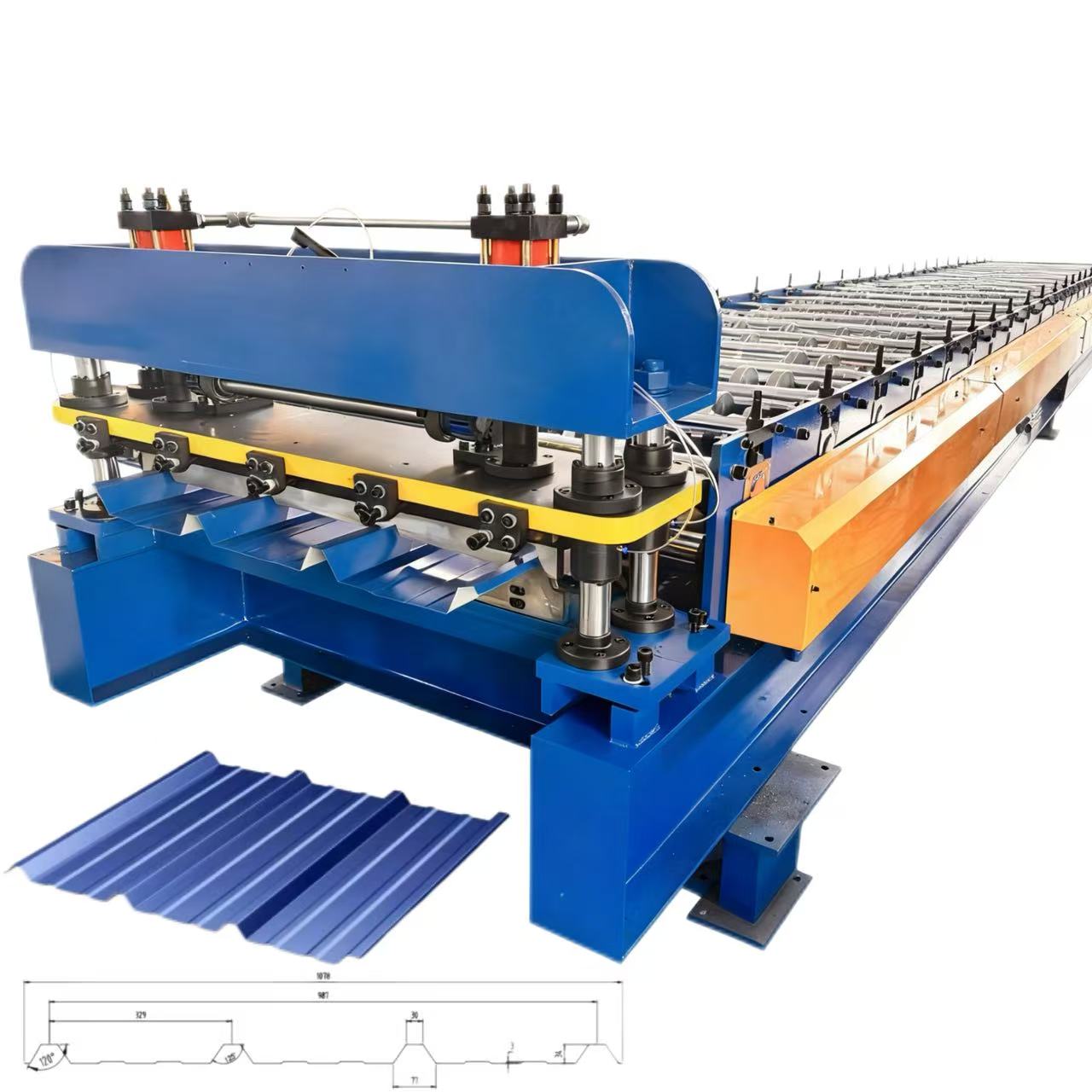

The TR4 Full Automatic Trapezoid Sheet Roofing Steel Metal Roof Forming Machine is an efficient automated production equipment developed to meet the needs of the construction industry for trapezoidal roof tiles (with strong waterproofing, neat and beautiful appearance, and durability). Its core value lies in helping users reduce production costs, improve product quality, expand production capacity, and adapt to multiple scenarios such as building materials factories, engineering supporting production, and entrepreneurial projects. It is a core production tool for seizing the roof tile market.

Core functions and advantages:

1.Efficient production:

from raw material feeding, molding to cutting, the entire process is automated, and batch orders are delivered quickly, bidding farewell to delivery time pressure; Less raw material waste, directly reducing production costs.

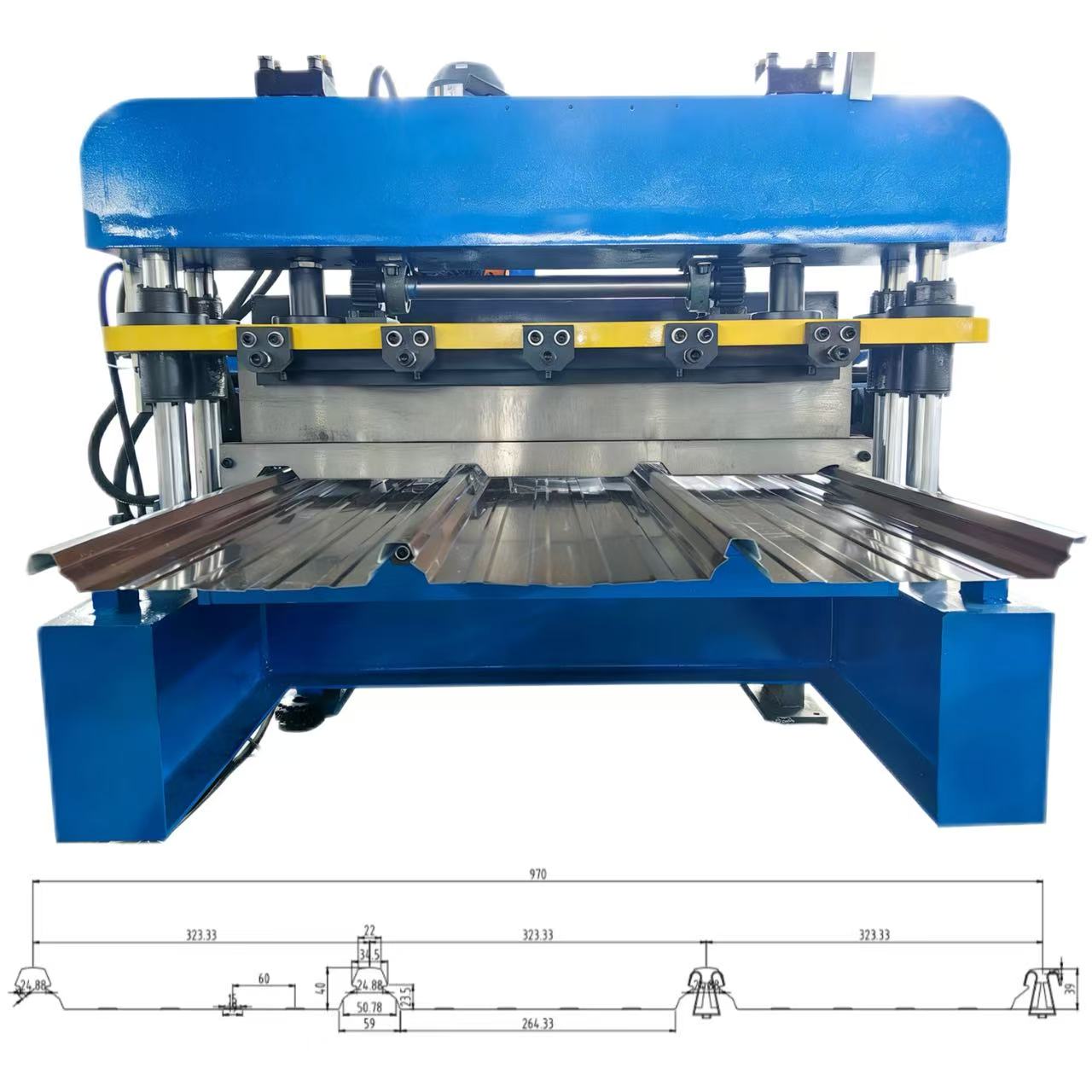

2.Stable quality:

The tile shape is regular, the color is uniform, the finished product is resistant to pressure, wind, corrosion, and wear, with a pass rate of over 99%, helping to accumulate customer reputation and expand the market.

3.Easy to operate and maintain:

Ordinary workers can operate independently after 1-2 days of training, reducing the threshold for manual labor; Daily maintenance only requires cleaning and lubrication, reducing maintenance costs by 40% and minimizing downtime.

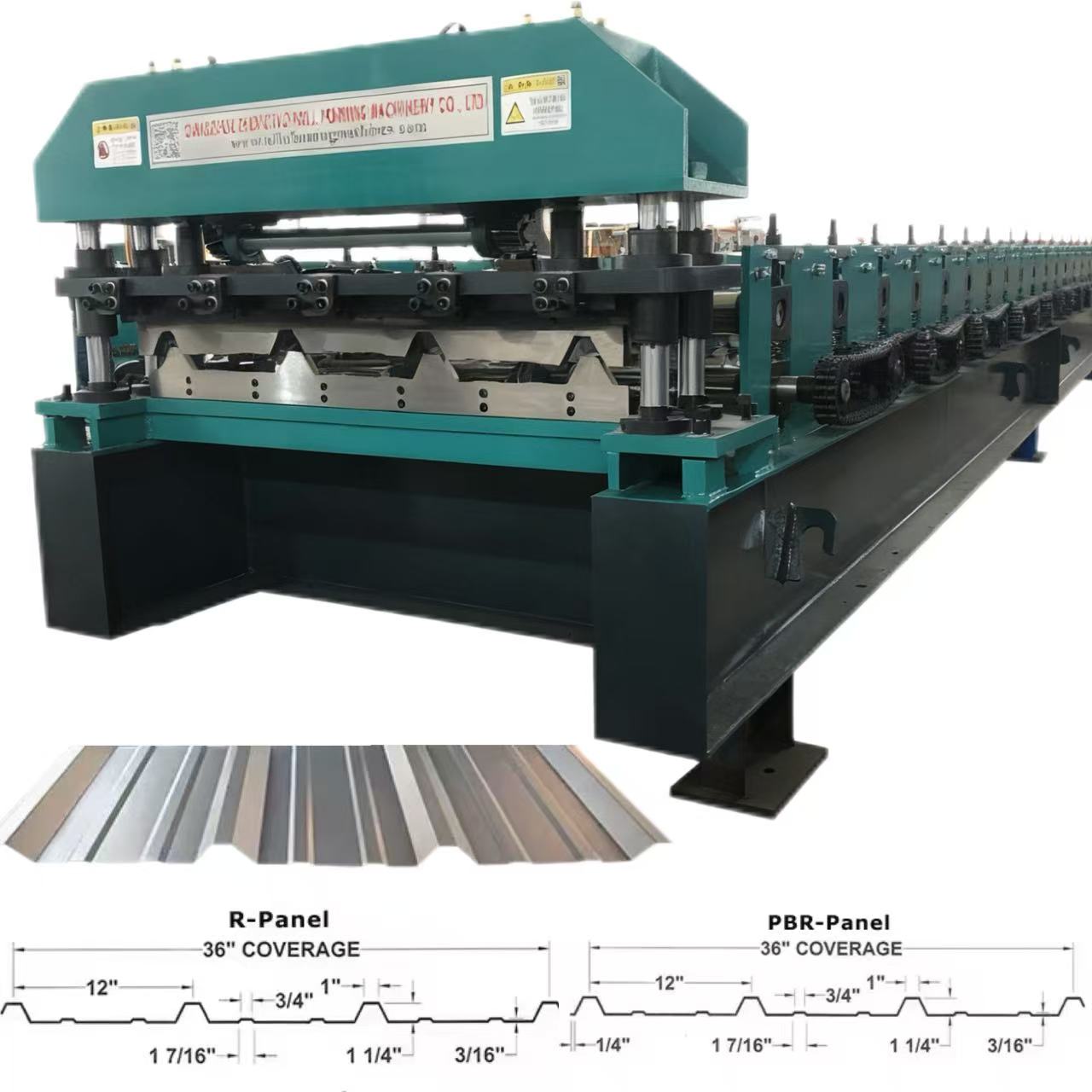

4.Flexible customization:

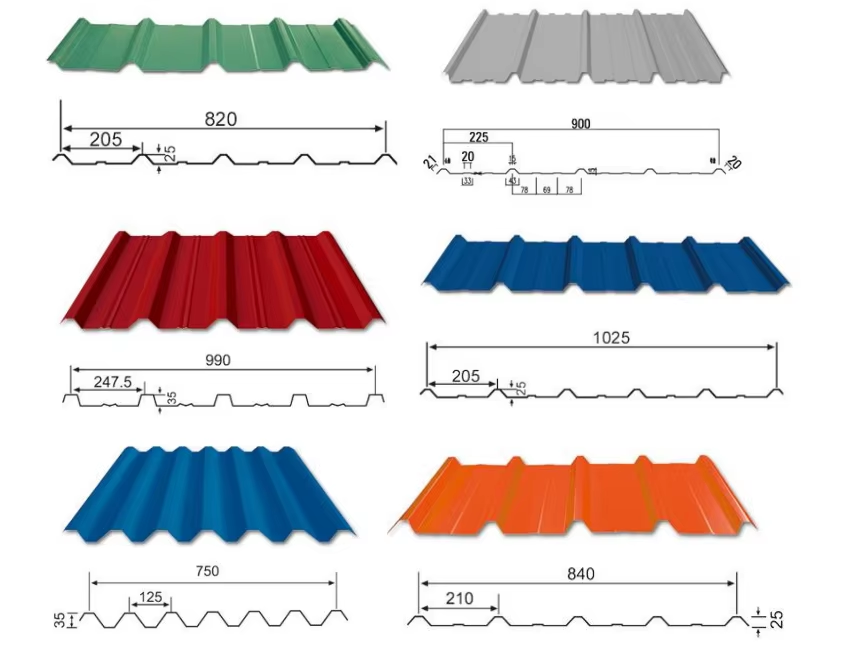

The parameters of trapezoidal tile height, wave distance, effective width, etc. can be adjusted according to the needs, adapting to the roof requirements of different buildings such as industrial plants, residential villas, warehousing and logistics centers. The product differentiation advantage is obvious.

Applicable scenarios:

• Steel structure factory building: The three-dimensional shape and drainage advantages of trapezoidal tiles can enhance the aesthetics and functionality of the factory roof.

• Ancient building roofs: The trapezoidal tiles designed in an antique style can blend with traditional architectural styles while meeting drainage requirements.

• The “flat to sloping” project: When transforming a flat roof into a sloping roof, trapezoidal tiles can balance waterproofing and drainage effects.

• Rainy areas: Trapezoidal tiles have excellent drainage performance and are suitable for rainy or high humidity environments.

Product Attributes:

|

1.Formed Material

|

PPGI,PPGL

|

Material Thickness:24/26 Gauge (0.3-0.6 mm)

Width:43inch(1092mm)

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

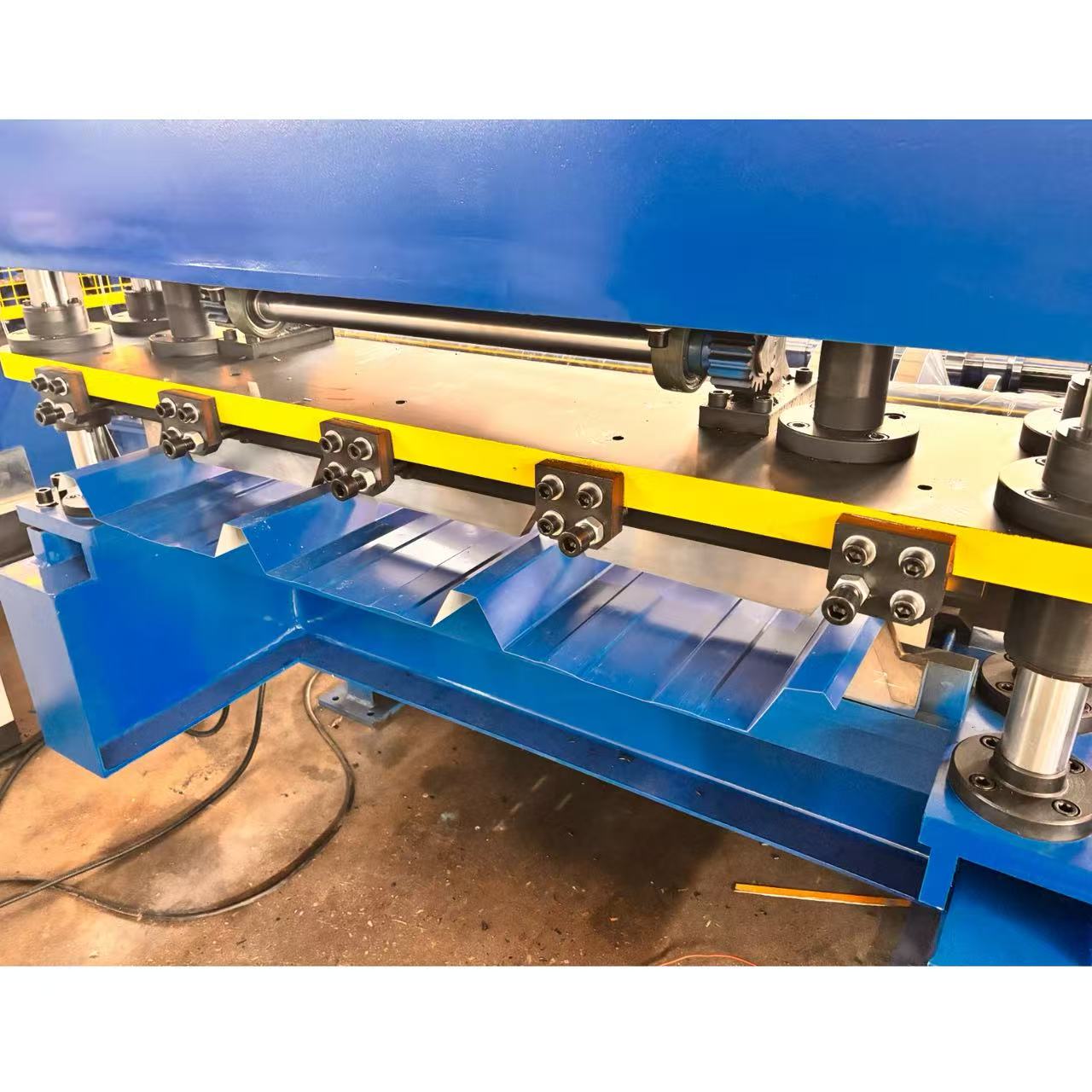

3.Main body

|

Roller station

|

18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

Dimension(L*W*H)

|

9.5m*1.65m*1.5m

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||