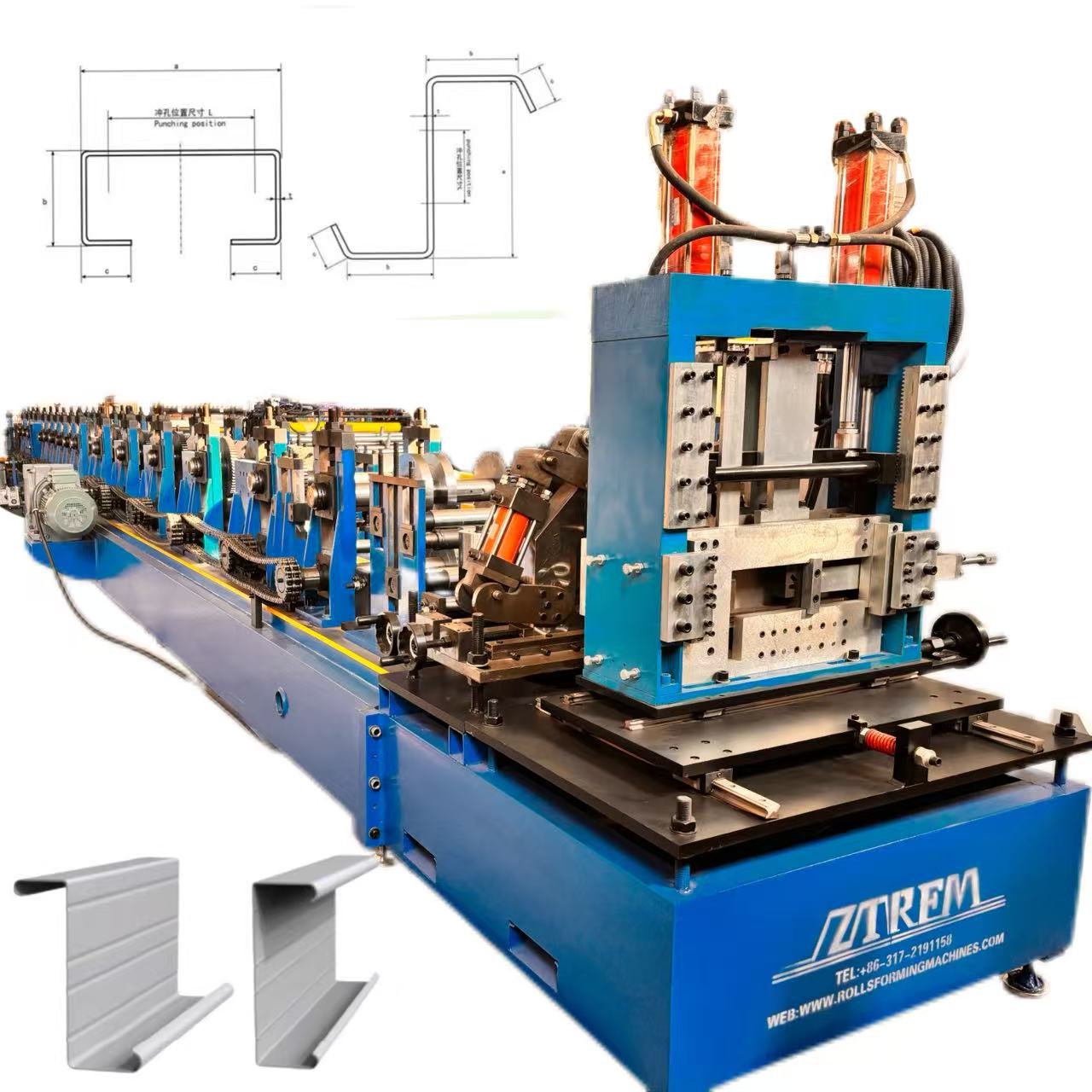

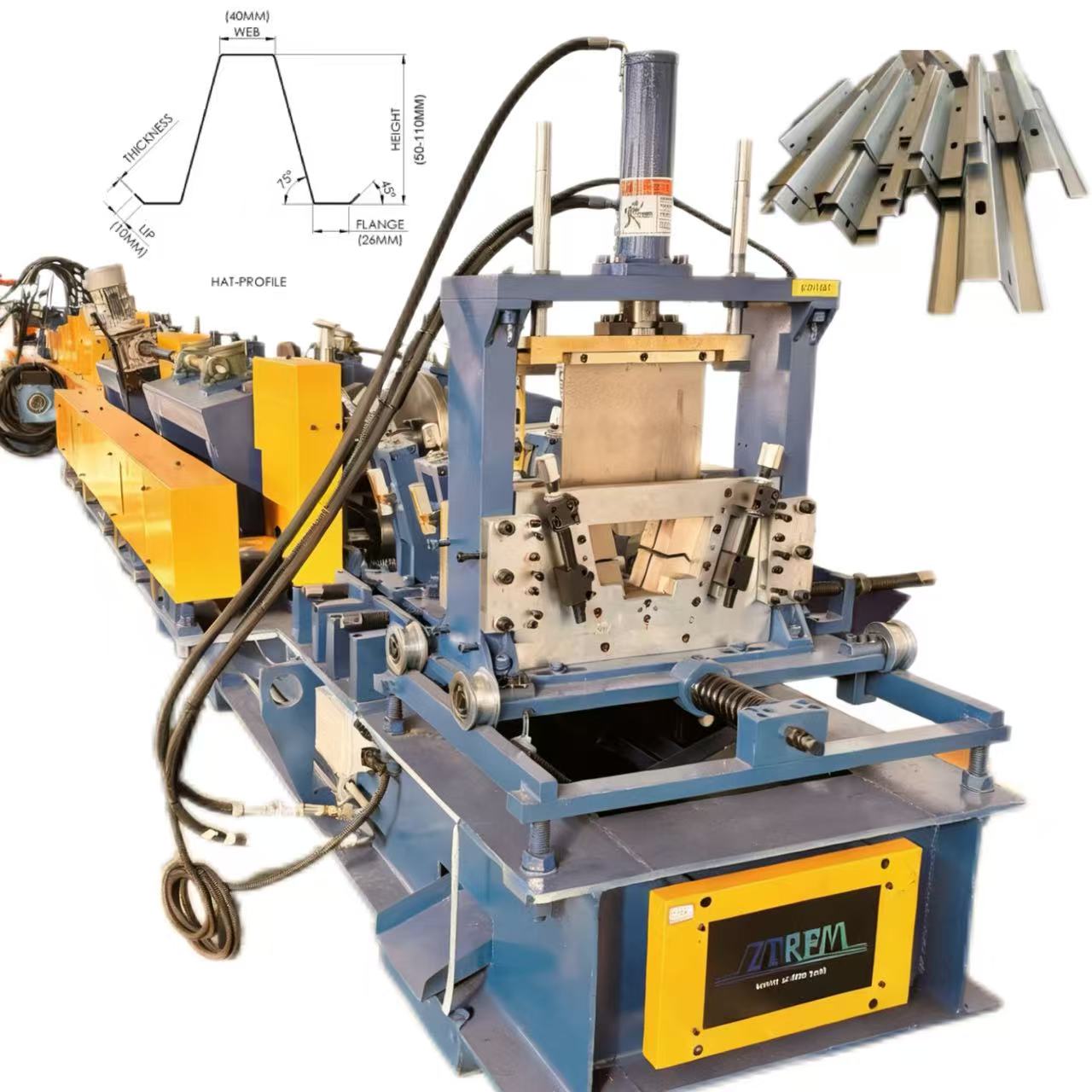

The Fully Automatic CZ Purlin Roll Forming Machine (25m/min) is designed with the core concept of “unmanned operation,” achieving full automation in the entire process from raw material feeding, precise conveying, multi-process machining to finished product discharge. Compared to traditional manual operation, it eliminates the need for dedicated supervision and intervention, with a single machine’s daily processing capacity reaching 3-5 times that of conventional equipment, significantly shortening production cycles. Its high-speed feeding system features a positioning response speed of up to 0.1 seconds, combined with continuous machining processes, effectively reducing process switching gaps. This enables a qualitative leap in steel section processing efficiency, effortlessly meeting the demands of mass production orders.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

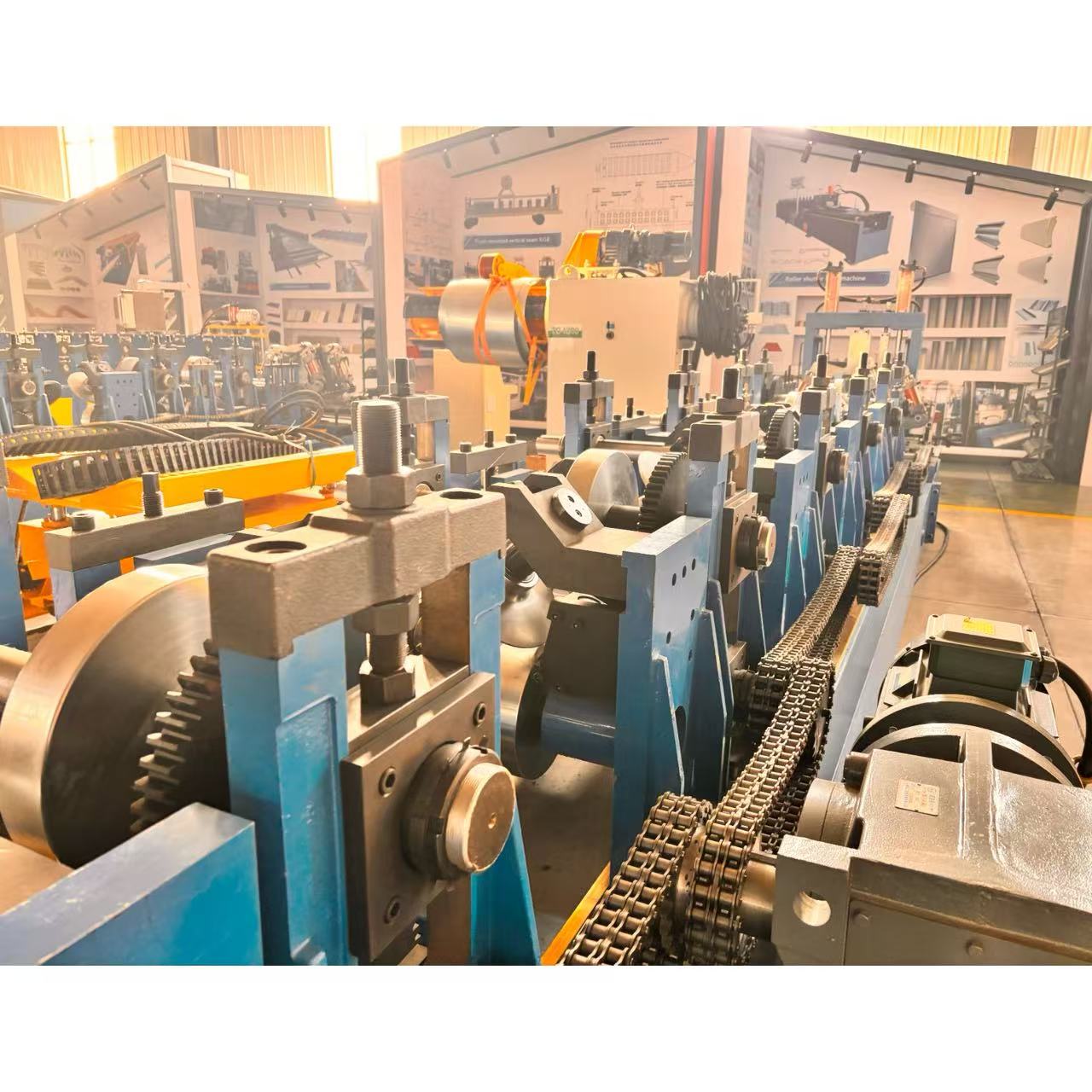

3.Main body

|

Roller station

|

24 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 14T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Core application scenarios

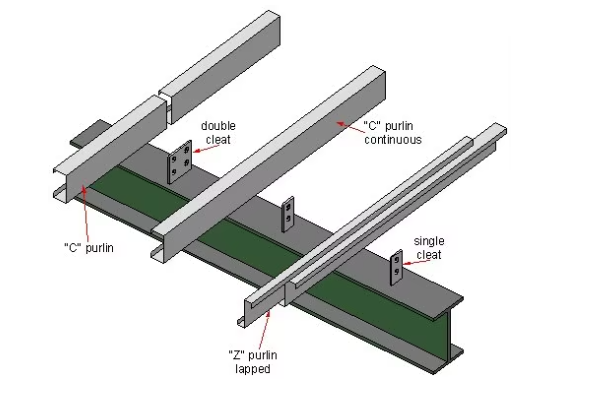

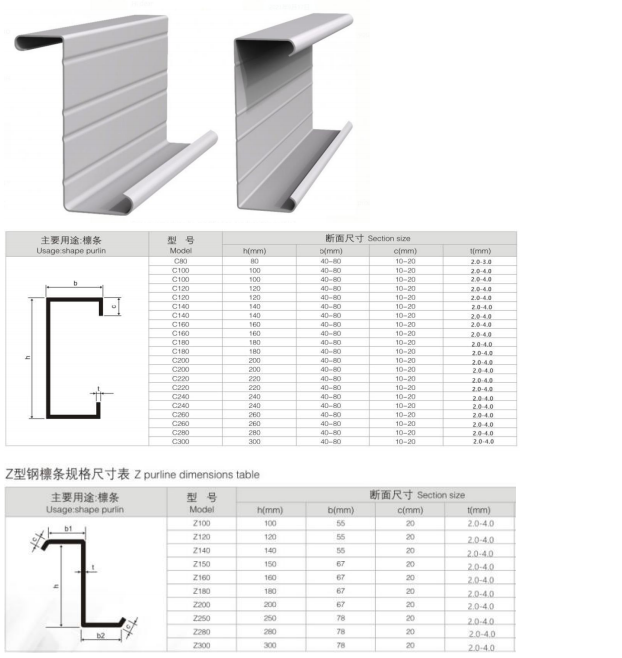

1、 Steel structure construction industry

• Adaptation processing requirements: The main frame processing of steel structure buildings such as factories, warehouses, office buildings, and sports halls, including cutting, punching, and bending integrated processing of C/Z-shaped steel purlins, steel columns, steel beams, and supporting components.

• Adaptation logic: The full process automation of the equipment can meet the large-scale steel processing needs of construction projects, with a high precision of ± 0.02mm to ensure component splicing and matching, reduce on-site installation errors, and significantly shorten the construction period.

2、 Bridge and Traffic Engineering

• Adaptation processing requirements: Processing of auxiliary steel structures for highway bridges and railway bridges (such as guardrail brackets, crossbeams, and connectors), as well as processing of supporting steel and embedded components for tunnels and subway stations.

• Adaptation logic: The high-strength body can withstand the processing load of thick walled steel, and the intelligent detection and error compensation functions ensure that the components meet the strict safety standards of bridge engineering. The durability is suitable for long-term outdoor use scenarios.

Advantages and Characteristics:

1、 Efficiency advantage: full process automation, doubled production capacity

2、 Precision advantage: Micron level control, stable and reliable quality

3、 Intelligent advantages: simple operation, efficient management

4、 Adaptation advantages: Multi scenario compatibility, flexible response to customized needs

5、 Economic advantages: energy conservation, consumption reduction, and overall cost reduction