In the field of villa construction, the keel serves as the core structural component supporting walls, ceilings, and floors, with its machining precision and efficiency directly determining the stability, aesthetics, and construction timeline of the villa. Tailored specifically for high-end villa construction, the High Efficiency Automatic Interchanging Villa Frame Forming Machine stands as an indispensable core equipment in modern villa projects, delivering precise machining capabilities, flexible adaptability, and high-efficiency performance to lay a solid foundation for quality villas.

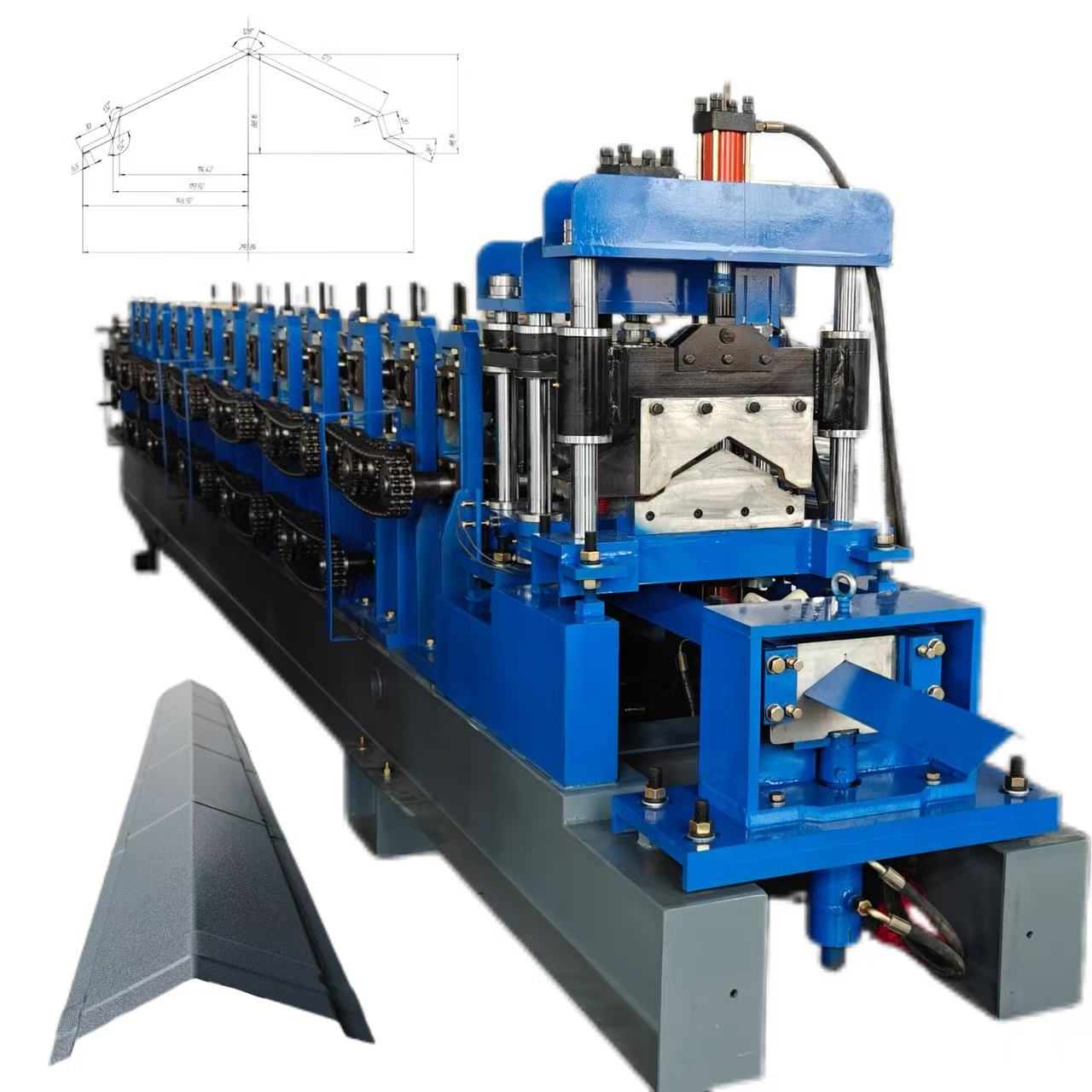

Pattern diagram:

Core features:

Empowering construction with technology and safeguarding living spaces with quality. The High Efficiency Automatic Interchanging Villa Frame Forming Machine, with its precise, efficient, and flexible core advantages, breaks the limitations of traditional keel processing and injects new vitality into the villa construction industry. Choosing a high-quality villa keel machine is not only a wise decision to enhance construction efficiency and reduce costs but also a solid guarantee for building century-quality villas and practicing the concept of high-end living. Let every villa space begin with precise keels and end with worry-free living.

Main components:

| No. | Equipment name | Quantity(set) | Remarks |

| 1 | Hydraulic decoiler | 1 | 6 tons |

| 2 | Forming machine (forming, punching and grooving) | 1 | |

| 3 | Control system | 1 | PLC control |

| 4 | Transmission and hydraulic station | 1 | |

| 5 | Inkjet printer | 2 | |

| 6 | Hydraulic Cutting | 1 | |

| 7 | Receive table | 1 | 2*3 m |

| 8 | Safety Guard | 1 | Seagull like in picture |

| 9 | Computer system | 1 | With manual remote control |

| 10 | Methods of Design Data Export | 1 | |

| 11 | Free Spare Parts ( easy wear parts) | 1 |

Machine Introduction:

1.6 Tons auto hydraulic decoiler

Function: Carry strip steel coil, rotating steel coil. With micro-braking device to prevent inertia from moving forward during emergency stop.

• Drive mode: hydraulic

• Bearing weight: 6.0T

• Inner diameter range: 480-510mm

• Outer diameter requirement: ≤1250mm

• Bracing method:Hand crank connecting rod type, with the center supporting outwards

• motor drive, automatic feeding

2.Feeding and Leveling Device

• Leveling device:2 groups for upper and 3 groups for down

• Feeding:guide shaft + guide wheel

• Feeding motor: help feeding material

• Width adjusting: by hand

• Adjusting the thickness fully automatic

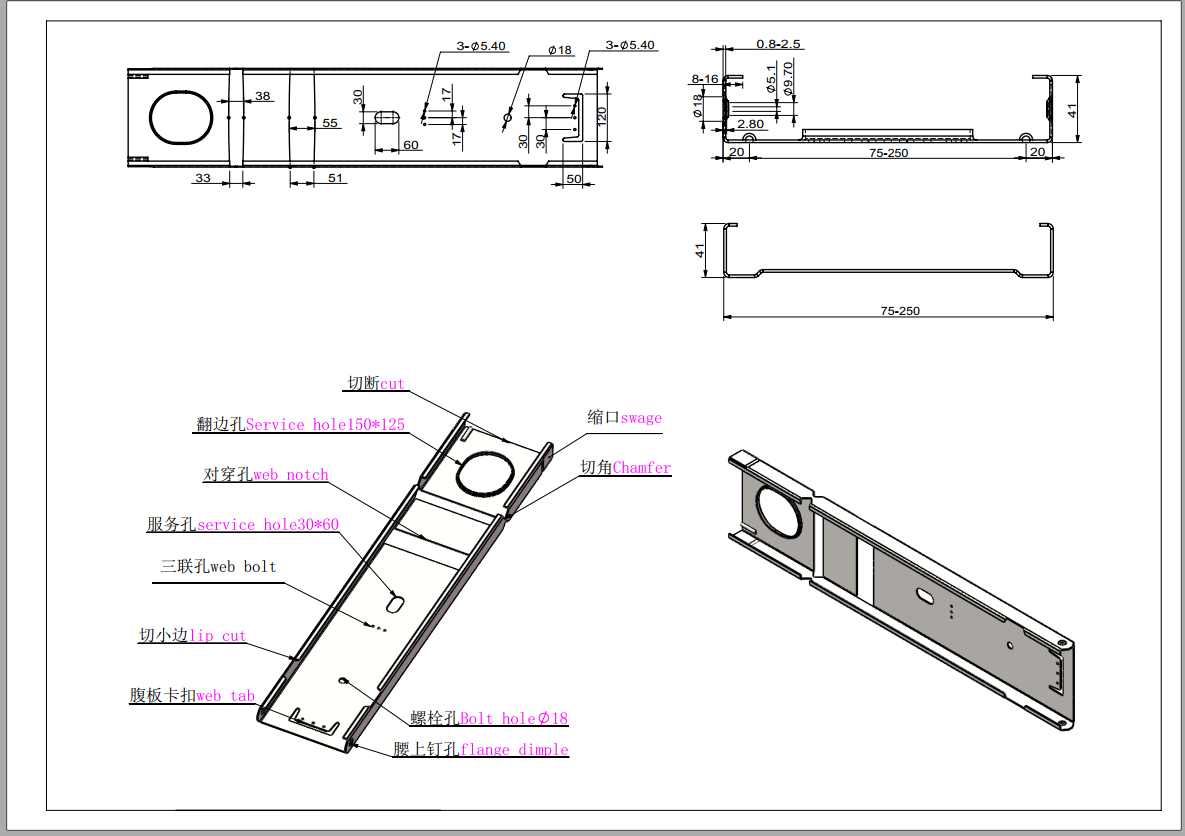

3.Punching device

• Punching type: hydraulic punching,driven by servo motor

• full automatic continuous punching die(pipe holes, web holes, small side cuts, fixing holes, chamfers, web necking, shearing, nail socket bolt holes, etc.); Punching precision within+/-1mm

• There has 4 sets web notch molds and end truss molds in total

4.Main rolling forming machine

• Changing sizes: Full-automatic (change sizes automatically by PLC control, pressing button is compatible)

• Transmission: chains with tension stabilization device

• Drive: servo motor 22kw +arc bevel gear reducer

• Roller material: Cr12,heat treat to HRC58-60 after CNC processing, and then finish turning, polishing and electroplating

• Shaft material:40Cr, after CNC processing, HRC28-32 is quenched and tempered, and then polished and electroplated

• Forming speed: High speed 30 m/min (depending on the number of punches and cutting length)

• Forming station:19 sets of spindle roll forming(5 stations forming lip;11 stations forming flange;3 stations for straight the keel

• Frame structure: Arch type

• Total weight of the machine: 8 tons

• Total machine length: 11.5m x 3.0m x 1.95m (length * width * height)