Here is the operation video for this machine for your viewing:

Definition and Functions of Equipment Core

Cable Tray Roll Forming Machine Quick Change Profile Making Machine is not a single product, but a modular system composed of supporting structures, trays/ladders/trough boxes, connectors, cover plates, and other components. Its main functions can be summarized into three categories:

1.Cable support and fixation:

By using standardized brackets, arms, and other components, cables are stably supported along planned paths (horizontal, vertical, and turning) to avoid insulation layer wear or signal interference caused by cable sagging or disorderly stacking due to their own weight;

2.Environmental protection:

Based on different usage scenarios, provide structures with different levels of protection (such as enclosed trough boxes for dust and water prevention, anti-corrosion bridge trays for acid and alkali resistance), isolate external environmental erosion of cables, and extend cable service life;

3.Management and maintenance convenience:

Modular design allows for flexible disassembly and assembly, facilitating the addition of cables and replacement of faulty cables in the later stage. At the same time, clear laying paths can significantly shorten maintenance time and reduce operation and maintenance costs.

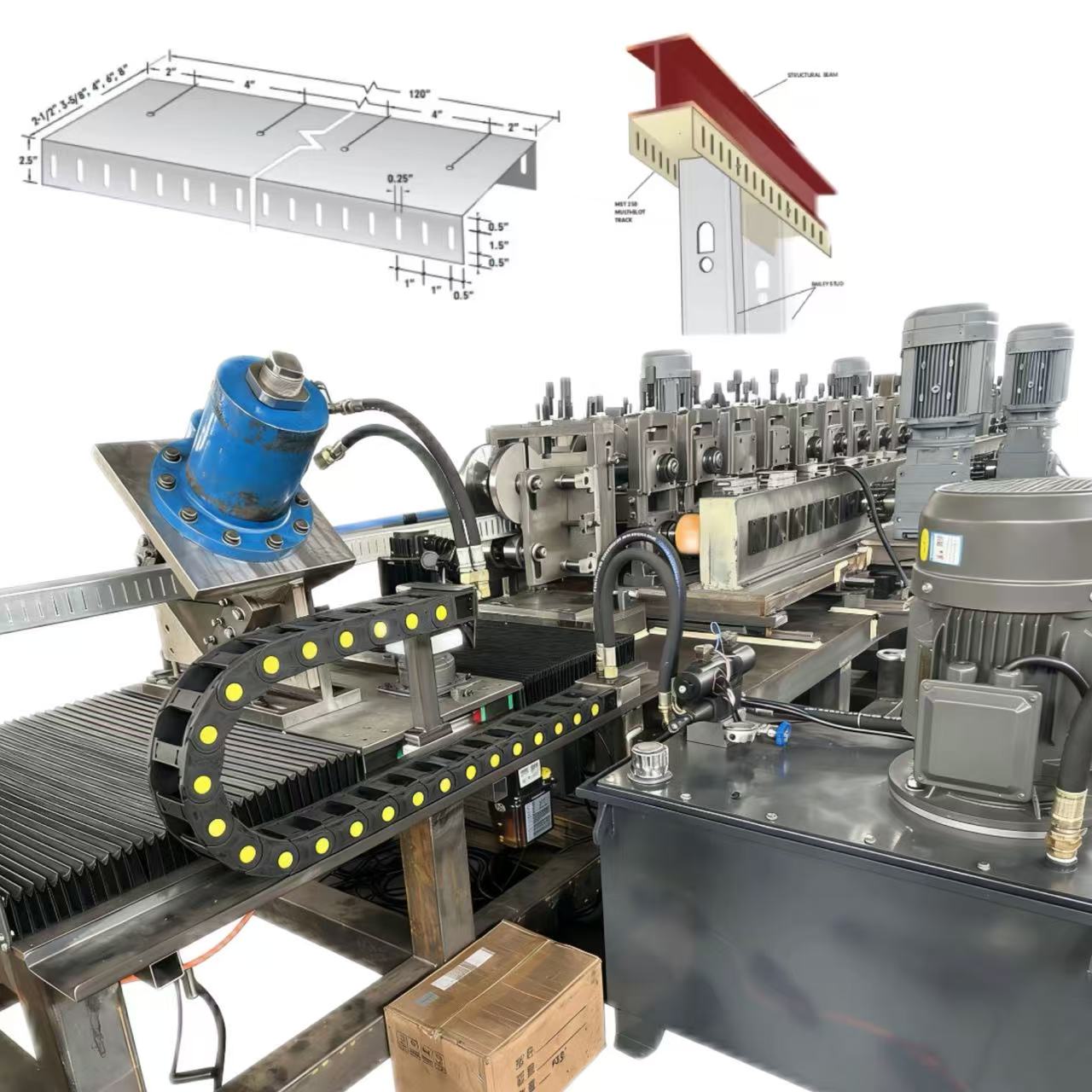

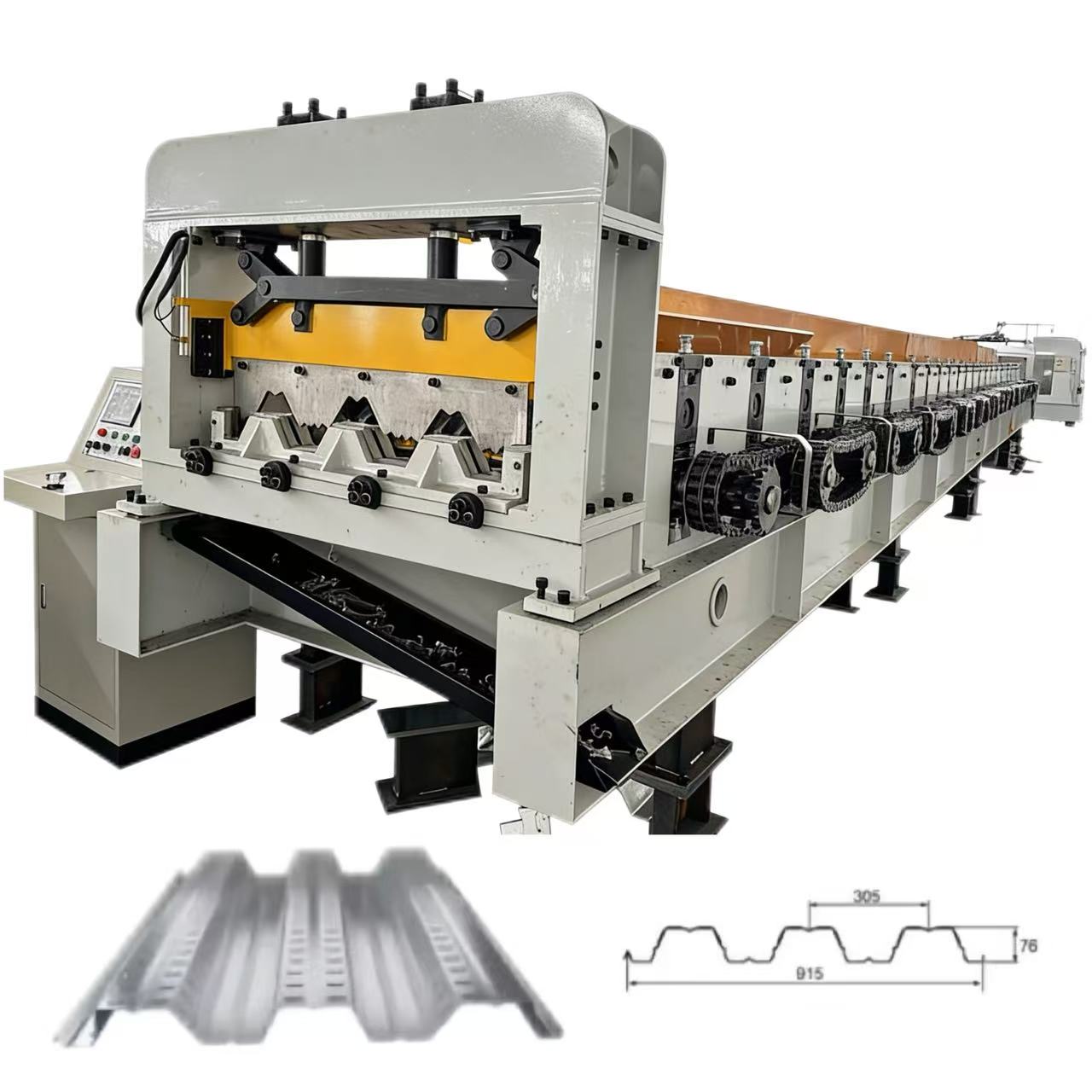

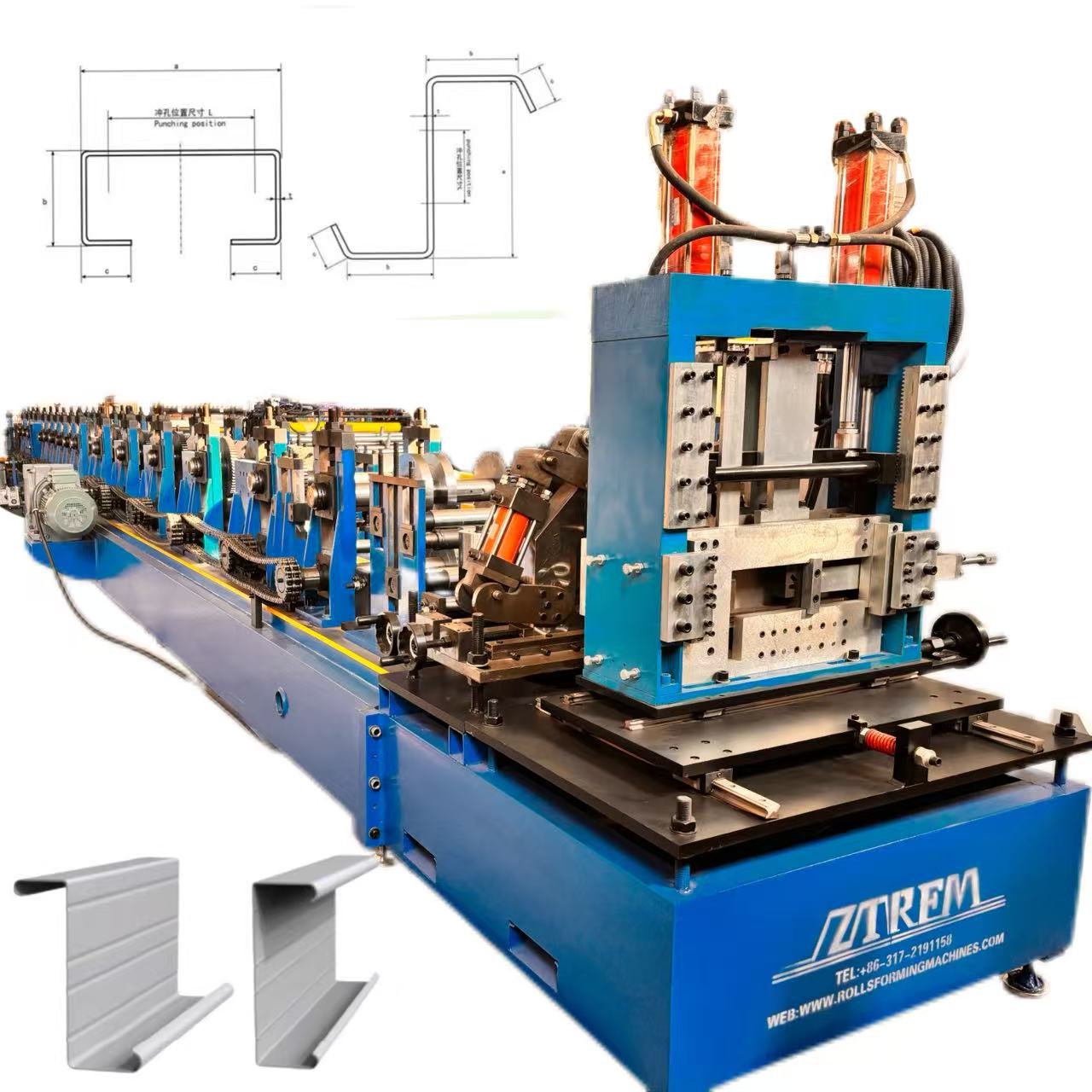

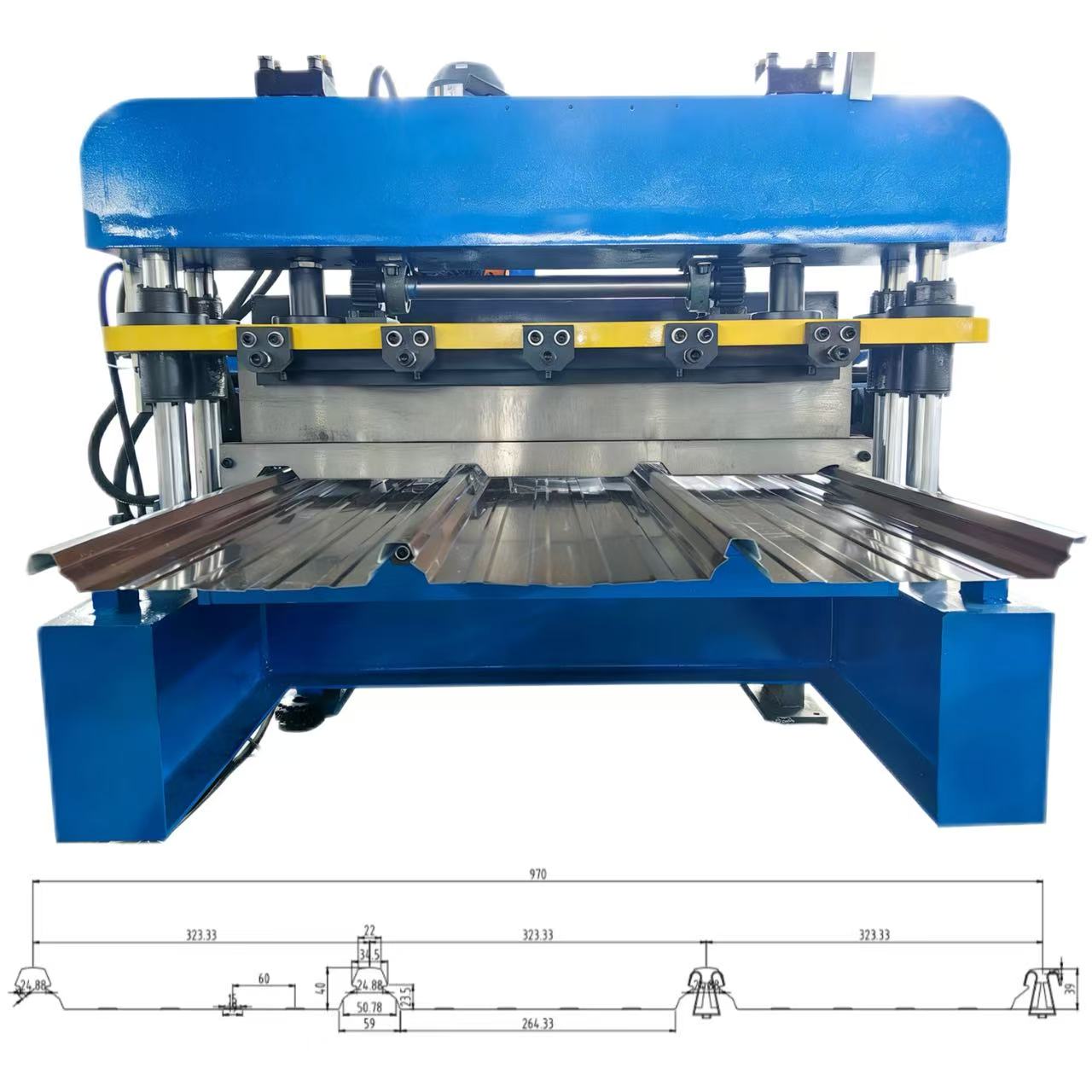

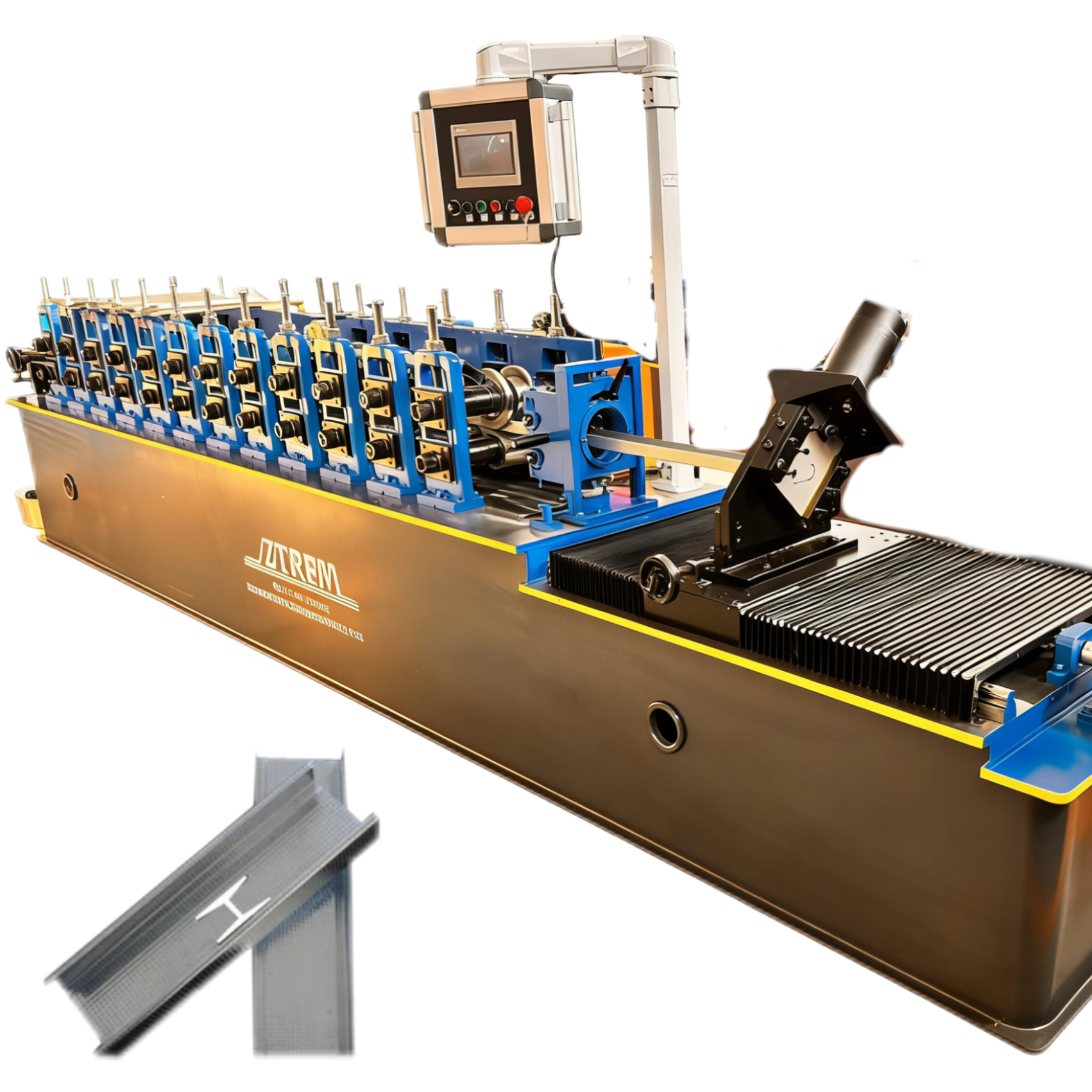

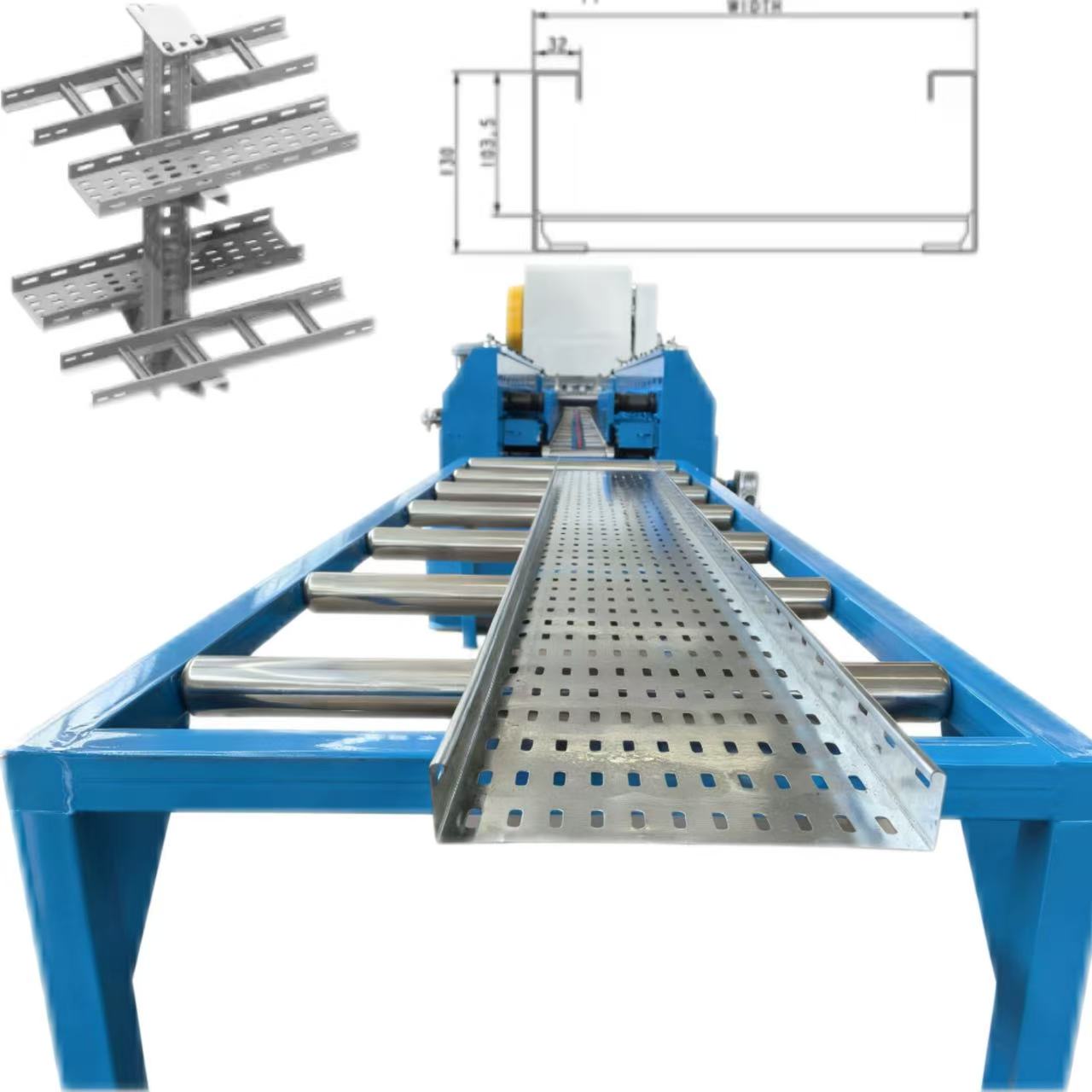

Pattern diagram:

Main equipment types and applicable scenarios

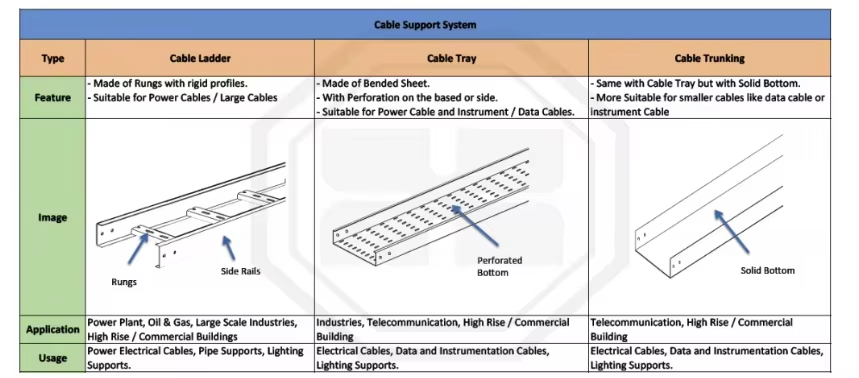

1. Ladder style bridge

Structural features: Composed of two side panels and a trapezoidal grid in the middle, it has good breathability, light weight, and is easy to observe the cable laying status.

Applicable scenarios: Dry, dust-free or less dusty indoor environments (such as factory workshops, substations), especially suitable for laying large-diameter power cables. The advantage of heat dissipation can avoid cable aging due to overheating.

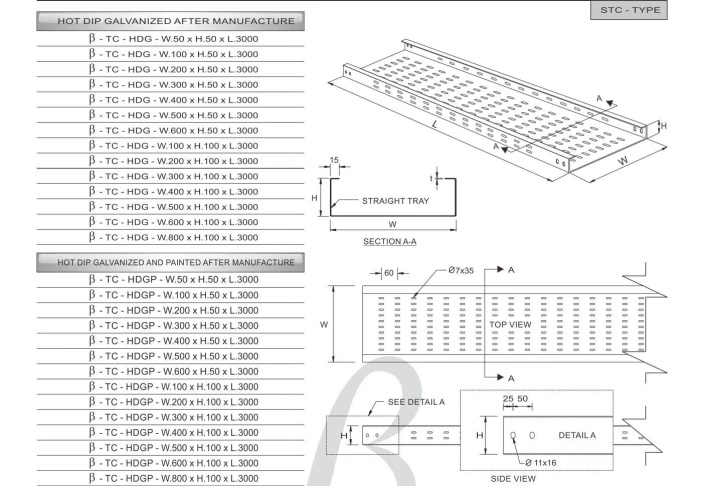

2. Tray type bridge

Structural features: The bottom is a flat plate (or a flat plate with ventilation holes), with side plates on both sides, providing both support and protection, and can be used with a cover plate.

Applicable scenarios: In general indoor and outdoor environments (such as office buildings and commercial complexes), power and control cables can be laid, and ventilation hole design balances heat dissipation and dust prevention requirements.

3. Trough type bridge frame

Structural features: Fully enclosed or semi enclosed box structure, with the strongest protection, can effectively isolate dust, water vapor, oil stains, and mechanical impacts.

Applicable scenarios: harsh environments with humidity (such as underground garages, above bathrooms), high dust (such as cement plants, flour mills), corrosive gases (such as chemical workshops), or high requirements for cable protection in communication rooms and data centers.

4. Modular bridge frame

Structural features: Components such as ladder racks, trays, and trough boxes can be flexibly combined according to needs to achieve customized laying solutions such as “ladder racks for horizontal sections+trough boxes for vertical sections”.

Applicable scenarios: In complex wiring environments (such as large factories and rail transit platforms), it is more cost-effective to consider the protection and heat dissipation needs of different areas.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

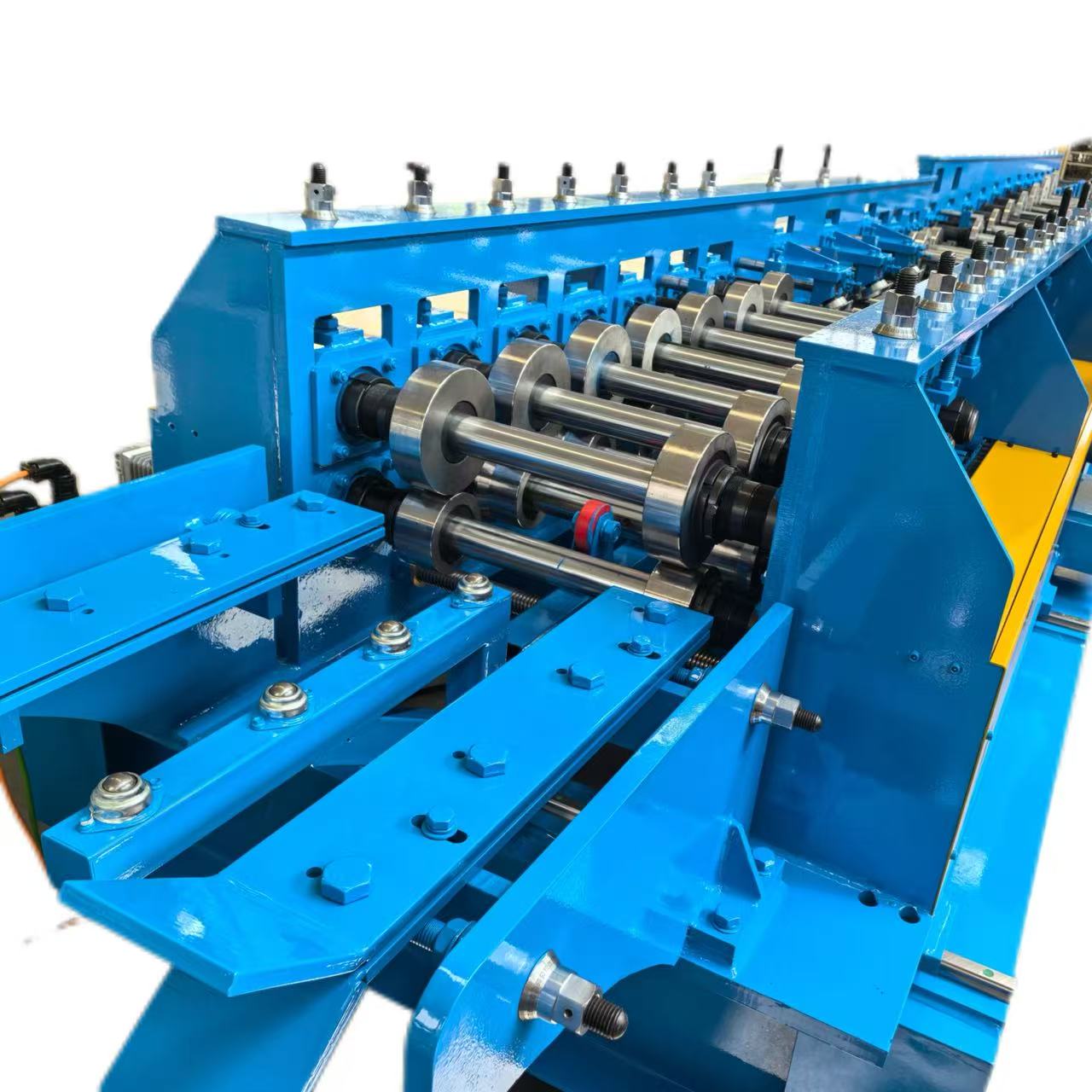

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

65mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

Customize

|

|||

|

Weight

|

About 6T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||