In today’s rapid development of prefabricated construction, floor trussing plates, as a core component of steel structure buildings, have their processing efficiency and precision directly determining project timelines and quality. Traditional manual processing or inefficient equipment often faces challenges such as significant forming errors, insufficient production capacity, and high labor costs, becoming a “bottleneck” that hinders construction companies from reducing costs and improving efficiency. A professional floor trussing plate machine is precisely the key to breaking through this dilemma—its core advantages of automation, high precision, and high production capacity redefine the processing standards for floor trussing plates, injecting new momentum into the construction industry.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.8-1.2mm Width:as request

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

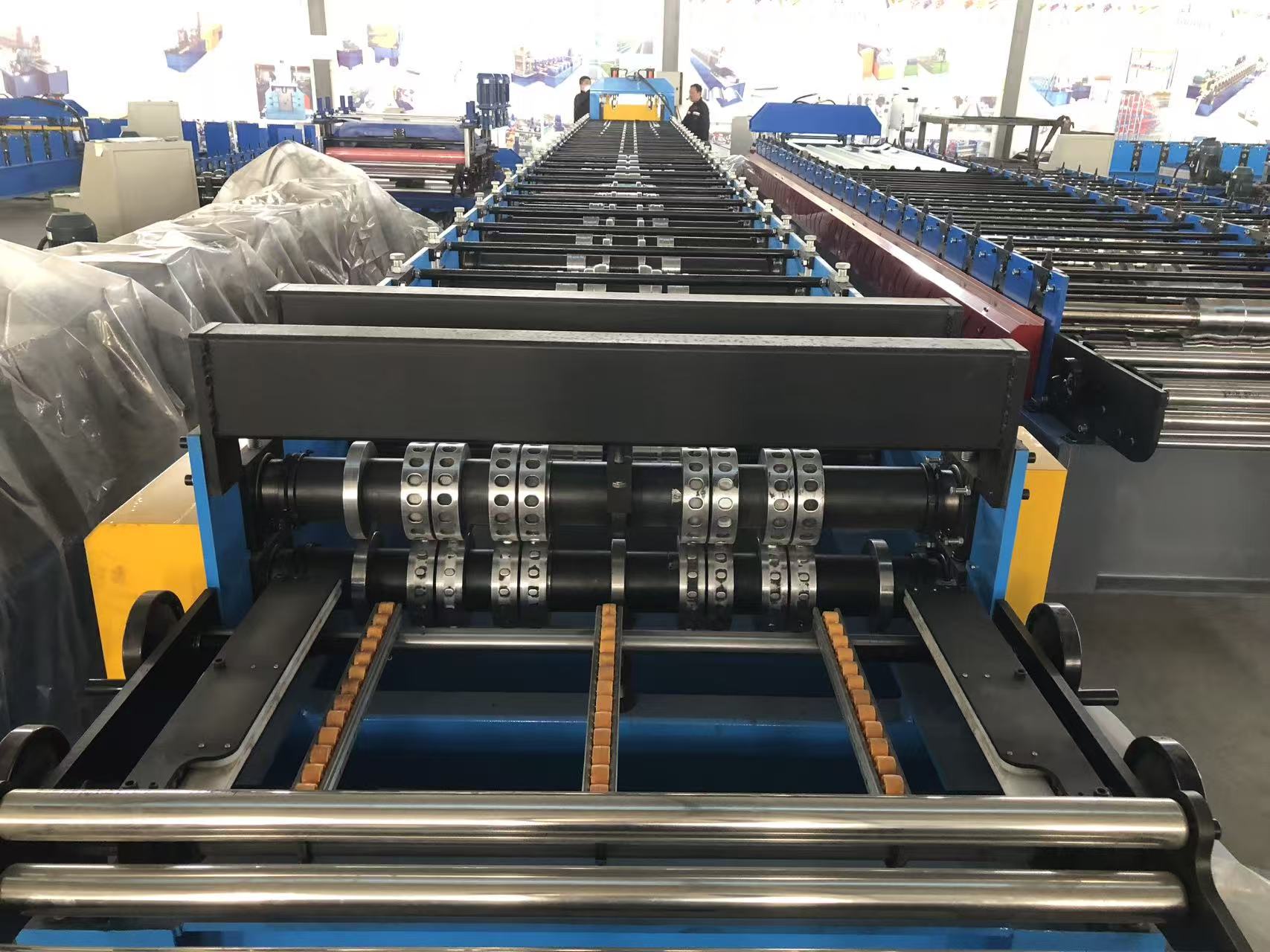

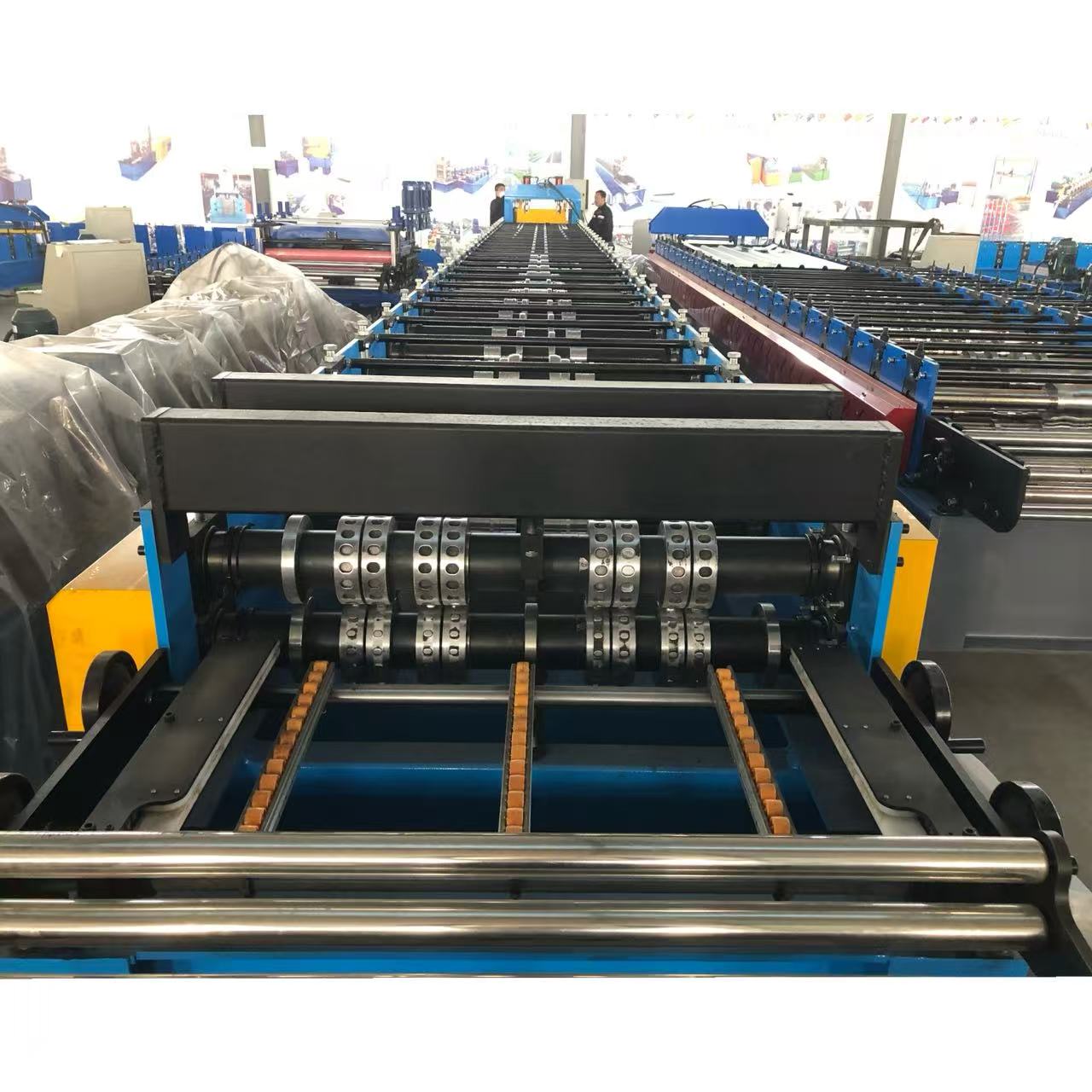

3.Main body

|

Roller station

|

24 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

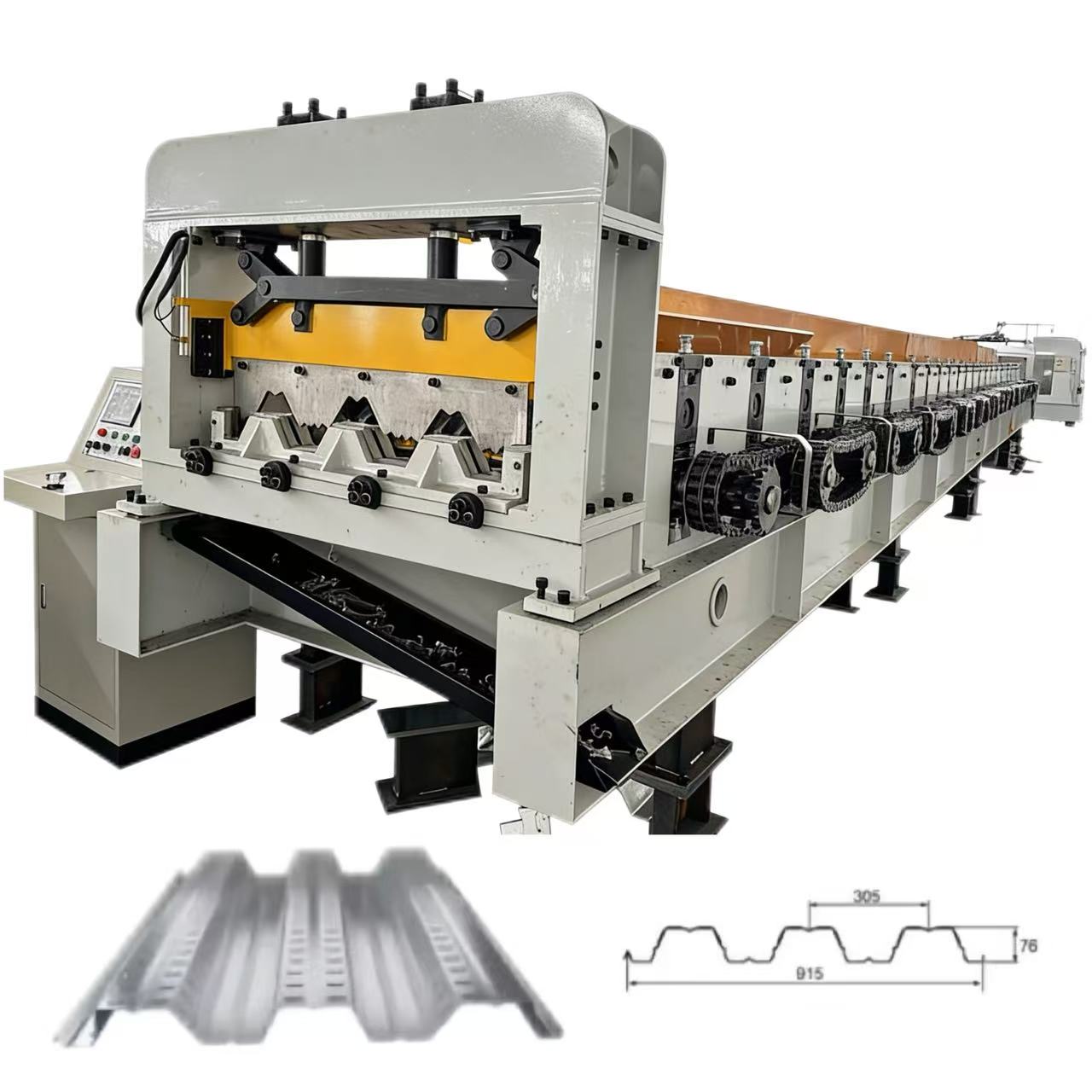

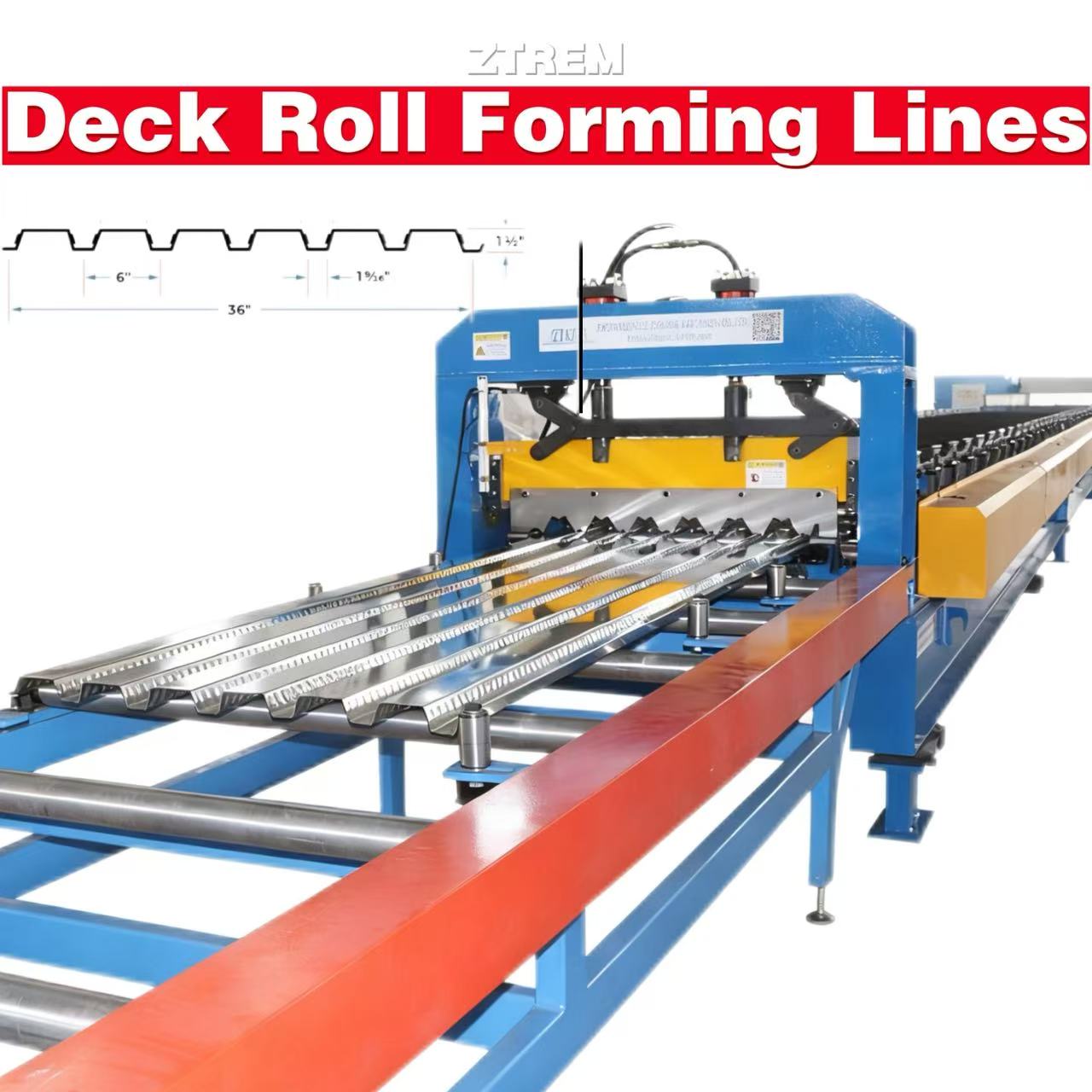

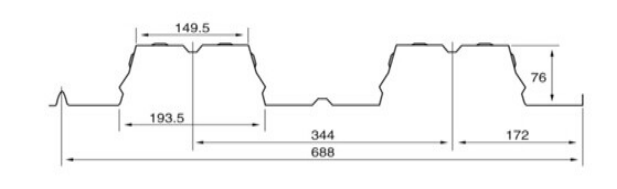

Pattern diagram:

Finished product image:

Finished product image:

Three Core Advantages to Address Processing Pain Points

1. High-efficiency mass production, surpassing the schedule

The floor deck machine is equipped with a high-speed feeding system and a continuous forming mechanism, enabling one-stop processing from “raw material input to finished product output” without the need for repeated manual handling and adjustment. Taking the common closed-type floor deck as an example, the equipment can achieve a forming speed of 15-20 meters per minute, with a daily production capacity easily exceeding 2,000 square meters, which is 5-8 times the efficiency of traditional manual processing. Whether for large industrial park factories, high-rise residential buildings, or commercial complex projects, it can quickly meet bulk order demands, completely eliminating the passive situation of “rushing to meet deadlines and overtime work.”.

2. Precision Molding, Uncompromised Quality

Precision is the “lifeline” of floor deck plates—if the formed dimensions deviate, it will not only cause installation delays but also potentially compromise the stability of the building structure. Our floor deck plate machine employs a CNC servo control system, paired with high-precision forming molds (error ≤ 0.1mm), to accurately control key parameters such as plate height, width, and bite depth. This ensures uniform dimensions, smooth edges, and tight bites for every floor deck plate. The processed plates require no secondary adjustments and can be directly connected to steel structures for installation, significantly reducing rework rates and facilitating effortless quality acceptance for projects.

3. Intelligent and Convenient, Cost-Efficient and Hassle-Free

The equipment is equipped with a 7-inch touch-operated screen and built-in parameters for various common deck plate models (e.g., YXB65-170-510, YXB76-344-688, etc.). Operators can start processing with a single click to retrieve parameters, making it easy for beginners to operate. Additionally, the machine features automatic raw material margin monitoring and fault alarm functions, reducing manual inspection costs. The entire machine is constructed with wear-resistant steel and a sealed transmission structure, resulting in low failure rates and simple maintenance. With an average service life exceeding 10 years, the long-term operating costs are significantly lower than those of traditional equipment.

Finished product image:

Finished product image: