In today’s booming fields such as steel structure construction, industrial plants, and residential buildings, roof tiles, as key enclosure building materials, continue to rise in market demand. Due to its high strength, good waterproofing, and easy installation, trapezoidal roof tiles have become a popular choice among many building material manufacturers. But if you want to seize the opportunity in the fierce market competition, an efficient, precise, and stable trapezoidal roof tile equipment is your indispensable production “weapon”!

Say goodbye to traditional production pain points, this device redefines efficiency and quality

Still troubled by various issues with traditional production methods?

The efficiency of manual processing is low, with a daily output of less than a hundred pieces, and the delivery of orders is always “rushed”?

Semi automated equipment has poor accuracy, uneven tile sizes, and deformed cross-sections, leading to continuous customer complaints?

Frequent equipment malfunctions and shutdowns, high maintenance costs, production interruptions, and witnessing the loss of orders?

Now, these problems can be easily solved through professional trapezoidal roof tile equipment! This Zhongtuo equipment is centered around “automation, high precision, and high stability”. From feeding to forming to cutting, there is no need for manual intervention throughout the entire process, making your production process “smooth” and easily overcoming the pain points and difficulties of traditional production.

From factories to villas, the tiles you produce can cover the needs of all scenarios

With this trapezoidal roof tile device, your products can easily adapt to various fields of scenarios:

Industrial field: Steel structure factory buildings, warehouses, workshop roofs/wall enclosures, wind and pressure resistance, strong durability;

Civilian field: roof decoration for prefabricated houses, rural self built houses, and villas, balancing waterproofing and aesthetics;

Special fields: Roofing materials (made of stainless steel) for breeding farms, food factories, and chemical workshops, which are corrosion-resistant and easy to clean;

Public facilities: roofs of gas stations, toll stations, and sports stands to meet high-frequency usage needs.

Rich application scenarios make your product market coverage wider and order sources more stable!

Three core advantages inject strong power into your production

1. Efficient mass production, no matter how many orders you have, you are not afraid

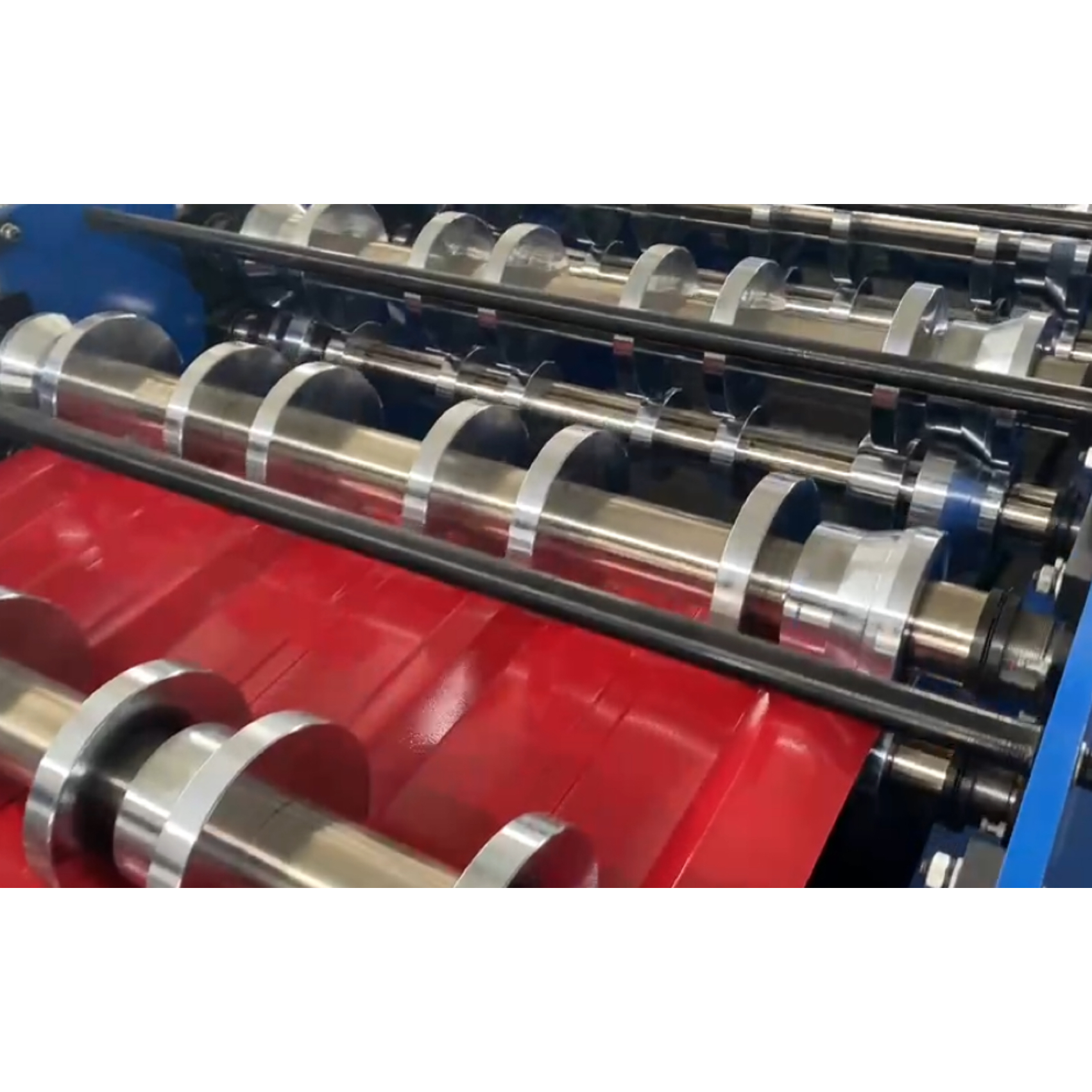

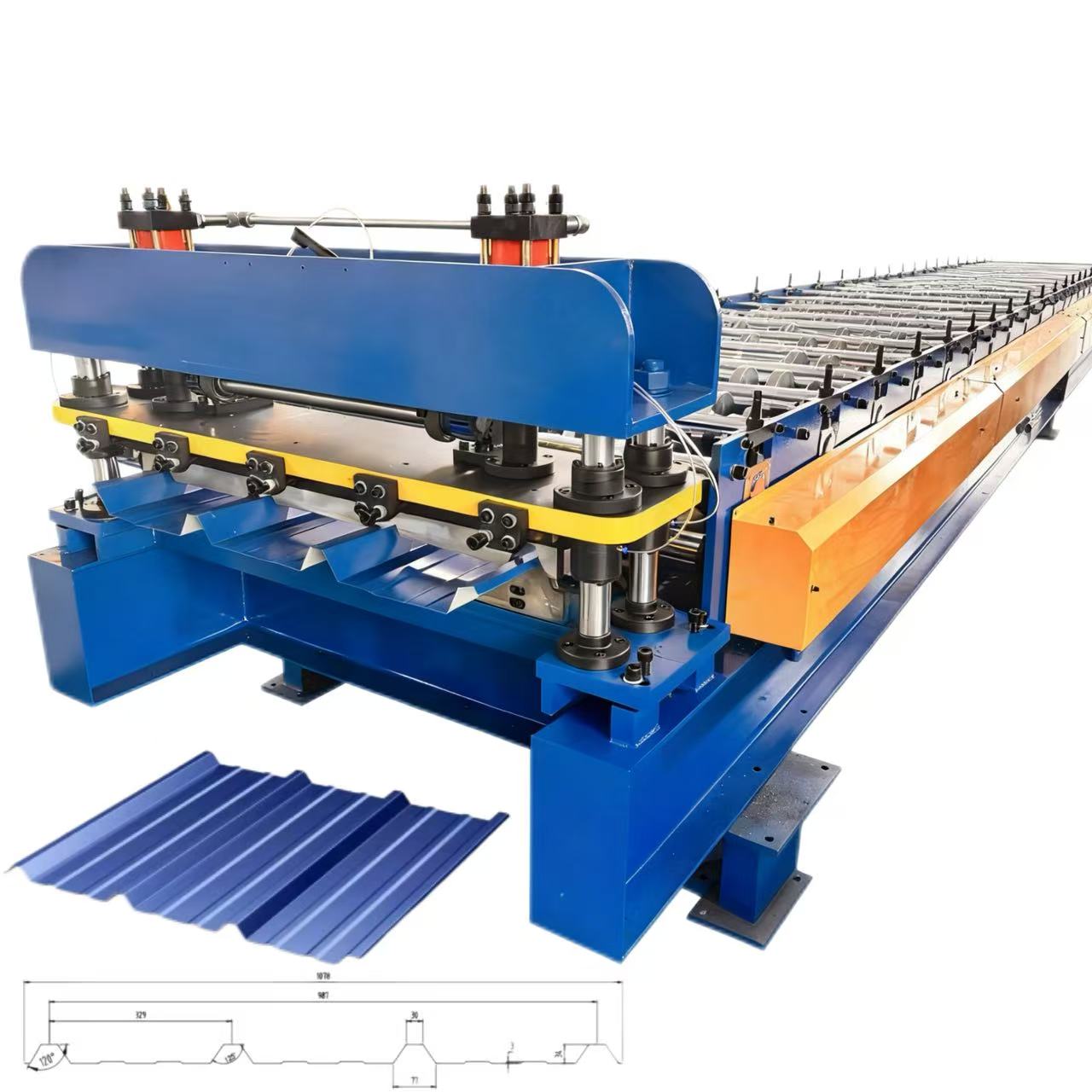

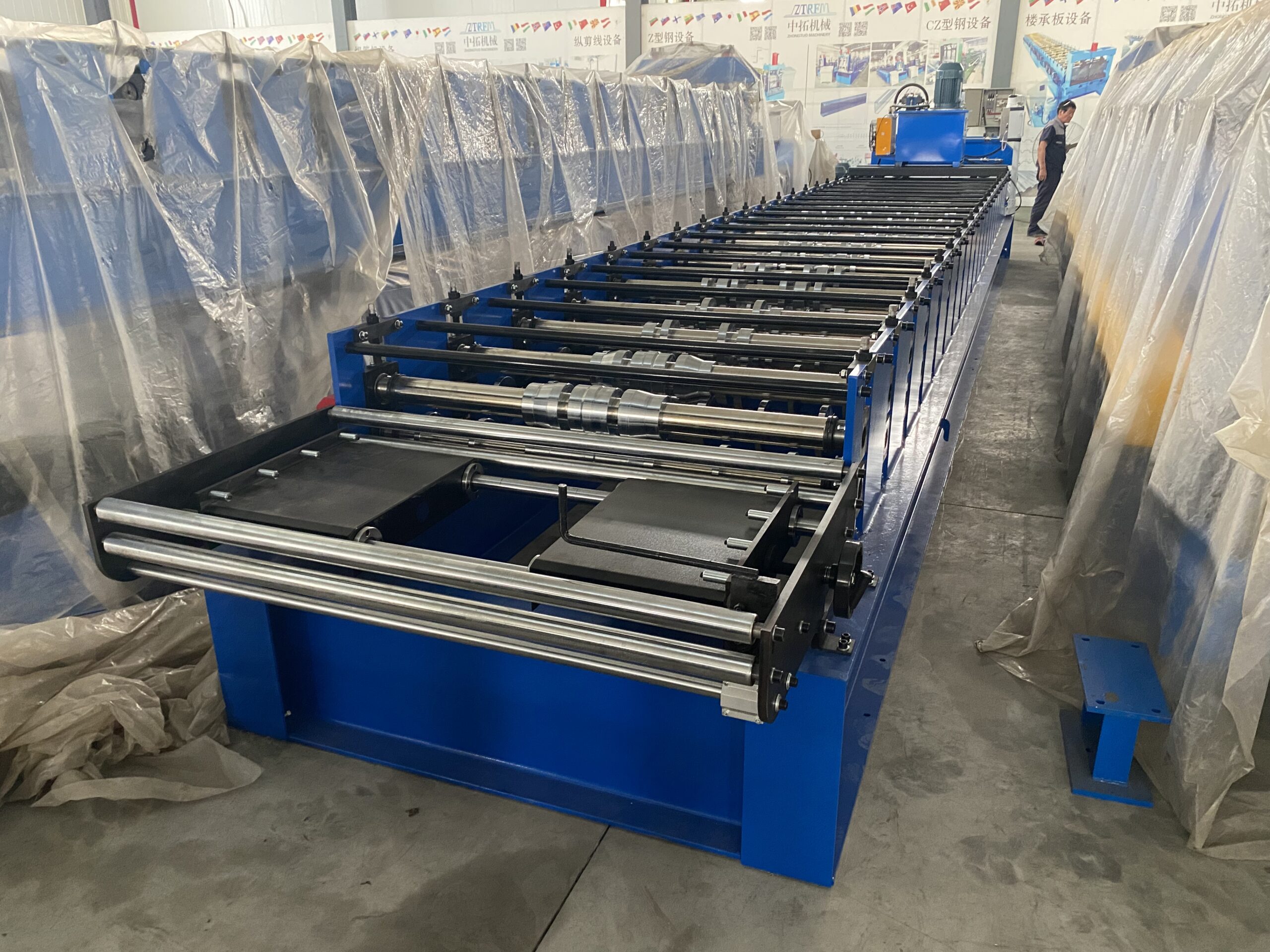

The equipment uses continuous rolling technology and servo motor drive, with a production speed of 5-15m/min, and can produce dozens of standard trapezoidal tiles per hour, which is 3-5 times more efficient than traditional manual labor. The automatic counting function displays production in real-time, helping you easily handle large orders and efficiently deliver without pressure.

2. Millimeter level precision, creating high-quality tiles

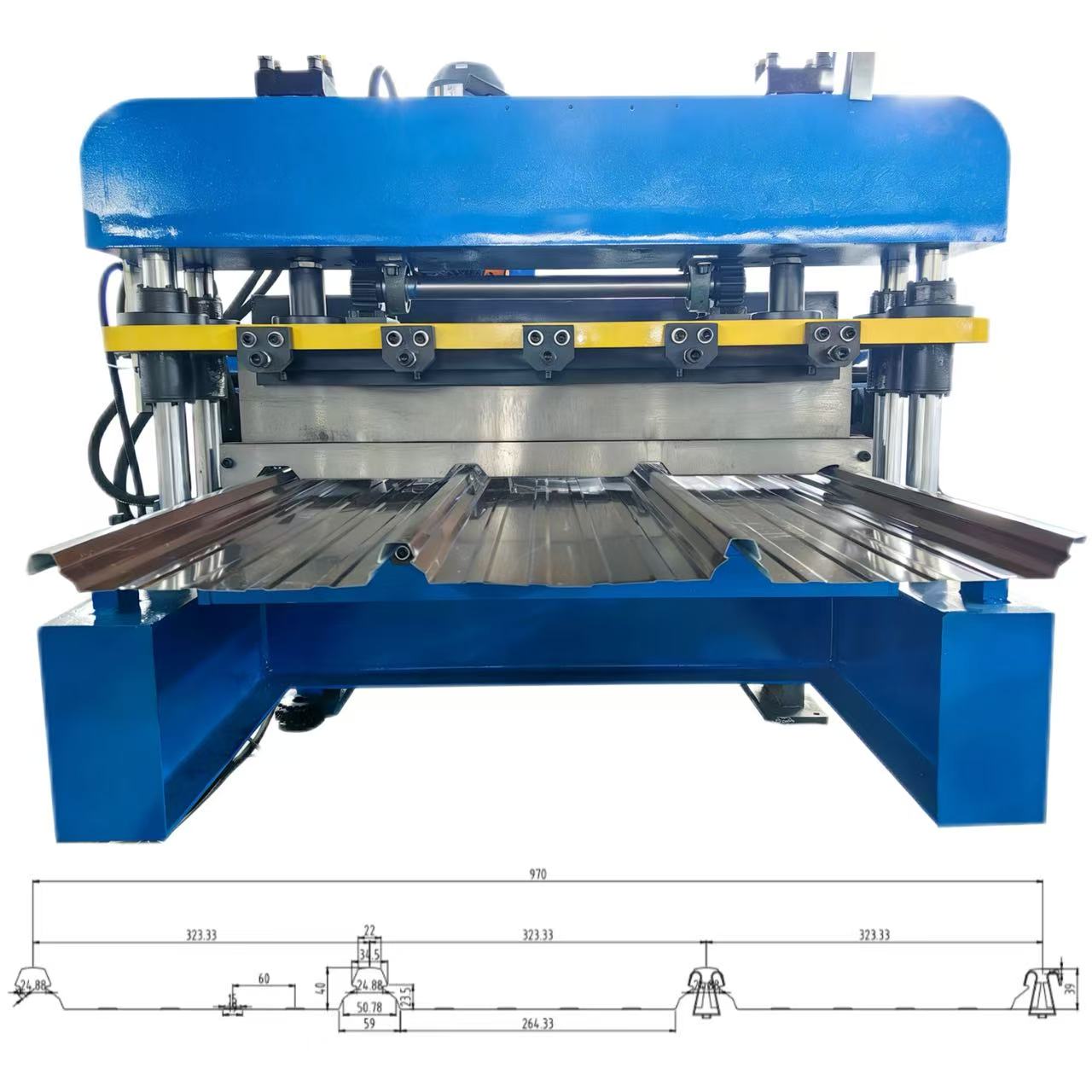

Excellent equipment accuracy performance: leveling error ≤ 0.1mm, forming roller group processed by CNC, trapezoidal tile section error ≤ 0.5mm, hydraulic/servo drive cutting without burrs. The tiles produced have precise dimensions, exquisite appearance, seamless installation, and far superior quality compared to similar products.

3. Flexible adaptation+stable and durable, with full cost-effectiveness

The equipment has strong adaptability. By replacing the roller group and adjusting the parameters, single/double wave trapezoidal tiles with a height of 15-50mm and a length of 1-12m can be produced, suitable for various types of boards ranging from 0.3-1.2mm. The key components are made of high-quality steel and equipped with an automatic lubrication system, which ensures stable operation and a service life of up to 8-10 years, achieving cost reduction and efficiency improvement in one step.

Seize the market opportunity by choosing this trapezoidal roof tile equipment!

Currently, the demand for trapezoidal roof tiles in the market continues to grow. Whoever can produce high-quality products faster and better can seize the market initiative. This efficient, precise, and stable trapezoidal roof tile equipment can not only help you improve production capacity and ensure quality, but also reduce costs and expand the market, allowing you to easily stand out in the competition of the building materials industry!

Simple operation+thoughtful after-sales service, ensuring worry free production for you

Worried about the complexity of equipment operation and the need for professional technicians? This device is equipped with a PLC electronic control system and a touch screen operation interface. The parameter settings (tile length, production speed, etc.) are simple and easy to understand. Operators can get started after 1-2 days of training without the need to hire high paying technicians.

More importantly, we provide attentive after-sales service throughout the process: equipment installation and debugging, operator training, regular on-site maintenance, rapid supply of vulnerable parts… No matter what problems you encounter, our team is always responsive to ensure uninterrupted production.