The Heavy Duty Upright Roll Forming Machine is an advanced and robust solution for manufacturing heavy-duty uprights used in storage and racking systems. This cutting-edge machine is specifically designed to produce high-quality uprights with precision and efficiency, capable of handling heavy loads. With automated controls and precision engineering, it ensures seamless and accurate roll forming, resulting in consistent and durable upright profiles. The machine is ideal for heavy-duty storage applications, providing reliable and sturdy upright production for industrial and commercial use. Elevate your storage systems with this reliable and high-performance Heavy Duty Upright Roll Forming Machine, ensuring safe and efficient storage solutions for heavy loads.

There are three types of shelf shelves: light shelves, medium shelves, and heavy shelves. Light shelf column parameters: height 2m, 38*38 (mm), each layer bears weight: 100kg-150kg; The column specification of the medium-sized laminate shelf is 80*40 (mm), and each layer can carry 200-250KG. Column height 2m;

Our machine can produce different sizes and thickness for both light upright and heavy upright.

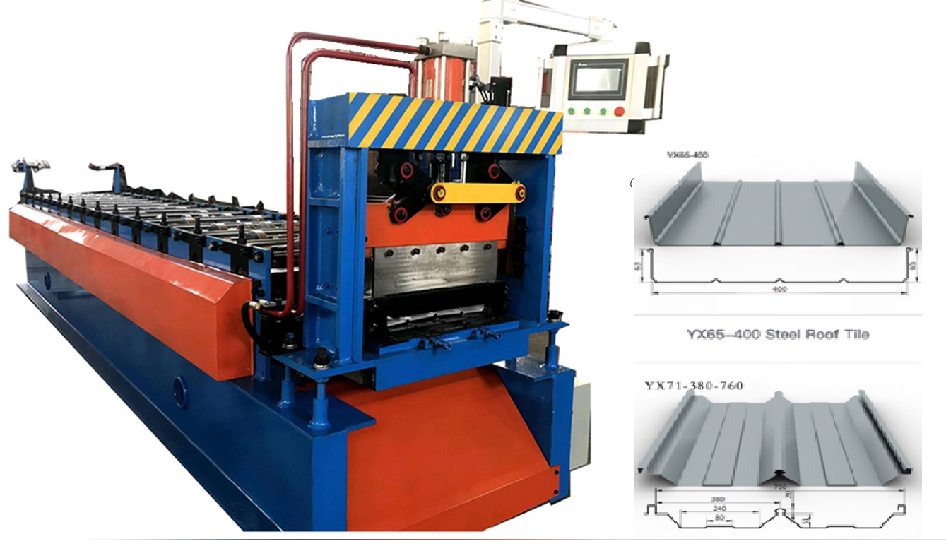

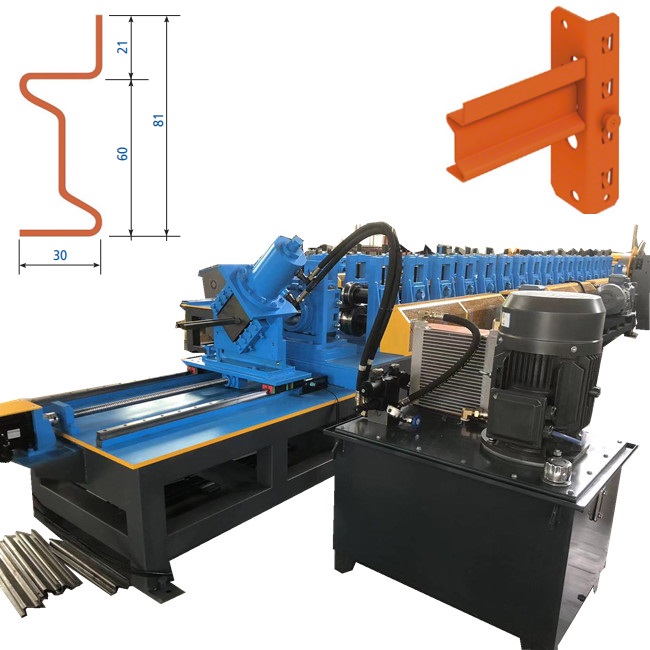

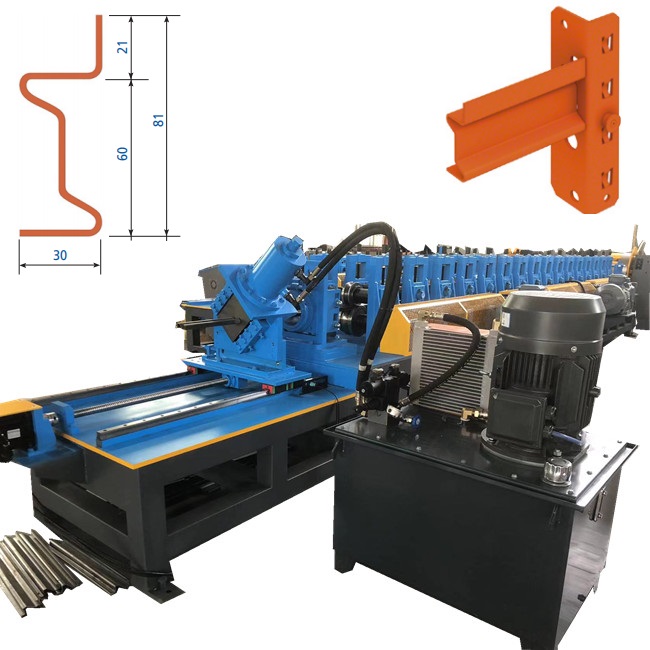

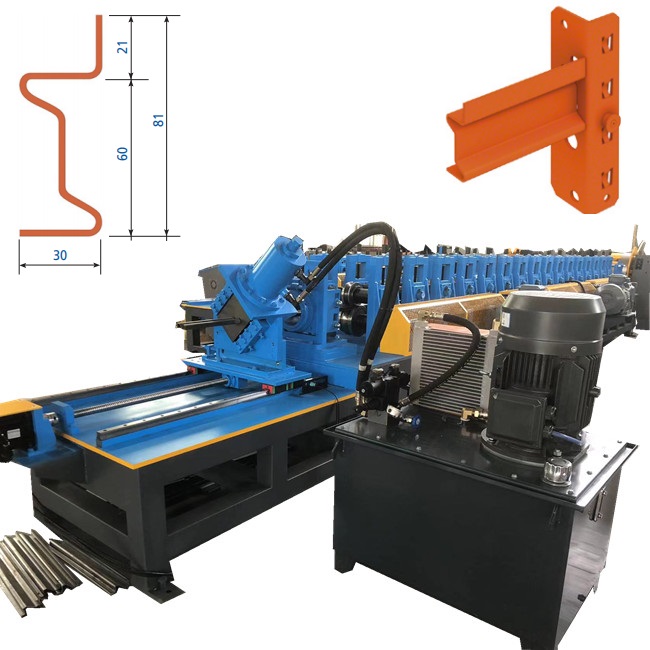

The composition and picture of the fnished shelf:

The profile drawings of the Upright:

The layout of the whole production line:

The main technical specifications:

1. Hydraulic decoiler: 5 tons capacity(support customization)

2.Leveler: 7 rollers,up 3 down 4

3.Punching machine:Yangli brand,pneumatic,80Tons,with servo feeder

4. Roll forming machine:

- 16 roller stations

- Roller material:Cr12 with quenched treatment

- 70mm shaft diameter

- Shaft material:45# steel

- Main motor power:11kw*2 sets

- Transmission:By chain(Gear and gearbox for optional)

- Cutting system:Hydraulic cutting system,no waste material

- Hydraulic power:5.5kw

- Cutting length tolerance:+/-0.5mm

5.Run-out table:6 meters

6.Control system:PLC system,DELTA brand or Siemens brand

The finished product: