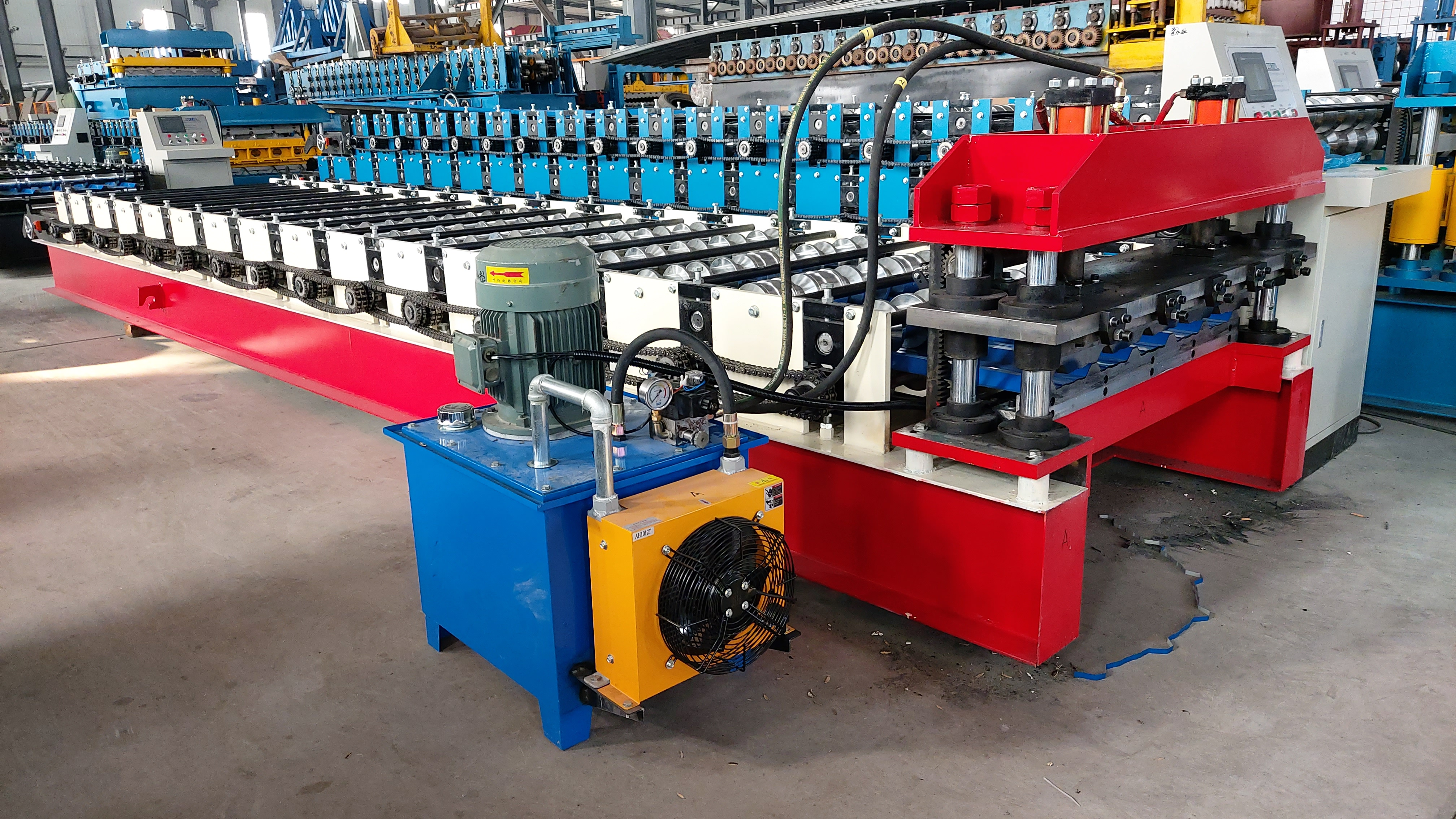

In the field of building roofing material production, trapezoidal roof tiles have become a commonly used roofing material in industrial plants, residential buildings, public buildings, and other scenarios due to their good load-bearing, waterproof, and aesthetic properties. As the core equipment for producing such roof tiles, the trapezoidal roof tile machine, with its automated and efficient production capacity, has completely changed the limitations of traditional manual or semi-automatic production, providing stable and high-quality roof tile solutions for the construction industry. This article will comprehensively interpret the value of trapezoidal roof tile machines from three aspects: machine introduction, application scenarios, and core features.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness(0.4-0.7mm) Width(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Ordinary decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

10-20 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive chain

|

1.2inch(As your requirement)

|

|||

|

Dimension(L*W*H)

|

10000*1600*1600(customize)

|

|||

|

Weight

|

4-6T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application scenarios: covering multiple fields of building needs

With the production capacity of different materials and specifications of roof tiles, the trapezoidal roof tile machine has a wide range of application scenarios, covering multiple fields such as industrial, civil, and public buildings, meeting the functional and appearance requirements of different projects for roof tiles.

1. Industrial construction field: efficient adaptation to large-scale demand

In industrial plants (such as machinery processing plants, food processing plants), logistics warehouses, industrial parks and other scenarios, the roof area is large, and the demand for roof tiles is high (single project demand can reach thousands or even tens of thousands of square meters), and roof tiles are required to have good load-bearing and waterproof properties to ensure the safety of equipment and goods in the plant. The trapezoidal roof tile machine can achieve large-scale production, with an average daily output of 2000-5000 square meters, which can quickly meet the batch demand of projects; At the same time, the trapezoidal roof tile structure produced by the machine is stable, and the precise size of the peaks and valleys can improve the drainage efficiency of the roof, avoid leakage problems caused by rainwater accumulation, and adapt to the long-term use needs of industrial buildings.

2. Civil architecture field: balancing practicality and aesthetics

In residential areas such as rural self built houses and steel structure villas, as well as residential communities, roof tiles not only need to have waterproof and thermal insulation functions, but also need to match the overall style of the building and focus on aesthetic appearance. The trapezoidal roof tile machine can produce trapezoidal roof tiles of different colors (such as red, blue, gray) and heights (such as 30mm, 50mm, 70mm), suitable for various architectural styles such as Chinese, European, and modern; At the same time, machine produced roof tiles have high precision and small gaps during installation, which can improve the sealing of the roof and reduce the risk of rainwater leakage. Metal roof tiles also have the advantages of corrosion resistance and long service life (up to 15-20 years), reducing maintenance costs for residents in the later stage.

3. Public building field: meeting complex design requirements

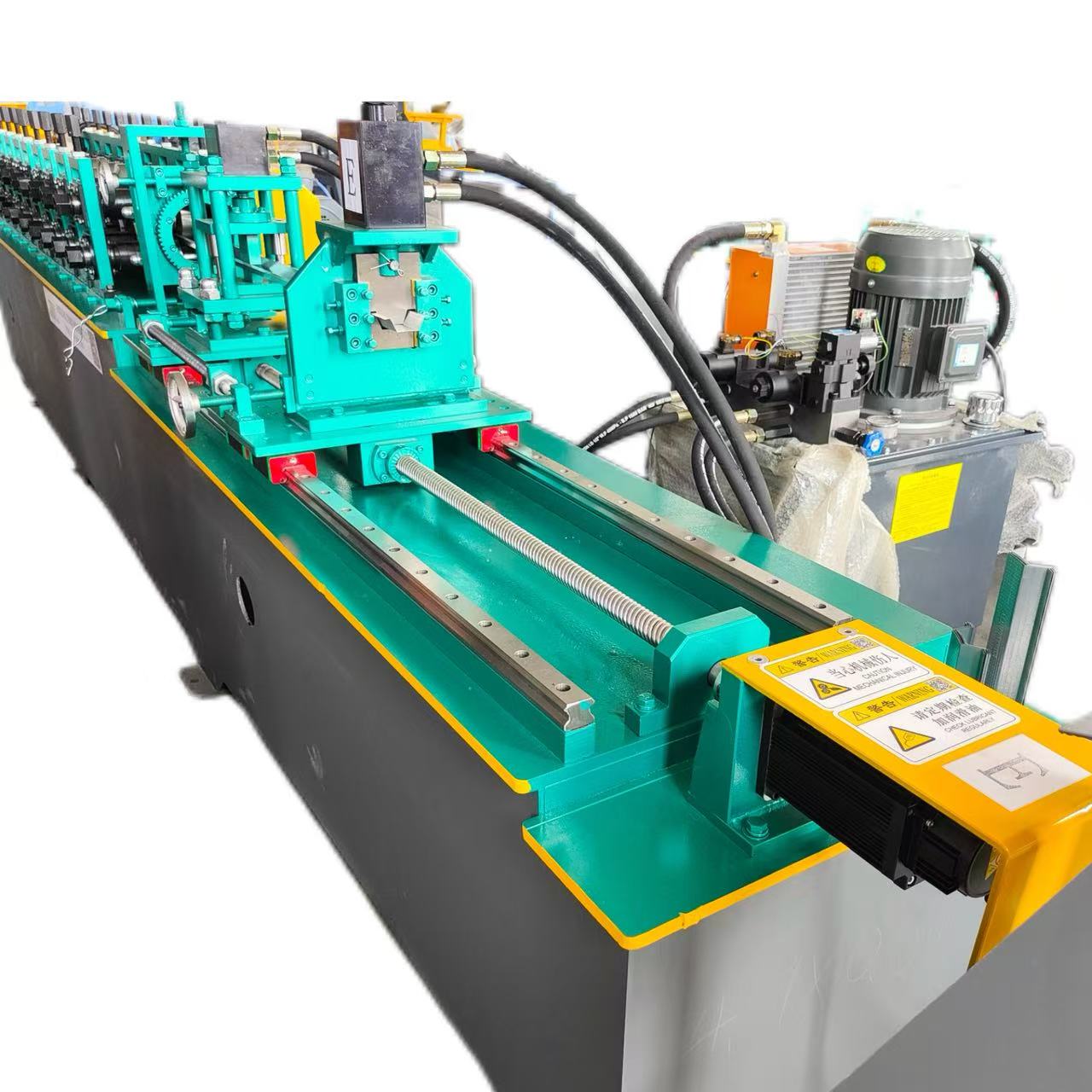

In public buildings such as sports halls, convention centers, airport terminals, and school teaching buildings, roof design is often more complex (such as large-span and irregular roofs), requiring higher specifications and installation adaptability of roof tiles. The trapezoidal roof tile machine can quickly switch and produce trapezoidal roof tiles of different specifications by replacing the forming rollers (replacement time only takes 1-2 hours) and adjusting the control system parameters. For example, it can produce roof tiles with higher wave height and stronger load-bearing capacity for large-span venues, and customized length roof tiles for irregular roofs; In addition, the machine produced roof tiles have a smooth surface and uniform color, which can enhance the appearance and texture of public buildings and meet the aesthetic needs of public spaces.

The core characteristics are high efficiency, high quality, and flexible production advantages:

Compared with traditional manual production or semi-automatic equipment, trapezoidal roof tile machines have significant advantages in production efficiency, product quality, and operational flexibility, and have become a key equipment for construction enterprises to improve production capacity.

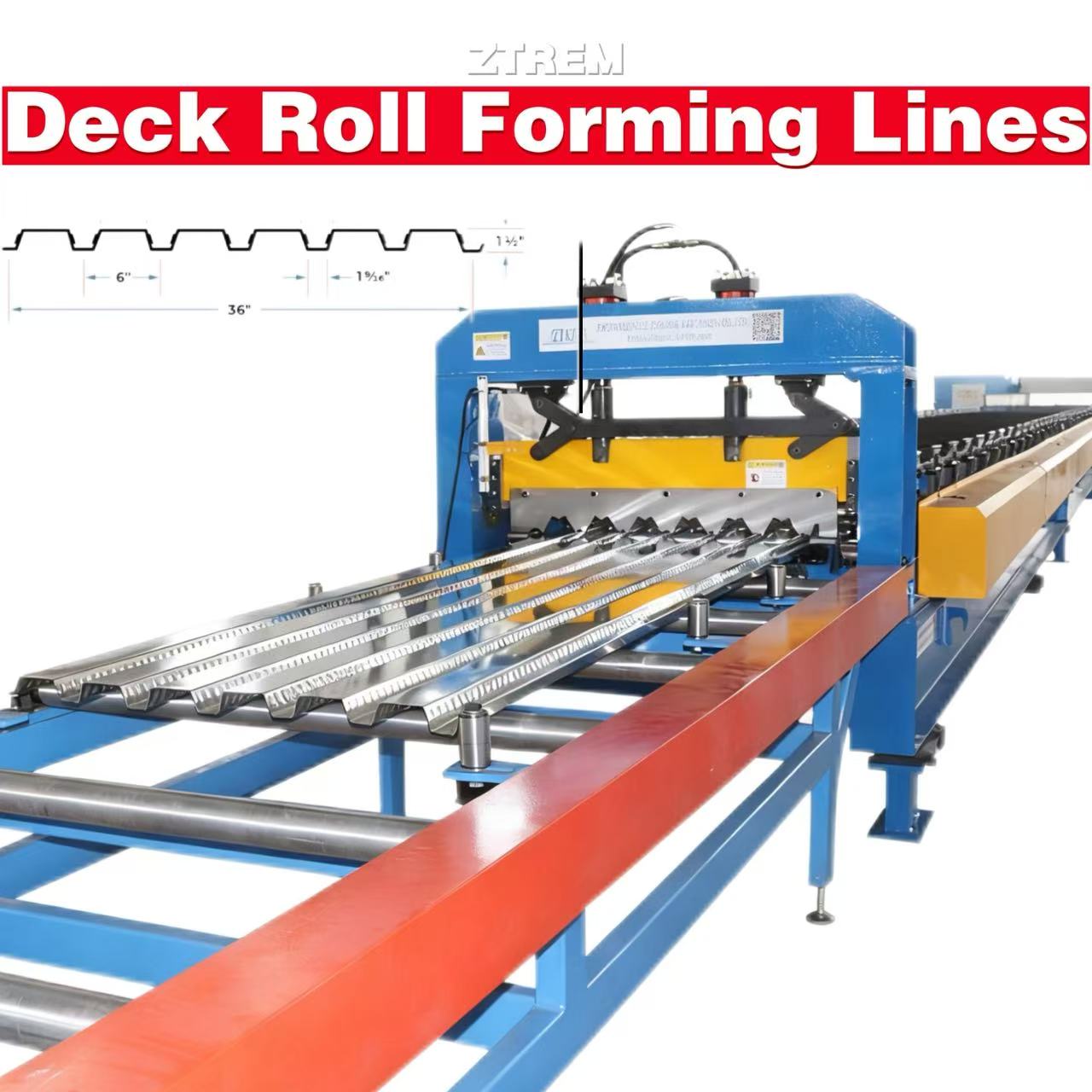

1. High production efficiency: significantly shortened project cycle

Traditional handmade production of trapezoidal roof tiles requires 3-5 people to cooperate in cutting, bending, and forming, with an average daily output of only 300-500 square meters, and is affected by artificial fatigue, resulting in large fluctuations in output; The forming speed of the trapezoidal roof tile machine can reach 5-20m/min, and the daily output can reach 2000-5000 square meters, increasing production efficiency by 4-10 times. For construction projects with tight schedules, machines can quickly complete the production of roof tiles, avoiding construction delays caused by insufficient supply of roof tiles and helping companies deliver projects on time.

2. Stable product quality: reducing rework and maintenance costs

Due to the influence of technological level and operational experience, roof tiles are prone to problems such as uneven wave peaks, edge warping, and cutting length deviation in manual production. The product qualification rate is only 80% -85%; The trapezoidal roof tile machine, through precision mechanical structure and intelligent control, controls the forming error and cutting error at the millimeter level, and the product qualification rate can reach over 99%. Stable product quality not only reduces rework and repair costs caused by roof tile quality issues, but also improves the waterproofing and load-bearing capacity of the roof, extends the service life of the building roof, and reduces maintenance costs in the later stage.

3. Flexible operation: adapted to diverse needs

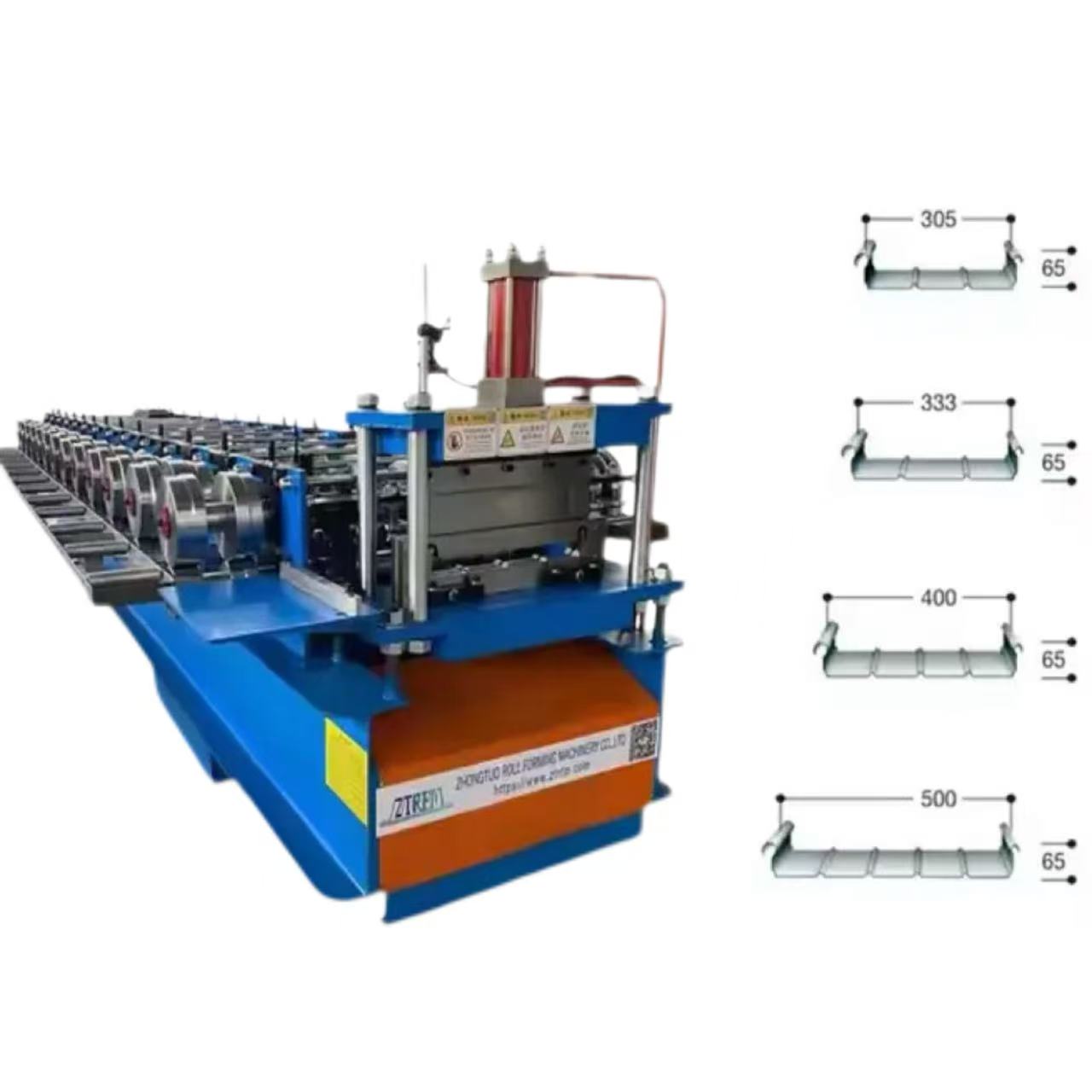

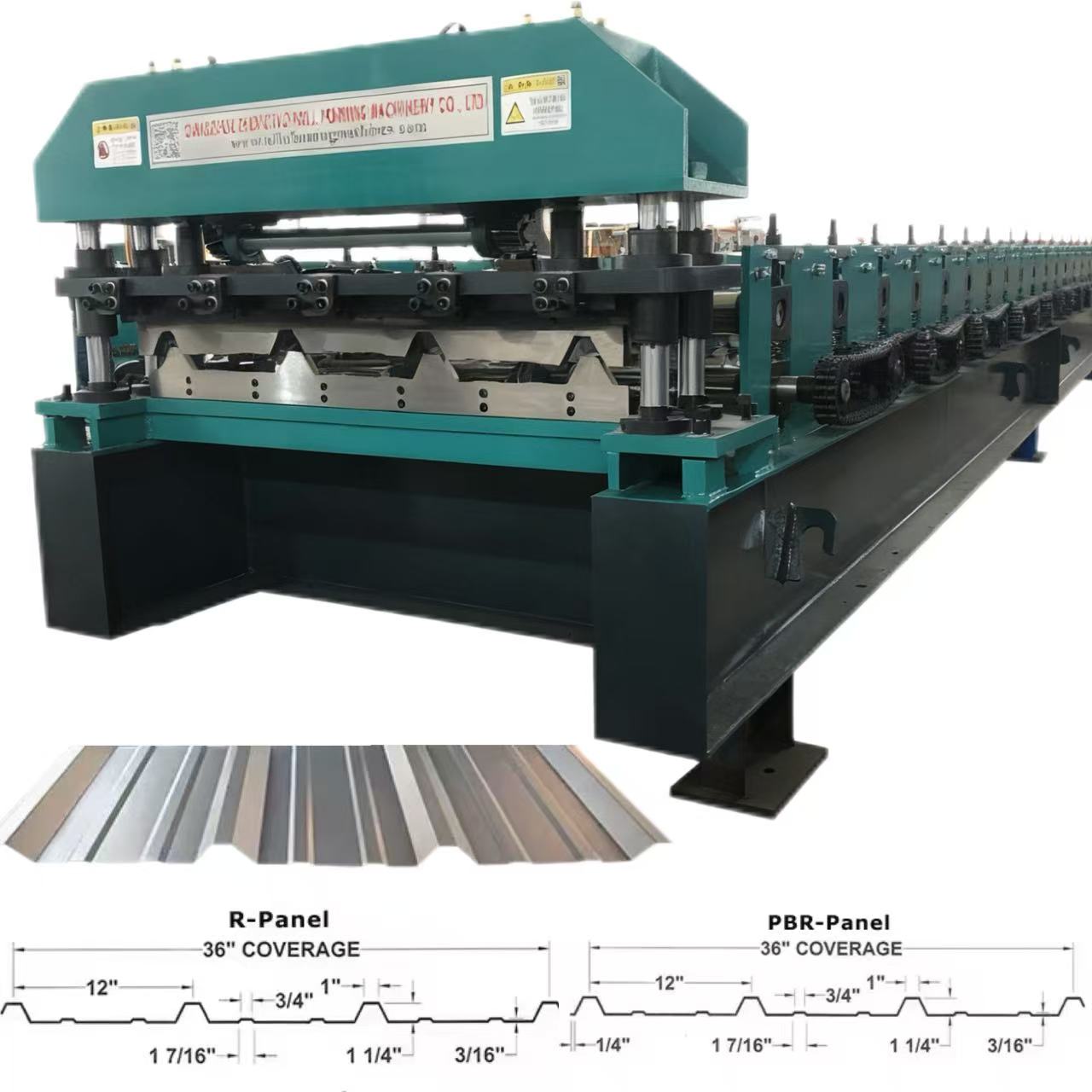

With the diversification of architectural design, the market’s demand for specifications and materials of trapezoidal roof tiles is becoming increasingly diverse. The trapezoidal roof tile machine does not require rebuilding the production line. It only needs to replace the forming rollers (for different wave heights and distances) and adjust the control system parameters (for different materials and lengths), and can switch production specifications in 1-2 hours. It can produce various trapezoidal roof tiles with wave heights of 20-100mm and plate widths of 500-1200mm, suitable for various materials such as color steel, galvanized, aluminum magnesium manganese, etc. This flexibility allows enterprises to quickly respond to customized customer needs, expand their business scope, and gain an advantage in market competition.

4. Cost controllable: reduce labor and material waste

On the one hand, the trapezoidal roof tile machine only requires 1-2 people for equipment monitoring and material replenishment, reducing labor requirements by more than 70% compared to traditional production methods, significantly reducing labor costs such as wages and social security; On the other hand, machine production can maximize the utilization of metal coils through precise parameter control, with a raw material utilization rate of over 98% (traditional manual production has a utilization rate of only 85% -90%), reducing raw material waste. Taking the daily production of 3000 square meters of roof tiles as an example, using a trapezoidal roof tile machine can save comprehensive costs of 400000 to 800000 yuan per year, increasing the profit margin for enterprises.

5.Safety and Environmental Protection: Compliant with Modern Production Standards

The trapezoidal roof tile machine is equipped with complete safety protection devices, such as emergency stop buttons, protective barriers, and photoelectric protection devices. When the operator accidentally touches the dangerous area, the equipment will immediately stop to ensure operational safety; At the same time, the cutting system of the machine is equipped with dust covers and noise reduction devices to reduce dust and noise pollution during the production process (noise ≤ 85 decibels), which meets national environmental and occupational health standards and creates a good production environment for workers.