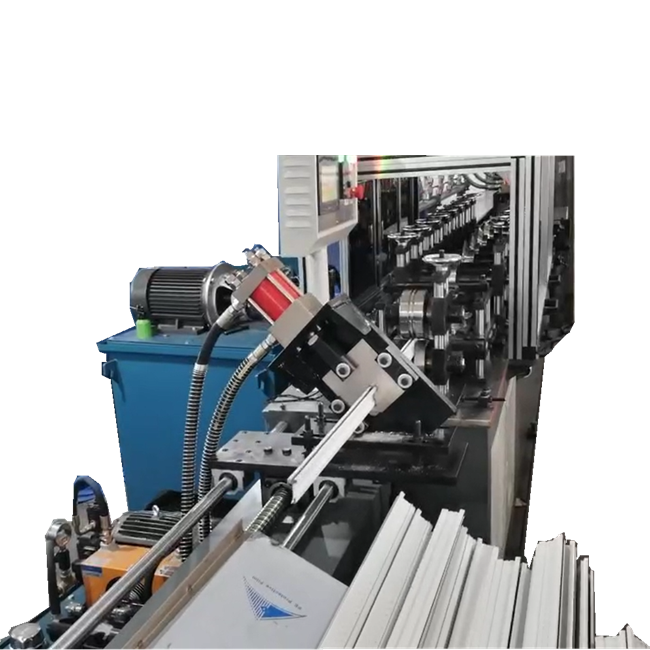

3D groove T-grid T-runner rolling forming machine fully automatic type is designed to make the 3D groove T-grid T-runner in batch fully automatically.

3D groove T-grid T-runner rolling forming machine fully automatic type

3D groove T-grid T-runner rolling forming machine fully automatic type is designed to make the 3D groove T-grid T-runner in batch fully automatically. The T3D groove T-grid T-runner mainly solves the shortcomings of traditional ceiling suspended T-shaped keels, such as low load-bearing capacity, weak bending resistance, poor decoration, and difficulty in fixing heavy objects when decorating the ceiling, which cannot provide support for large ceilings. The T-shaped three-dimensional groove through keel is composed of a vertical rib plate part and a groove profile part, and the cavity and slide rail of the groove profile part are more conducive to the suspension and movement of the decorative object, The groove profile has a more three-dimensional visual effect。

Here are some popular sizes for your reference:

3D groove T-grid T-runner rolling forming machine fully automatic type:

rame welding: thickness 20mm, rust removal

Roller: Roller material Cr12MOV. Inner diameter 39, minimum roller outer diameter 90, quenched HRC 55-56, 19 roller station

Transmission: 4KW+reducer transmission, each track is chain transmission

Guide pillar: thickness 25, cadmium plated

Axis: 40CR steel adjusted to processing

Electric control: PLC+touch screen, fully automatic 8 mold materials SKD11, HRC 58-60 machine comes with 6 sets of punching middle hole molds and 2 shear molds (a total of 8 sets)

Shear length 6/8/10/12 feet and Brazilian dimensions