In the modern building materials processing industry, U-shaped channels serve as core load-bearing components for ceiling and partition systems. Their processing quality and production efficiency directly determine project progress and quality. However, traditional processing methods often suffer from limitations such as insufficient precision, high material consumption, and limited production capacity. Manual cutting can easily lead to dimensional deviations, while cumbersome changeovers on traditional equipment lead to low batch production efficiency and high raw material waste. These issues not only increase costs but also hinder project delivery.

The advent of High-Speed U Profile Channel Roll Forming Machines has completely eliminated these bottlenecks. With its three core advantages of high precision, high efficiency, and high adaptability, they have become a key piece of equipment for upgrading and transformation for building materials processing companies.

Core Performance: A Leap from “Meeting Standards” to “Excellence”

1. High-Precision Forming, Ensuring Project Quality

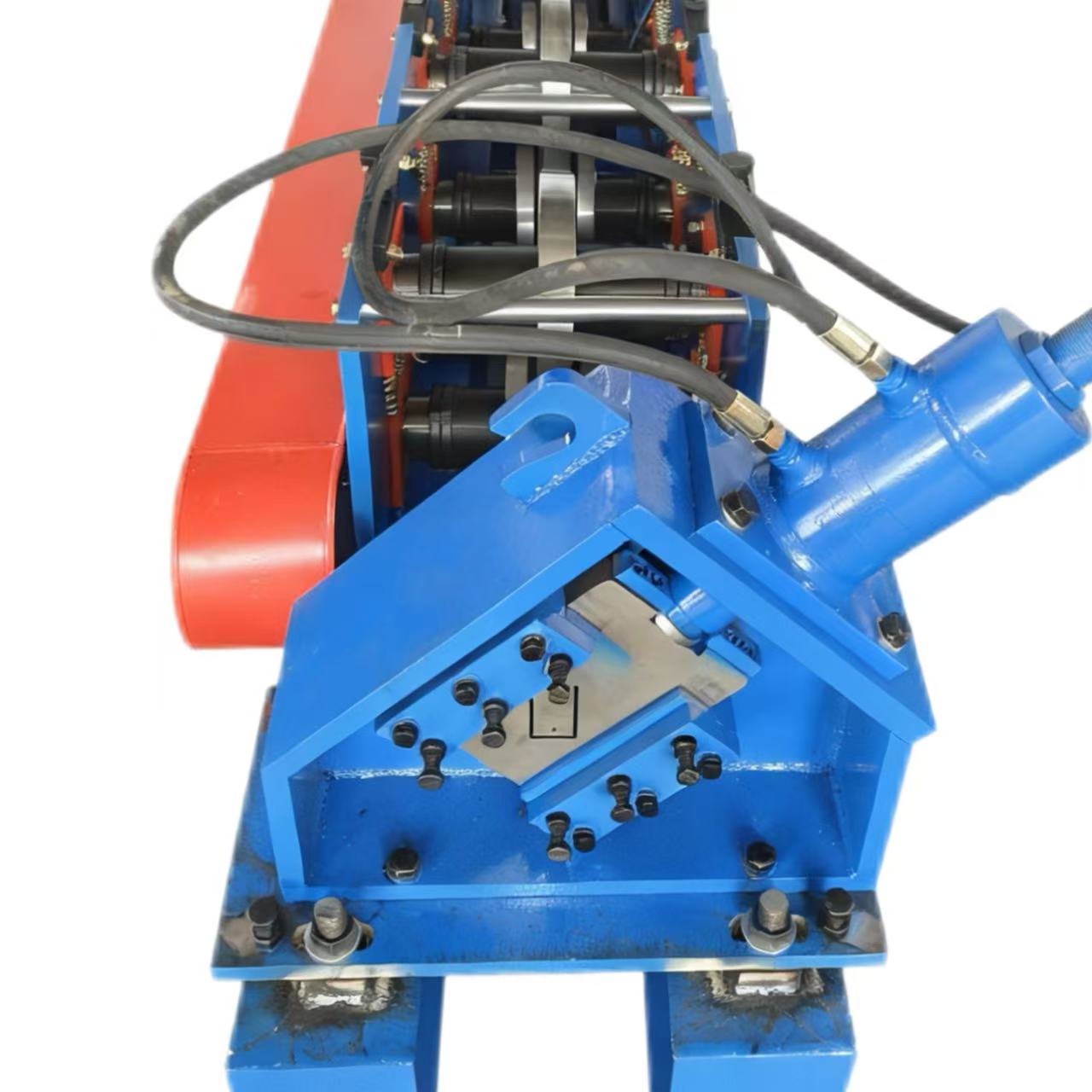

The equipment utilizes a servo motor drive coupled with a CNC system, achieving a forming accuracy of ±0.1mm, far exceeding the industry standard of ±0.5mm. From strip feeding, punching, forming, to cutting, the entire process is automated, eliminating errors caused by manual intervention. The formed U-shaped channels have straight sides and smooth cuts, eliminating the need for secondary polishing. This directly meets the installation requirements for ceiling and partition studs, effectively reducing rework later in the project and helping companies build a reputation for high-quality projects.

2. High-Efficiency Production, Breaking Capacity Bottlenecks

Targeting mass production needs, the U-shaped channel forming machine enables “one-button start, continuous operation.” For example, for a standard 50mm-wide U-shaped channel, the machine can complete 20-30 meters of forming per minute, achieving a production capacity of 9,600-14,400 meters in an 8-hour day, representing 8-10 times the efficiency of traditional manual processing. The equipment is also equipped with an automatic feeder and finished product collection device, reducing manual loading and unloading time and enabling a streamlined “raw materials in, finished products out” process, significantly improving overall workshop efficiency.

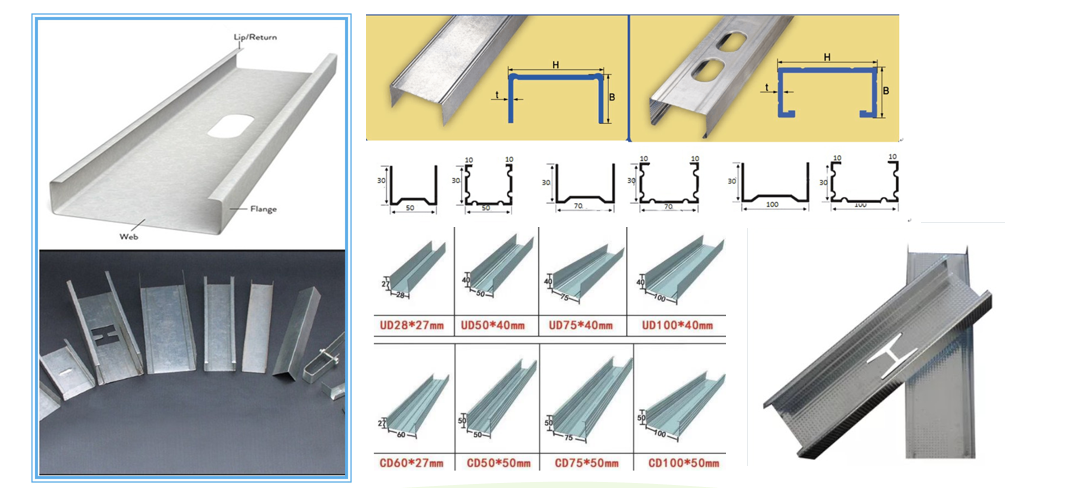

3. Highly adaptable design to meet diverse needs

The equipment can stably adapt to both cold-dip galvanized and hot-dip galvanized steel strips, as well as raw materials with thicknesses ranging from 0.3 to 1.2 mm. By changing molds, it can quickly switch between production of U-shaped channels of varying sizes, such as 50 mm, 75 mm, and 100 mm. Mold changeover time is reduced to less than 30 minutes, making it easy to handle high-variety, small-batch orders. This overcomes the limitations of traditional “one-machine-for-one” equipment and helps companies flexibly respond to market demand.

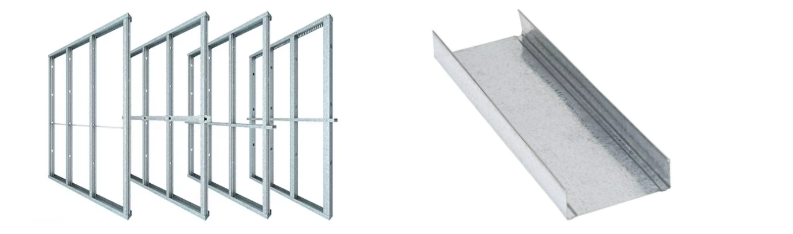

Scenario Empowerment: Covering Processing Needs Across the Entire Industry Chain

1. Building Materials Manufacturers:

This system can be equipped with a coil unwinder and leveling machine to create a fully automated U-shaped stud production line, achieving a seamless transition from raw materials to finished product. This reduces labor costs by over 30%, minimizes raw material waste, and increases material utilization to 98%.

2. Decoration Engineering Companies:

This small, mobile U-shaped stud forming machine can be deployed directly on-site, producing parts in real time based on actual dimensions. This prevents damage caused by stud deformation during transportation, shortens construction time, and improves project delivery efficiency.

3. Hardware Accessories Manufacturers:

This equipment can precisely process U-shaped studs with holes to meet the requirements of subsequent accessory assembly. Punching position error is controlled within 0.05mm, ensuring secure accessory installation and improving overall product stability.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.8 to 1.8 mm (standard)

|

||

|

2.Decoiler

|

3 Tons decoiler

|

3 Tons Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16 rows (As your requirement)

|

||

|

Diameter of shaft

|

60 mm solid shaft

|

|||

|

Material of rollers

|

Gcr15

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gear and chains transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

5T

|

|||

|

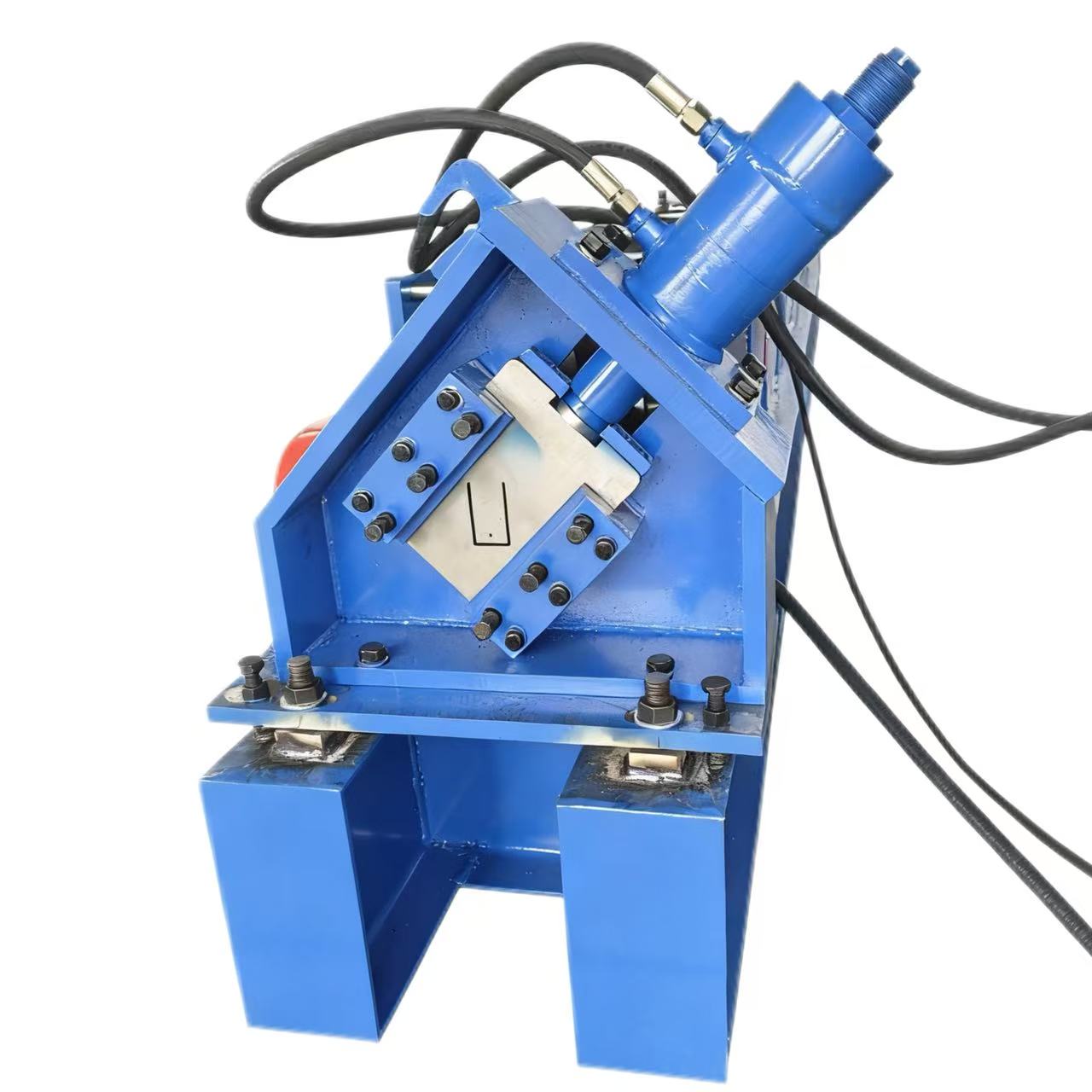

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

15 KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

25 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

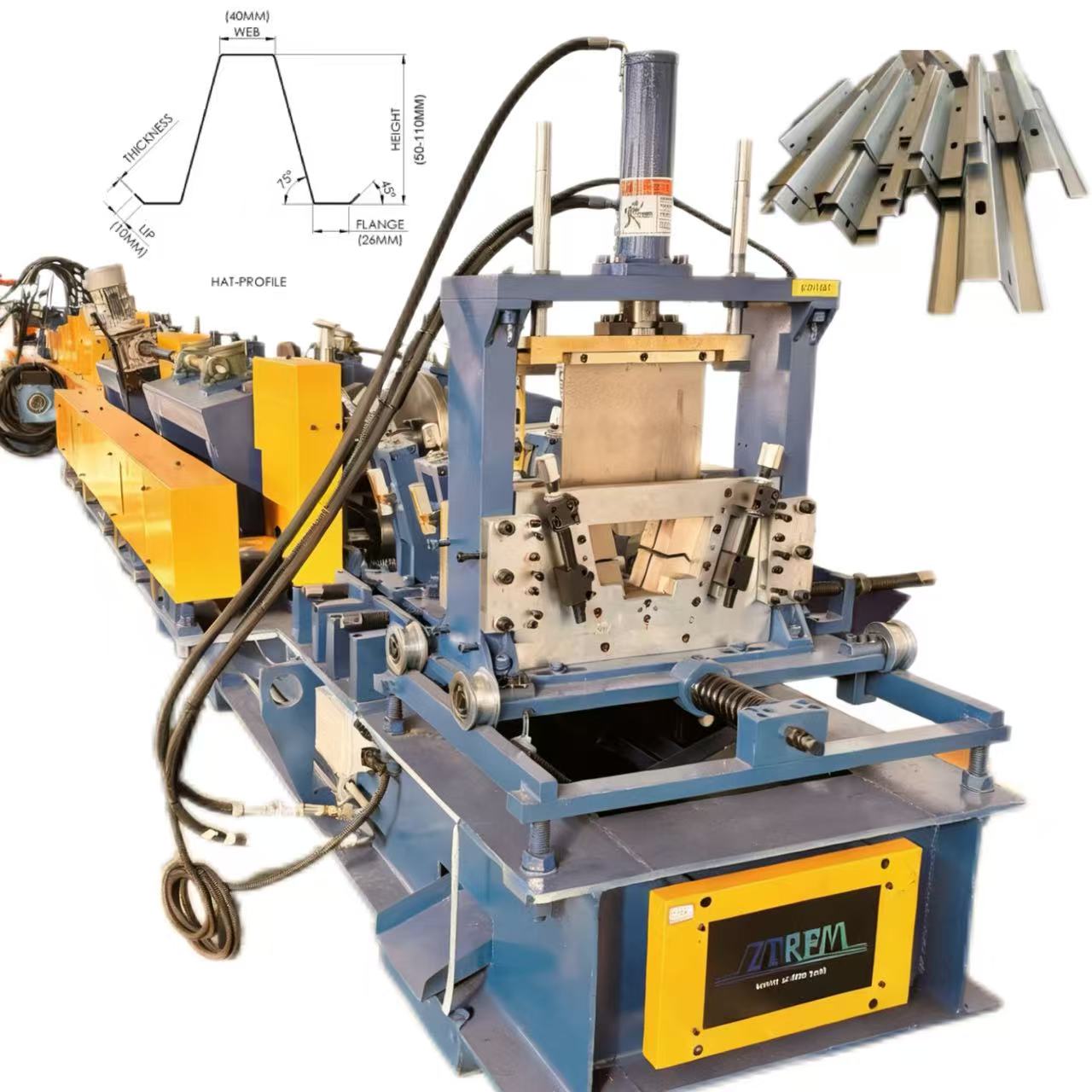

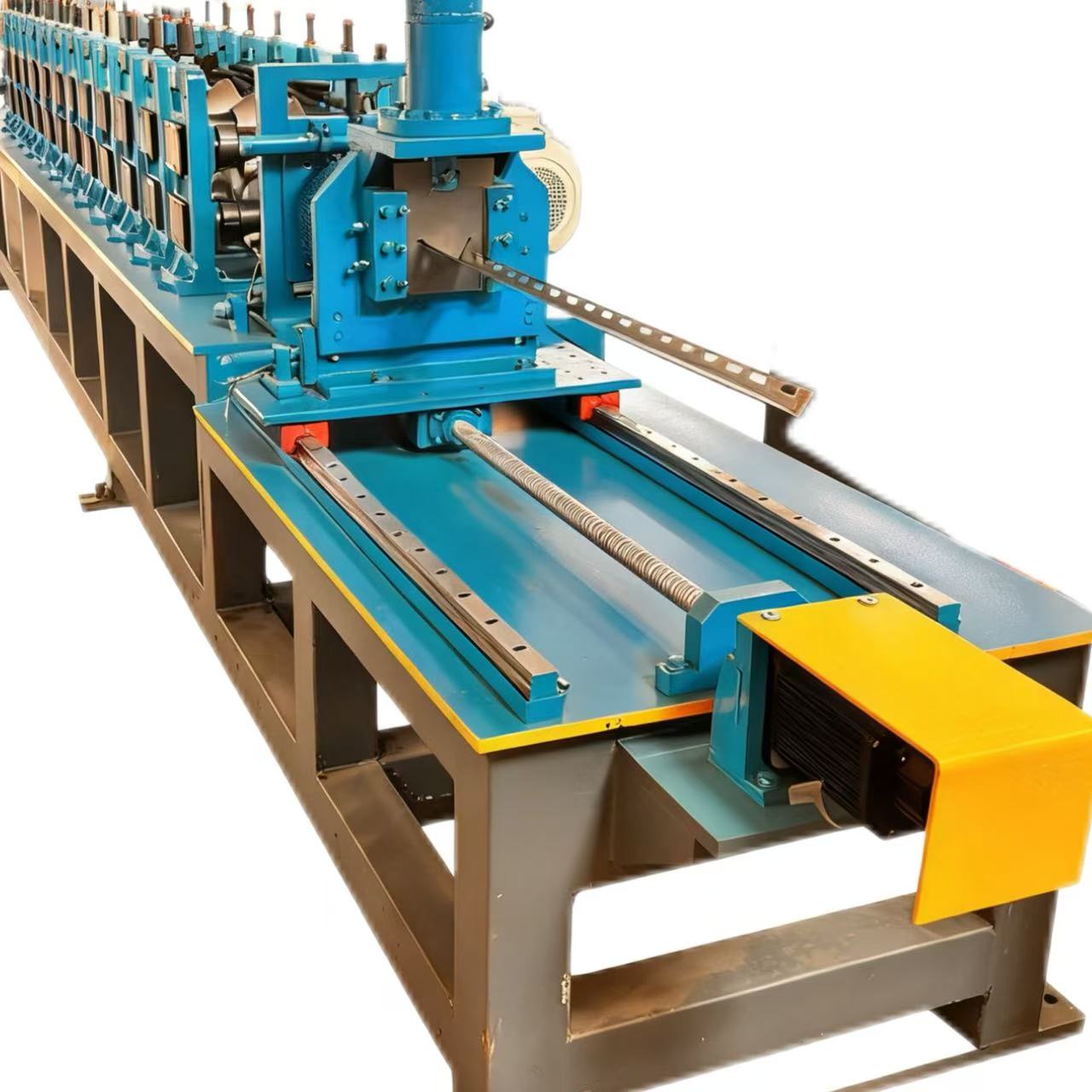

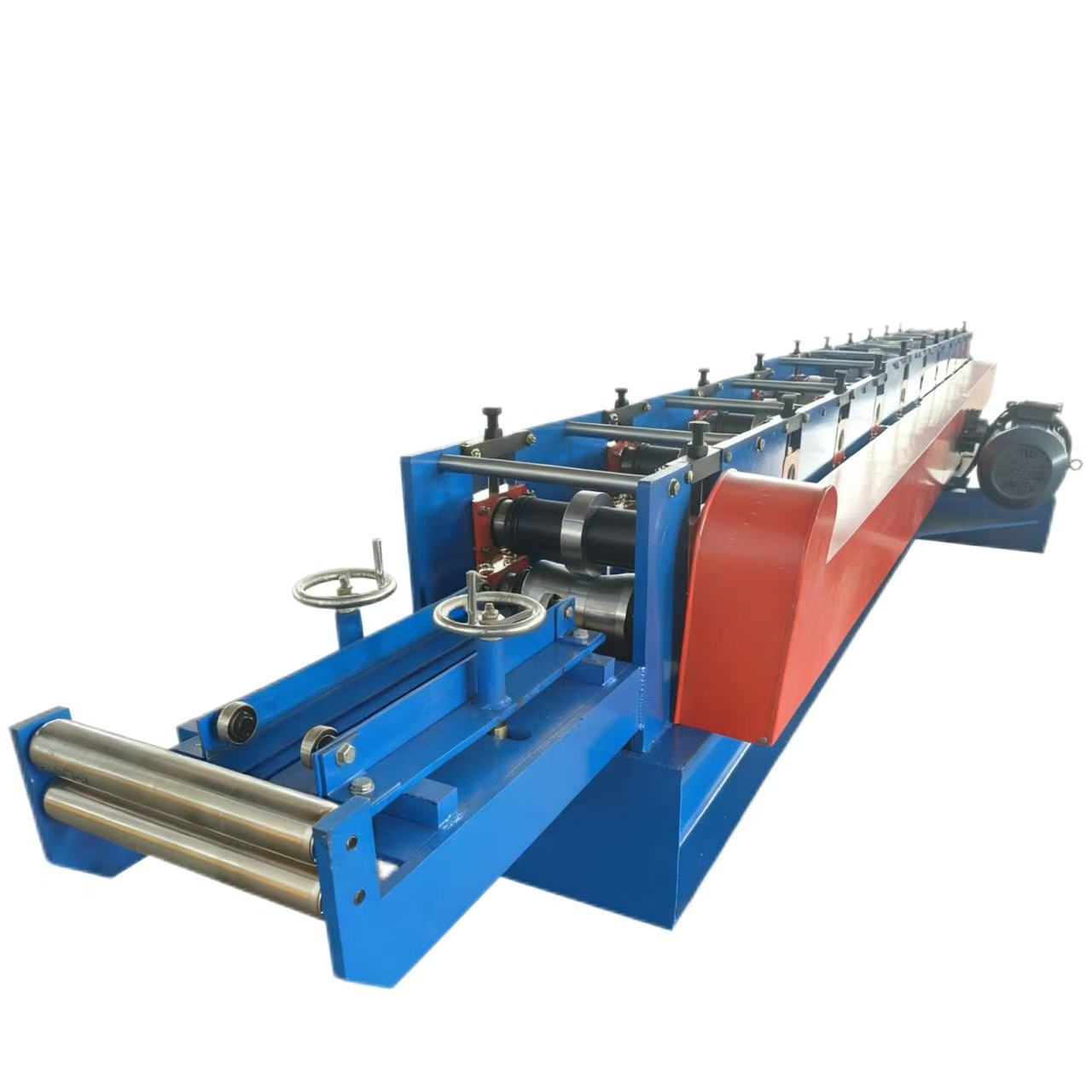

Product images: