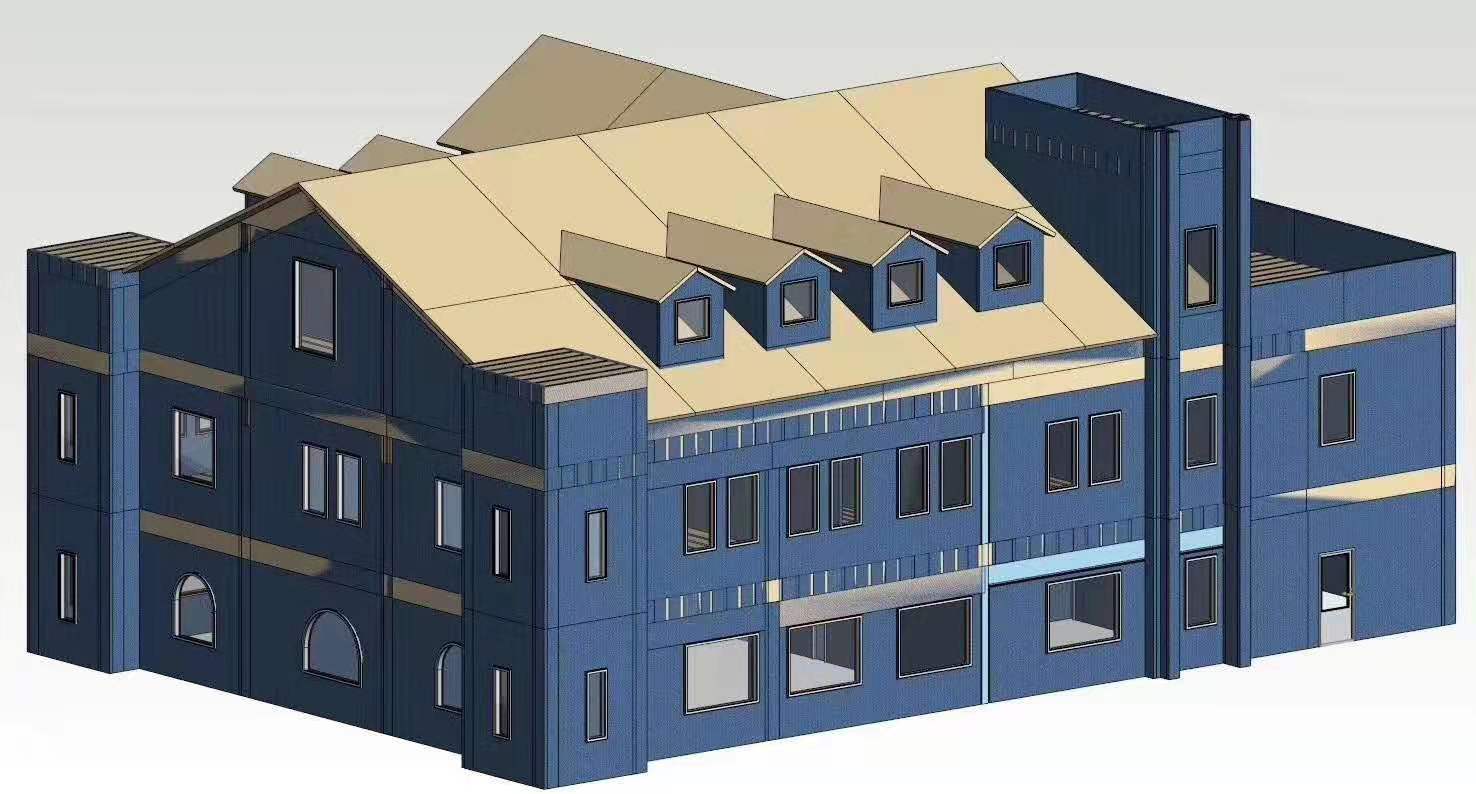

In the field of modern villa construction, the keel, as the “skeleton” of walls, ceilings, and floors, directly determines the structural stability, space utilization, and decoration aesthetics of the villa. As the core equipment specialized in producing villa keels, villa keel equipment breaks the limitations of traditional manual processing or universal keel equipment with precise and customized production capabilities, providing a more adaptable and high-quality keel solution for villa construction. This article will comprehensively interpret the important value of villa keel equipment for modern villa construction from three aspects: equipment introduction, application scenarios, and core features.

Application scenarios :

The keel produced by villa keel equipment can be applied to the three core systems of wall, ceiling, and floor in villa construction, adapting to different styles and structures of villas (such as light steel villas, brick concrete villas, detached villas, and row villas), meeting the dual requirements of functionality and aesthetics.

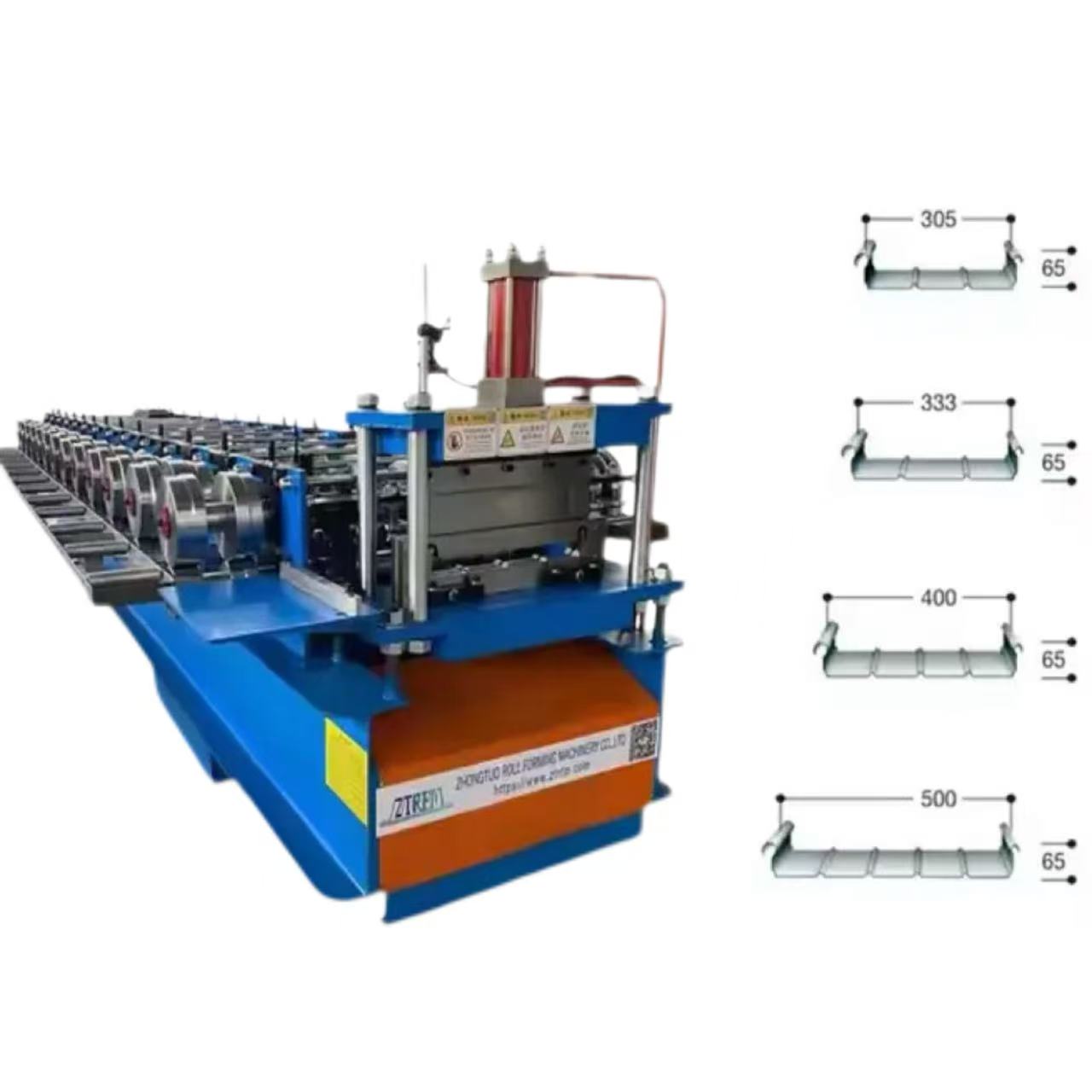

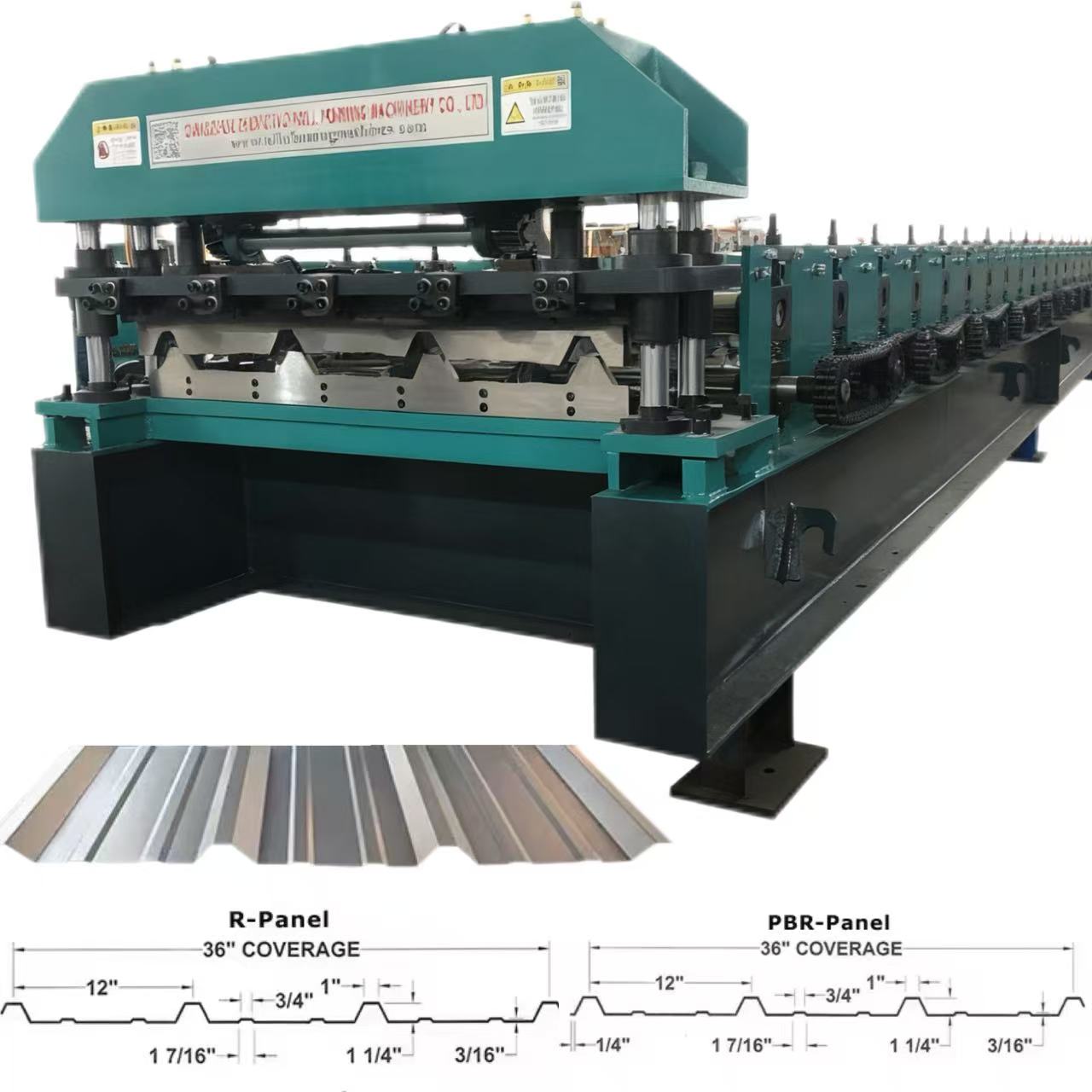

1. Villa wall system: Building a strong structural safety defense line

In the construction of villa walls, C-shaped and U-shaped light steel keels produced by equipment are the core load-bearing components. On the one hand, light steel keel is lightweight (only 1/30 of traditional brick walls), which can reduce the overall load of villas and lower foundation pressure, especially suitable for scenarios such as mountain villas and sloping villas that are sensitive to foundation load-bearing; On the other hand, the precision of the keel produced by the equipment is high, and the perpendicularity error between the flange and the web plate is small. When assembled, it can be precisely docked to form a stable wall frame. After filling with insulation cotton and gypsum board, it can not only improve the insulation and sound insulation performance of the wall (the sound insulation volume can reach more than 40dB), but also ensure the flatness of the wall, laying the foundation for subsequent wall decoration (such as tiling and painting latex paint). In addition, for the decoration needs of villa exterior walls, the equipment can also produce special section keels for fixing decorative materials such as stone and metal curtain walls, enhancing the appearance and texture of the villa.

2. Villa Ceiling System: Creating Flexible and Beautiful Top Space

Villa ceilings have extremely high requirements for the flatness and load-bearing capacity of the keel, and the U-shaped and T-shaped ceiling keels produced by the equipment can perfectly meet this demand. For large spaces such as living rooms and dining rooms, the equipment can produce long keels up to 6m in length, reducing the number of splicing times and avoiding ceiling cracking caused by splicing gaps; For small space ceilings such as bedrooms and study rooms, short size keels can be produced by adjusting the cutting length to adapt to complex ceiling shapes (such as double eyelid ceilings and curved ceilings). At the same time, the surface of the keel produced by the equipment is smooth (treated with galvanizing or spraying technology), not easy to rust, and can extend the service life of the ceiling; The reserved punching holes on the keel can facilitate threading, reduce the damage to the keel structure caused by later punching, and meet the installation needs of equipment such as lighting fixtures and fresh air systems for villa ceilings.

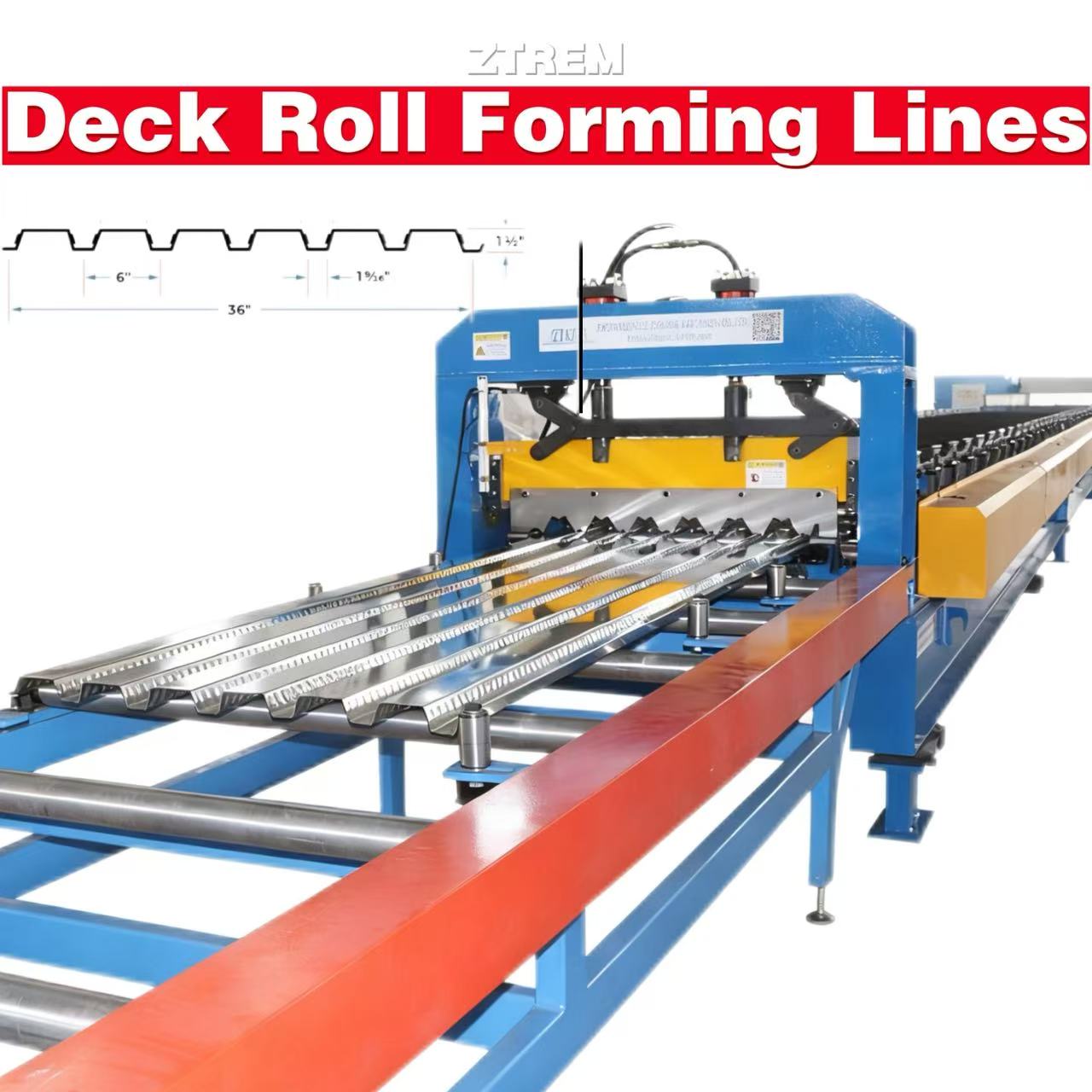

3. Villa flooring system: ensuring ground stability and comfort

In the installation of villa flooring, the T-shaped and L-shaped floor keels produced by the equipment are key components that connect the ground and the floor. Traditional solid wood keels are prone to moisture and deformation, while metal floor keels produced by equipment (such as galvanized steel keels) have the advantages of corrosion resistance and deformation resistance, especially suitable for damp environments such as villa floors and basements; At the same time, the equipment can adjust the height of the keel according to the thickness of the floor (such as 15mm solid wood floor, 8mm composite floor), ensuring that the flatness error of the floor after laying is ≤ 2mm, and improving walking comfort. In addition, for the underfloor heating system of villas, the equipment can also produce dedicated floor keels with heat dissipation slots, which not only do not affect the heat transfer of underfloor heating, but also ensure the load-bearing performance of the keels, achieving a combination of functionality and practicality.

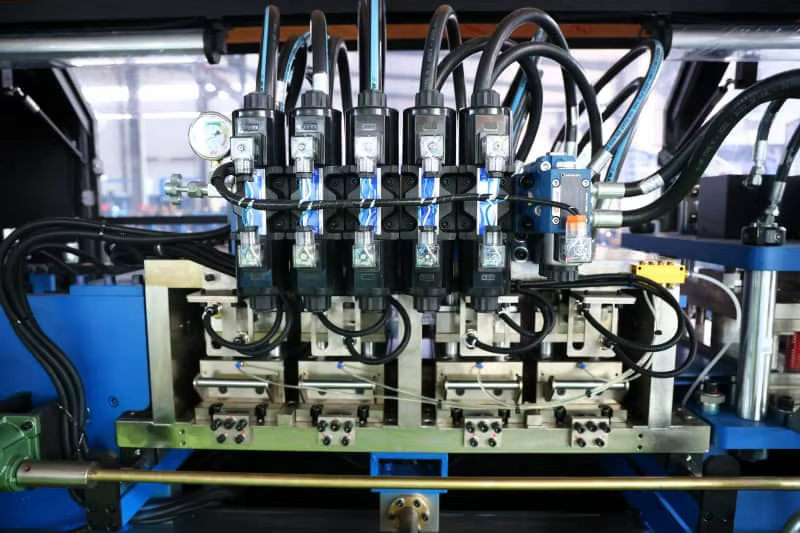

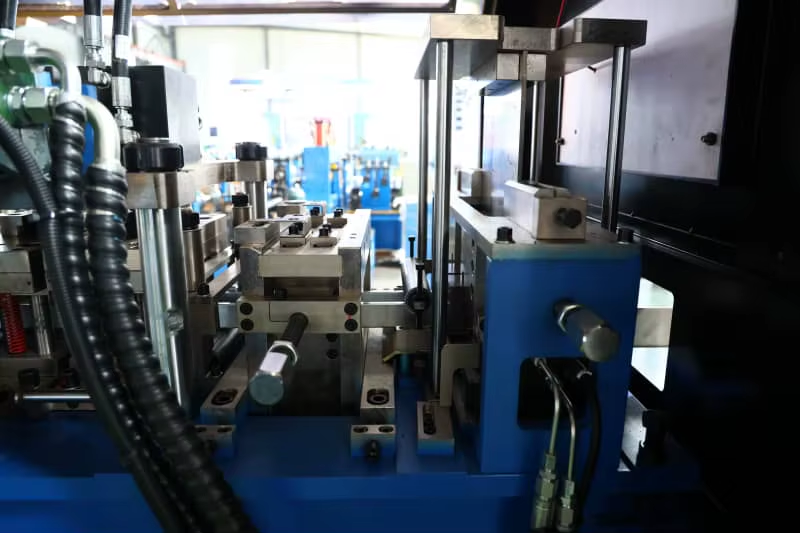

The core feature: exclusive advantages for adapting to villa construction

Compared to general keel equipment or manual processing, villa keel equipment has significant advantages in production accuracy, customization ability, cost control, etc., perfectly meeting the special needs of villa construction for keels.

1. High precision production: ensuring the stability of villa structure and decoration effect

The requirements for the accuracy of the keel in villa construction are much higher than those in ordinary buildings (such as the allowable error of the keel in ordinary buildings being ≤ 1mm, and the requirement for the keel in villas being ≤ 0.5mm). Villa keel equipment achieves high-precision production through three major technologies: firstly, modular forming rollers are used, processed by CNC machine tools, with a roller accuracy of 0.05mm, ensuring consistent cross-sectional dimensions of the keel; The second is a servo driven punching and cutting system with a positioning accuracy of 0.01mm, which avoids hole displacement and length deviation; The third is real-time pressure monitoring, which dynamically adjusts the pressing force during the molding process to prevent the keel from deforming due to excessive pressure or becoming loose due to insufficient pressure. High precision keels can not only improve the structural stability of villas (such as the wind resistance of walls and the load-bearing capacity of ceilings), but also reduce the adjustment costs during the decoration stage, such as eliminating the need for additional leveling of walls and repeated polishing of floors.

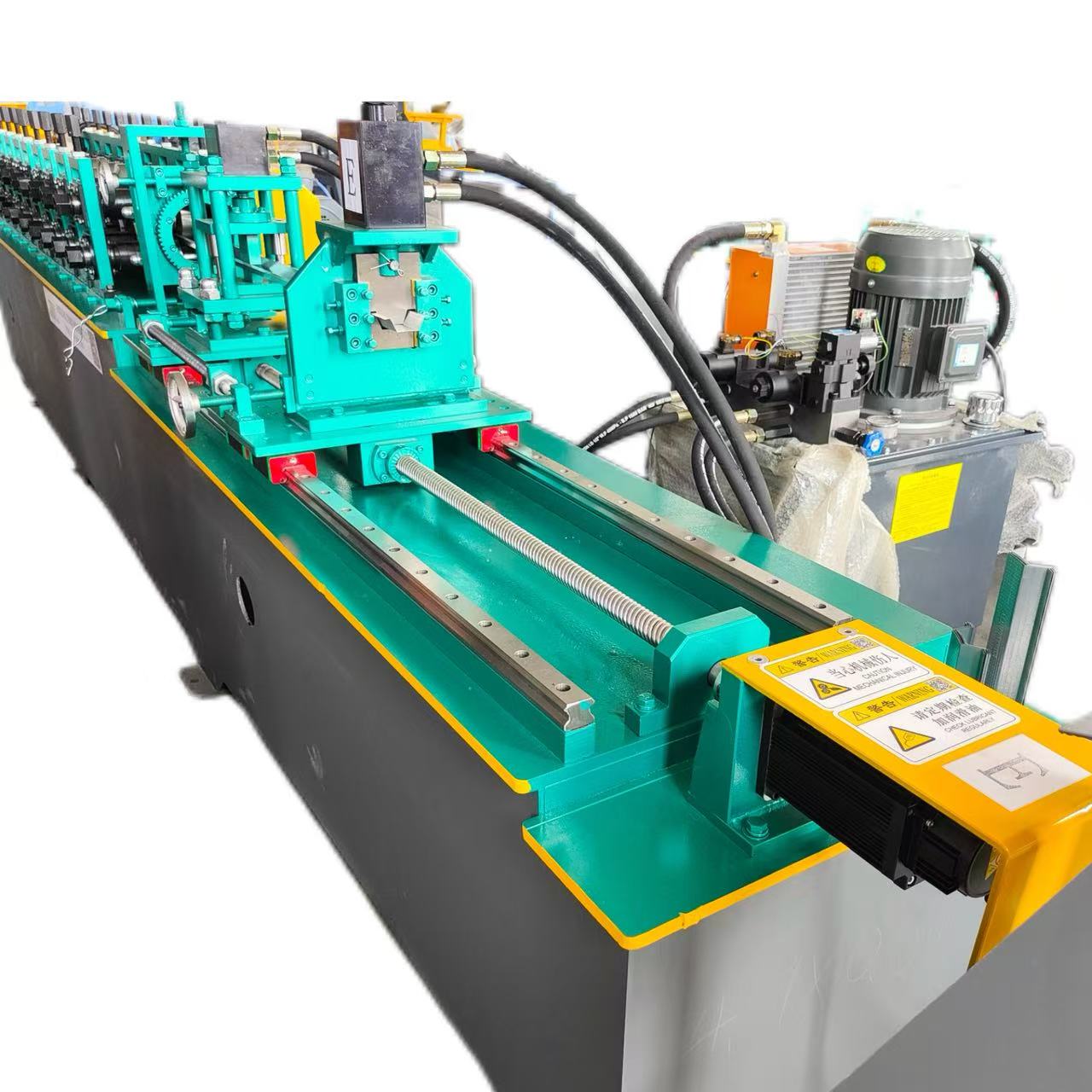

2. Strong customization: adapted to the diverse design needs of villas

Modern villa design styles are diverse (such as Chinese, European, and modern simplicity), and there are significant differences in the specifications and shape requirements of the keel. Villa keel equipment achieves strong customization through two advantages: first, the ability to quickly change molds. The forming rollers and dies adopt modular design, and changing a set of molds only takes 1.5-3 hours. It can produce keels with various cross-sections such as C, U, T, L, etc., and the cross-sectional size can be adjusted within the range of 50mm-200mm; The second is flexible parameter setting. The control system supports personalized parameter input, such as adjusting the forming parameters to produce curved keels for the requirements of curved ceilings; For special installation requirements, the punching position and hole diameter can be customized. This customization capability allows the equipment to quickly respond to the creative needs of villa designers, avoiding design compromises caused by mismatched keel specifications.

3. Efficient Production: Shortening the Villa Construction Cycle

The construction period of villas is usually tight (such as a standalone villa with a construction period of about 6-12 months), and the supply speed of the keel as a preliminary structural material directly affects the subsequent construction progress. The forming speed of villa keel equipment can reach 3-15m/min, and the daily output can reach 800-2000m, which is 8-10 times more efficient than manual processing (with a daily output of about 100-200m); At the same time, the equipment realizes integrated production of forming, punching, and cutting, without the need for subsequent processing, greatly reducing the production cycle of keel. Taking a 300 square meter villa as an example, the equipment only takes 2-3 days to complete the production of all the keel, while the traditional method takes 15-20 days, saving a lot of time for villa construction.

4.Low cost and controllable: reducing villa construction costs

Villa keel equipment helps reduce costs in three ways: firstly, it reduces labor costs. The equipment only requires 1-2 people to operate, which reduces labor demand by more than 70% compared to manual processing (which requires 5-8 people), and can save labor costs of 200000 to 400000 yuan per year; The second is to reduce raw material waste. The utilization rate of equipment raw materials reaches over 98% (about 85% for manual processing). Calculated based on the daily production of 1000m keel, about 5 tons of metal raw materials can be saved annually, reducing raw material costs by 30000 to 50000 yuan; The third is to reduce maintenance costs. The core components of the equipment, such as forming rollers and servo motors, are made of high-strength materials with a service life of 5-8 years. The control system also has a fault warning function, which can identify hidden dangers in advance and reduce maintenance frequency and costs.

5. Green and environmentally friendly: in line with the concept of green construction for villas

Modern villas are increasingly focusing on green environmental protection (such as low-carbon, energy-saving, and pollution-free). Villa keel equipment practices the green concept from two aspects: first, the raw materials are environmentally friendly, and the metal keels that are compatible with the equipment (such as light steel and galvanized steel) can be recycled, which reduces wood cutting compared to traditional solid wood keels and meets the requirements of sustainable development; The second is environmental protection in production. The equipment adopts low-noise motors (operating noise ≤ 80 decibels) and is equipped with dust collection devices to reduce noise and dust pollution during the production process, which meets national environmental standards; At the same time, metal keels do not require painting for corrosion prevention during use, avoiding the release of harmful substances such as formaldehyde and benzene, and ensuring the health of the indoor environment of the villa.