Machine video

Outstanding Performance: Ensuring High-Quality Steel Sections

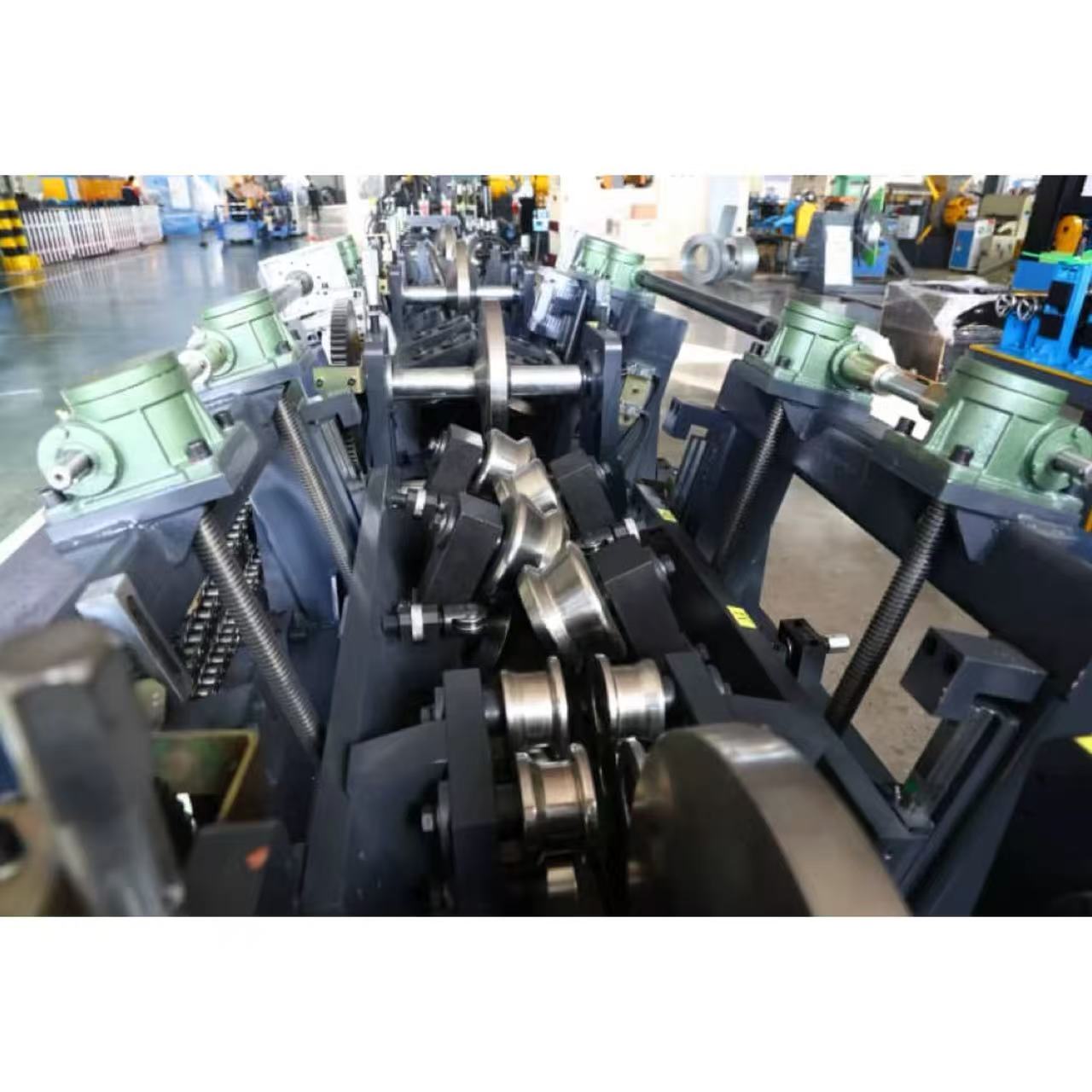

• Durable and Stable:

Key components are made of high-quality alloy steel, precision-machined and subjected to rigorous heat treatment, ensuring strong body rigidity and resistance to deformation. This allows the equipment to withstand prolonged high-intensity processing loads, extending its service life.

• High-precision machining:

Equipped with an advanced CNC system and high-precision servo drive devices, it precisely controls the roller speed, pressure, and feed rate, ensuring dimensional accuracy of processed steel sections within ±0.1mm, meeting national high-standard construction engineering requirements. The rollers are made from special wear-resistant materials and undergo professional surface treatment, resulting in smooth, scratch-free steel section surfaces while reducing roller wear and lowering maintenance costs.

• Excellent Forming Capability:

Compatible with various materials such as plain carbon steel, stainless steel, and high-strength alloy steel. By adjusting process parameters, it achieves one-time precision forming without the need for subsequent correction processes, enhancing machining efficiency and product yield.

Intelligent and Efficient: Enhancing Production Performance

• Intelligent Control:

Equipped with a new intelligent control system featuring a high-definition touch screen interface for simple operation, allowing workers to quickly get up to speed with minimal training. It includes a variety of built-in machining parameter templates that can be directly accessed or fine-tuned, reducing production preparation time. The system also boasts real-time data collection and monitoring capabilities, enabling the tracking of equipment status, machining parameters, and more. In case of abnormalities, it automatically triggers alarms and shuts down to prevent malfunctions and quality issues.

• High-Efficiency Production:

Utilizing a continuous rolling process combined with a high-speed servo drive system, the rolling speed reaches 10-20 meters per minute, achieving over 30% higher efficiency than traditional equipment. It also features automatic feeding, cutting, and stacking functions, enabling fully automated production. This reduces manual intervention, lowers labor costs, and minimizes the impact of human factors on product quality.

Wide Applicability: Meets Needs Across Multiple Fields

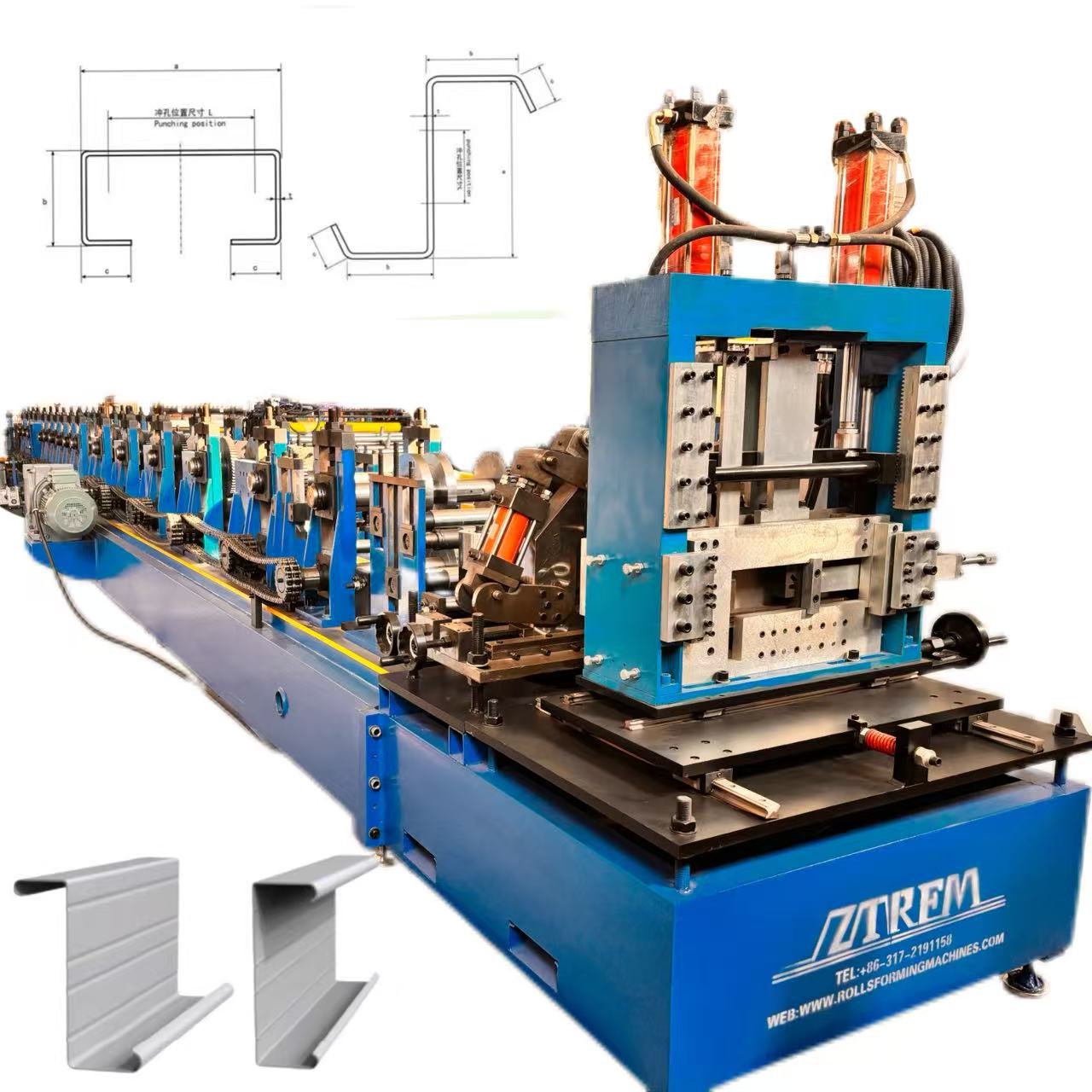

• Wide Application Scenarios:

It can be used in fields such as construction, bridges, mechanical manufacturing, ships, and automobiles. For example, in construction, it is used to make factory shed purlins and beams; in bridges, it serves as guardrails and crossbeams; in mechanical manufacturing, it is employed to create equipment frames and guide rails.

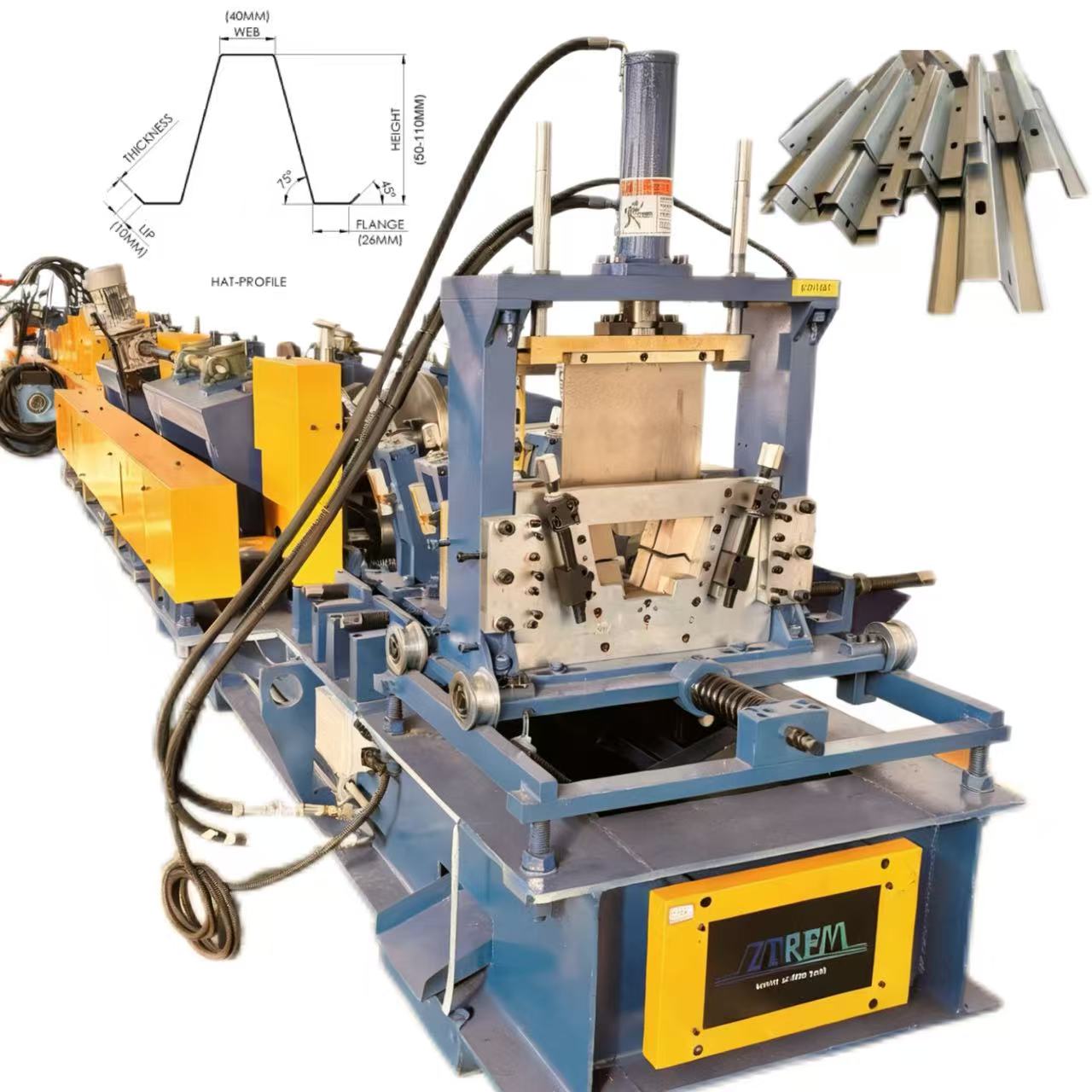

• Customized Configuration:

Capable of equipping with rollers, cutting devices, and control systems of different specifications according to customers’ special requirements, enabling the processing of hat-shaped steel sections with varying cross-sectional dimensions and materials, achieving “one machine for multiple uses.”.

Product Attributes

|

1.Formed Material

|

Material yield strength: Just standard steel G350 or similar

|

Thickness:0.8 to 2.0 mm (standard)

|

||

|

2.profile

|

size

|

100-300mm (it can be adjusted automatically )

|

||

|

Hat purline sizes

|

changed by manual or Automatically

|

|||

|

3.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

4.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.CAD drawing input

|

|||

|

5.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||