Machine video:

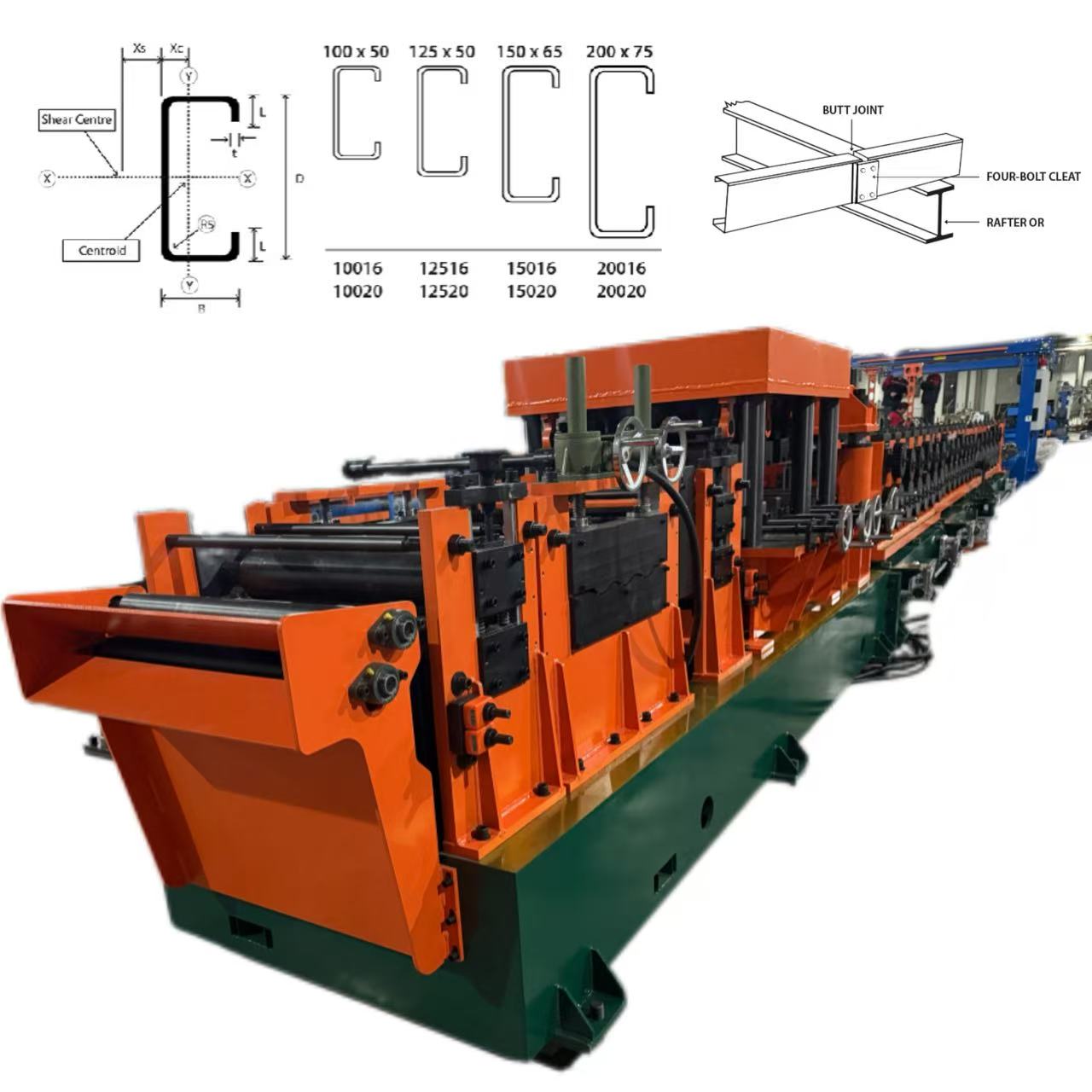

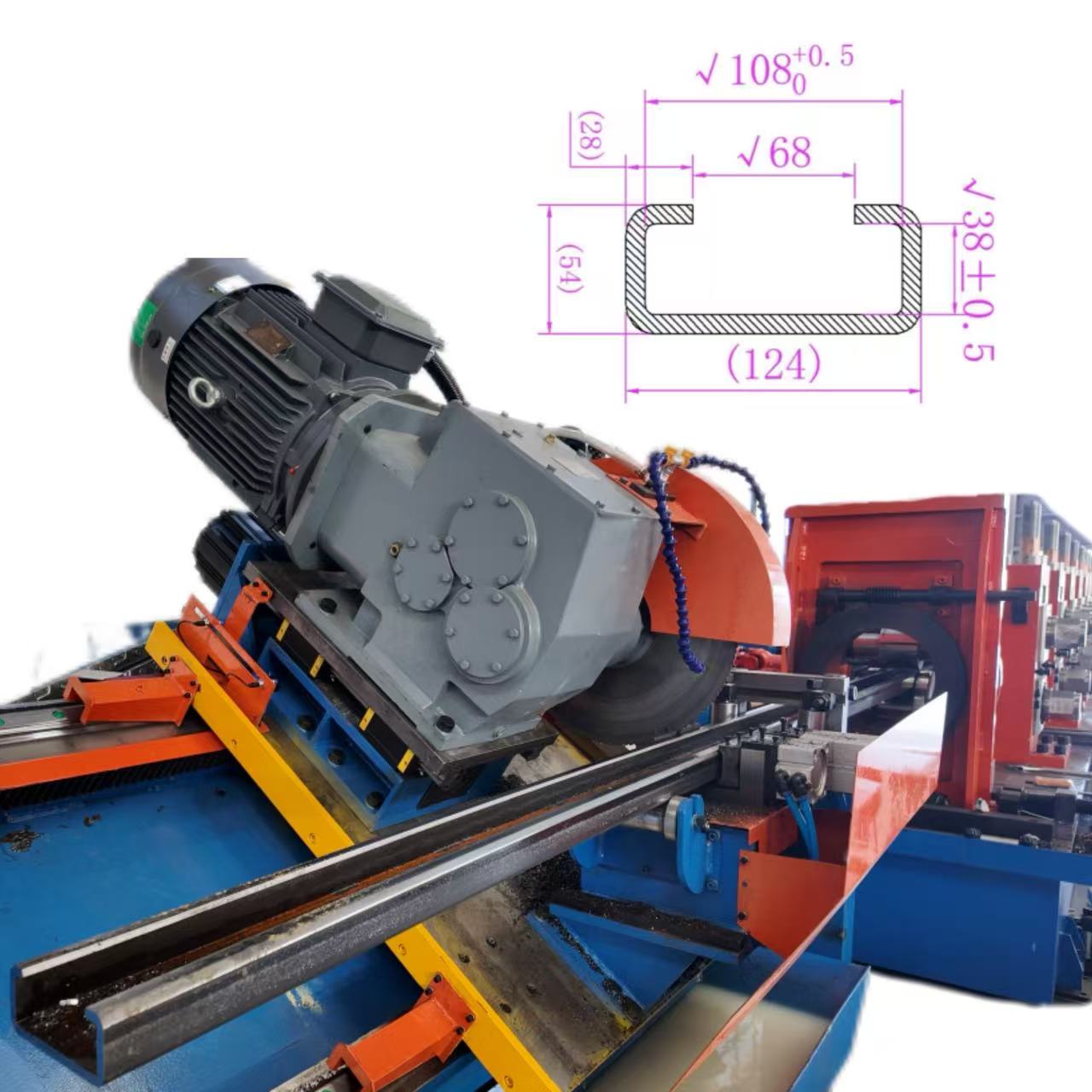

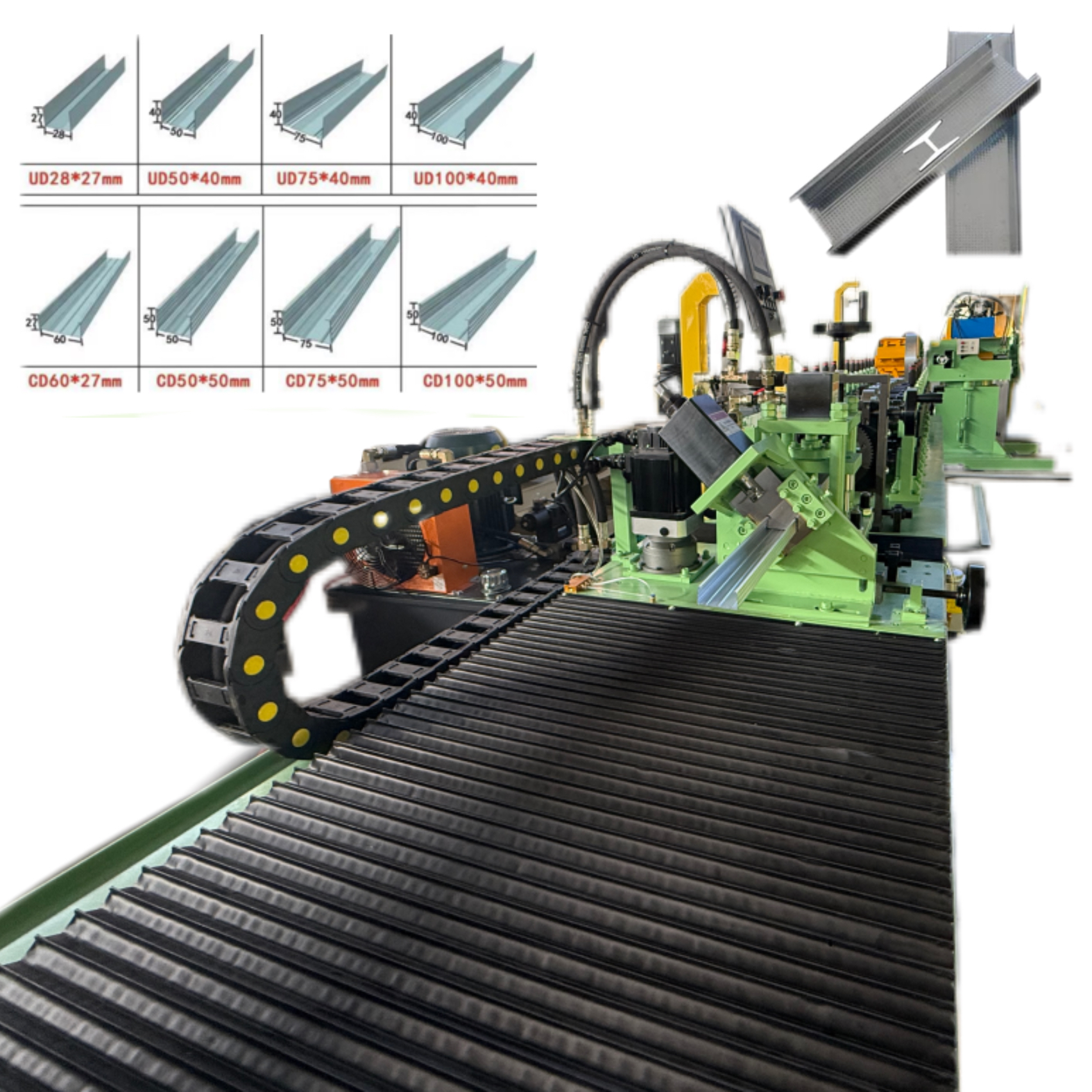

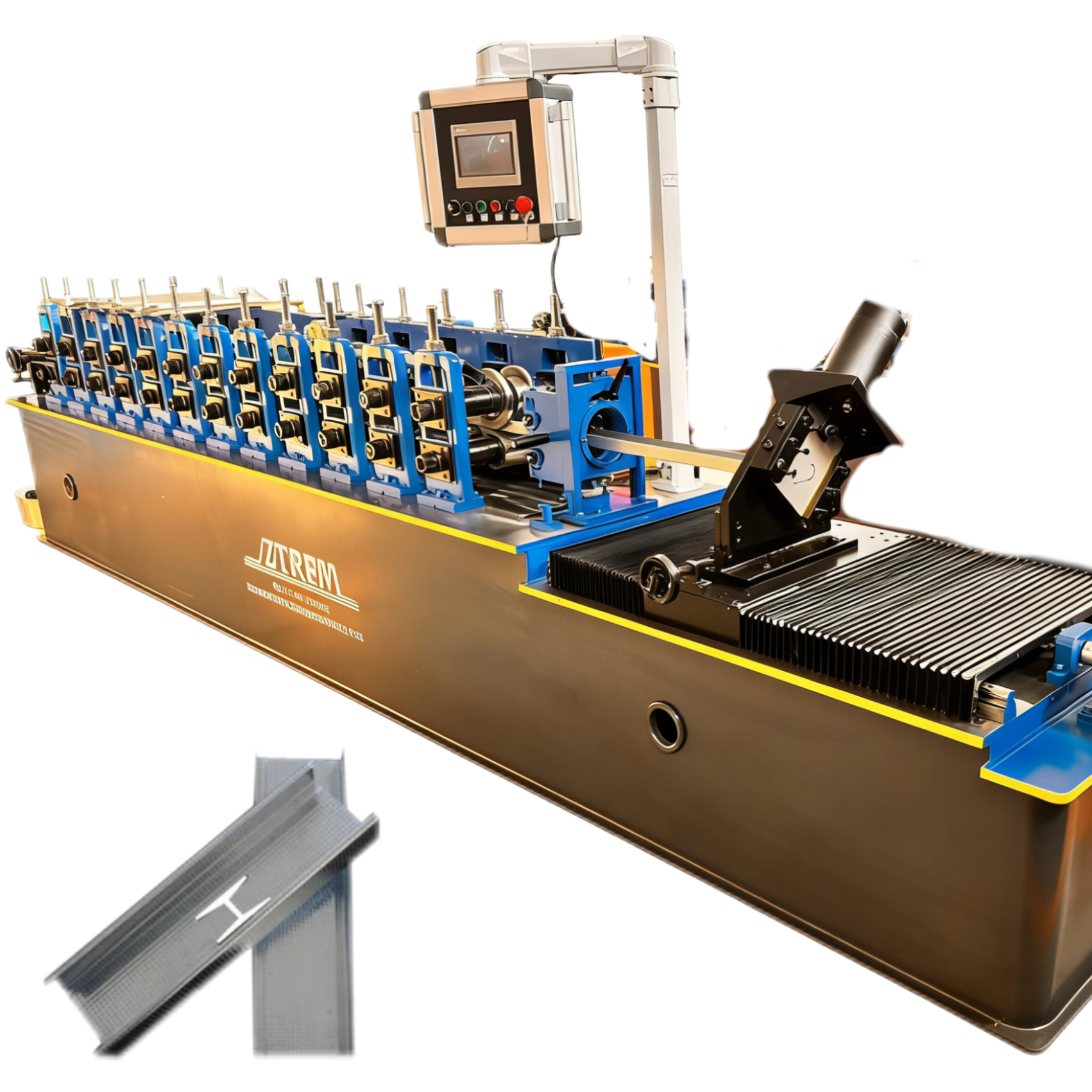

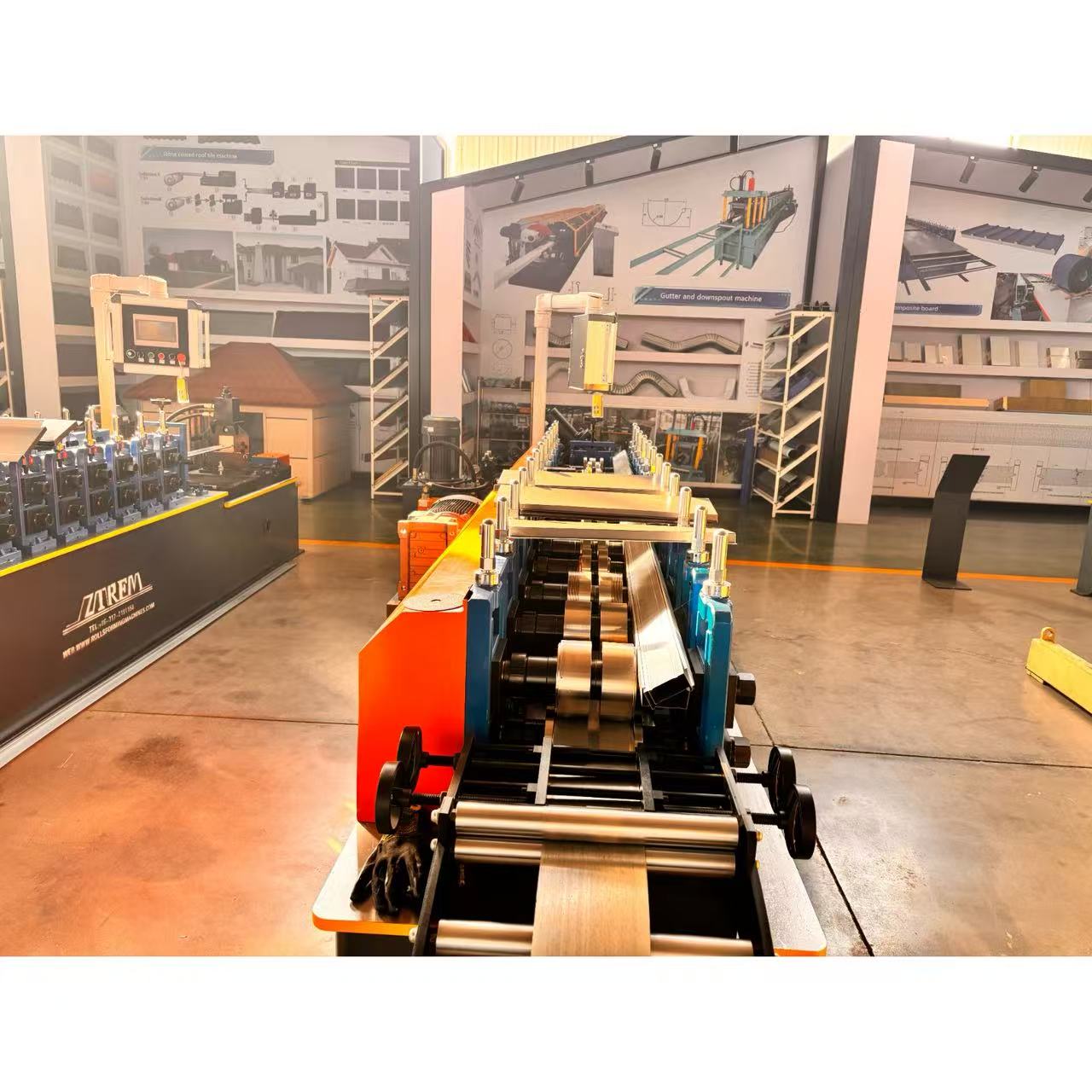

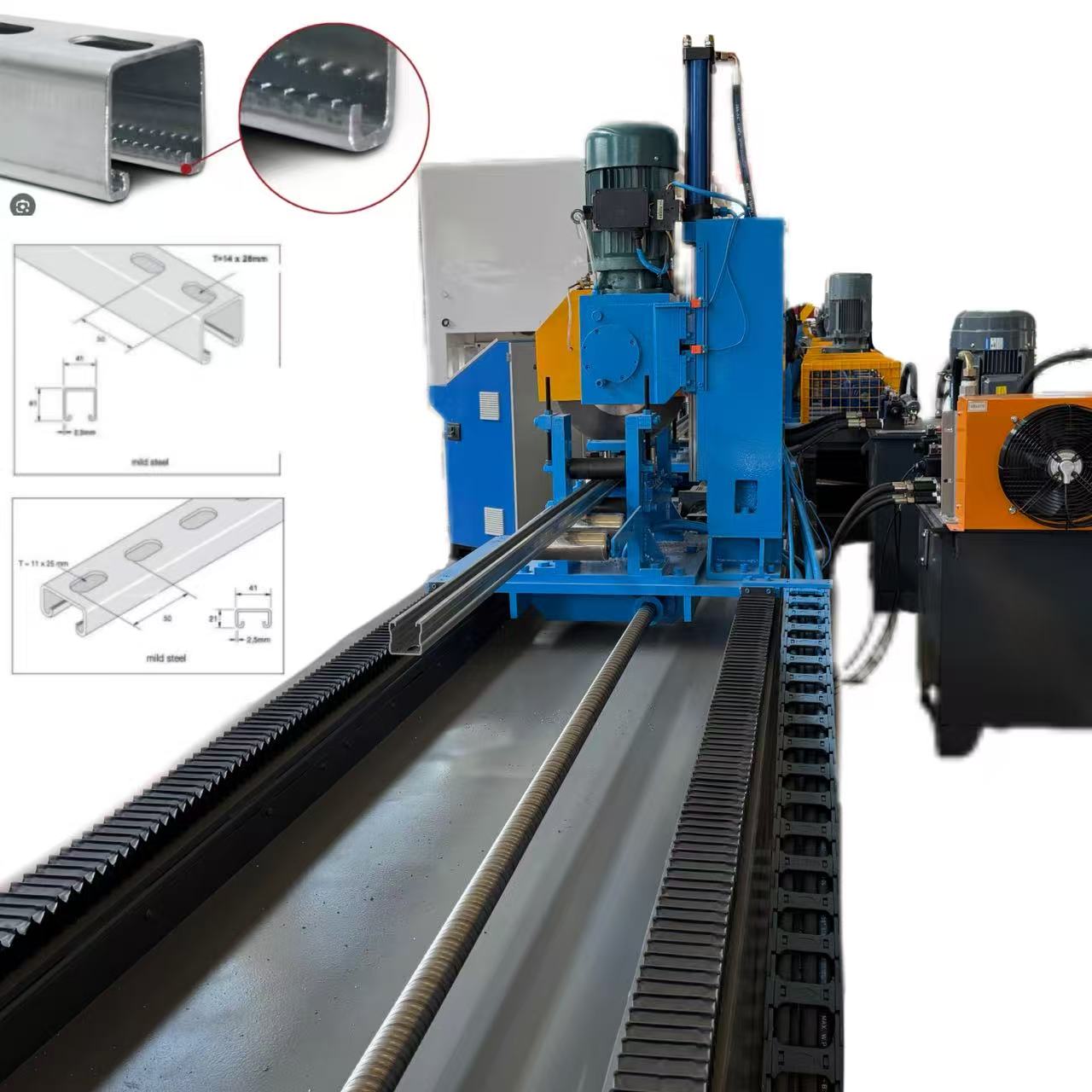

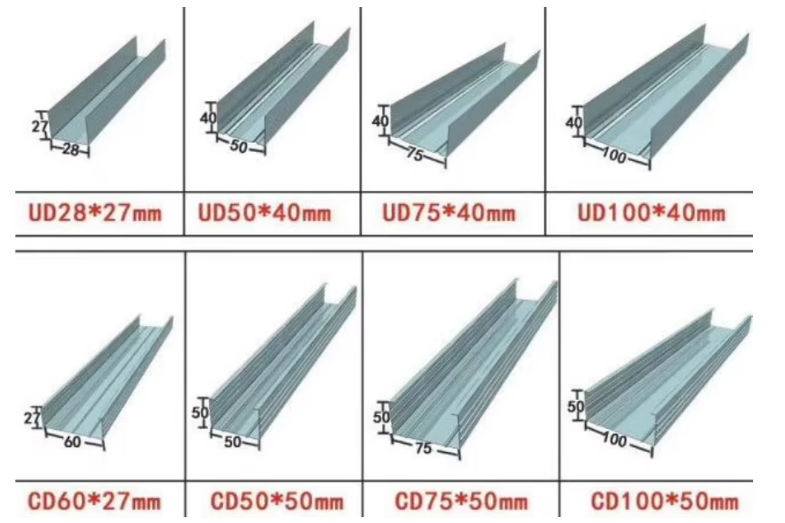

CU Profile Stud and Track Steel Drywall Roll Forming Machine is a specialized light steel keel forming equipment designed for the needs of the construction and decoration industry. It is mainly used to process metal raw materials such as cold-rolled steel strips and hot-dip galvanized steel strips into standardized CU type keels (core load-bearing components of ceiling and partition systems) through continuous rolling forming technology. It is widely used in the construction of ceiling and partition walls in various buildings and is the core equipment for achieving large-scale and precision production of keels.

Core Features

1.High degree of automation:

from feeding, forming to cutting, the entire process is automated, reducing manual intervention and labor intensity;

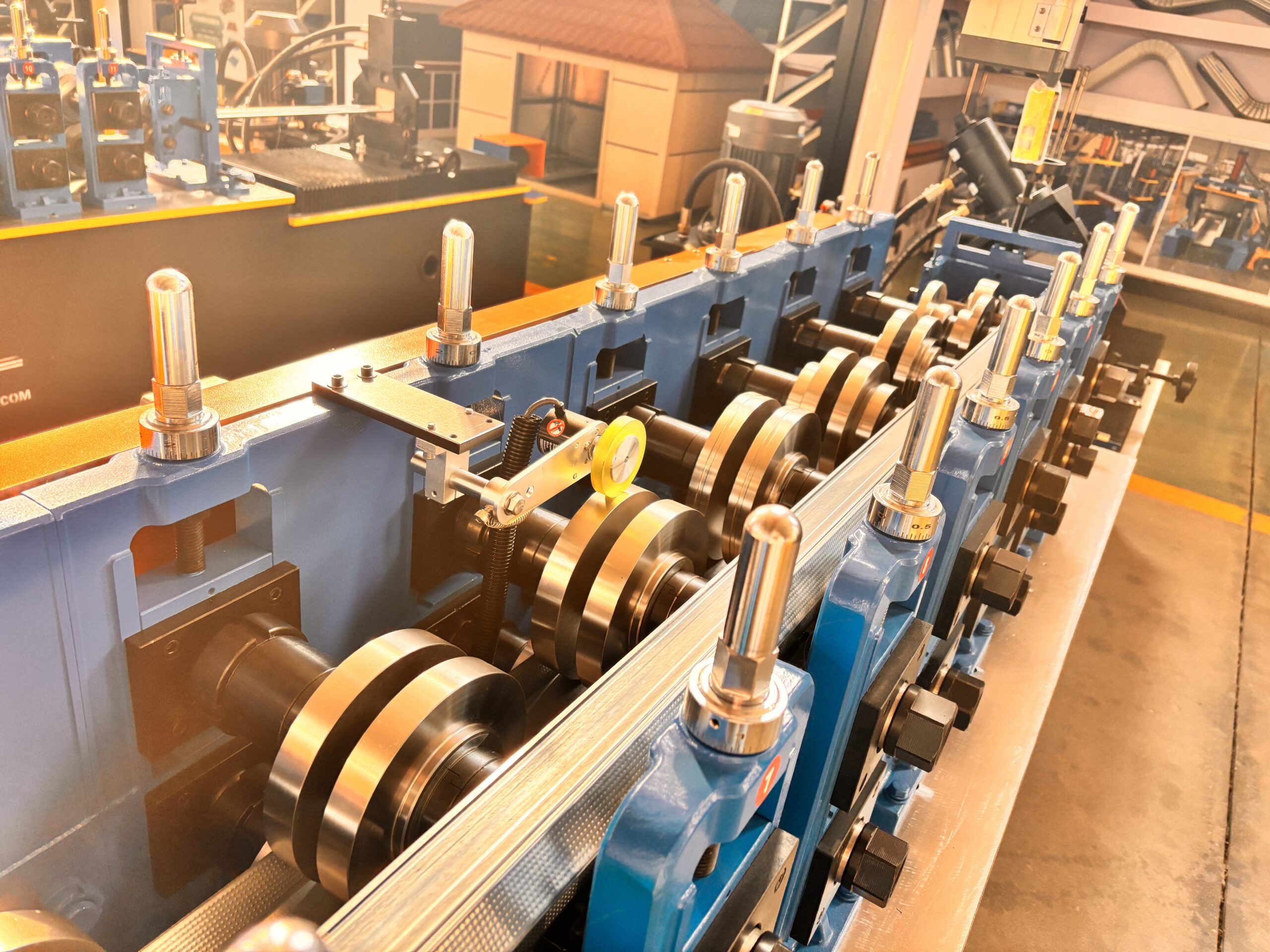

2.High forming accuracy:

The combination of precision rollers and servo control ensures that the keel size is regular and the cross-section is consistent, meeting high standard engineering requirements;

3.Stable efficiency:

Continuous processing without interruption, with production capacity more than three times higher than traditional processing methods, suitable for mass production;

4.Strong universality:

can adapt to different specifications of CU type keel processing by changing molds, flexibly responding to diverse orders;

5.Convenient operation and maintenance:

Standardized design of key components, easy disassembly and replacement, built-in fault self checking system, reducing maintenance costs.

Application Scenario:

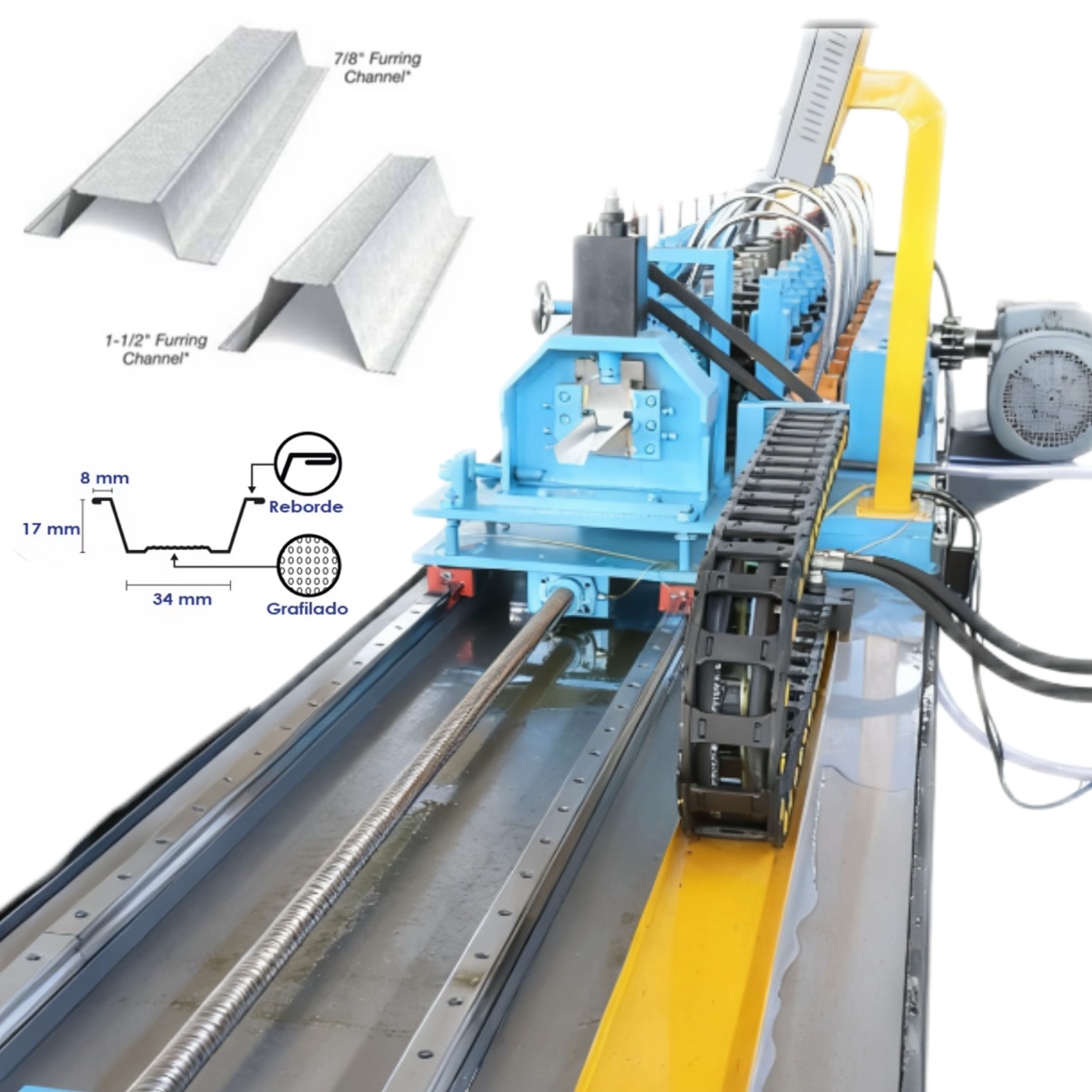

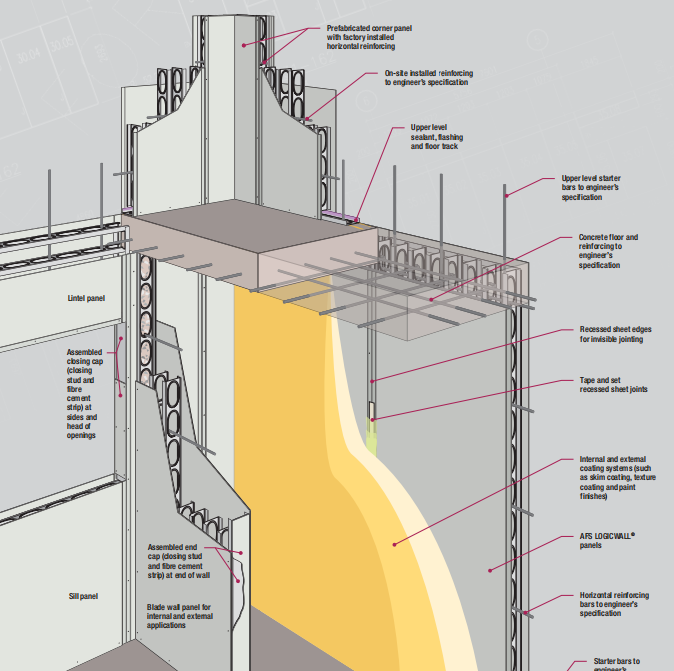

• Decoration and renovation:

U-shaped keels are widely used in ceiling keels, main keels, auxiliary keels, hanging rods, horizontal bracing keels, etc. in decoration and renovation.

• High rise partition wall:

With the gradual opening of the light steel prefabricated market, aluminum zinc U-shaped keel is used for the top guide beam, bottom guide beam, and vertical column of light steel composite partition wall, which is fast to construct and has low pollution.

• Basic architecture:

U-shaped keel is also used in the field of basic architecture such as cable trays.

• Light steel villa:

C-shaped keel is mainly used for the construction of the main material of light steel villa and is the main application material in the field of building construction.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.8-1.2 mm (As your requirement)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

3.Main body

|

Roller station

|

10-20rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

customized

|

The speed depends on the shape of the tile and the thickness of the material.

|

||