In the family of glazed tile machines, the metal glazed tile forming machine, with its unique technology, uses metal raw materials such as color steel plates and aluminum alloy plates to produce products that combine metal strength and glazed tile decoration through processes such as rolling, punching, bending, and spraying. It meets the diverse needs of modern architecture for high-strength, aesthetic, and durable roof materials.

Core performance advantages:

1.High strength and durability:

Metal materials endow glazed tiles with higher strength. The tensile strength of color steel glazed tiles can reach 300-500MPa, and the strength of aluminum alloy glazed tiles is also between 100-300MPa, far higher than that of clay tiles (compressive strength 10-20MPa) and cement tiles (compressive strength 30-50MPa). At the same time, the surface coating has good UV resistance and corrosion resistance, which can resist acid rain and sea breeze erosion, with a service life of up to 30-50 years, suitable for harsh environments such as coastal areas and industrial pollution areas.

2.Lightweight and easy to install:

Metal glazed tiles are lightweight, with color steel tiles weighing approximately 10-15kg per square meter and aluminum alloy tiles weighing only 5-8kg, which is one-third to one-fifth of the weight of cement tiles (approximately 40-50kg per square meter). Lightweight design is convenient for transportation and installation, and can be carried by a single person. In addition, the installation process requires low load-bearing capacity for the roof structure, which can save installation costs and construction time. It is especially suitable for roof renovation and lightweight building projects.

3.Rich colors and customization:

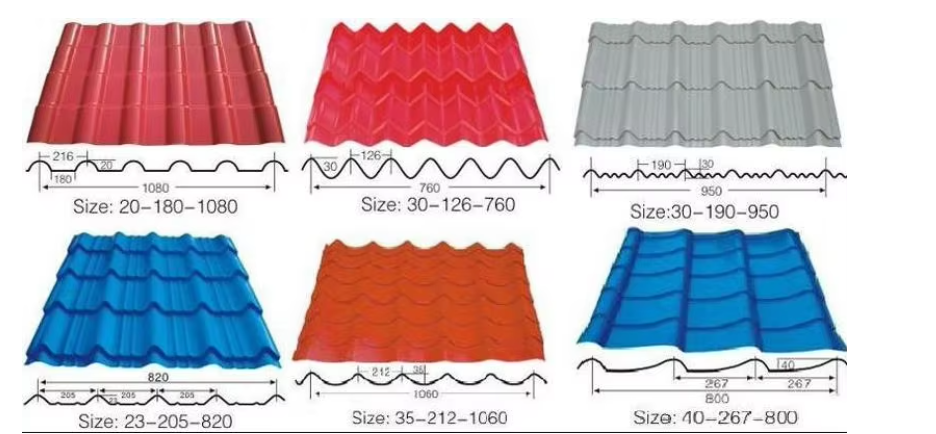

Surface spraying technology can achieve various color customization. In addition to traditional glazed tile colors, it can also simulate special textures such as wood grain and stone grain to meet personalized design needs. At the same time, the molding machine can quickly adjust the mold and parameters according to customer requirements to produce different specifications and shapes of glazed tiles, such as large-sized tiles for large buildings and small-sized tiles for courtyard decoration, with much more flexibility than traditional glazed tile production methods.

4.Environmental protection and energy conservation:

The production process does not require high-temperature firing (traditional clay tile firing has high energy consumption and pollution), and the metal raw materials can be recycled and reused, which is in line with the concept of green building. At the same time, the molding machine adopts advanced energy-saving motors and control systems, which reduce energy consumption by 15% -20% compared to similar equipment. Long term use can save a lot of electricity costs.

Applicable scenarios and industry applications

1.Modern Chinese architecture:

In modern Chinese style buildings such as villas, residential communities, and commercial complexes, metal glazed tiles can create a roof effect that combines tradition and modernity, retaining the cultural charm of glazed tiles while meeting the demand for lightweight and high-strength materials in modern architecture, enhancing the overall quality and aesthetics of the building.

2.Industrial plants and warehouses:

Industrial buildings require high strength and durability of roof materials. The high strength and corrosion resistance of metal glazed tiles can effectively resist industrial waste gas and dust erosion, extend the service life of roofs, and reduce maintenance costs. At the same time, it has rich colors that can be selected to coordinate with the factory environment, enhancing the overall image of the factory.

3.Municipal public buildings:

such as pavilions and towers in urban parks, tourist service centers in scenic areas, cultural venues and other municipal projects. The beauty and durability of metal glazed tiles can be integrated with the surrounding landscape to create a building style with regional cultural characteristics. They are easy to install and can be completed in a short period of time, reducing the impact on public activities.

4.Roof renovation:

For the renovation of old buildings, metal glazed tiles are lightweight and can be directly laid on the original roof without dismantling the old roof structure, saving construction costs and time. At the same time, its rich colors can quickly change the appearance of buildings, achieving a “new look for the old” and enhancing the value of buildings.

Product Attributes :

|

raw material

|

PPGI

|

|

material thickness:0.32-0.8mm

|

|

|

machine frame

|

350#H steel frame welded

|

|

machine structure

|

vertical arch frame structure

|

|

material of rollers

|

45# steel chromed treatment (Cr Thickness:0.05mm), anti-corrosion, increase hardness, ensure the precision and good abrasion performance

|

|

forming stations

|

16 stations

|

|

diameter of shafts

|

φ80mm

|

|

material of shafts

|

45# steel tampering treament prevent deformed and improve the hardness

|

|

forming speed

|

about 0-8m/min

|

|

voltage

|

380v 50hz 3ph or as required

|

|

transmission

|

gear box transmission

|

|

material of gear box: iron casting

|

|

|

material of gear:20 Crmnti

|

|

|

the connection between gear boxes are chains

|

|

|

gear box will connect with the rolling station one for one

|

|

|

advantage : can improve the speed directly after cutting

|

|

|

work power

|

11kw (gear reducer and servo motor driving)

|

|

cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|

cutting type

|

hydraulic cutting

|