Product Introduction

In the modern construction industry, double-layer roof panels are widely used on the roofs and walls of various industrial plants, warehouses, residential buildings, etc. due to their excellent performance, such as good insulation and sound insulation effects, as well as high structural strength. The double-layer roof panel machine, as a key equipment for producing these high-quality panels, is playing an increasingly important role.

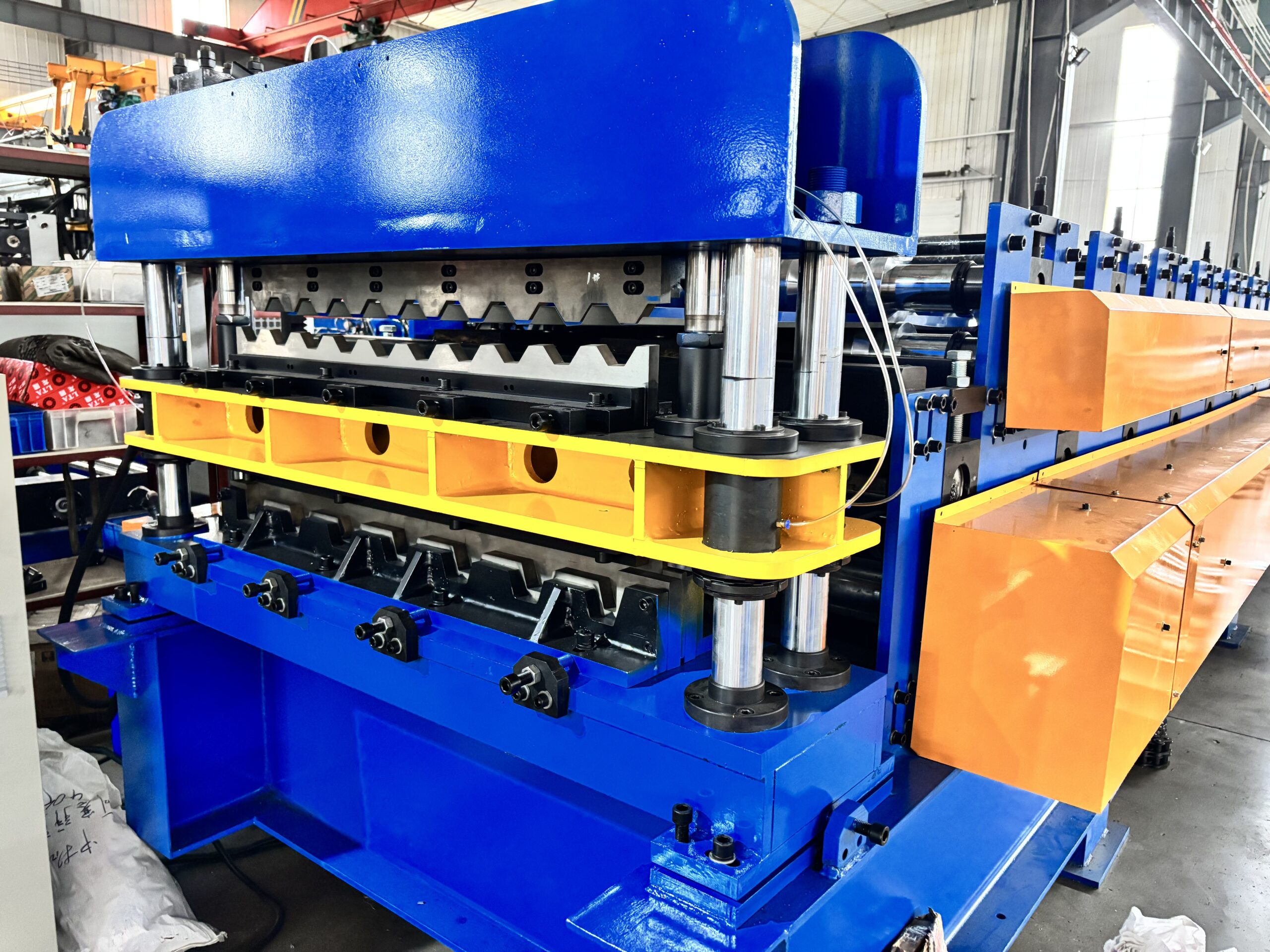

The working principle of the double-layer roof panel machine is based on advanced rolling forming technology. It gradually rolls metal coils (such as galvanized steel plates, color coated plates, etc.) into specific shapes of double-layer roof panels through a series of precision designed rollers. During the entire production process, the coil is first fed into the unwinding machine, which smoothly unfolds the coil and then enters the forming unit through a guiding device. The forming unit consists of multiple rolling rolls arranged according to the preset plate shape, which continuously cold bend the plate to gradually form the required double-layer corrugated shape. The formed board is then cut precisely by a cutting device according to the set length, and finally the double-layer roof panel product that meets the specifications is obtained.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(As per profile drawing)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16+18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

10500*1600*1600(customize)

|

|||

|

Weight

|

11.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application Fields

In practical applications, the double-layer roof panel machine has demonstrated wide applicability. In the construction of industrial plants, the roof panels produced can provide a sturdy roof and wall covering for the plant, effectively resisting harsh weather conditions. At the same time, good insulation performance helps regulate the temperature inside the plant and reduce energy consumption. In terms of warehouse construction, double-layer roof panels can provide reliable protection for stored goods due to their waterproofing, moisture resistance, and high structural strength. In the field of residential buildings, double-layer roof panels can not only be used for the roofs of high-end residences such as villas to enhance the aesthetics and overall quality of the building, but also create a more comfortable living environment for residents due to their excellent thermal and sound insulation performance. For example, in some large industrial plant projects, using double-layer roof panel machines to produce roof panels is easy and fast to install, greatly shortening the construction period and reducing maintenance costs in the later stage.

Machine advantages

Compared to traditional single-layer panel production equipment, double-layer roof panel machines have many advantages. Firstly, in terms of production efficiency, the double-layer roof panel machine can form double-layer panels in one go, which greatly improves production speed and reduces production time and labor costs compared to the method of producing single-layer panels and then assembling them. Secondly, in terms of product quality, due to continuous rolling forming, the overall structure of the double-layer roof panel is more stable, and the connection between panels is tighter, reducing problems such as water leakage and air leakage caused by improper splicing, and improving the waterproof, windproof, and sound insulation performance of the roof panel. Furthermore, in terms of material utilization, the double-layer roof panel machine can accurately control the amount of material used according to the specifications of the board, reduce the generation of waste, improve material utilization, and reduce production costs.

Maintenance and upkeep

Daily maintenance is crucial to ensure the efficient operation and stable production of the double-layer roof panel machine. In terms of maintenance of key components of the machine, the roller shaft assembly needs to be cleaned and lubricated regularly. As the core component of the machine, the spindle needs to ensure its accuracy and surface smoothness. The spindle diameter should be checked regularly for wear, and if wear occurs, it should be repaired or replaced in a timely manner. The roller material is 45 # steel, which is precision processed and plated with hard chromium and subjected to wire drawing and polishing treatment. During use, attention should be paid to preventing surface damage to avoid affecting the forming quality of the board. As a power source, it is necessary to regularly check the operating status of the motor to ensure stable power output, clean the dust inside the motor in a timely manner, and avoid affecting the service life of the motor due to overheating. The maintenance of the cutting blade should not be ignored. The blade material is Cr12Mov. Due to the significant impact and friction during the cutting process, the wear of the blade should be regularly checked, and timely grinding or replacement should be carried out to ensure the quality of the incision. At the same time, regular inspections and maintenance should be carried out on the lubrication system, electrical control system, etc. of the machine to ensure that the collaborative work between each component is normal.

Development Trends

With the continuous advancement of technology, double-layer roof panel machines are also constantly developing and innovating. In terms of automation control, more and more machines are adopting high-precision PLC electronic devices and heavy-duty frequency converters, such as Schneider’s related products. Through the PLC control system, operators only need to input production data on the touch screen, and the machine can automatically complete production requirements, running efficiently and steadily, greatly improving the accuracy and stability of production, and reducing the impact of human factors on production quality. In the trend of intelligent development of equipment, future double-layer roof panel machines are expected to achieve remote monitoring and fault diagnosis functions. Manufacturers can understand the operating status of the machines in real time through the network, discover and solve potential problems in a timely manner, and further improve the reliability and production efficiency of the equipment. At the same time, in terms of energy-saving technology, the application of new motor technology and transmission systems will make machines more energy-efficient and reduce energy consumption during operation, which is in line with the current development concept of green environmental protection.