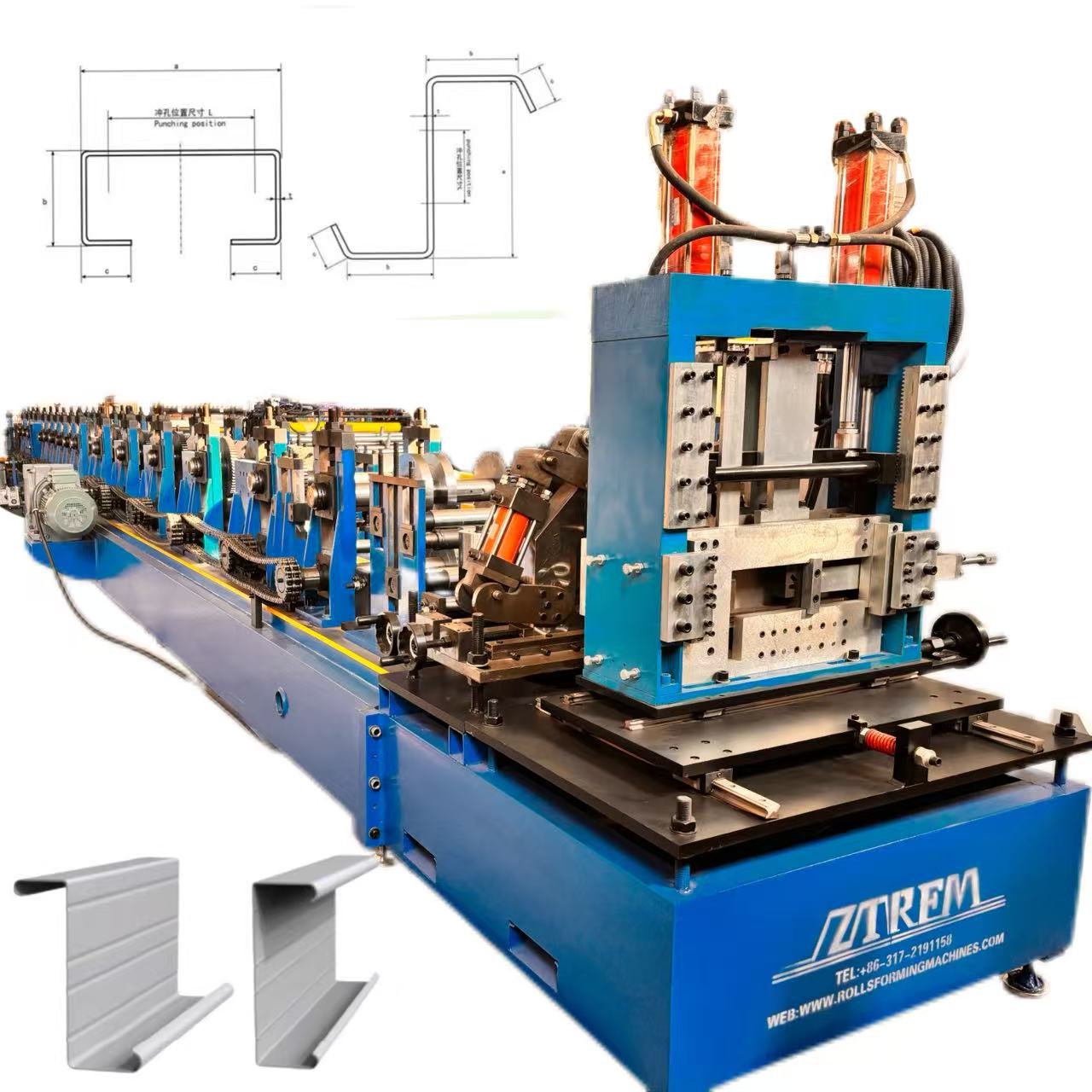

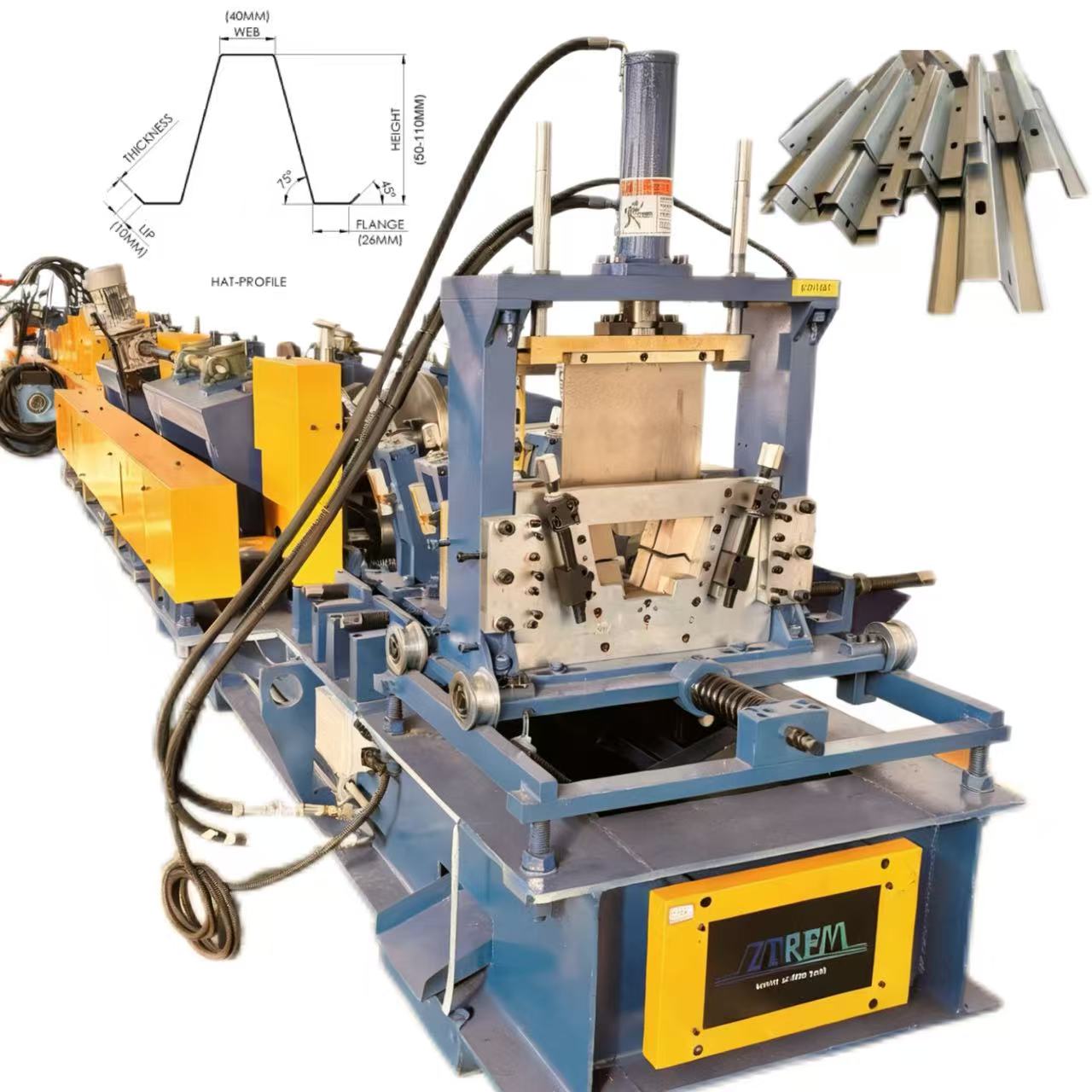

In the field of modern construction and industry, CZ steel has become a key material for building stable building structures and supporting industrial equipment with its unique structural advantages and wide applicability. As the core equipment for the production of CZ steel, CZ steel machine is reshaping the production pattern of building materials with its excellent performance, efficient production capacity and precise processing technology, injecting strong impetus into the development of the industry. CZ steel machines use a cold-forming process to gradually process hot-rolled steel plates or strips into specific C-section and Z-section shapes. Under the precise control of the PLC automation system, the steel is gradually bent into the desired shape under the continuous and stable mechanical action through multiple carefully designed rolling processes. The system can flexibly and accurately adjust key indicators such as bending angle and radian according to preset parameters, and can quickly switch between C-type and Z-type production modes, greatly improving production efficiency and product accuracy.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:1.5-3 mm (standard)

|

||

|

2.Decoiler

|

3 Tons Hydraulic automatic decoiler

|

3 Tons Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

18 rows (As your requirement)

|

||

|

Diameter of shaft

|

80 mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gear and chains transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

15 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

25 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

working flow:

The significant advantages of CZ steel machine

1.Efficient production and increased production capacity Quick changeover technology:

(1) Quick change technology:

Some advanced CZ steel machines are equipped with rapid change systems, such as Nantong Huaheng’s servo CZ all-in-one machine, whose main forming unit is equipped with 13 sets of CZ interchange modules, operators only need to use electric buttons, can easily complete the switching of C-type and Z-shaped steel production specifications in just a few minutes, greatly reducing equipment downtime caused by product model adjustments and significantly improving production efficiency. In the face of diverse order needs, it can respond quickly to achieve continuous production of products of different specifications and meet the market’s requirements for rapid product delivery.

(2) High-speed forming capacity:

On the basis of stable equipment operation, CZ steel machine has the ability to form at high speed. With an average production speed of 25 to 40 meters per minute, the production efficiency is a qualitative leap compared to conventional profile processing equipment. At the same time, the equipment can also automatically adjust the production speed according to the thickness of the steel being processed, and automatically reduce the speed when encountering thicker steel to ensure that the steel can be fully formed and ensure product quality; When processing thinner steel, it accelerates production speed, further increases production capacity, and achieves a perfect balance between production efficiency and product quality to meet the needs of production enterprises of different sizes.

(3) Continuous production mode:

From raw material feeding and leveling to forming and shearing, CZ steel machine realizes continuous automated production of the whole process. This continuous production mode avoids the time waste caused by process interruptions in traditional production methods, reduces manual intervention, and reduces the impact of human factors on production efficiency. At the same time, continuous production can also ensure the stability of product quality, avoid product quality fluctuations caused by multiple start-stop equipment, and enable enterprises to produce a large number of high-quality CZ steel products in a short period of time and improve market competitiveness.

2. Precise molding to ensure quality High-precision molds and processing technology:

(1) High-precision mold and processing technology:

The forming mold of CZ steel machine is manufactured using advanced CNC machining technology, and the dimensional accuracy of the mold cavity can reach the micron level. During the production process, the steel can be precisely pressed into the shape required by the design under the action of high-precision molds, ensuring that the cross-sectional dimensional error of the profile is extremely small. At the same time, the rolls and spindles of the equipment are made of high-quality materials, and have undergone strict heat treatment and polishing electroplating and other processes, which not only improve the hardness and wear resistance of the rolls and spindles, extend the service life of the equipment, but also ensure that the steel can be stably processed in a high-speed and high-pressure production environment, so as to produce CZ steel products with accurate dimensions and regular appearance, meeting the strict standards of high-quality construction and industrial projects.

(2) Automated quality monitoring and adjustment:

Modern CZ steel machines are equipped with advanced automated quality monitoring systems, which can monitor key indicators such as product size, shape, and surface quality in real time during the production process. With sensors installed in key parts of the equipment, the system can quickly collect production data and transmit it to the control system for analysis and processing. Once a deviation in product quality is found, the control system can immediately automatically adjust the operating parameters of the equipment, such as rolling pressure, bending angle, etc., to correct problems in the production process in time and ensure that product quality is always maintained at a high standard. This automated quality monitoring and adjustment mechanism greatly reduces the defective product rate, improves product consistency and stability, reduces production costs for enterprises, and enhances product reputation.

3. Intelligent operation to reduce costs Intelligent control system:

(1) Intelligent control system:

The intelligent control system with PLC as the core makes the operation of CZ steel machine simple and convenient. Operators only need to enter the relevant parameters of the product on the touch screen operation interface, such as the specifications, length, quantity of profiles, etc., and the equipment can automatically complete the production task according to the preset program. Once the equipment is found to have a hidden danger of fault, the system will immediately issue an alarm, and analyze the cause of the fault through the fault diagnosis program, provide detailed fault information for maintenance personnel, help them quickly locate and solve problems, avoid long-term downtime and production due to equipment failure, and reduce the operating cost of the enterprise.

(2) Energy-saving and efficient design:

In terms of energy consumption, CZ steel machines adopt a series of energy-saving design measures. For example, the drive system of the equipment uses high-efficiency and energy-saving motors, combined with advanced frequency conversion speed regulation technology, which can automatically adjust the motor speed according to the actual operating load of the equipment, avoid energy waste during low-load operation, and achieve energy-saving operation. At the same time, the equipment has also been optimized in terms of hydraulic system and lubrication system, reducing the energy loss of the system and improving energy utilization efficiency. In addition, labor costs are reduced through automated production, and raw material waste is reduced through precise production control, which reduces the production cost of enterprises from multiple dimensions and improves the economic benefits of enterprises.

Wide application of CZ steel machine

1. Application in the construction field

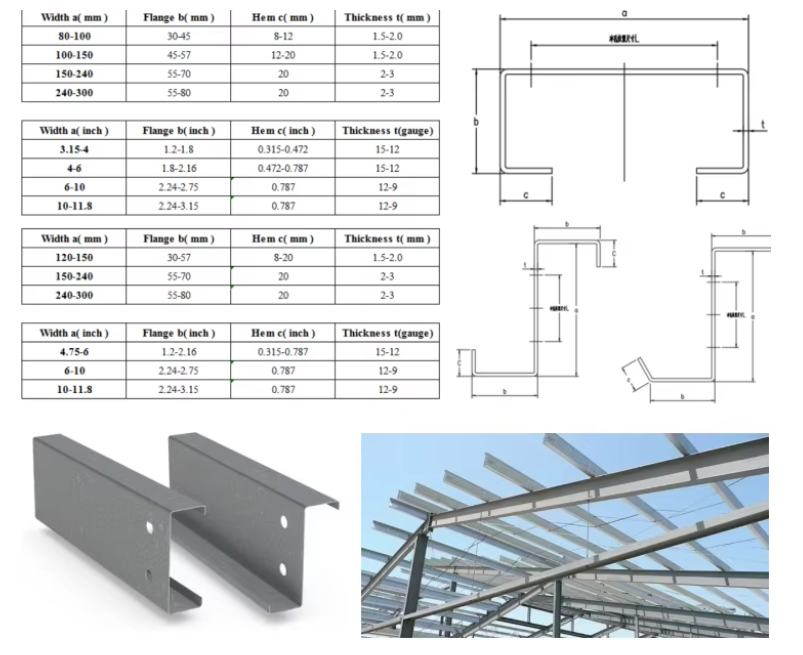

(1) Purlin construction of steel structure houses:

In the construction of steel structure houses, CZ beam is often used as purlins for roofs and walls. The C-type and Z-type purlins produced by CZ steel machine have the advantages of light weight, high strength, and easy installation, which can effectively support the envelope structure of the roof and walls, ensuring the overall stability of the house. Its standardized specifications and good versatility make it easy to select and install in the construction of steel structure houses of different sizes and types, greatly improving construction efficiency.

(2) Structural support for high-rise buildings:

In high-rise buildings, CZ steel can be used to build some secondary structural support systems, such as the support frame of the stairwell, the structural platform of the equipment floor, etc. These parts have high requirements for the strength of materials and installation convenience, and the profiles produced by CZ steel machines can meet these needs, while their relatively light weight also helps to reduce the overall weight of the building, reduce the cost of foundation works, and improve the economy and safety of the building structure.

(3) Light steel villa construction:

Light steel villas have been favored by more and more consumers in recent years due to their environmental protection, energy saving, and fast construction speed. CZ steel produced by CZ steel machine is one of the main structural materials of light steel villas, which is used to build the main frame of villas. Its good mechanical properties and processability can meet the complex structural design requirements of light steel villas, and the rapid production speed also provides a strong guarantee for the large-scale promotion of light steel villas.

2. Application in industrial field

(1) Industrial plant construction:

Industrial plants usually require a large space span and bearing capacity, and the CZ steel produced by CZ steel machine can be used to make important structural components such as roof trusses, crane beams, and wall purlins of the plant. In the construction of large-scale industrial plants, the efficient production and installation of CZ steel can shorten the construction period and reduce construction costs, and its good durability and stability can meet the requirements of long-term use of industrial plants and provide reliable space guarantee for industrial production.

(2) Warehousing shelf manufacturing:

With the rapid development of the modern logistics industry, the demand for warehousing shelves is growing. CZ steel produced by CZ steel machine is an ideal material for manufacturing storage shelves due to its reasonable cross-sectional shape and high strength. By properly processing and assembling CZ steel, storage shelves of various specifications and load-bearing capacities can be made to meet the needs of different cargo storage. Its standardized production process also makes the manufacturing of storage shelves more efficient and standardized, improving the quality and versatility of shelves.

(3) Equipment support structure:

In industrial production, many large-scale equipment requires a strong support structure to ensure its stable operation. The CZ steel produced by CZ steel machine can be customized and processed into various forms of equipment support structures, such as equipment foundation frames, pipe supports, etc., according to the weight, size and installation requirements of the equipment. These support structures have good load-bearing capacity and stability, can effectively distribute the weight of equipment, protect equipment from vibration and shock, and ensure the safe and stable progress of industrial production.

The process flow of CZ steel machine

1.Raw material preparation

(1)Steel selection: According to the performance requirements of the product, hot-rolled steel plates/steel strips are selected as raw materials, and the specifications and parameters of commonly used materials such as Q235 and Q345 are strictly controlled to ensure that the strength and toughness of the profile meet the standards.

(2)Material inspection: Before putting into production, the appearance, size and mechanical properties of the steel are comprehensively tested to eliminate cracks, dimensional deviations and other problems, and the next process can only be entered after qualification.

(3)Loading and unwinding: Lifting coils of steel onto a discharge rack equipped with automatic holding devices, with a load capacity of more than 5 tons designed to meet the needs of large-scale production.

2.Leveling process

(1)Material leveling: The inlet leveling device eliminates the deformation of steel wavy bending through multiple sets of staggered rollers, and high-precision leveling lays the foundation for the forming quality.

(2)”One drag and one pressure” conveying: the active conveying roller and the pressing roller work together to restrain the material runout and ensure the stability of conveying and processing accuracy.

3.Molding process

(1)C/Z type conversion molding: Under PLC control, the steel is continuously bent through multiple sets of roller dies, and the C/Z type is quickly switched through parameter adjustment to ensure the accuracy of the section.

(2)Multi-pass rolling process: Adopt multi-pass rolling to accurately control the amount of deformation, optimize stress distribution, and improve the dimensional accuracy and mechanical properties of the profile.

4. Punching process (if necessary)

(1)Punching equipment and process: Hydraulic punching equipment quickly makes holes according to preset parameters, the hole wall is smooth, the error is extremely small, and some equipment supports synchronous processing of multiple rows of holes.

(2)Precise control of hole position: The control system is linked to the punching equipment and automatically positions according to the profile parameters to ensure the accuracy of hole installation.

5.Shearing process

(1)Precise shearing after forming: Hydraulic shears or flying saws are controlled by PLC to complete the cutting after the profile is formed, with a length error of less than ±1mm to avoid port deformation.

(2)Waste collection and treatment: The waste collection device automatically collects leftovers, and some equipment supports classification and recycling to improve resource utilization.

6.Finished product inspection and palletizing

(1)Quality inspection: Combined with manual and instrument, the size, shape, surface and mechanical properties are detected, and the key indicators are controlled by high-precision measurement equipment.

(2)Finished product palletizing: Qualified products are transferred to the palletizing area through the conveying device, and the equipment is neatly stacked according to the rules.