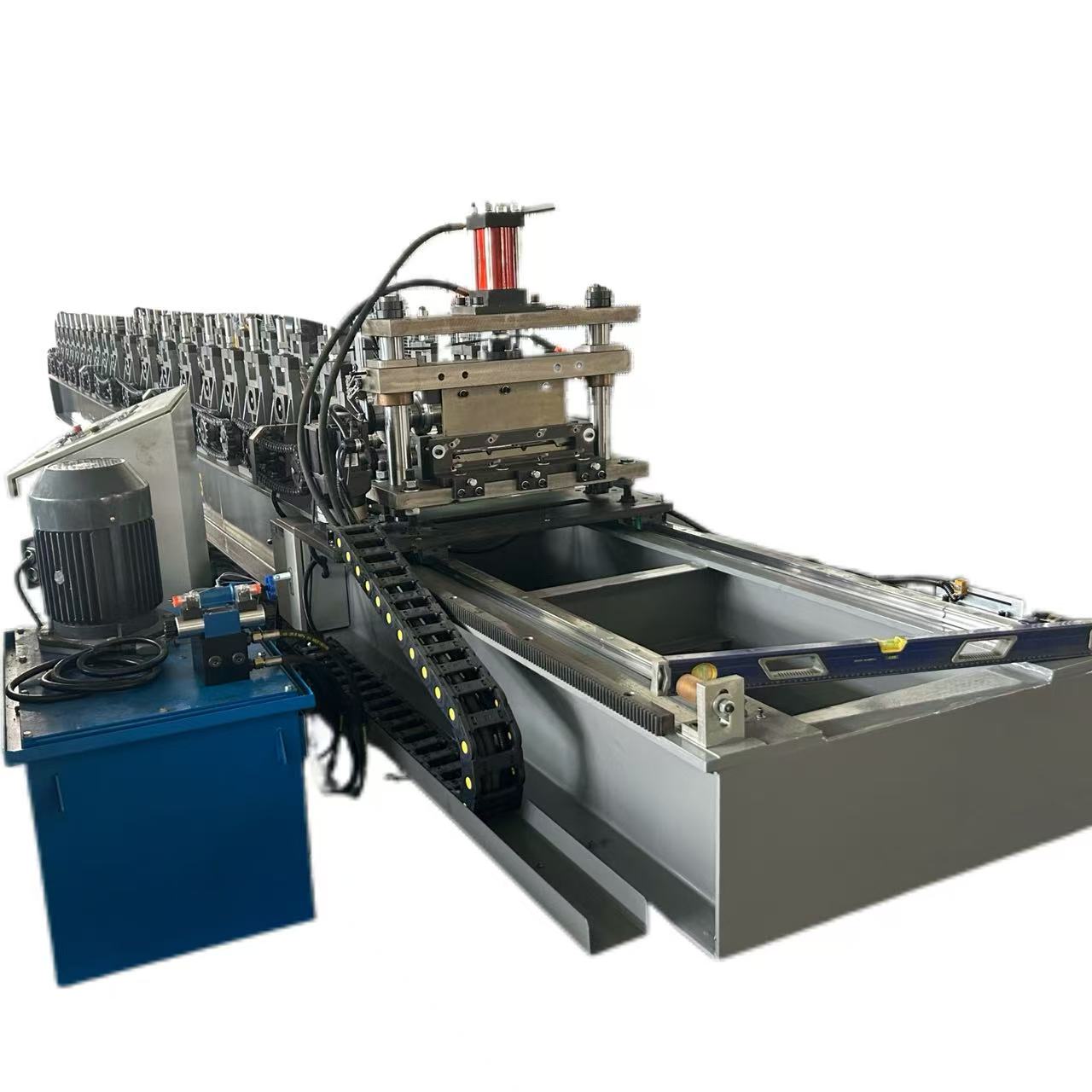

In the field of modern architectural decoration, metal ceilings have become the preferred choice for many public buildings and high-end venues due to their unique texture, diverse shapes, and excellent performance. Behind this, the metal ceiling panel forming machine plays a crucial role. It is the core equipment that transforms metal sheets into exquisite ceiling components. With advanced technology and efficient production capacity, it provides solid support for the aesthetic presentation and quality assurance of building ceilings.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive way

|

gear

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 8T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

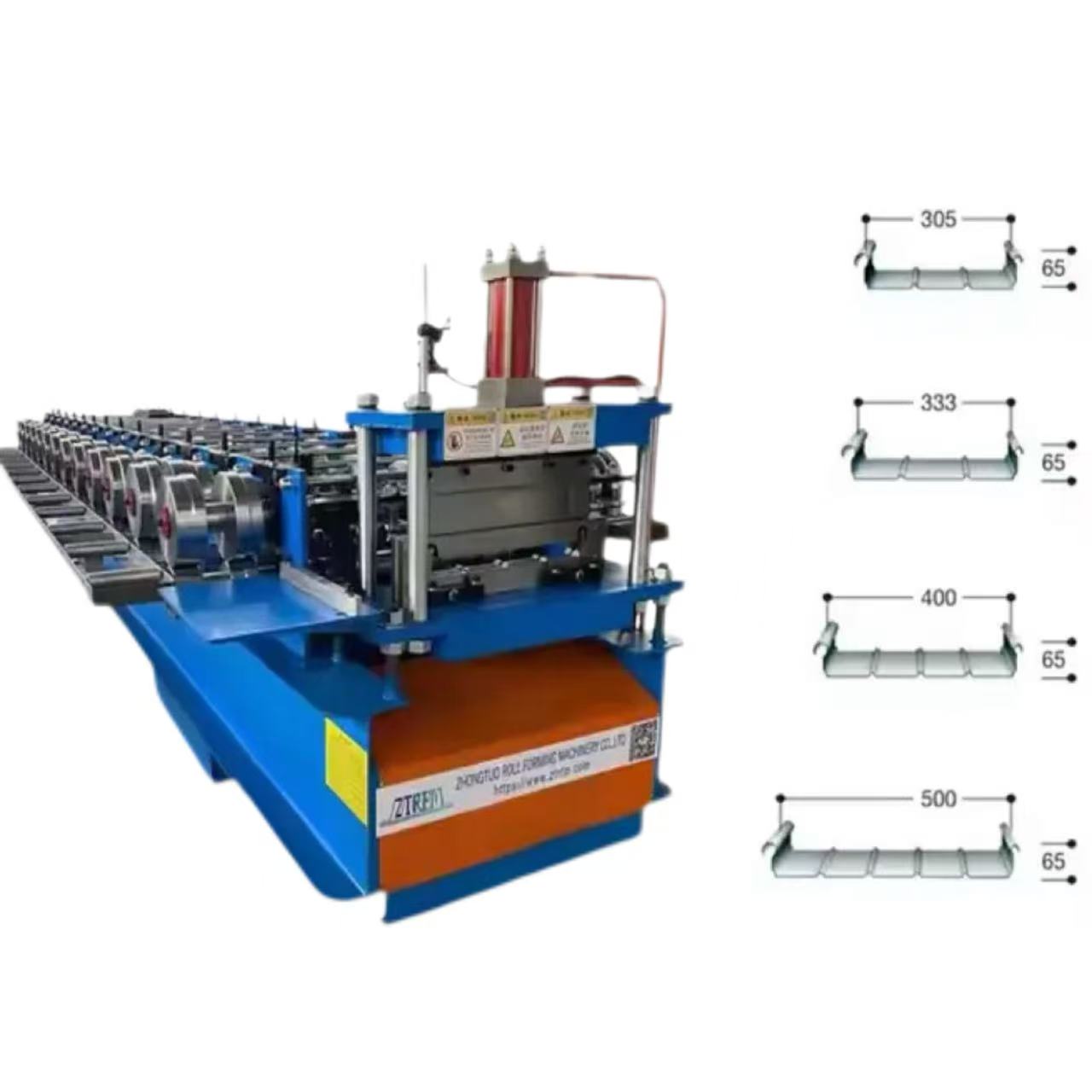

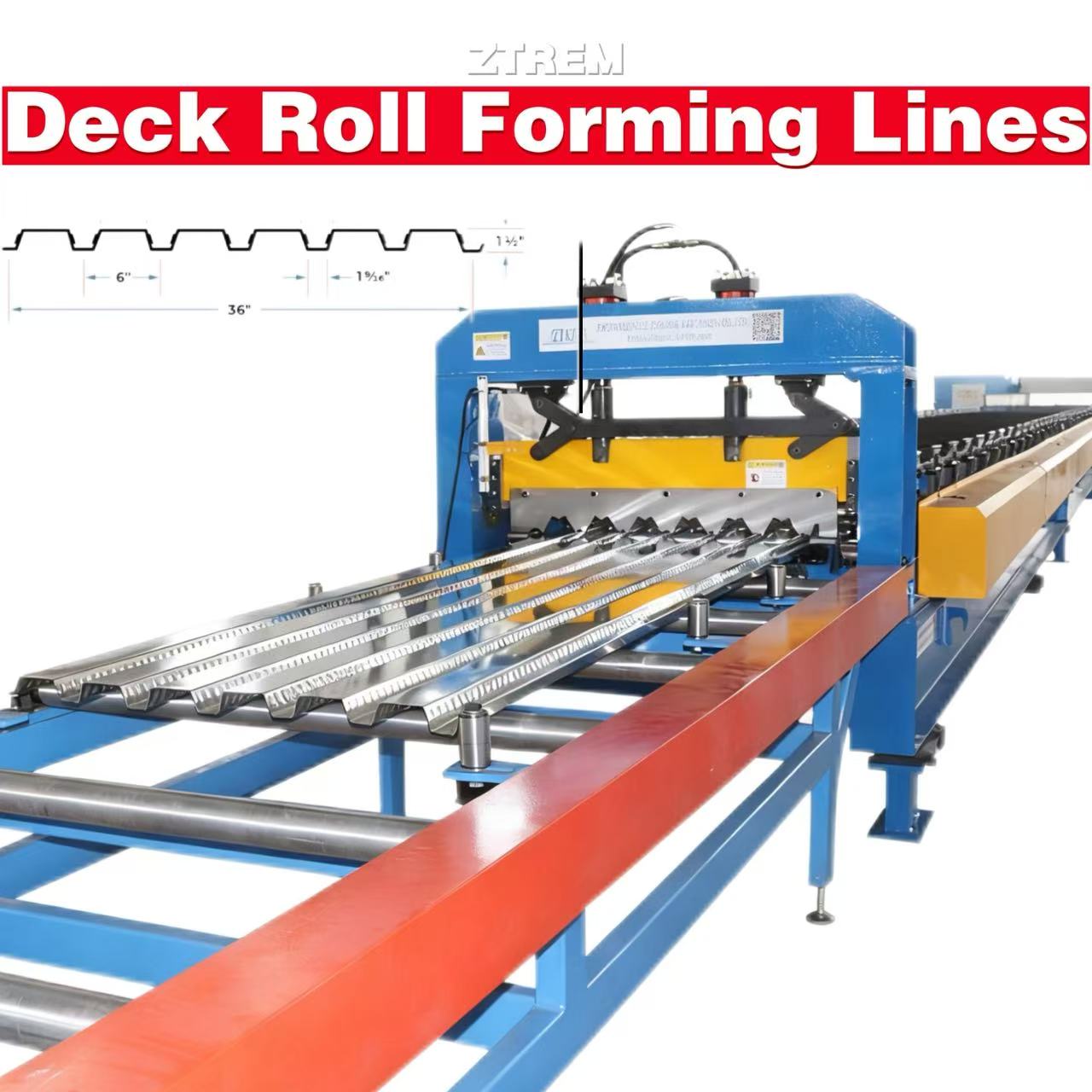

1. Equipment construction and workflow

The metal ceiling panel forming machine is an automated production line that integrates multiple precision components. Its structural design fully considers the precision and efficiency of production.

The equipment usually includes an uncoiler, which can stably carry and release rolled metal sheets such as aluminum plates, steel plates, stainless steel plates, etc., providing a continuous supply of raw materials for subsequent processing, and can be flexibly adjusted according to the weight and size of the coil. Next is the leveling device. Metal sheets that have undergone long-distance transportation or long-term storage are inevitably prone to bending, wrinkling, and other problems. The leveling device flattens the sheets through the collaborative action of multiple sets of precision rollers, ensuring that the sheets entering the next stage have good flatness and laying the foundation for subsequent forming quality.

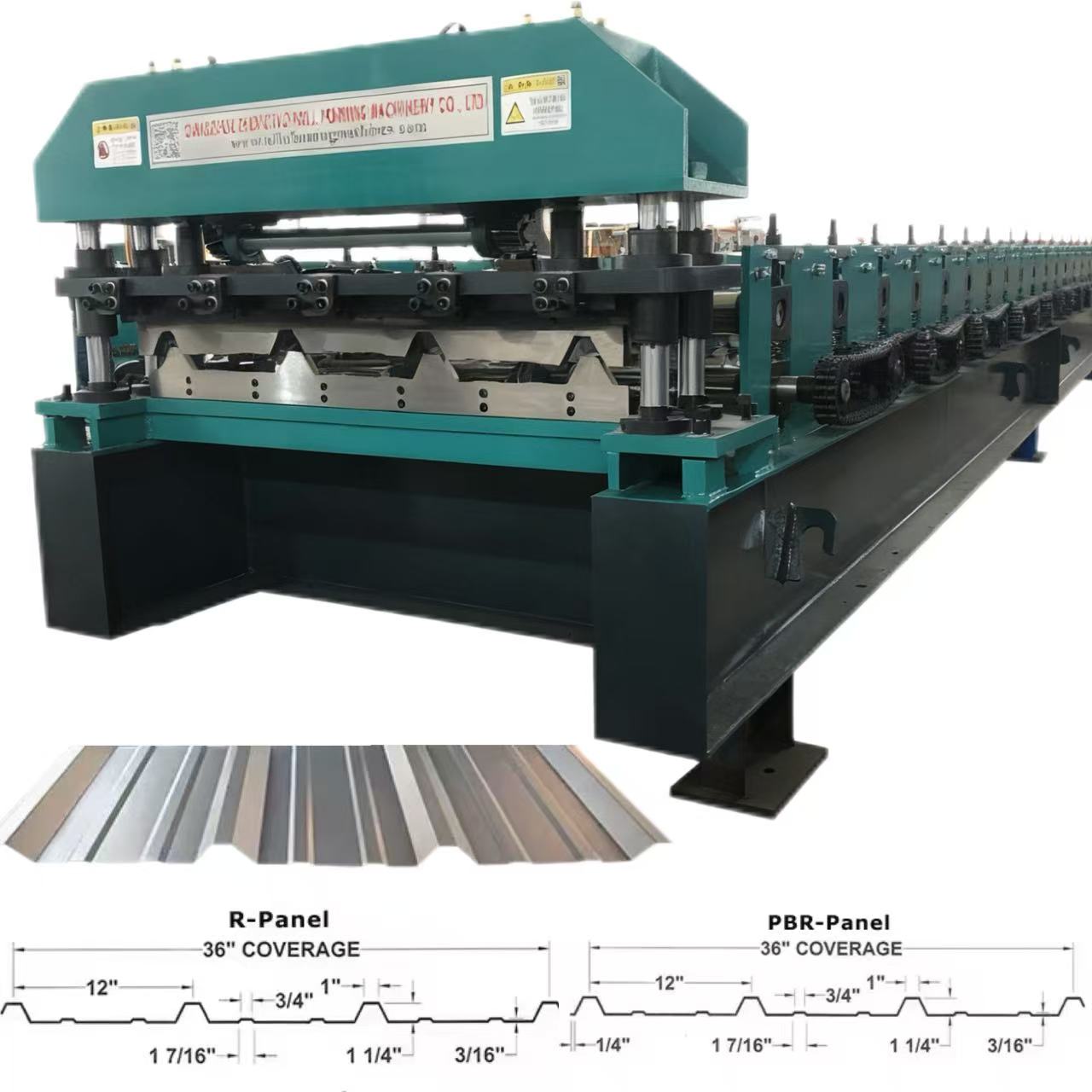

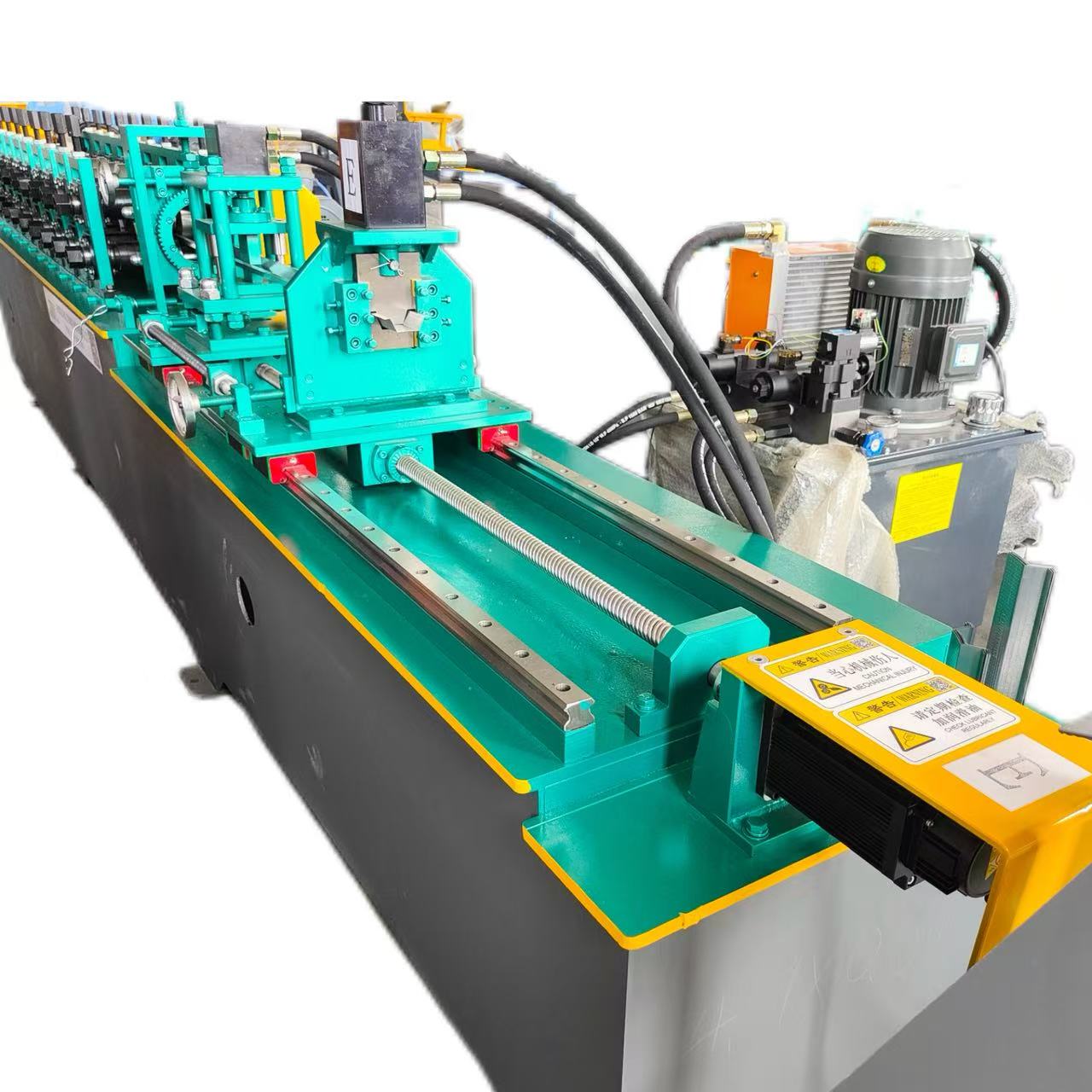

The forming host is the core of the entire equipment, consisting of a series of forming rollers arranged according to the preset mold trajectory. After the flat metal sheet enters the forming machine, it is gradually rolled, bent, stretched and processed into ceiling panels with specific cross-sectional shapes, such as common bar, square, irregular and other styles, to meet different decorative needs. The formed ceiling panels also need to go through a cutting device, which uses high-precision cutting technology such as hydraulic cutting or pneumatic cutting to accurately cut the continuously formed ceiling panels according to the set length, ensuring that the size error of each ceiling panel is controlled within a very small range.

In addition, the equipment is equipped with an advanced control system, using well-known brands of PLC (Programmable Logic Controller) and touch screen. Operators can intuitively set production parameters such as sheet thickness, forming speed, cutting length, etc. through the touch screen. The system will automatically control the collaborative work of various components, achieving automation and intelligence of the entire production process.

Its workflow is clear and efficient: firstly, the metal coil is installed on the unwinding machine, and after being leveled by the leveling device, it enters the forming host; In the forming host, the board is gradually formed into the desired shape of the ceiling board according to the preset mold trajectory; Finally, the cutting device cuts the formed ceiling panel into a set length to complete the entire production process.

2. Core advantage: Dual guarantee of efficiency and quality

The reason why metal ceiling panel forming machines can occupy an important position in the building decoration industry is closely related to their outstanding advantages.

Efficient production capacity is one of its prominent features. The equipment adopts an automated production mode, from raw material input to finished product output without excessive manual intervention, with fast production speed. It can produce metal ceiling panels of tens or even hundreds of meters per hour, which can meet the large demand for ceiling panels in large-scale construction projects, greatly shorten the production cycle, and save valuable time for the smooth progress of the project.

Accurate molding precision is its core competitiveness. The forming rollers of the equipment are manufactured using high-precision processing technology, with precise mold design and advanced control systems to ensure that the produced metal ceiling panels have consistent dimensions and shapes, clear cross-sectional contours, smooth corners, and minimal errors. This not only ensures smooth splicing of the ceiling panels during installation, reducing adjustment work during the installation process, but also enhances the aesthetics and stability of the entire ceiling system.

The strong material adaptability makes the equipment more flexible. It can process various metal materials such as aluminum plates, galvanized steel plates, stainless steel plates, etc. with a thickness between 0.3-1.5mm, and can adjust production parameters according to different material characteristics to ensure that ideal forming effects can be achieved when processing different materials, meeting the diverse needs of different buildings for ceiling panel materials.

Convenient operation and easy maintenance also add a lot of points to the equipment. The intelligent control system enables operators to proficiently master the operation methods of the equipment with only simple training, reducing the requirements for the skill level of operators. At the same time, the layout of each component of the equipment is reasonable, which facilitates daily inspection, maintenance, and upkeep, reduces the occurrence of equipment failures, and improves the service life and operational stability of the equipment.

3. Wide application: versatile in the field of decoration

The ceiling panels produced by the metal ceiling panel forming machine have been widely used in many building scenarios due to their excellent performance. :

In commercial places such as large shopping malls, shopping centers, and brand stores, metal ceiling panels can create a fashionable and modern atmosphere. By using different styling designs and surface treatments (such as spraying, anodizing, drawing, etc.), the overall decoration style of the mall can be matched, enhancing the level and attractiveness of the commercial space.

In office buildings, metal ceiling panels not only have good decorative effects, but also have certain functionality. It can be integrated and installed with air conditioning and lighting systems, hiding pipelines to keep the ceiling clean and orderly. At the same time, it has a certain sound insulation and thermal insulation effect, creating a comfortable working environment for office workers.

In transportation hubs such as airport terminals, train station waiting halls, subway platforms, etc., where there is a high flow of people, the durability and safety requirements for suspended ceilings are extremely high. The metal ceiling panel forming machine produces ceiling panels with high strength and good impact resistance, which can withstand the pressure caused by long-term use and personnel activities. At the same time, it has fire and moisture resistance properties, ensuring the safe operation of transportation hubs.

In addition, metal ceiling panels have become an ideal choice for decoration and decoration in cultural and sports venues (such as sports halls, exhibition halls, theaters, etc.), hotels, restaurants, and other places due to their unique advantages, adding a unique charm to these places.

The metal ceiling panel forming machine, with its efficient production capacity, precise forming accuracy, and wide applicability, has become an indispensable and important equipment in the building decoration industry. It not only promotes the diversification and high-quality development of metal ceiling products, but also provides unlimited possibilities for the aesthetic design and functional realization of modern building roofs, helping to create more architectural spaces that are both beautiful and practical.