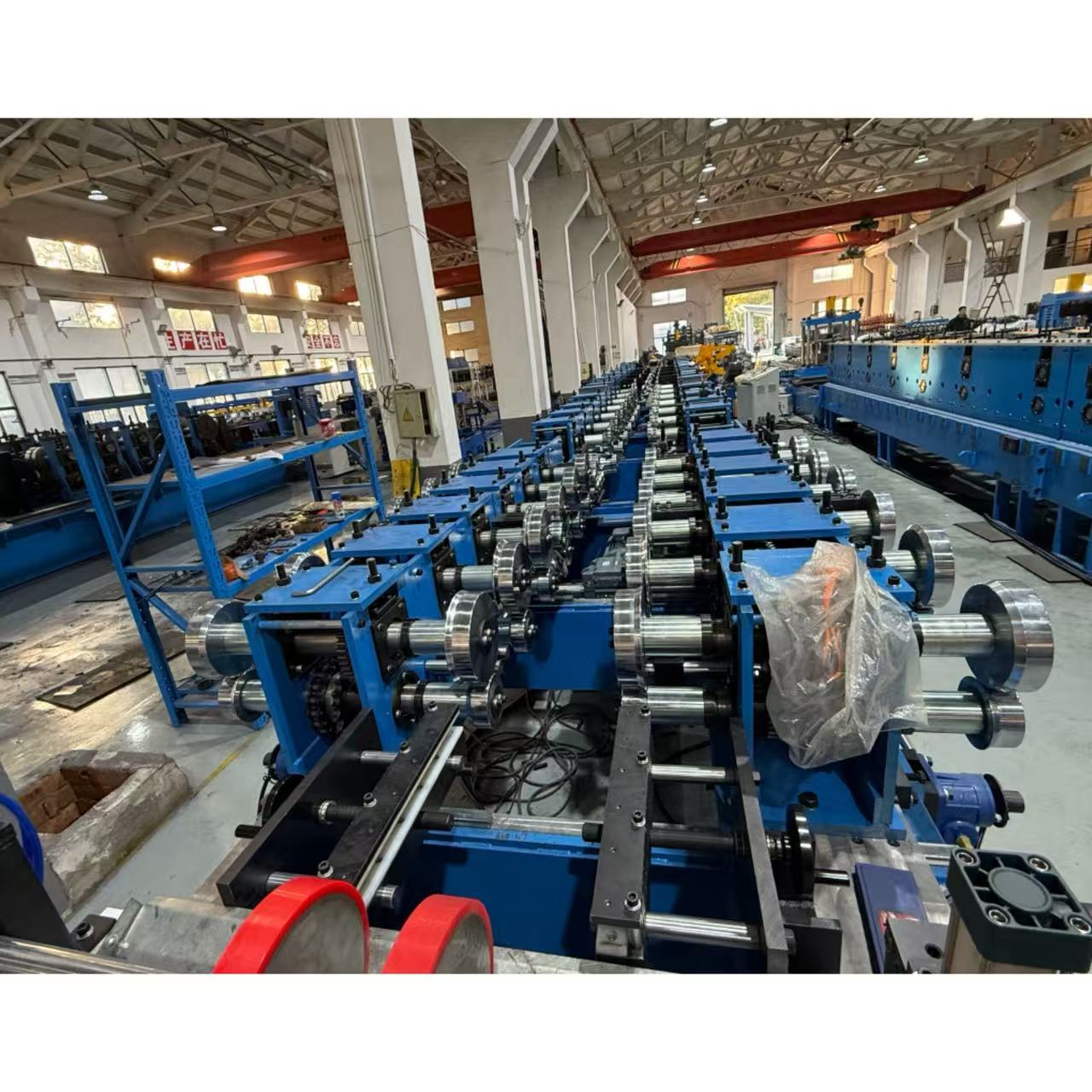

3.Main body

|

Roller station

|

22 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

35×1.5×1.6m

|

|||

|

Weight

|

About 60KW

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

5-10m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Equipment Advantage:

1.Provide a safe electrical environment:

Cable trays can provide a safe and stable laying environment for cables, effectively protecting them from external environmental damage such as mechanical damage, chemical corrosion, etc. At the same time, it also facilitates the management and maintenance of cables, ensuring the normal operation of the electrical system.

2.Strong flexibility:

The design of cable trays is flexible and diverse, and can be customized and installed according to the specific direction and layout of buildings or structures. Whether it is straight or curved laying, it can be easily handled to meet the needs of different scenarios.

3.Good ventilation and heat dissipation effect:

The structural design of the cable tray is reasonable and has good ventilation and heat dissipation effect. This helps to reduce the heat generated by the cable during operation and extend the service life of the cable.

4.Easy installation and improved construction efficiency:

The installation process of cable trays is relatively simple and does not require complex tools and equipment. This greatly improves construction efficiency, shortens the construction period, and reduces construction costs.

Profile drawing:

Application scenario:

• Power Engineering:

Cable trays are the core carrier for cable laying in power systems, widely used in power plants, substations, transmission and distribution lines, and industrial plants for power wiring, ensuring the safe and orderly transmission of electrical energy through cables.

• Communication and Data Center:

In the construction of communication networks and data centers, cable trays are used to carry optical fibers, network cables, etc. Their non-magnetic properties can effectively reduce electromagnetic interference and ensure the stability of signal transmission, such as in projects such as the Yangtze River Delta (Jinhua) data center.

• Transportation infrastructure:

in railway, highway and urban rail transit projects, cable bridges are used for power and communication wiring of tunnels, bridges and facilities along the line, such as Dayao Mountains Tunnel of Beijing Guangzhou Railway, Songshanhu Railway Tunnel and other projects.