Extensively applied scenarios, supporting the development of multiple industries

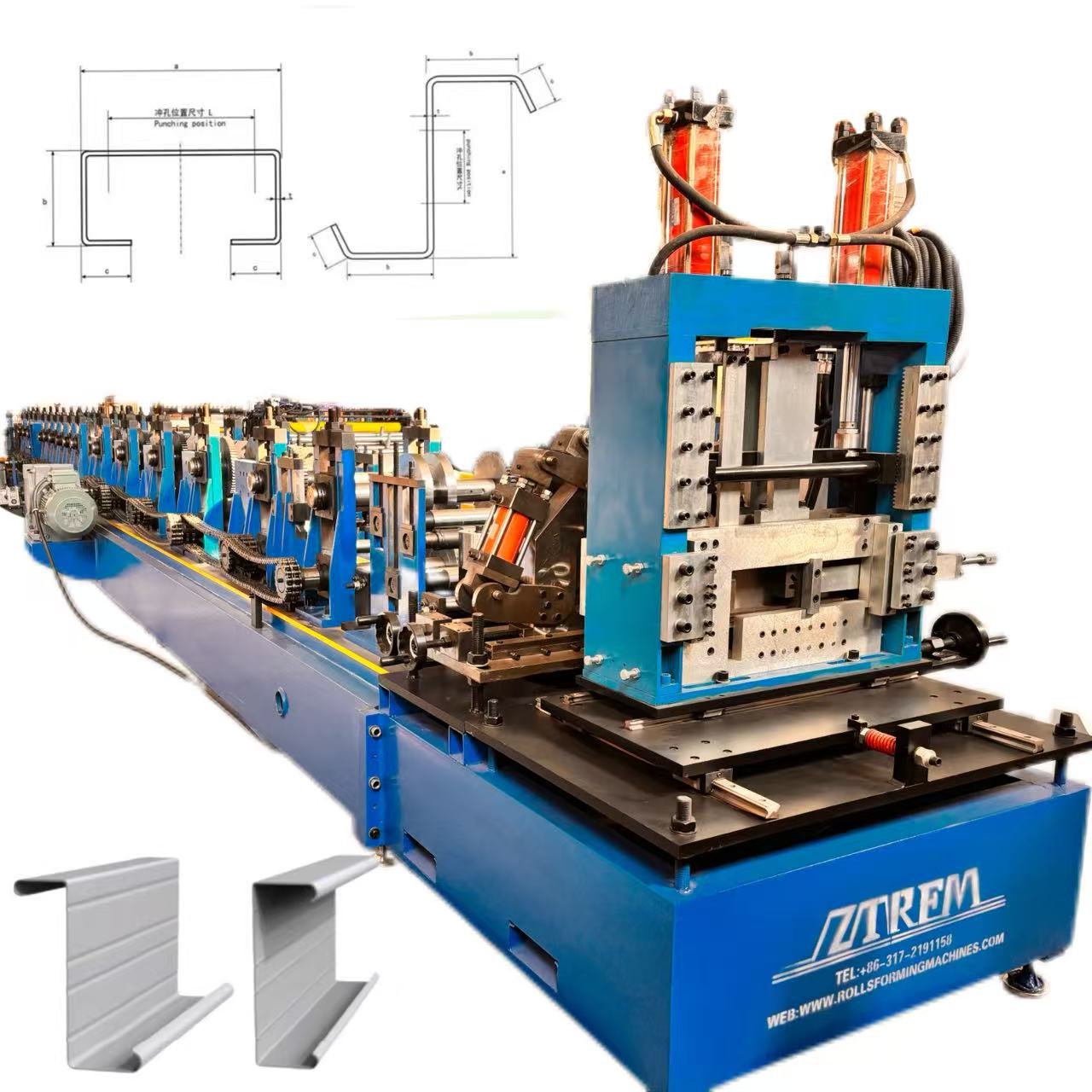

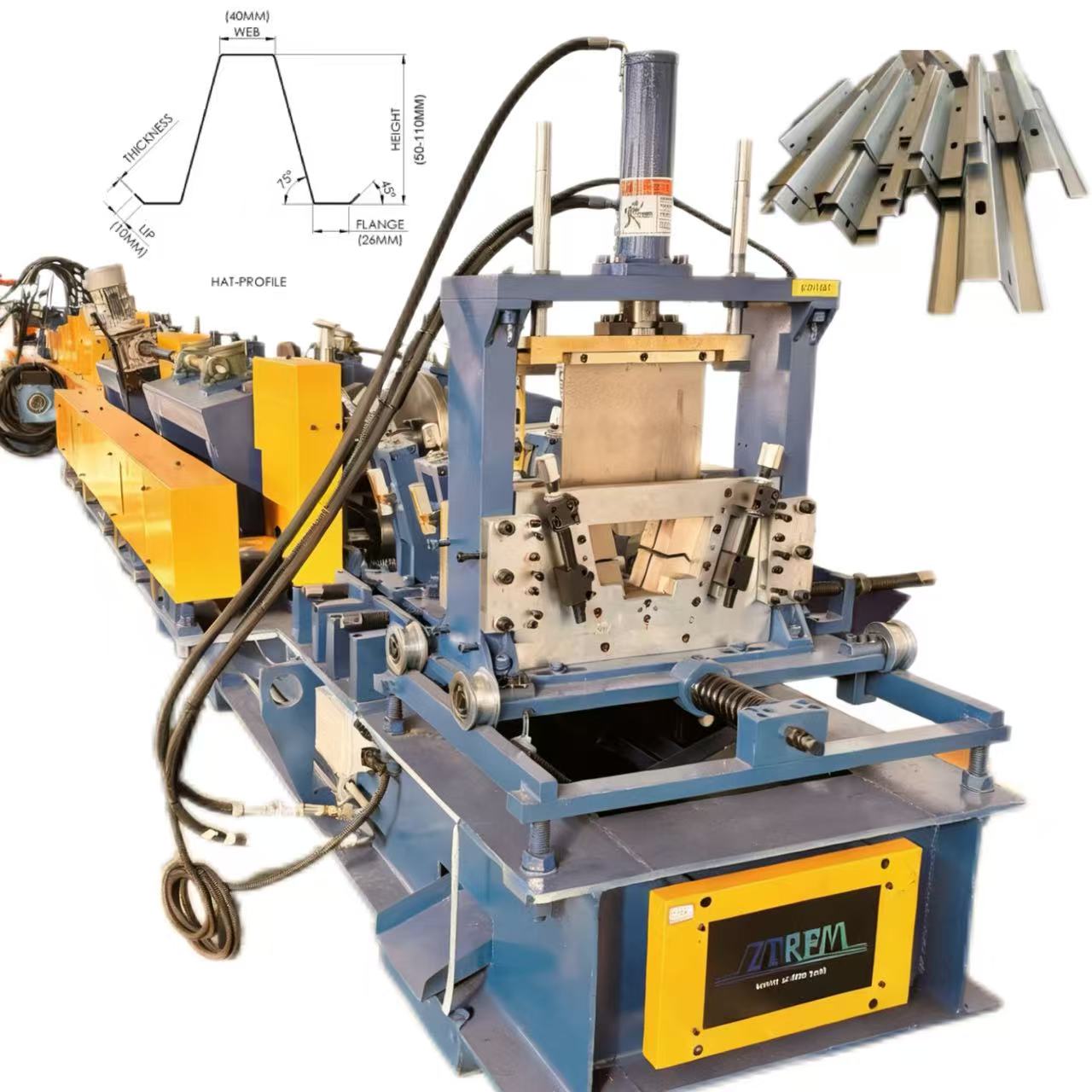

The Fully Automatic C Z Purlin in One Producing Line C Purline Rolling Forming Machine, with its outstanding performance, is widely used in various fields such as steel structure construction, photovoltaic support systems, storage racks, containers, and automotive components:

1.In the field of steel structure construction, purlins and support components for workshops, warehouses, and office buildings can be produced, providing a stable structural foundation for construction;

2.In the field of photovoltaic new energy, we offer customized production of CZ-shaped steel for photovoltaic mounting systems, meeting the installation requirements of various photovoltaic power stations and supporting the development of green energy;

3.In the field of warehousing and logistics, we can produce accessories such as shelf beams and uprights to enhance the load-bearing capacity and stability of shelves;

4.In the automotive manufacturing sector, it is capable of producing small steel structural components such as car chassis and frames, meeting the industry’s high demands for precision and strength.

Whether it is a large steel structure enterprise or a small or medium-sized processing plant, each can select equipment models with varying capacities (such as 10-20 meters per minute) based on its production needs to maximize production efficiency and economic benefits.

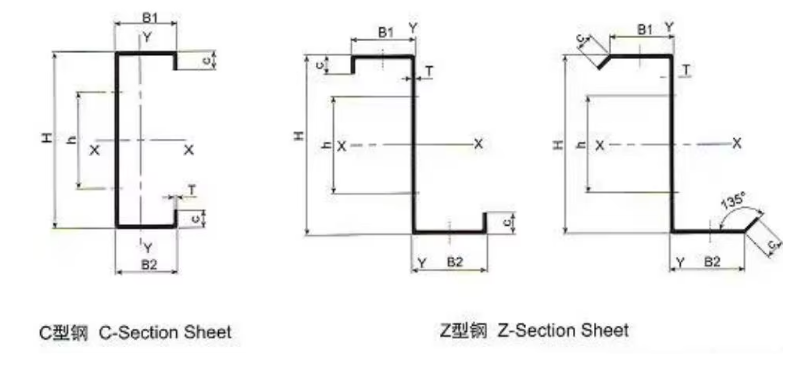

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Powered by core technologies, it delivers exceptional quality and performance

For a high-quality forming equipment, its core technology is the “soul.” The Fully Automatic C Z Purlin in One Producing Line C Purline Rolling Forming Machine achieves dual breakthroughs in quality and performance through multiple leading technologies:

1. High-precision molding ensures product quality

The equipment employs a servo drive system and precision gear transmission structure, paired with imported encoders for real-time monitoring of forming accuracy. This ensures that the produced C-shaped steel web and flange have vertical deviation ≤0.5mm and length error controlled within ±1mm, fully meeting the high standards of national steel structure engineering requirements. Whether used for factory roof purlins, villa supports, or large-scale venue steel structure components, it guarantees stability and safety.

2. Intelligent automation reduces labor costs

Equipped with an industrial-grade PLC control system and a 7-inch touch-screen operation panel, the operator only needs to input the specifications of the steel profiles (e.g., C-channel height 100-300mm, Z-channel height 120-350mm, thickness 1.5-4.0mm), and the equipment can automatically complete parameter adjustments, mold positioning, production counting, and other tasks. Additionally, the machine is fitted with an automatic feeding alignment device to effectively prevent material deviation and reduce material waste. The automatic stacking function for finished products eliminates the need for manual handling and piling, requiring only 1-2 operators to monitor the equipment for normal operation. Compared to traditional production methods, it can reduce labor costs by over 60%.

3. High-flexible production to meet diverse demands

To address the market’s diverse specifications of CZ steel, the fully automated CZ steel integrated forming machine features a rapid mold-changing design, requiring only 15-30 minutes to switch between different mold specifications—far less than the 2-3 hours needed by traditional equipment. Additionally, the machine supports one-button switching between “C-type” and “Z-type” steel production without the need to replace core components. This enables it to handle both large-volume orders for single specifications and flexibly accommodate small-batch, multi-specification custom orders, helping enterprises expand product categories and capture more market share.

4. Stable and durable, reducing maintenance costs

The equipment body is constructed from high-quality steel plates through seamless welding, followed by aging treatment to eliminate internal stress, ensuring strong rigidity and minimal deformation. Key components such as forming rollers are made of 40Cr material, treated with quenching and tempering, achieving a hardness of HRC58-62, offering superior wear resistance and significantly longer service life compared to ordinary rollers. Additionally, the equipment is equipped with a comprehensive lubrication system and fault alarm system, enabling real-time monitoring of operational status, timely maintenance alerts, effectively reducing downtime and lowering long-term maintenance costs.