The double-layer roofing roll forming machine can be applied to the production of various roof tile models, which enables enterprises to quickly adjust production models and improve market response speed when facing different market demands.

It is widely used in various construction fields, such as residential buildings, industrial plants, warehouses, airports, stations, etc. Suitable for the production of roof tiles for various purposes, including roofs, wall panels, decorative panels, etc.

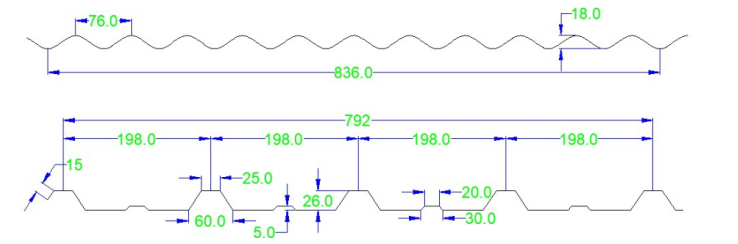

The profile drawing:

The pictures for the finished product:

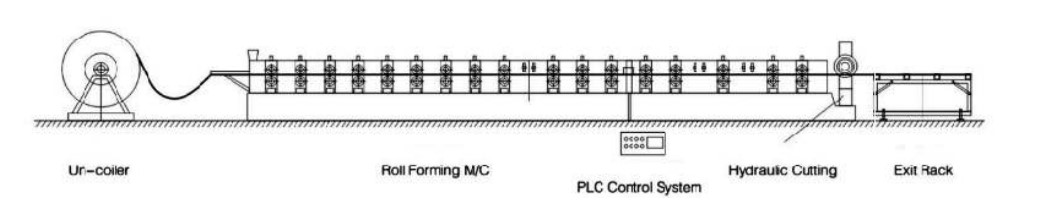

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Double Layer Roofing Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Roofing Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.4-0.5mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 16+19stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 4kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Double Layer Roofing Roll Forming Machine:

1.Improve production efficiency:

Simultaneously producing multiple specifications of products, the double-layer roofing roll forming machine adopts a double-layer design, which can produce two different specifications of roof tiles at the same time. This design significantly improves production efficiency, and compared with traditional single-layer, the output can be increased by nearly twice.

2.Reduce production costs:

Reducing labor costs, due to its high degree of automation, the double-layer roofing roll forming machine reduces its dependence on labor, thereby lowering labor costs. Reduce unit product cost: With fast production speed and high output, the production cost per unit product is significantly reduced. This saves a lot of production costs for the enterprise and improves the market competitiveness of the product.

3.Improve product quality:

The double-layer roofing roll forming machine is made of high-quality materials and undergoes strict quality control and durability testing to ensure the stability and durability of the equipment. The roof tiles produced have higher flatness, strength, and durability.

Machine photos: