The core advantage of the Full Automatic Cr12 C Purlin Roll Forming Machine stems from its innovative design and intelligent control system. The equipment adopts a fully automated production line, integrating passive loading racks, intelligent leveling devices, high-speed punching units, and precision cutting systems to achieve seamless connectivity from raw materials to finished products. Its unique secondary forming process ensures product squareness and straightness, with bending resistance significantly superior to traditional profiles, effortlessly meeting the load-bearing requirements of large-span roofs. The coordinated operation of the hydraulic power system and PLC control module not only enhances operational stability but also supports non-standard customization, catering to diverse working conditions.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

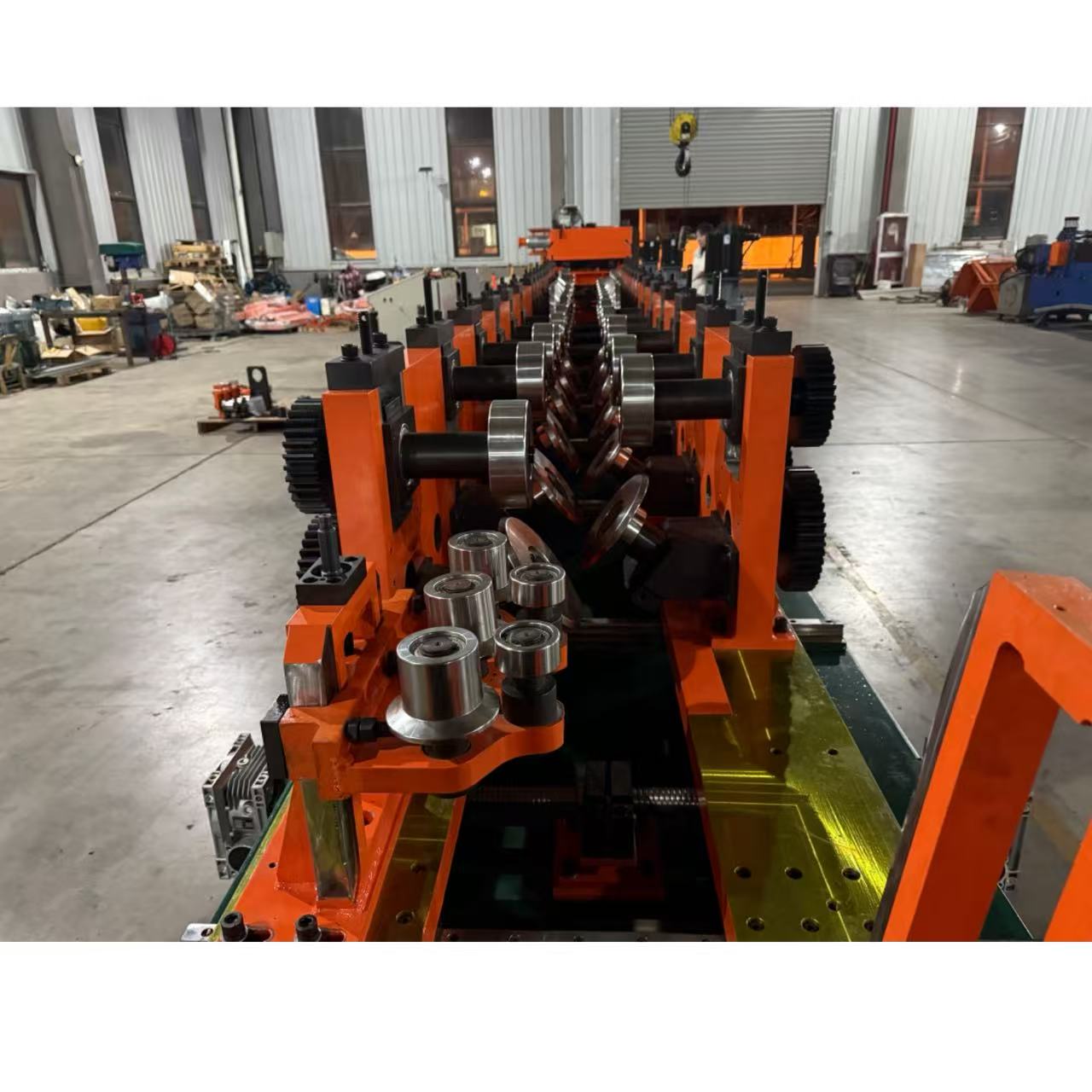

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

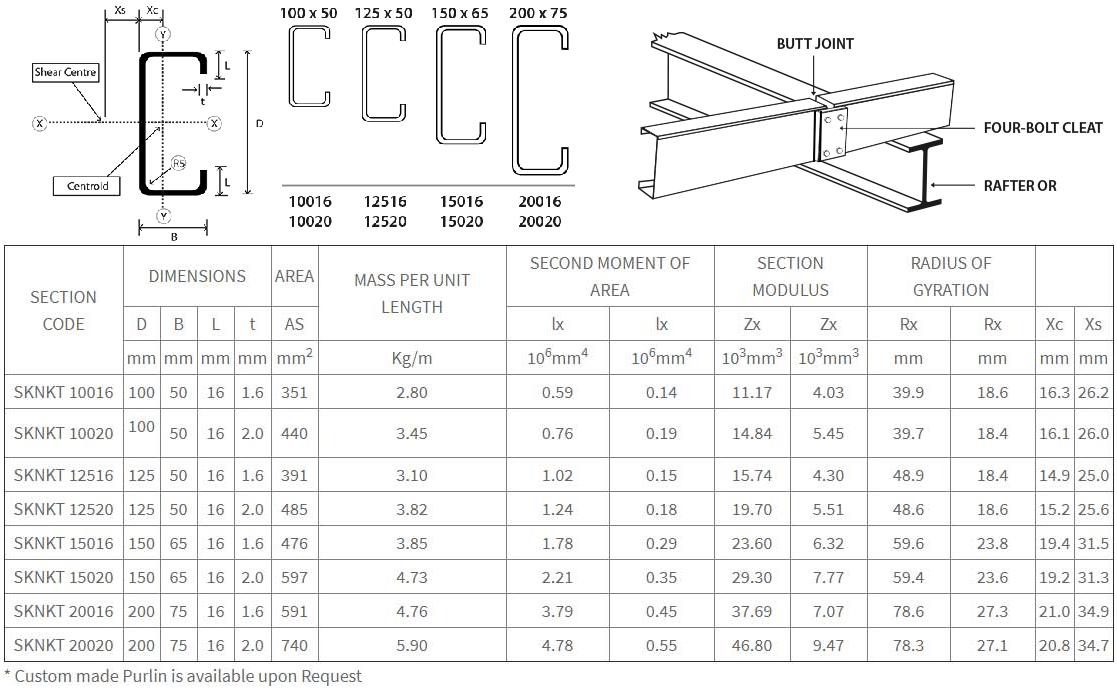

Application Scope: From Structural Skeleton to Industrial Circulatory System

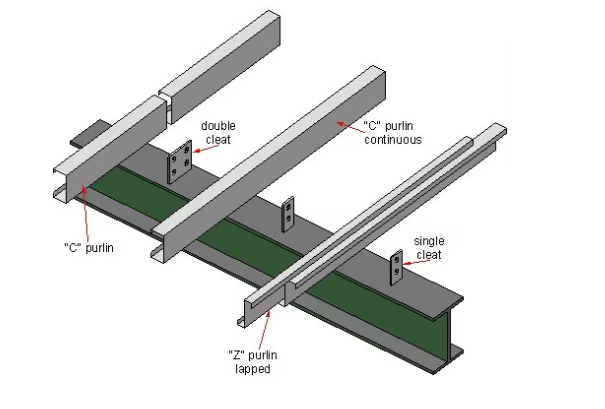

In the construction field, components produced by Full Automatic Cr12 C Purlin Roll Forming Machines serve as the mainstay of lightweight steel structures, widely used in roof load-bearing and wall bracing systems for factories, garages, and sports venues. Their galvanized corrosion-resistant properties endow the materials with long-term weather resistance, enabling them to withstand harsh environmental challenges. For instance, in large supermarkets or exhibition hall projects, C-shaped steel purlins utilize simply supported structures to streamline design, significantly reduce steel consumption while maintaining overall safety. Beyond construction, derivative products also extend to core manufacturing scenarios such as electrical cabinet enclosures, shelving frameworks, and key components of photovoltaic tracking systems, driving industrial upgrading through lightweight design.

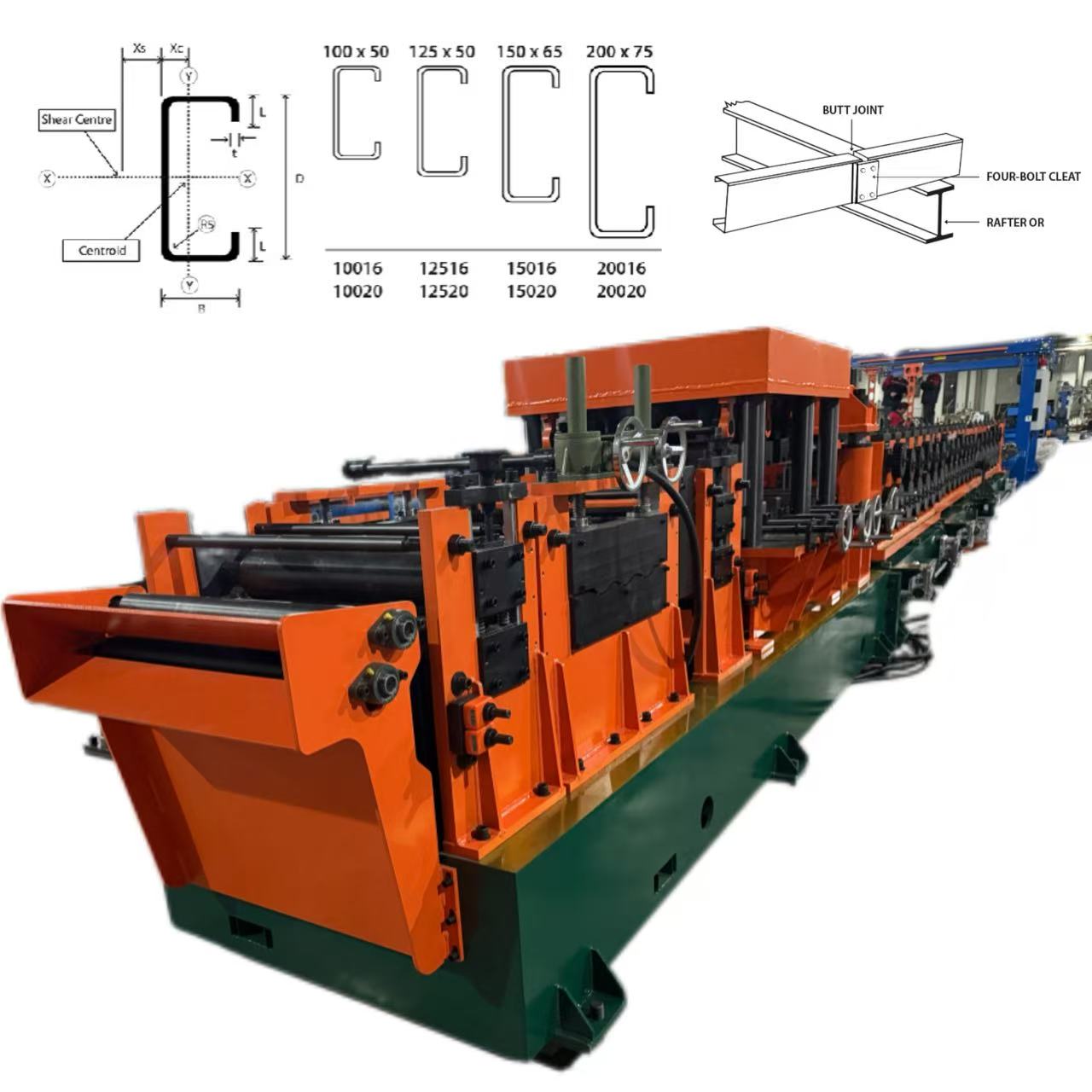

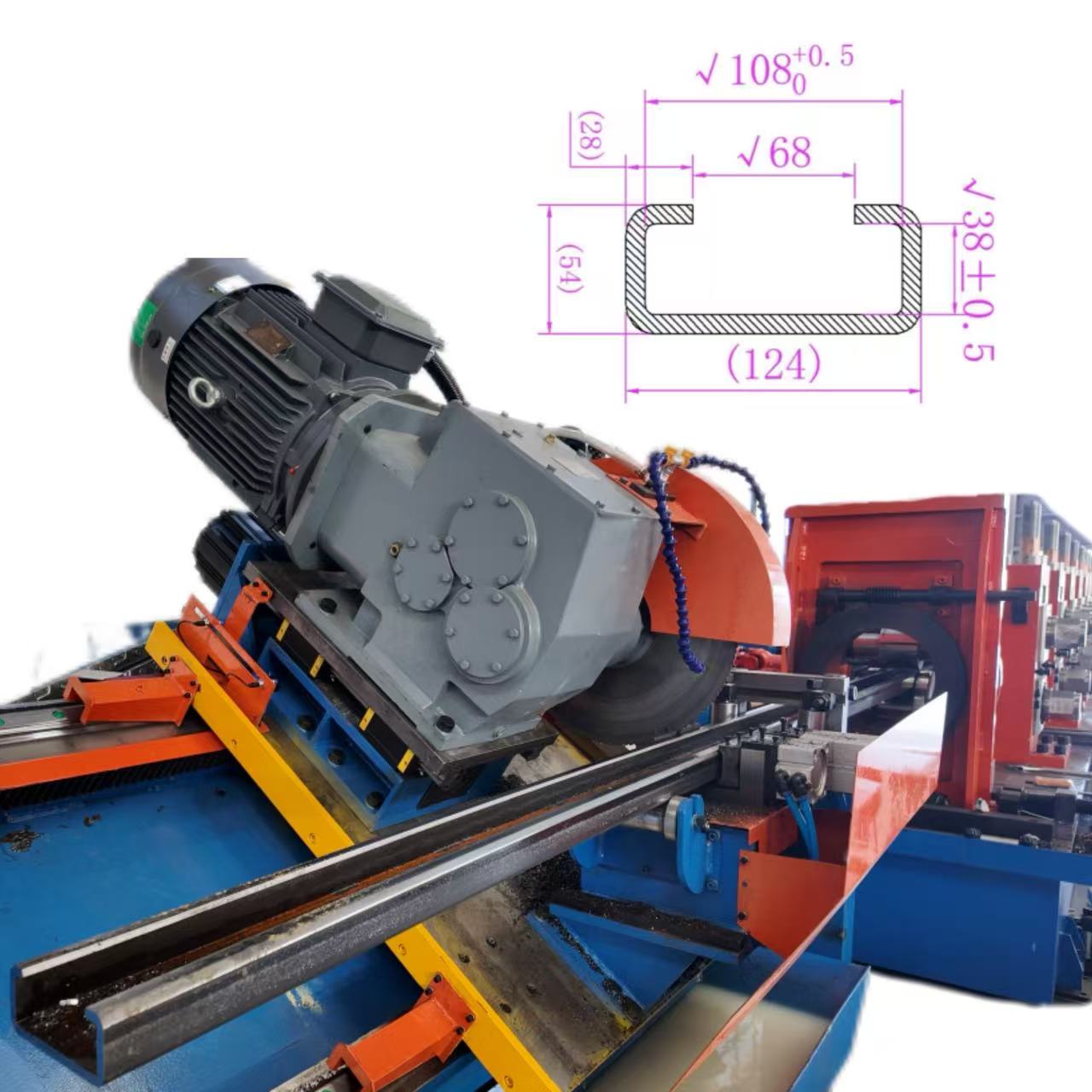

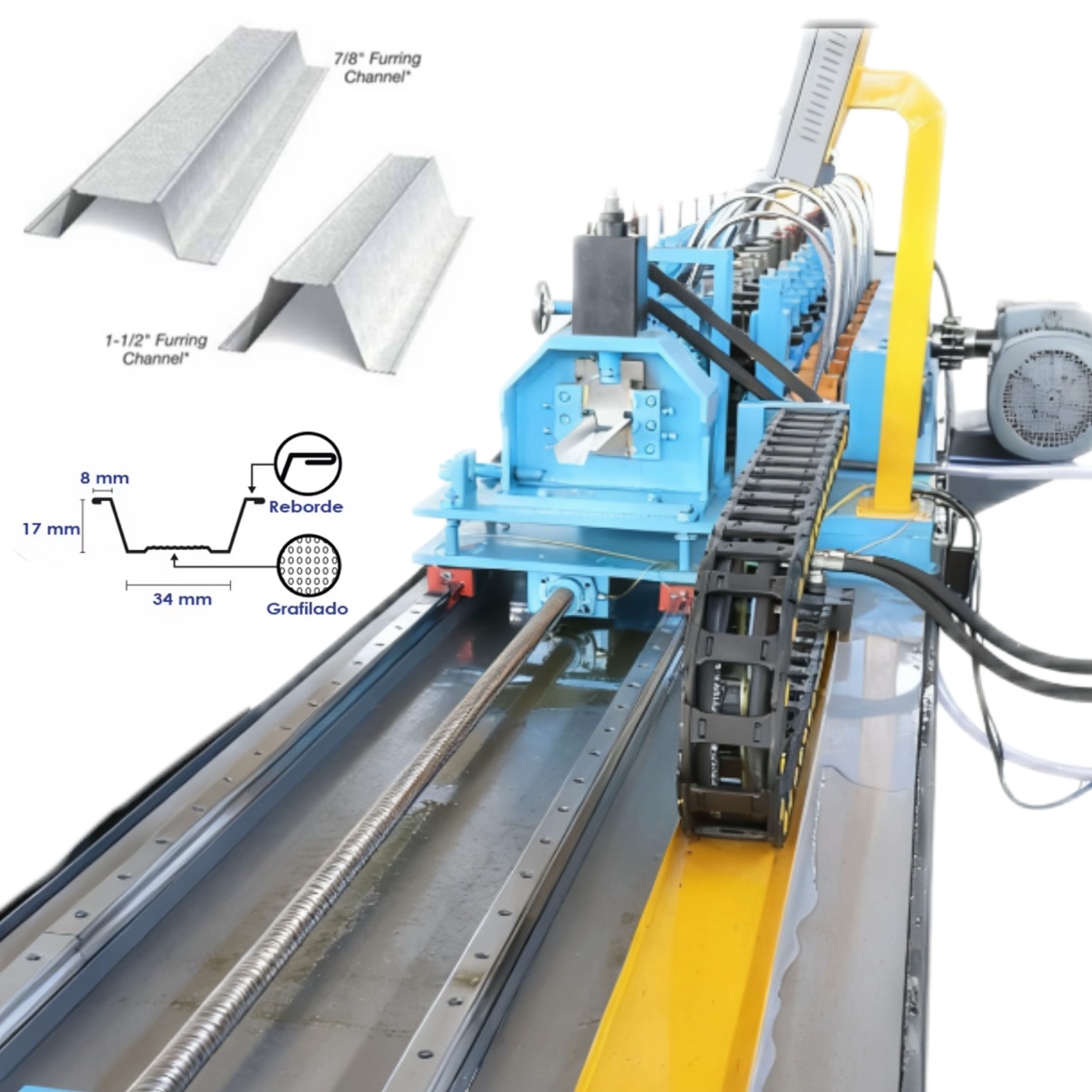

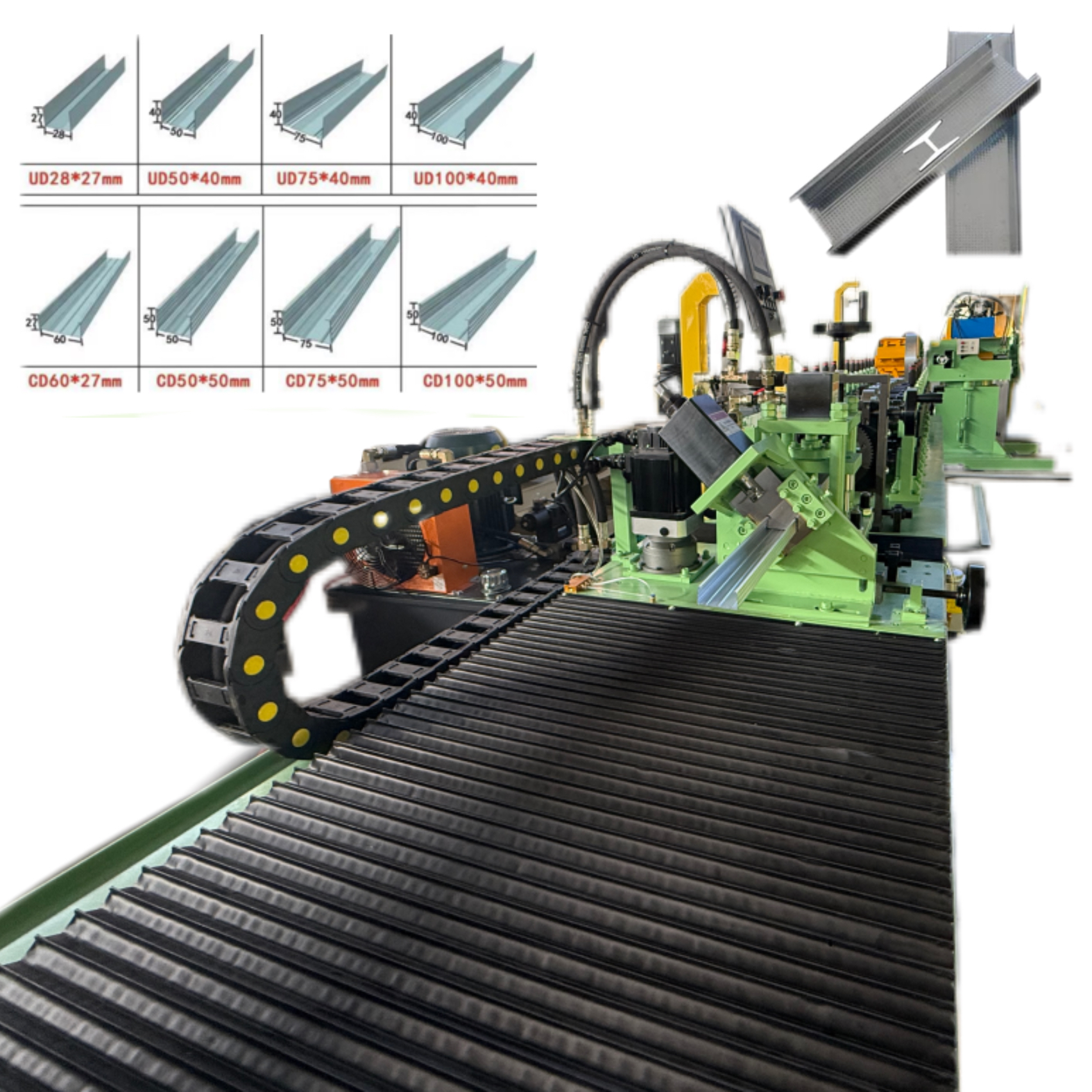

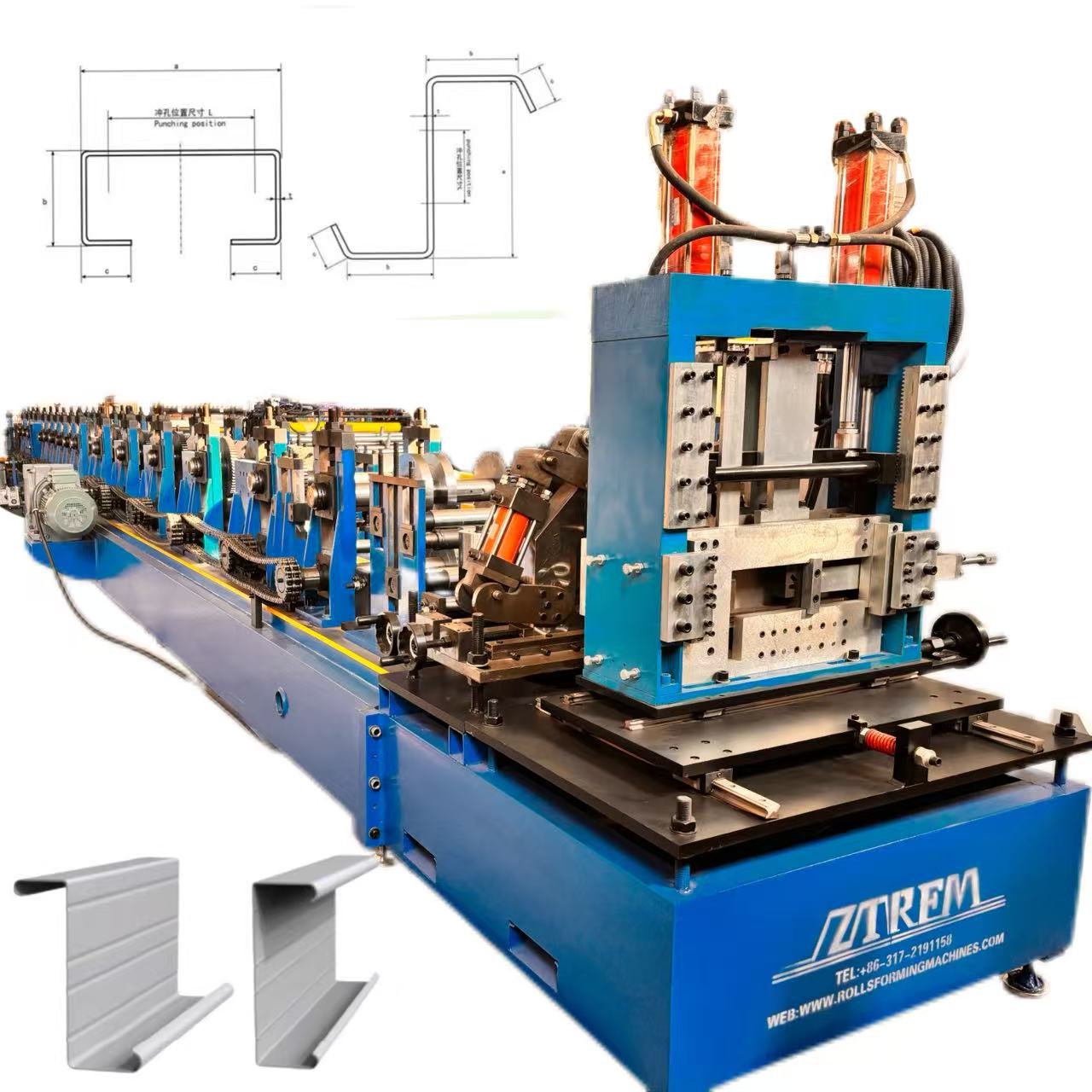

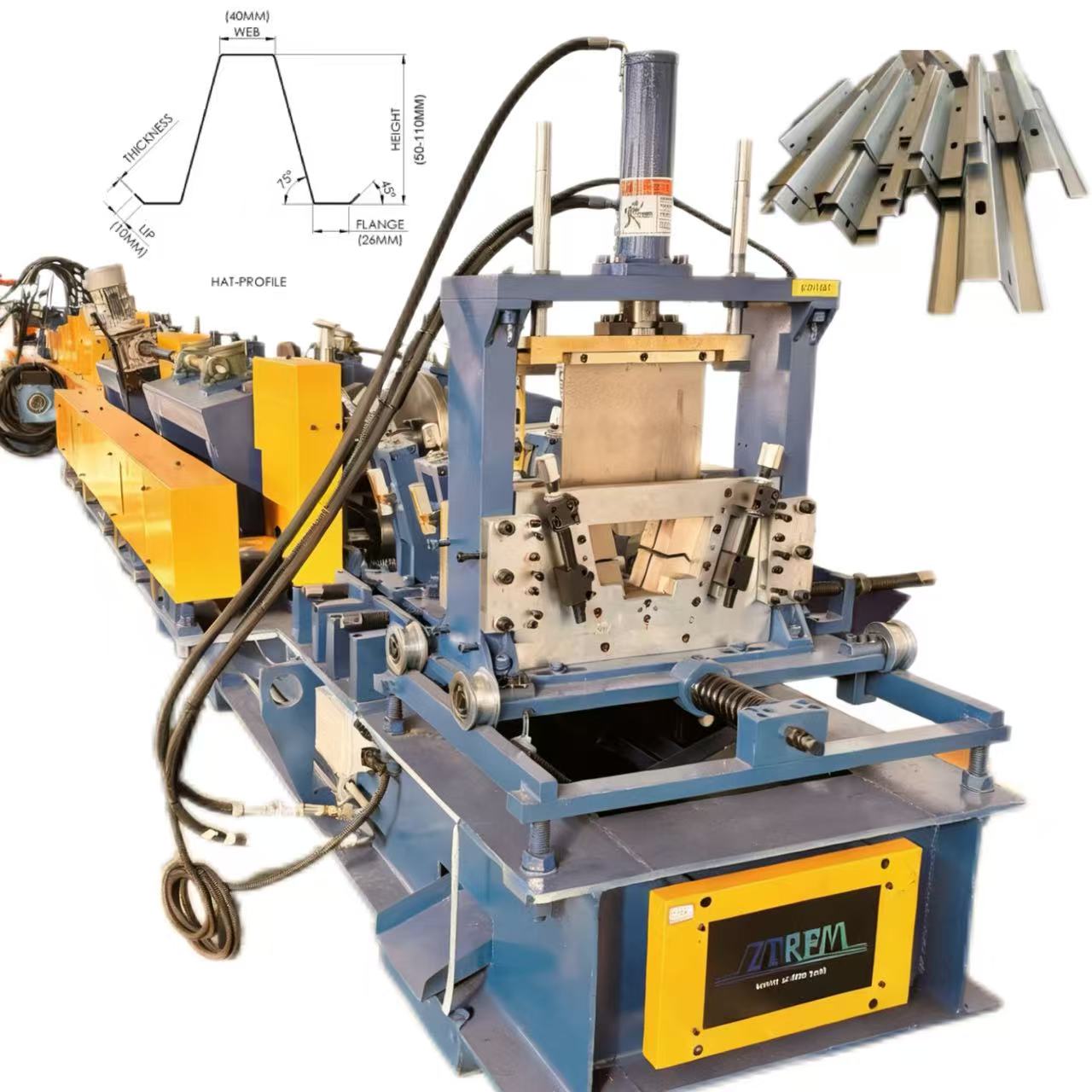

Pattern diagram:

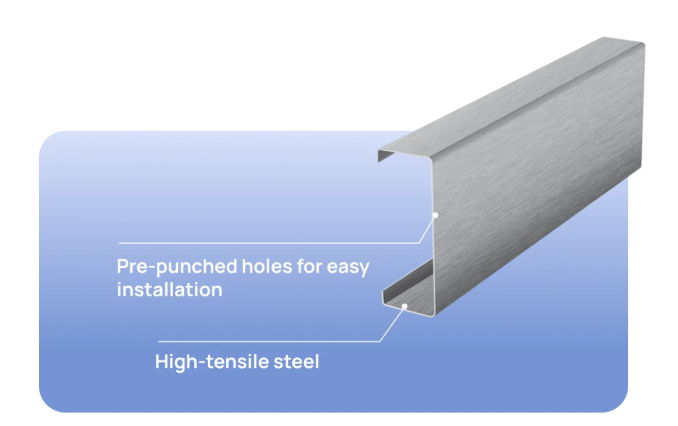

Finished product image:

Finished product image:

Core advantages of the product:

1.High level of automation:

The system employs a PLC (Programmable Logic Controller) computer control system, combined with automatic flying saw and punching technology, achieving full-process automation from material feeding, leveling, punching, forming to fixed-length cutting, significantly reducing manual intervention and enhancing production efficiency and precision.

2.High Efficiency and Energy Saving:

The equipment’s power system is typically hydraulically driven, with a power range of 11KW to 22KW, ensuring high energy efficiency. Some new models feature a “CZ-type steel integrated machine” design, enabling rapid switching between C-type and Z-type steel (minimum three minutes) without the need to replace the entire mold set, adapting to small-batch production of multiple varieties.

3.High forming accuracy:

The “secondary forming” process and “five down, four up” leveling system ensure square edges, right angles, and excellent straightness in the finished C-shaped steel. Most rollers are forged from GR15 bearing steel and undergo tempering treatment, offering strong wear resistance and a long service life.