In the field of architecture today, villas, as representatives of high-quality residences, are highly valued for their construction techniques and quality. From the exquisite carvings of traditional European villas to the smooth lines of modern minimalist villas, every villa carries the owner’s yearning for a better life. Behind this, the villa keel machine is quietly playing a key role. As a specialized equipment for producing villa light steel keel profiles, it integrates advanced automation technology and precise forming processes, and can efficiently process galvanized steel strips with a thickness of 0.6-2.0mm. Through the PLC intelligent control system, the forming size of the keel can be accurately controlled, and the error can be controlled within ± 0.5mm. Its efficient production capacity and stable product quality are bringing new changes to the villa construction industry.

The villa keel machine, with its efficient production capacity, excellent product quality, intelligent operation experience, and energy-saving and environmental protection advantages, is becoming an indispensable key equipment in the villa construction industry. It not only brings higher production efficiency and economic benefits to villa construction enterprises, but also creates safe, comfortable, and beautiful high-quality villa living spaces for the majority of homeowners. With the continuous development of the construction industry and the continuous innovation of technology, the villa keel machine will surely show broader application prospects in the future market, promoting the villa construction industry to move towards a new stage of development.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.7-1.2mm

|

||

|

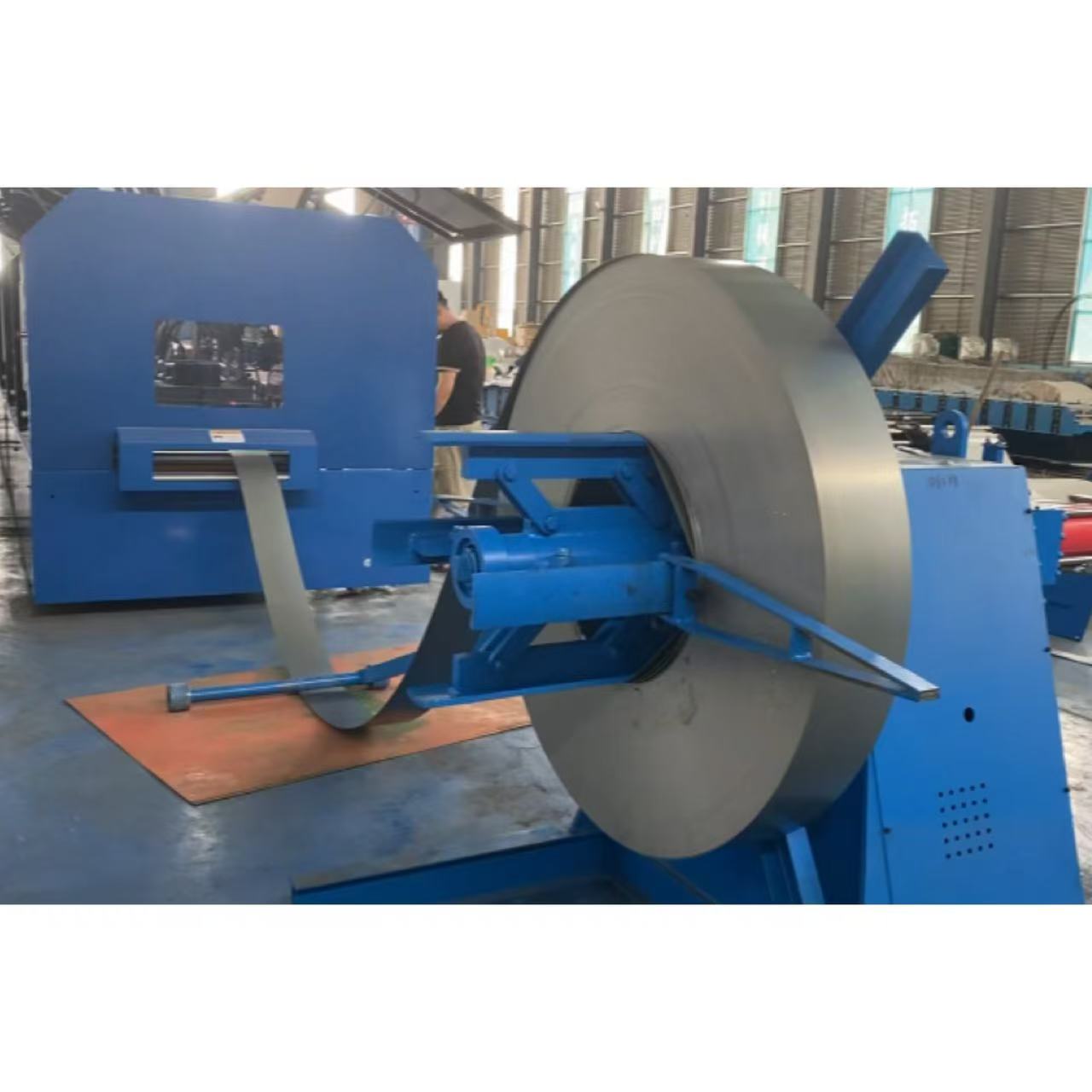

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

In depth analysis of villa keel machine

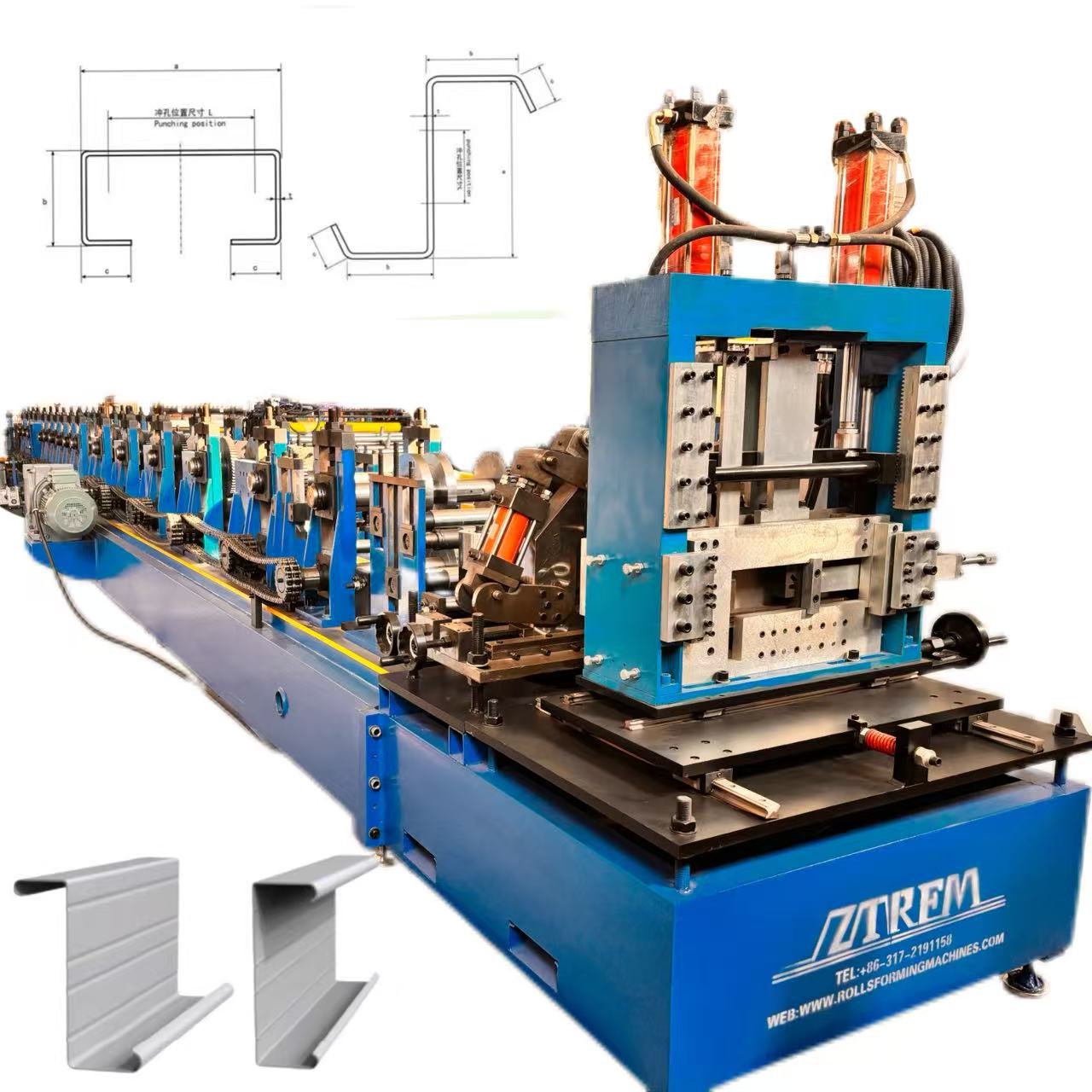

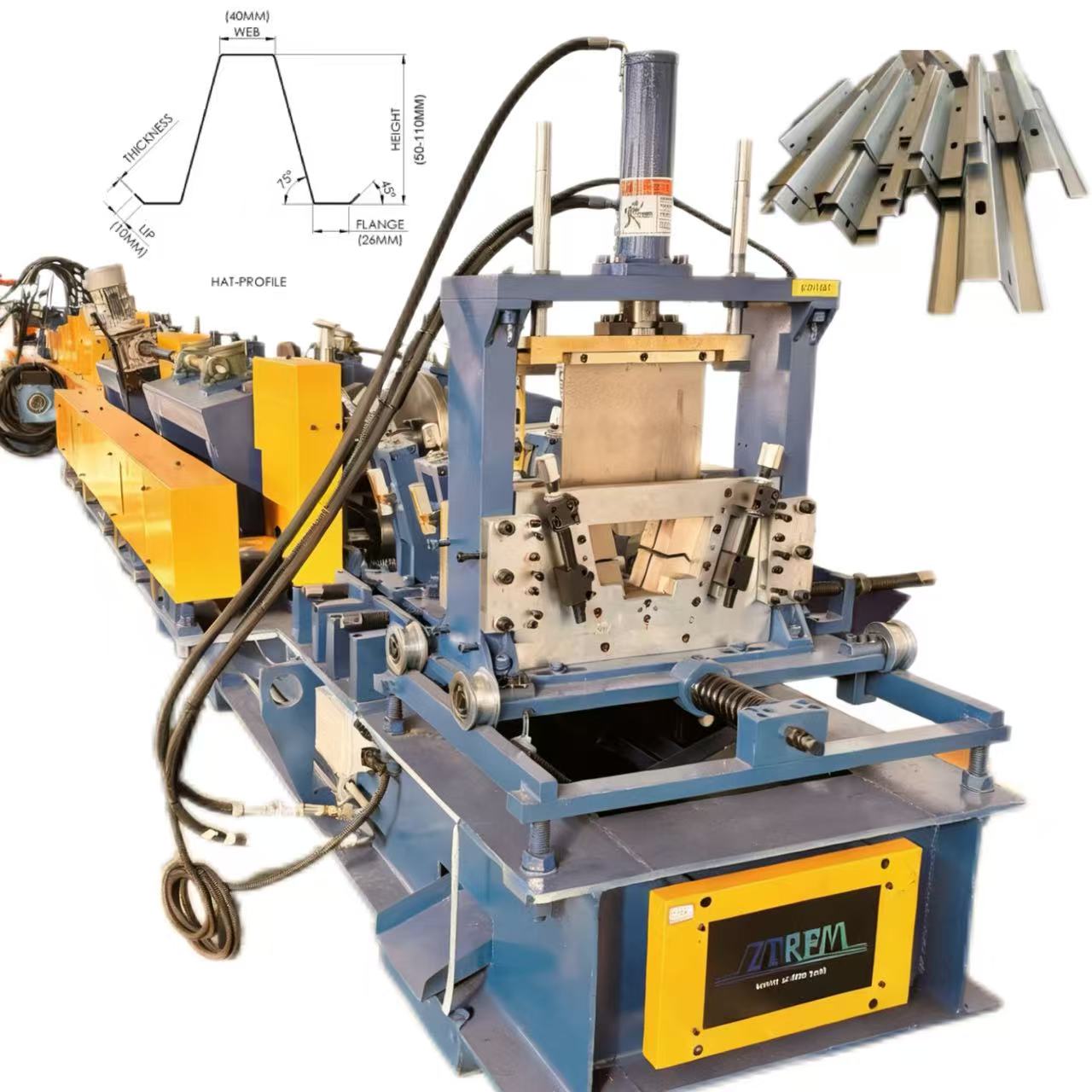

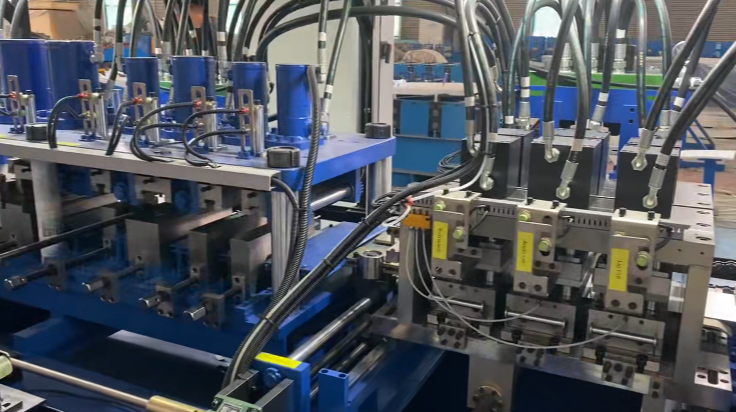

1.Basic Structure and Operating Principles

The villa keel machine usually consists of multiple key parts such as a discharge machine, hydraulic punching device, forming host, hydraulic shearing equipment, coding machine, fixed length cutting component, receiving platform, and electrical control system. When working, the feeding machine smoothly releases the rolled metal sheet, and then the sheet enters the hydraulic punching process, completing precise punching according to the preset hole pattern and spacing. Next, in the forming host, a series of carefully designed rollers are used to continuously bend and deform the sheet metal at room temperature, gradually forming the desired keel cross-sectional shape. During the molding process, the inkjet printer will simultaneously print product information and numbers on the surface of the keel. When the keel reaches the set length, the hydraulic shearing equipment quickly moves to accurately cut it. Finally, the cut keel is collected and organized by the receiving platform. The entire process is seamless, achieving efficient production through automation and assembly line.

2. Key parameters and performance indicators

(1)Processing specifications:

capable of producing various specifications of villa light steel keel, common ones such as C89 keel machine, mainly used for processing 89 light steel keel, suitable for light steel houses with three and a half floors or less; There are also different models such as 140 and 300, which can meet the diverse requirements of different building structure designs for the specifications and sizes of keel members.

(2)Material adaptability:

The thickness range of materials that can be processed is generally 0.6-2.0mm, which can adapt to various metal sheets such as galvanized sheet and aluminum zinc coated G550 steel strip. The keel made from these materials after processing has good strength and corrosion resistance, providing reliable structural support for villa buildings.

(3)Production speed:

Some advanced villa keel machines can form at a speed of up to 40 meters per minute, greatly improving production efficiency and meeting the supply needs of large-scale projects. For example, in some large-scale villa construction projects, efficient keel machines can significantly shorten the construction period and reduce time costs.

(4)Equipment power:

Taking common equipment as an example, the host power is generally between 7.5-18.5KW. Through reasonable power configuration, the equipment can operate efficiently while achieving reasonable utilization of energy and reducing energy consumption costs.

(5)Equipment footprint:

The overall footprint is relatively small, such as a size of about 4 meters long by 1.2 meters wide. For production workshops with limited space, it can be flexibly laid out without occupying too much space, improving site utilization.

Diversified application scenarios of villa keel machine:

1. The wide application of different styles of villas

(1)European classical villa:

In the construction of European classical style villas, the light steel keel produced by the villa keel machine serves as an important supporting part of the building structure, providing a stable foundation for its thick brick and stone walls and complex roof structure. For example, when constructing European style villas with domes and a large number of decorative components, the high-precision keel produced by the keel machine can ensure the precise installation of each structural component, making the villa have excellent structural stability while having a gorgeous appearance, and can withstand large loads and harsh weather tests.

(2)Modern minimalist villa:

For modern minimalist style villas that pursue simple lines and open spaces, the advantages of villa keel machines are also obvious. The light weight and high strength of light steel keel allow designers to freely express their creativity and create large-span spatial layouts. In some modern villas that adopt open design, the keel produced by the keel machine can be used to construct a framework for column free large spaces. Combined with lightweight wall materials, it not only reduces the overall weight of the building and lowers infrastructure costs, but also creates a transparent and bright living environment.

(3)American country villas:

American country style villas emphasize nature, comfort, and practicality. The keel produced by the villa keel machine not only meets the structural strength requirements, but also can be surface treated to blend with commonly used decorative materials such as wood and stone in American rural style, creating a harmonious and unified overall atmosphere. For example, light steel joists that have undergone special spray painting treatment can simulate the texture and color of wood, which can be used to build indoor ceilings or wall frames for villas. This not only ensures the stability of the structure, but also adds a natural charm of rural style.

2. Targeted applications for different functional areas

(1)Villa main structure:

In the construction of the main structure of the villa, the keel produced by the villa keel machine bears the main load-bearing task. Whether it is the vertical wall keel or the horizontal floor keel and roof keel, they are precisely connected and installed to form a sturdy overall framework, tightly integrating the various parts of the villa together to ensure the safety and stability of the entire building during long-term use.

(2)Interior partition of villa:

The partition used for dividing the interior space of the villa also relies on the assistance of the villa keel machine. The partition wall made of light steel keel has the advantages of light weight, easy installation, and good sound insulation effect. In the design of villas, the position and layout of partitions can be flexibly adjusted according to actual needs, creating diverse indoor spaces such as study rooms, dressing rooms, entertainment rooms, etc., to meet the different living needs of homeowners.

(3)Villa ancillary facilities:

In addition to the main building, some ancillary facilities of the villa, such as garages, sunshades, terraces, etc., can also be constructed using the keel produced by the villa keel machine. These keels can provide reliable structural support for ancillary facilities. At the same time, due to the strong processability of light steel keels, various shapes and sizes of keel components can be made according to different design requirements, achieving perfect unity between ancillary facilities and the overall style of the villa.

The significant advantages of villa keel machine:

1.Efficient production enhances efficiency

(1)Automated assembly line operation:

The villa keel machine adopts an automated assembly line production mode, from feeding, punching, forming, coding to cutting and receiving, each link is closely coordinated and runs continuously, greatly reducing manual intervention and waiting time between processes, and significantly improving production efficiency. Compared with traditional manual or semi-automatic processing methods, it can produce a large number of keel products in a short period of time, meet the rapid supply needs of large-scale villa projects, effectively shorten the project construction cycle, and win more market opportunities for enterprises.

(2)Quick changeover capability:

Some advanced villa keel machines have a quick changeover function, which can complete the production switching of different specifications of keels in a short period of time. For example, some devices can achieve automatic changeover of various widths of 65-200mm keels within minutes. Operators only need to input corresponding parameter instructions on the control panel, and the equipment can quickly adjust the internal mold and transmission system to switch to the required production state, greatly improving the flexibility of equipment use and adapting to diverse market demands.

2.Excellent quality assurance and safety

(1)High precision forming:

Through advanced roll forming technology and precise equipment calibration, the villa keel machine can ensure extremely high dimensional accuracy of the produced light steel keel, with errors strictly controlled within a very small range, generally up to ± 0.5mm. This high-precision keel product can achieve precise docking during installation, reduce installation problems caused by dimensional deviations, improve construction quality, and ensure the stability and safety of the overall structure of the villa.

(2)Stable structural performance:

After multiple cold bending forming processes and strict quality inspection, the internal structure of the light steel keel produced by the villa keel machine is denser, with higher strength and good toughness. In practical applications, it can withstand large loads and external impacts, effectively resist the invasion of natural disasters such as earthquakes and typhoons, provide reliable structural support for villa buildings, and extend the service life of buildings.

(3)High quality surface quality:

During the production process, the equipment conducts special treatment on the surface of the rolling mill and optimizes the processing technology, making the surface of the produced light steel keel smooth and flat, without obvious defects such as scratches, wrinkles, and deformations. Good surface quality not only enhances the aesthetics of keel products, but also reduces the workload of subsequent surface treatment processes and lowers production costs. Meanwhile, a smooth surface helps to improve the bonding performance between the keel and other building materials, enhancing the overall structural connection strength.

3.Intelligent operation lowers the threshold

(1)Intelligent control system:

Villa keel machines are usually equipped with advanced PLC intelligent control systems. Operators only need to input the specifications, production quantity, hole type settings and other related information of the keel on the touch screen, and the equipment can automatically produce according to the preset program. This intelligent operation method greatly reduces the requirement for professional skills of operators. Even workers without rich mechanical operation experience can proficiently learn after simple training, effectively improving production efficiency, reducing human operation errors, and ensuring product quality consistency.

(2)Remote operation and warning function:

Some high-end villa keel machines are equipped with remote operation and maintenance systems and fault warning functions. Through Internet connection, technicians of equipment manufacturers can monitor the running status of equipment in real time and carry out remote diagnosis and maintenance of equipment. At the same time, the built-in sensors of the device can collect various data in real time during the operation of the device, such as motor temperature, vibration frequency, component wear, etc. Once there is an abnormality in the data, the system will immediately issue a warning signal to remind the operator to check and repair in a timely manner, avoiding production interruption caused by sudden equipment failures, reducing equipment maintenance costs, and improving production continuity and stability.

4.Energy conservation and environmental protection follow the trend

(1)Energy saving design:

The villa keel machine fully considers energy utilization efficiency in the design and manufacturing process. By adopting energy-saving motors, optimizing transmission systems, and intelligent control systems for precise adjustment of equipment operating power, it is possible to reduce energy consumption while ensuring efficient production. Compared with traditional high-energy consumption profile processing equipment, the villa keel machine can effectively save a large amount of electricity, reduce production costs for enterprises, and also meet the policy requirements of national energy conservation and emission reduction.

(2)Environmentally friendly production:

During the production process, the villa keel machine causes minimal pollution to the environment. Due to the use of cold bending forming technology, there is no need for high-temperature heating or chemical treatment, which avoids the generation of harmful gases and waste. At the same time, the noise generated by the equipment during operation is relatively low. Through reasonable sound insulation and noise reduction design, the noise can be controlled within the environmental standard range, creating a relatively quiet and comfortable working environment for the production workshop and reducing the impact on the surrounding environment and residents.