Product Description:

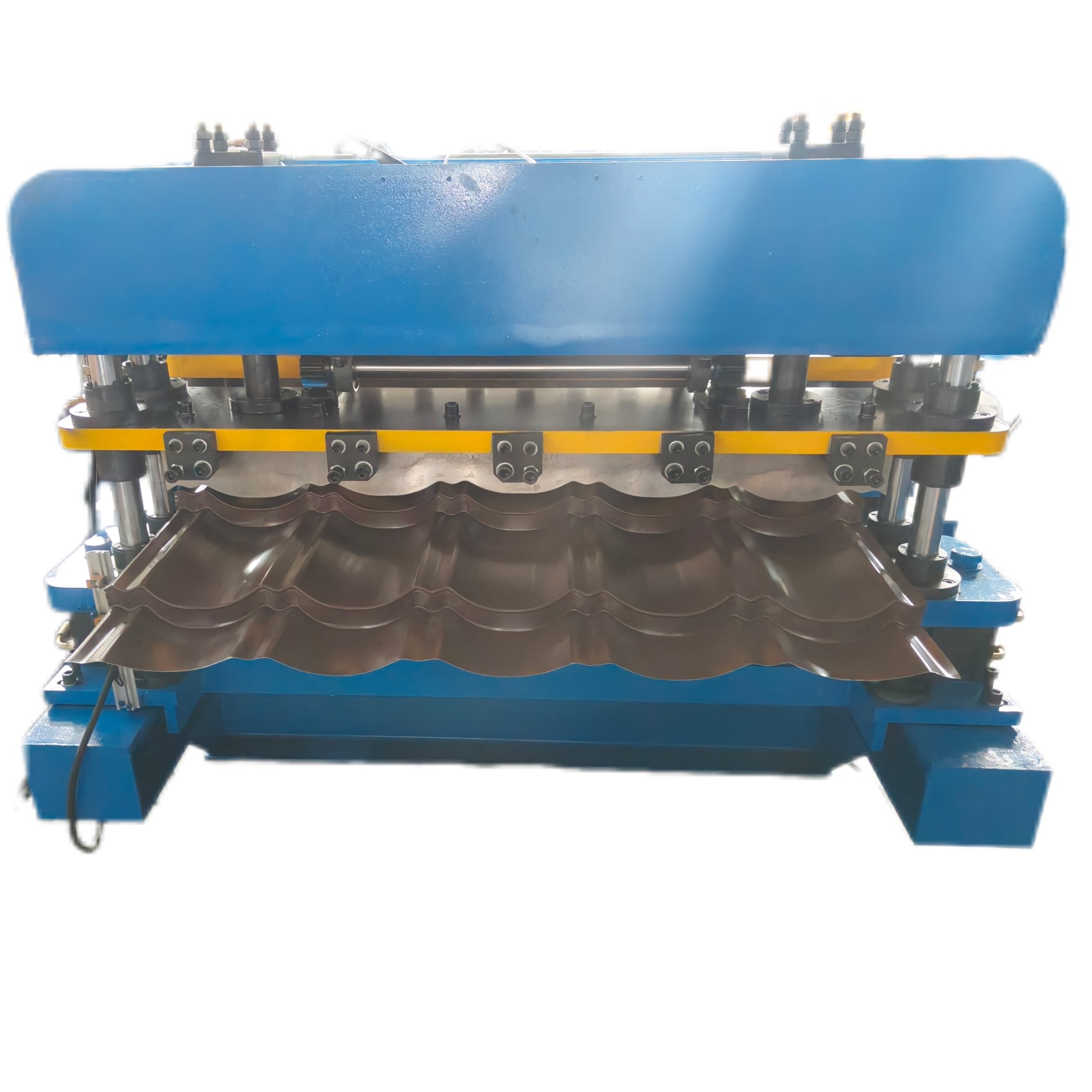

The glazed tile machine is a specialized mechanical equipment used for producing glazed tiles for antique buildings. It mainly processes metal sheets or synthetic resin materials into various types of glazed tile products through compression molding technology. The process of the glazed tile forming machine is simple and efficient, capable of rapid mass production, saving time and labor costs. In addition, glazed tile machines are usually small in size, light in weight, easy to move and transport, occupy small space, and have low power consumption, which is conducive to reducing production costs. The application of glazed tile machines in the construction field is very extensive, mainly used for producing external roof and wall panels, as well as internal decorative panels or ceilings for building houses. Glazed tiles are renowned for their elegant luster and color, which not only withstand high temperatures and wind and rain, but also effectively insulate and extend the lifespan of buildings.

Specific functions include:

- Efficient production:

able to quickly mass produce glazed tiles to meet large-scale production needs. - Precise processing:

With high processing accuracy, it can ensure the accurate size and uniform texture of the tiles produced. - Multifunctionality:

By selecting and using different machine heads, different varieties and specifications of bricks and tiles can be produced, making it easy to operate flexibly according to market demand. - Save energy and labor:

Use less power to save energy while reducing labor demand and intensity.Machine advantages:

1.Efficiency:

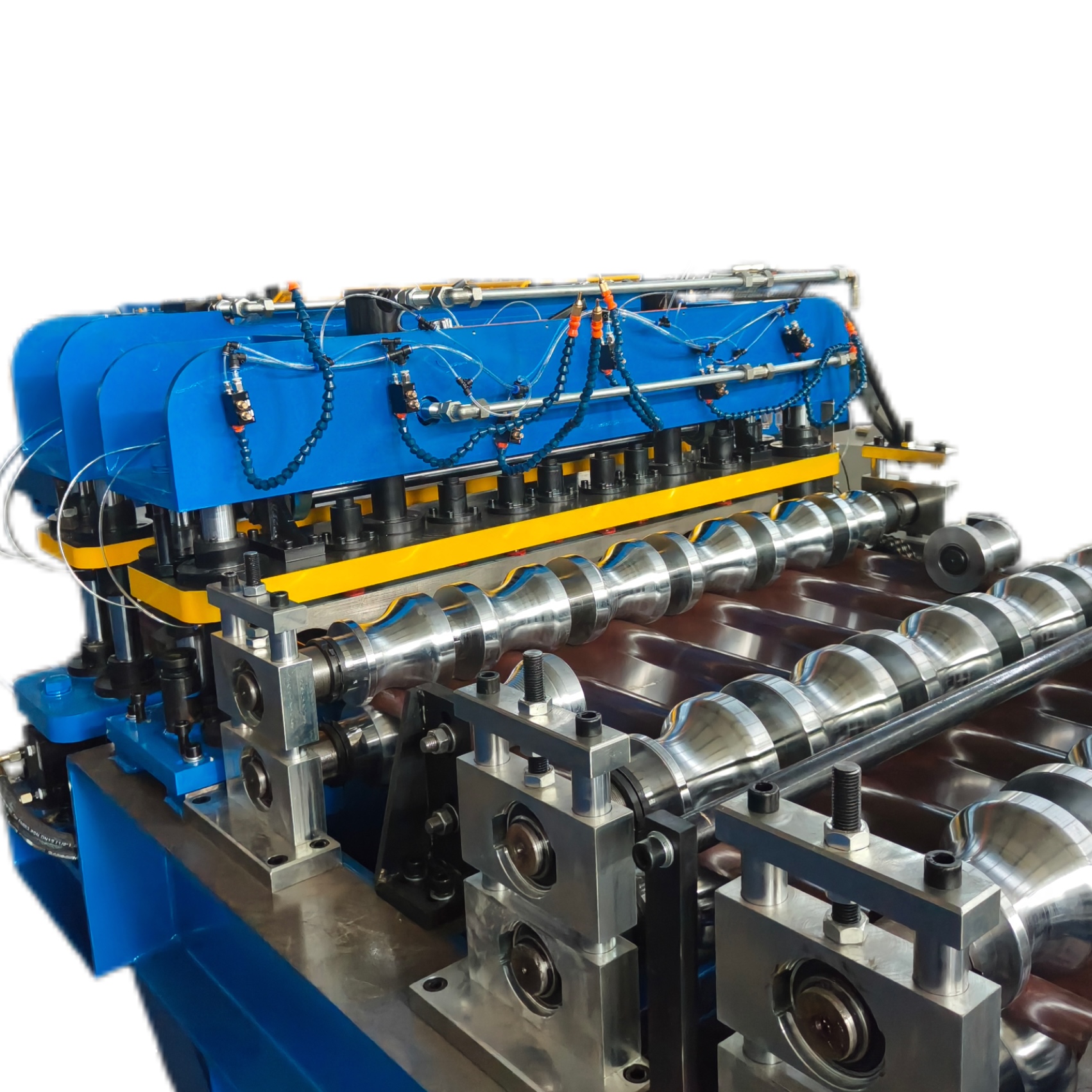

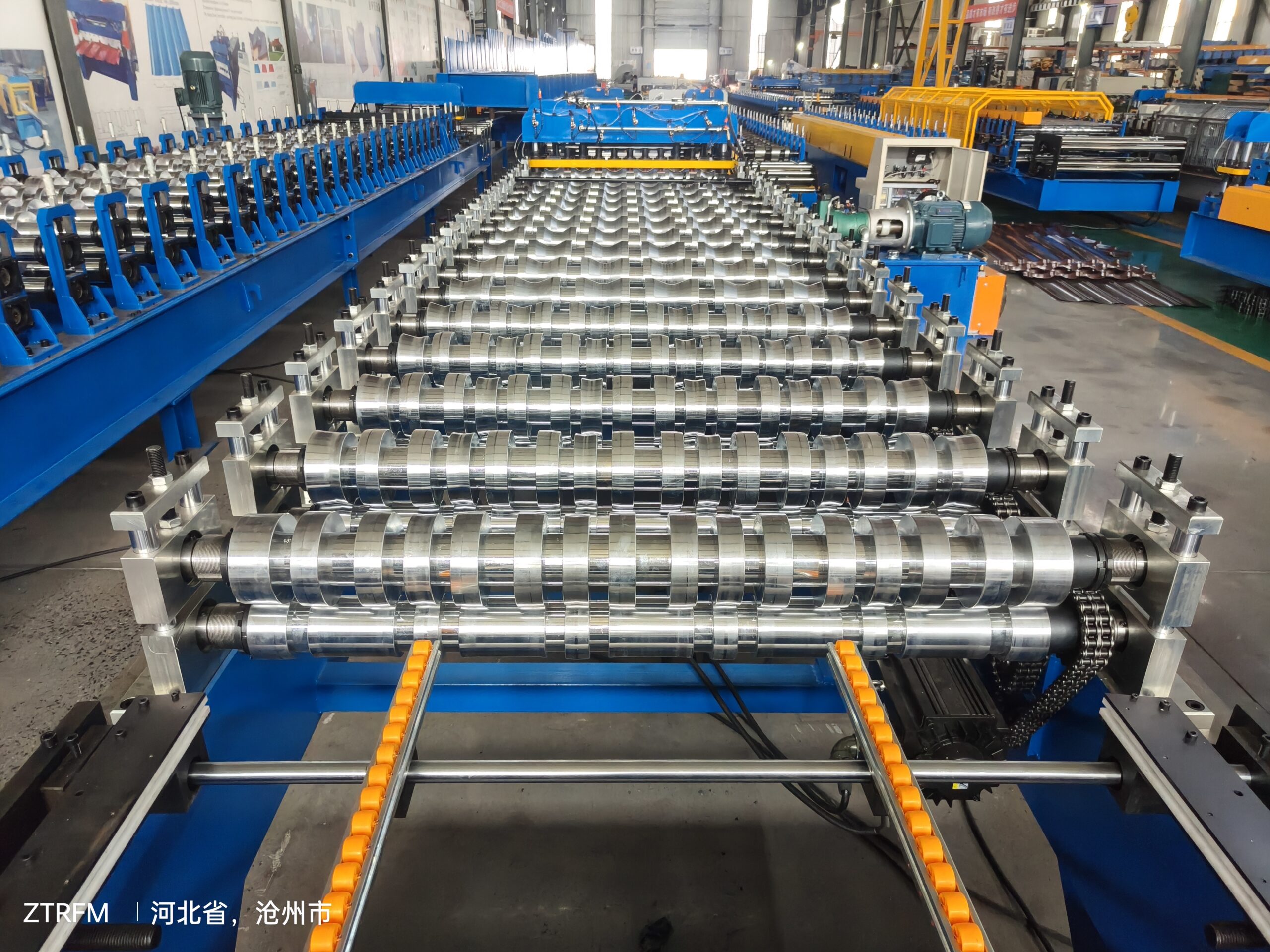

The glazed tile machine can achieve continuous production, greatly improving production efficiency and meeting the needs of large-scale production. The Zhongtuo glazed tile machine can efficiently produce high-quality and beautifully shaped glazed tiles, and its production efficiency far exceeds traditional tile making methods.2.Accuracy:

These machines use high-precision molds and advanced control systems to ensure the accurate size and smooth surface of the produced glazed tiles.3.Safety:

Modern glazed tile machines are equipped with various safety protection devices, effectively reducing safety risks during operation and ensuring the safety of operators.4.Reliability:

After strict quality control and testing, the glazed tile machine exhibits excellent reliability and stability, ensuring the continuity and stability of the production process. For example, the high degree of automation of the imitation resin glazed tile machine reduces manual intervention and lowers labor intensity.5.Multifunctionality:

Some glazed tile machines are designed flexibly and can produce different varieties and specifications of bricks and tiles by replacing different heads, adapting to changes in market demand and reducing market risks.6.Cost saving:

The automation level of the glazed tile machine is high, which can save a lot of labor costs, and the maintenance and upkeep costs of the equipment are relatively low.Product Attributes :

1.Formed MaterialPPGI,PPGL,AI,Etc.Material Thickness:0.3-0.8mm

2.DecoilerHydraulic decoiler(optional)Manual decoiler(will give you as free)3.Main bodyRoller stationDue to your requirement profileDiameter of shaftDue to your requirement profileMaterial of rollersHigh Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)Machine body frameDue to your requirement profileDrivegear and Double Chain transmission/gearbox transmission optionalDimension(L*W*H)Due to designWeightDue to design4.CutterAutomaticcr12mov material, no scratches, no deformation5.PowerMotor Power7.5KW(normally)Hydraulic system power4.5KW6.VoltageAs your requirementAs your requirement7.Control systemElectric BoxCustomized(famous brand)LanguageSupport multiple languagesPLCAutomatic production of the whole machine. Can set batch, length, quantity, etc.18.Forming Speed0-80m/minProvide customizedProducts Display:

Why Choose Us:

Company Profile:

Zhongtuo cold roll fonming machinery is one of the leading Chinese coil handling equipment brand founded in 2006.Our mission is to provide our customers with the very best quality metad rolling automalion solutions and afer-salesservice, Our machine offers a wide range of coil feeding equipment, ineluding Decoiler, Steel Straightener, Coil Feederas well as numerous rolling automation machines like color steel roofing sheet machines, purline machines, hotflming machine and others, Mletal eoll proeessing can be eanied out more eficiently and more accurately for betterneliability, less waste, and improved productivity.

Product packaging:

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

Collaboration case:

Collaboration case:

Our machines have been exported to multiple countries and have established cooperation with multiple countries. At present, the product has successfully entered emerging markets such as Southeast Asia, the Middle East, Africa, and South America, and has established long-term stable cooperative relationships with well-known local construction companies. Through strict ISO and CE certification, our machines have won wide recognition from international customers for their excellent stability, efficient production efficiency, and intelligent operation interface. In the future, we will continue to deepen our global layout.