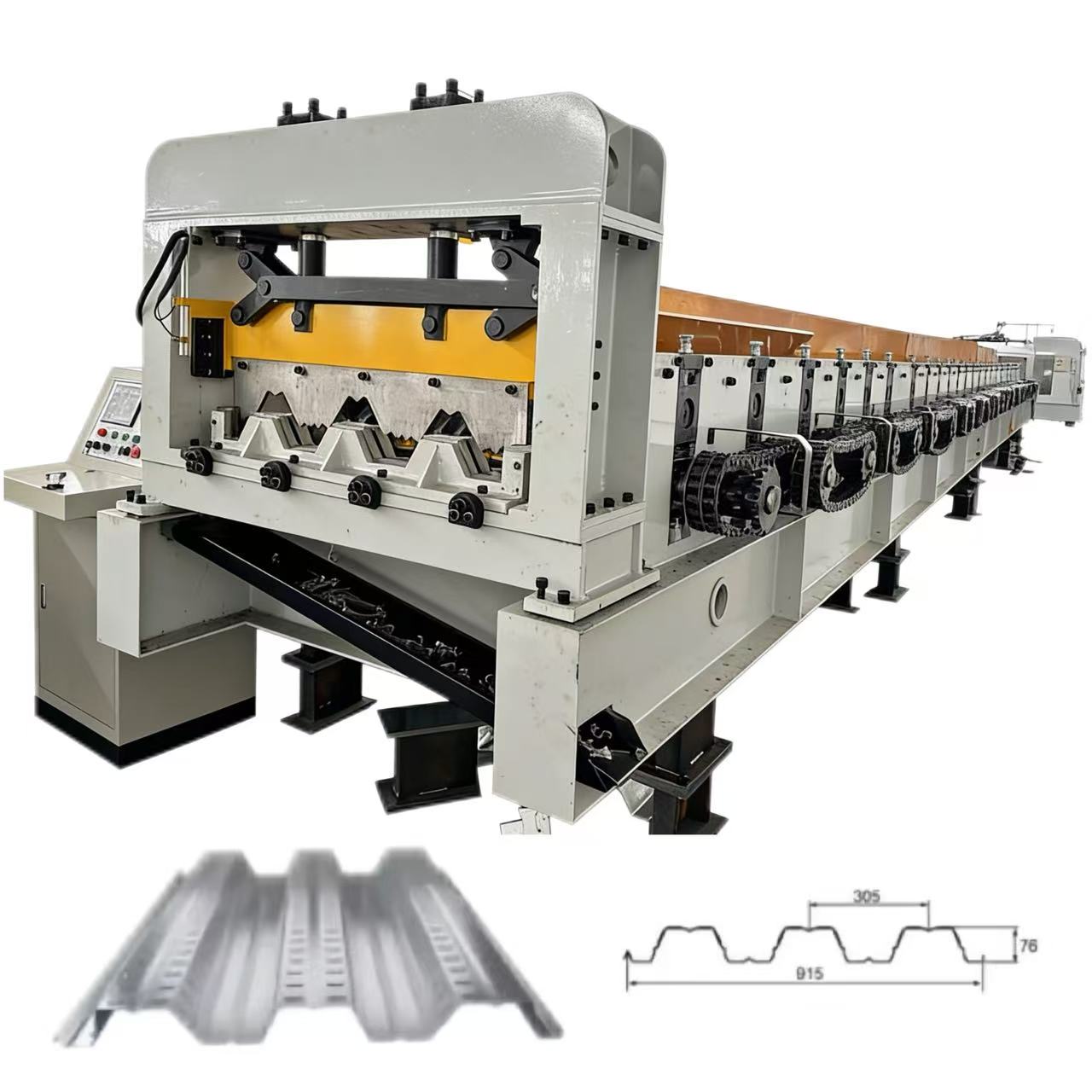

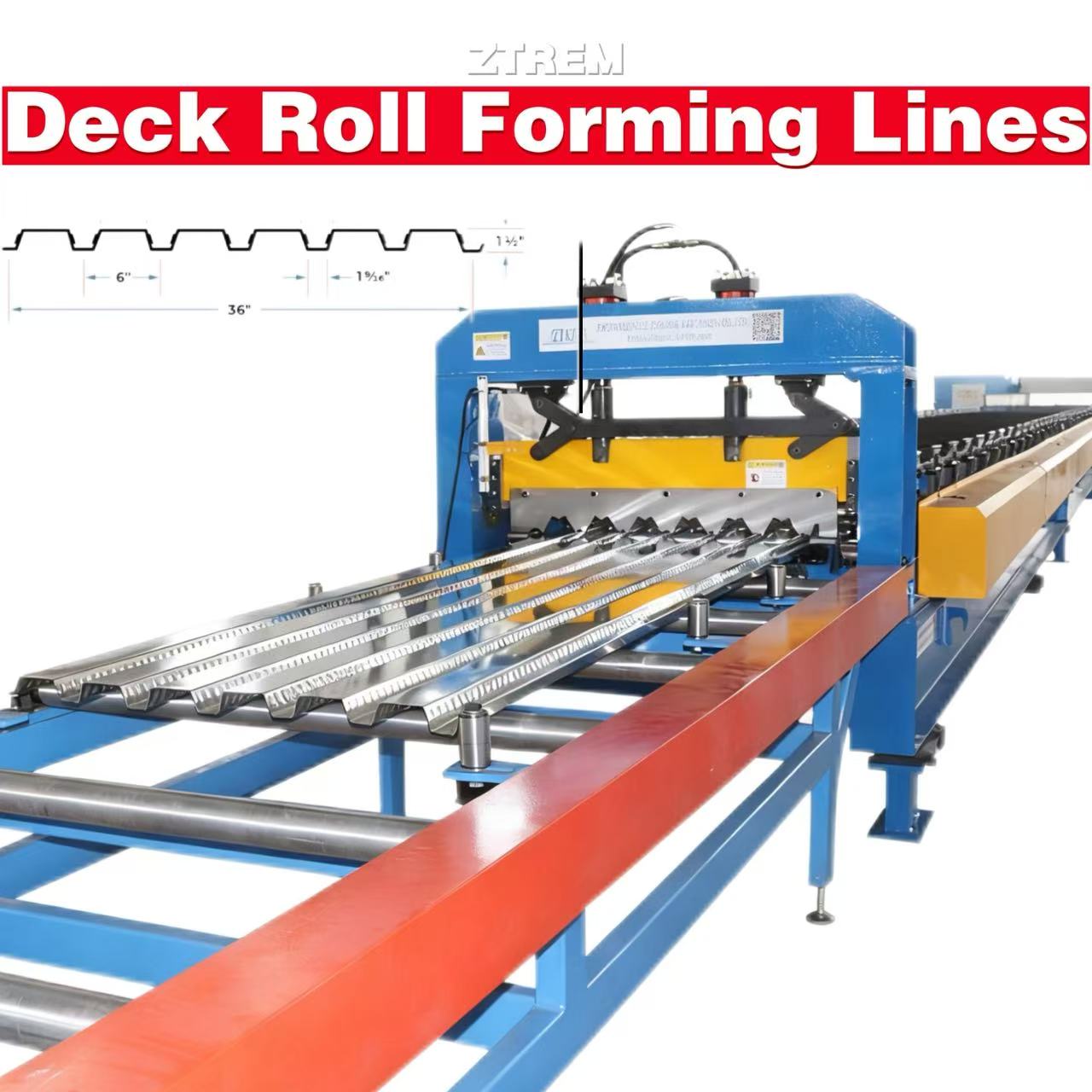

In today’s thriving era of prefabricated construction, steel deck plates, as the core components of steel structure buildings, directly determine project timelines and engineering safety through their production efficiency and quality. The new generation of Metal Deck Floor Roll Forming Machine Steel Structure Floor Decking Making Machine breaks through traditional production bottlenecks with technological innovation, injecting robust productivity power into your enterprise!

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.7-1.6mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

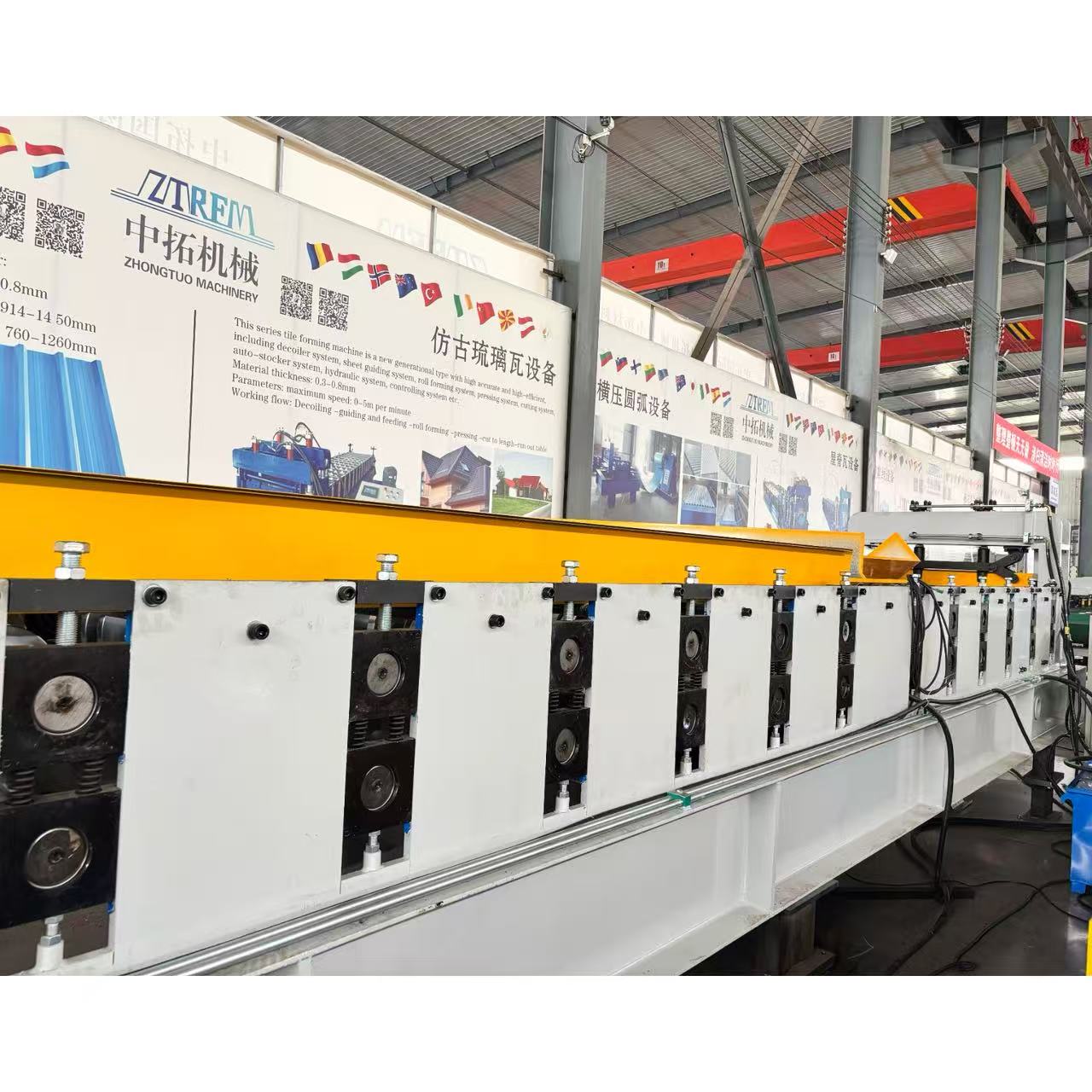

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600(customize)

|

|||

|

Weight

|

8T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

30KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Core strengths forge industry benchmarks

1.Ultra-high production capacity, efficiency doubled

Employing an integrated molding process, the system can produce up to 12 meters of floor decking per minute, with a daily output exceeding 8,000㎡. Compared to traditional equipment, it achieves over 50% improvement. Eliminating secondary processing, the one-step molding directly interfaces with construction, significantly shortening project cycles and enabling you to gain a competitive edge in scheduling.

2.Precision craftsmanship, zero tolerance for quality errors

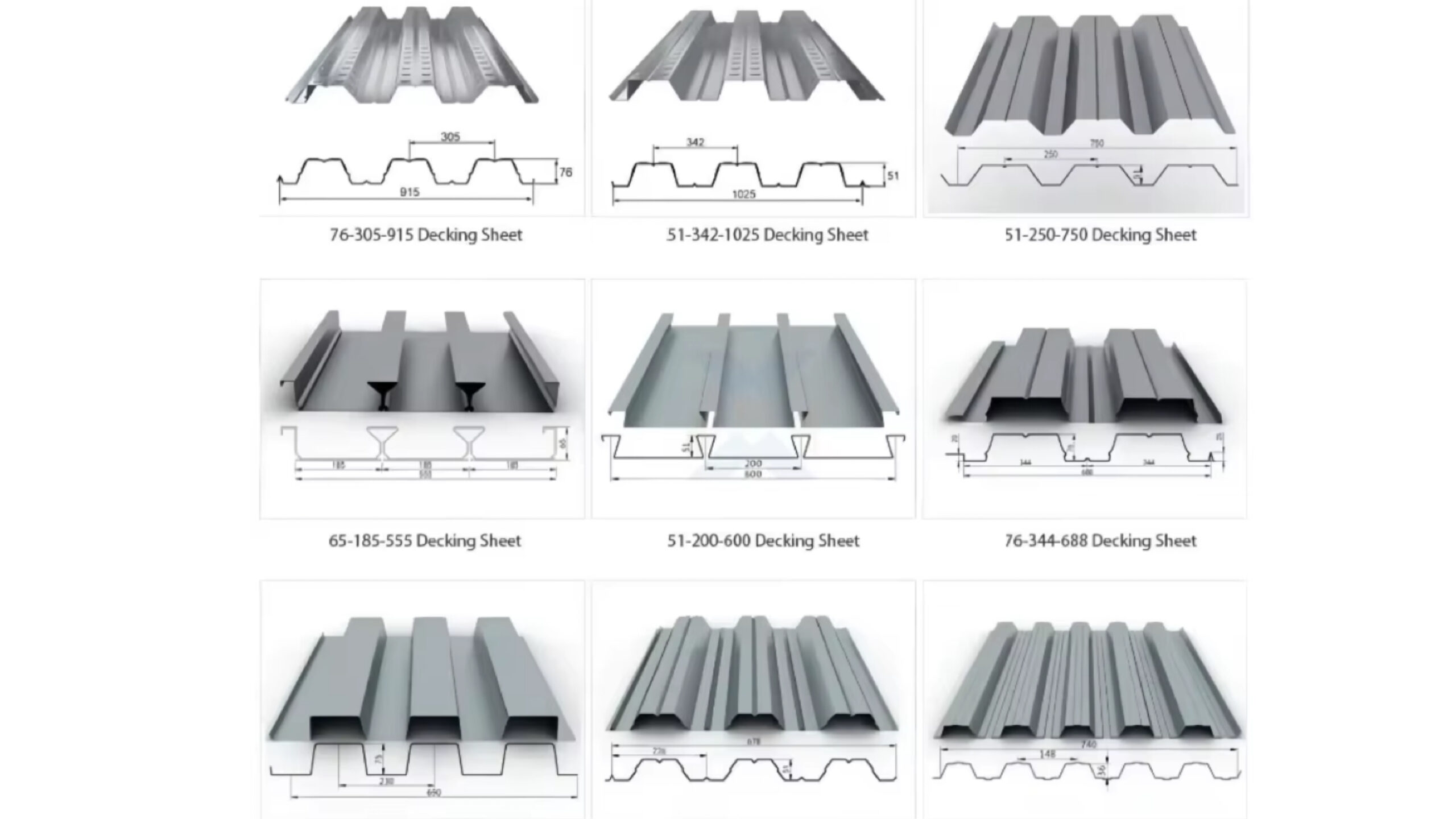

Equipped with an imported servo control system, the roller shaft accuracy error is ≤0.1mm, with plate flatness and bite sealing far exceeding industry standards. Compatible with the full range of floor deck models such as YXB51-305-915 and YXB65-185-555, it meets the requirements of various scenarios including industrial plants, high-rise buildings, bridges, and tunnels, ensuring every sheet of material withstands engineering inspection.

3. Intelligent control, lowering the threshold

7-inch touch display screen + PLC intelligent programming, parameter presetting, one-click startup, allowing ordinary workers to operate in just 30 minutes. Supports remote fault diagnosis and real-time production data statistics, reducing manual intervention and lowering operational costs, making production management more efficient and hassle-free.

4. Durable and sturdy, with stable output

The body is welded from 16mm thick steel plate, and the roller shaft is precision-machined from 45# tempered steel, treated with high-frequency quenching for wear and pressure resistance, with a service life exceeding 10 years. It is equipped with an independent hydraulic pump station and an overload protection system, enabling continuous 24-hour operation without pressure to ensure uninterrupted project production.

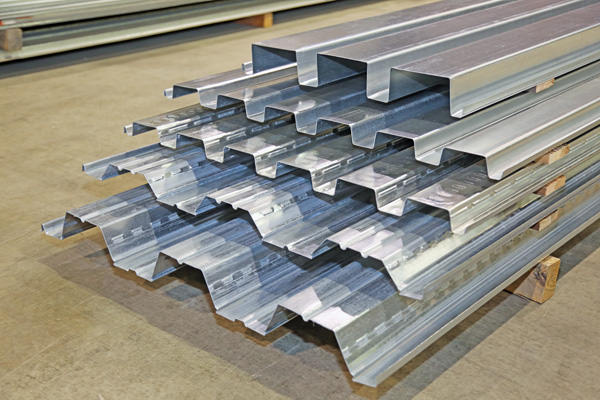

Application fields:

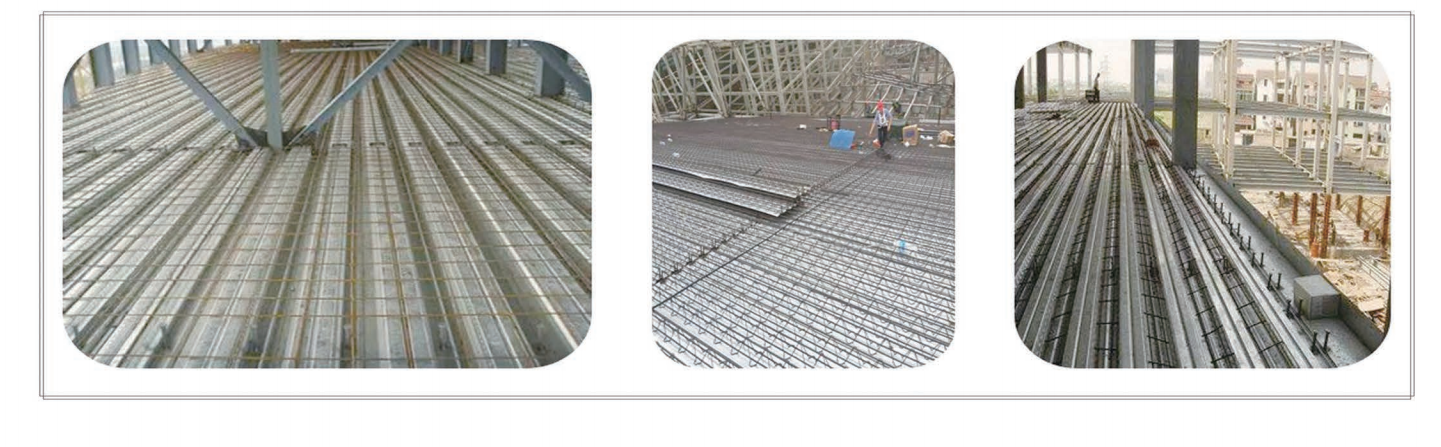

• Multi story and high-rise steel structure buildings:

The products produced by the floor slab machine have the characteristics of light weight, high load-bearing capacity, and good performance, and are widely used in multi story and high-rise steel structure buildings.

• Construction phase:

During the construction of the project, the steel truss floor support plate can support the building materials and the pressure generated during construction, providing a firm working platform. Multiple floors can be used to lay profiled steel plates and pour concrete slabs in layers for continuous construction.

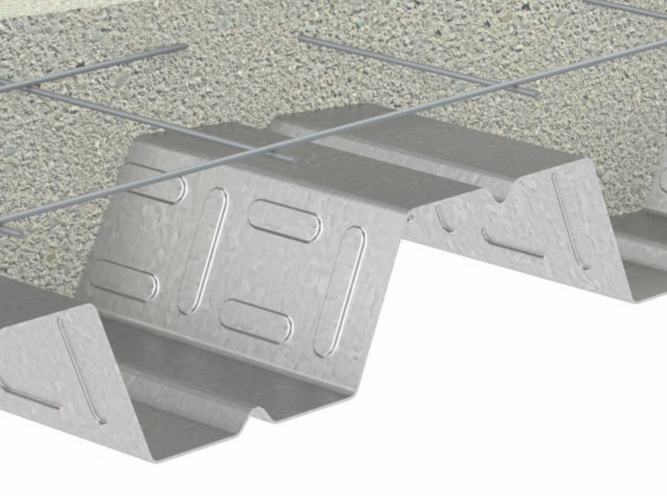

• Usage stage:

During the usage stage, the floor slab serves as the tensile steel reinforcement for the concrete floor slab, which increases the stiffness of the floor slab and saves the amount of steel and concrete used. The surface embossing of the profiled plate creates a bonding force between the floor slab and the concrete, forming a cohesive whole.

• Large scale construction projects:

Closed end floor support equipment is suitable for construction scenarios, especially for floor support in large-scale construction projects. It can quickly and safely build floor support systems, reduce the labor intensity of construction personnel, and improve construction efficiency.

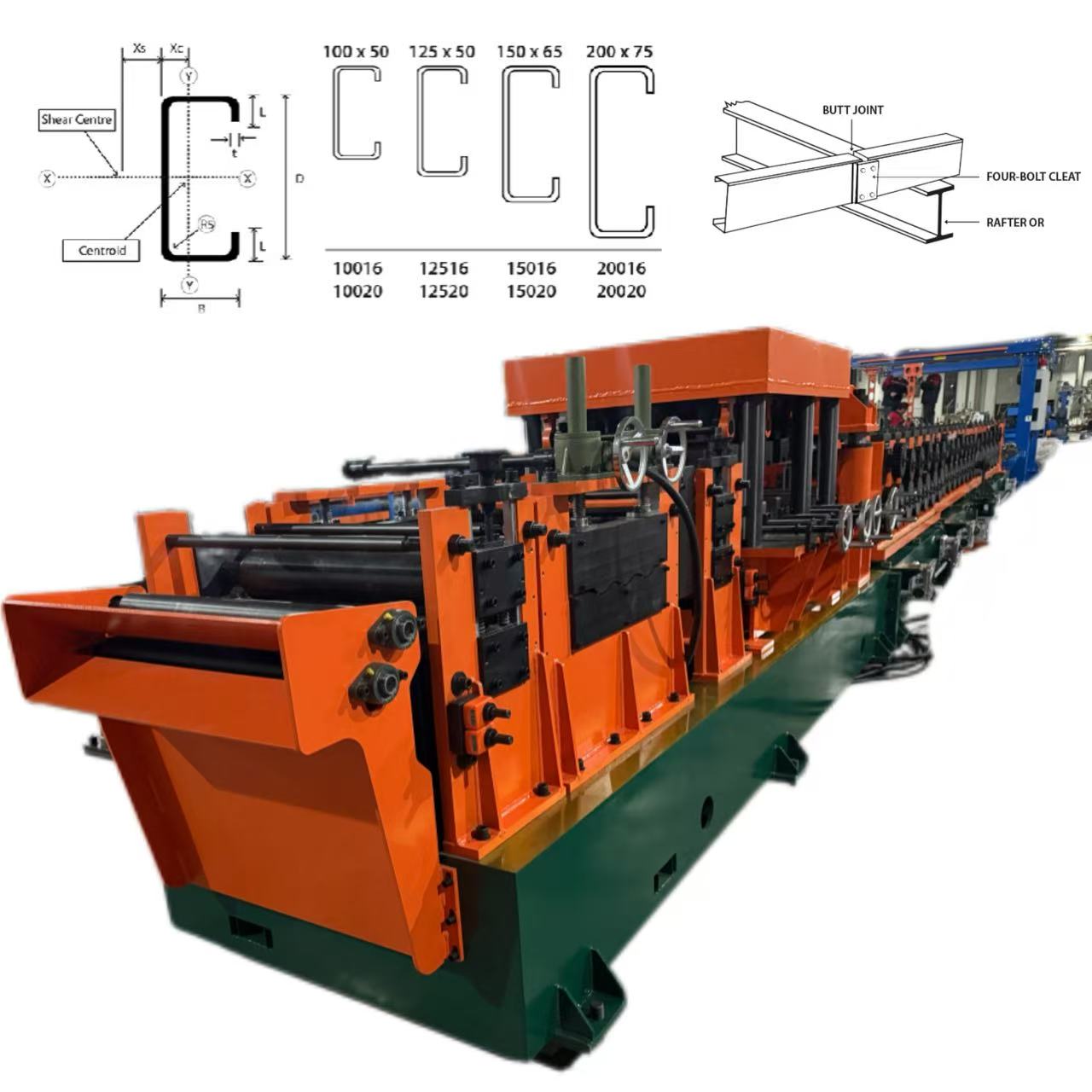

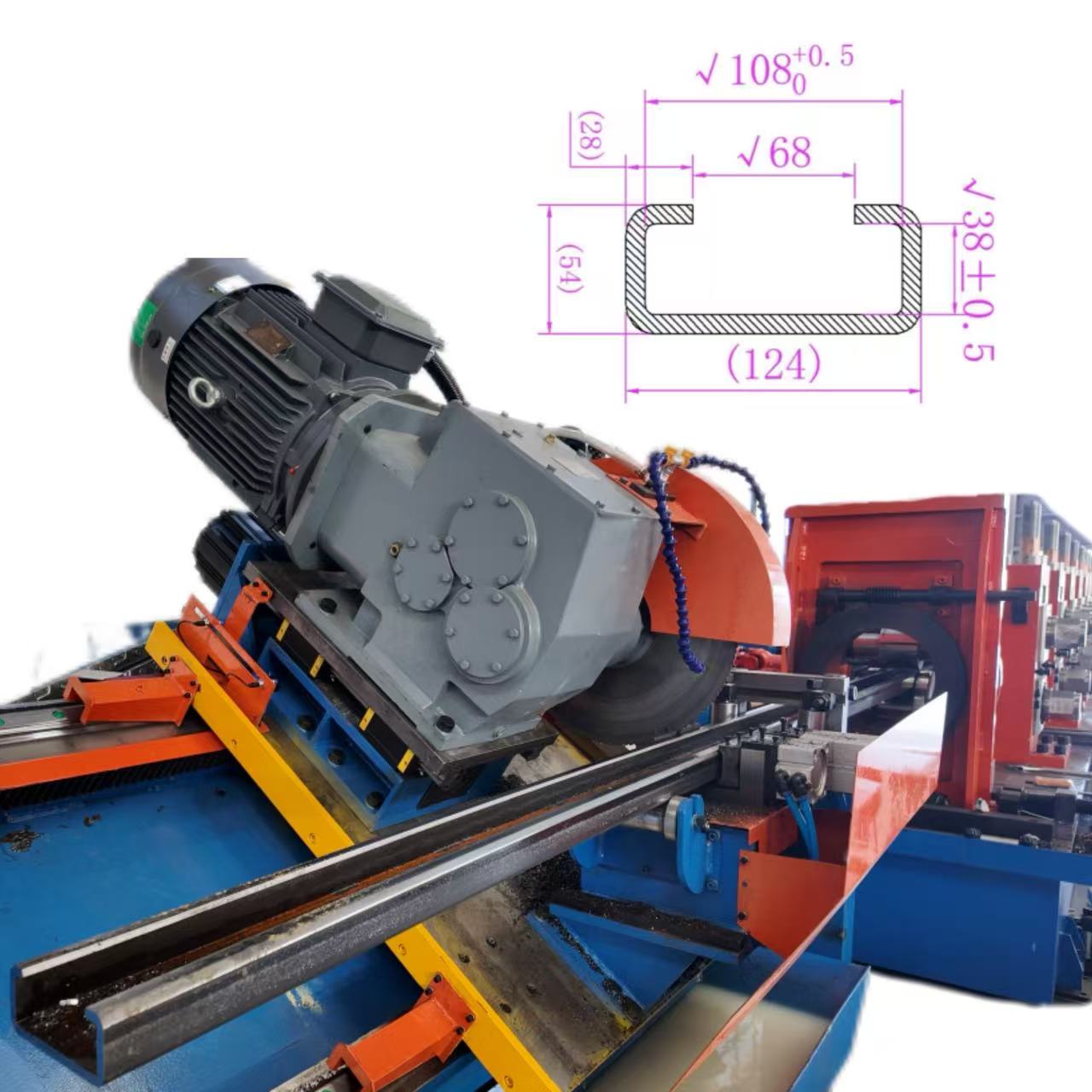

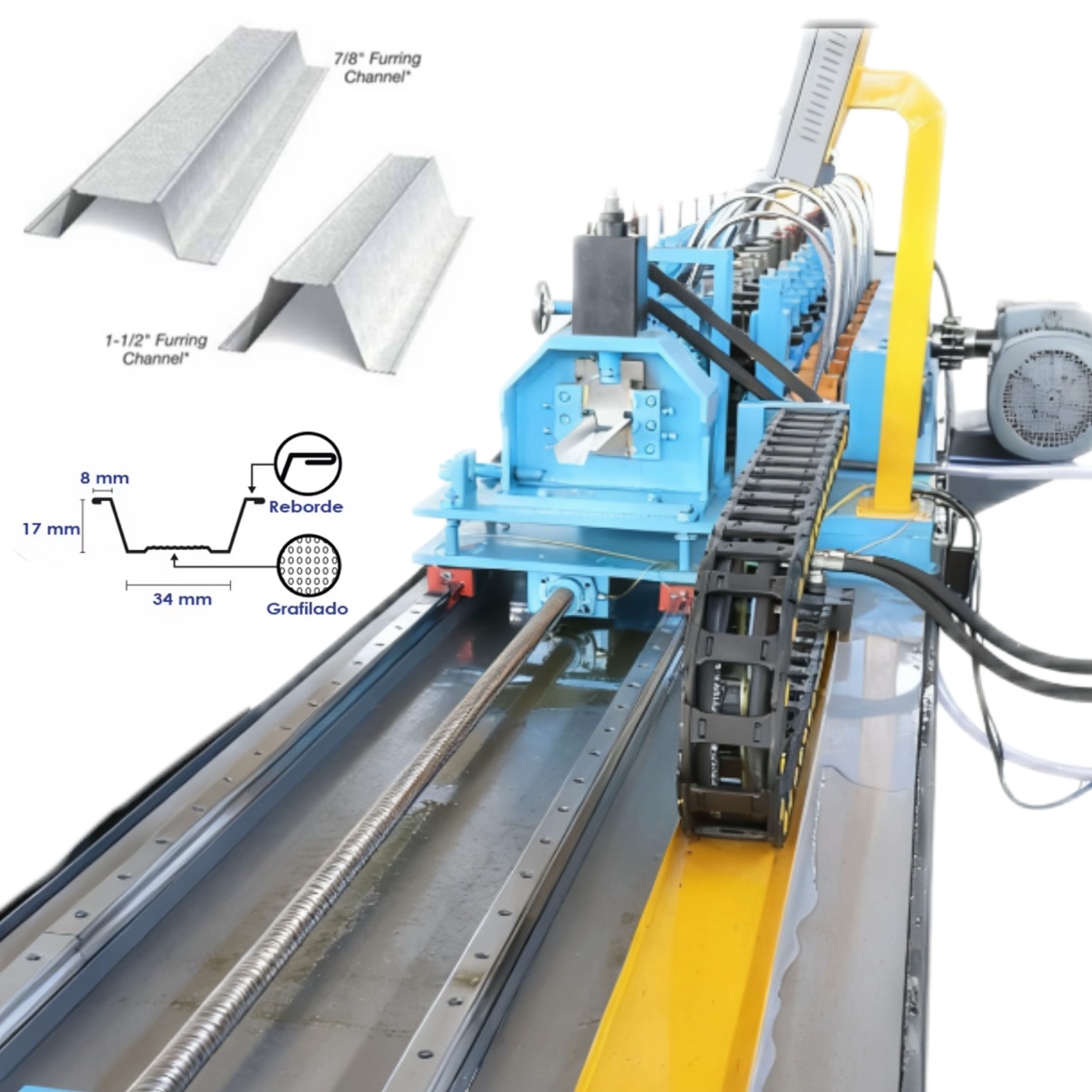

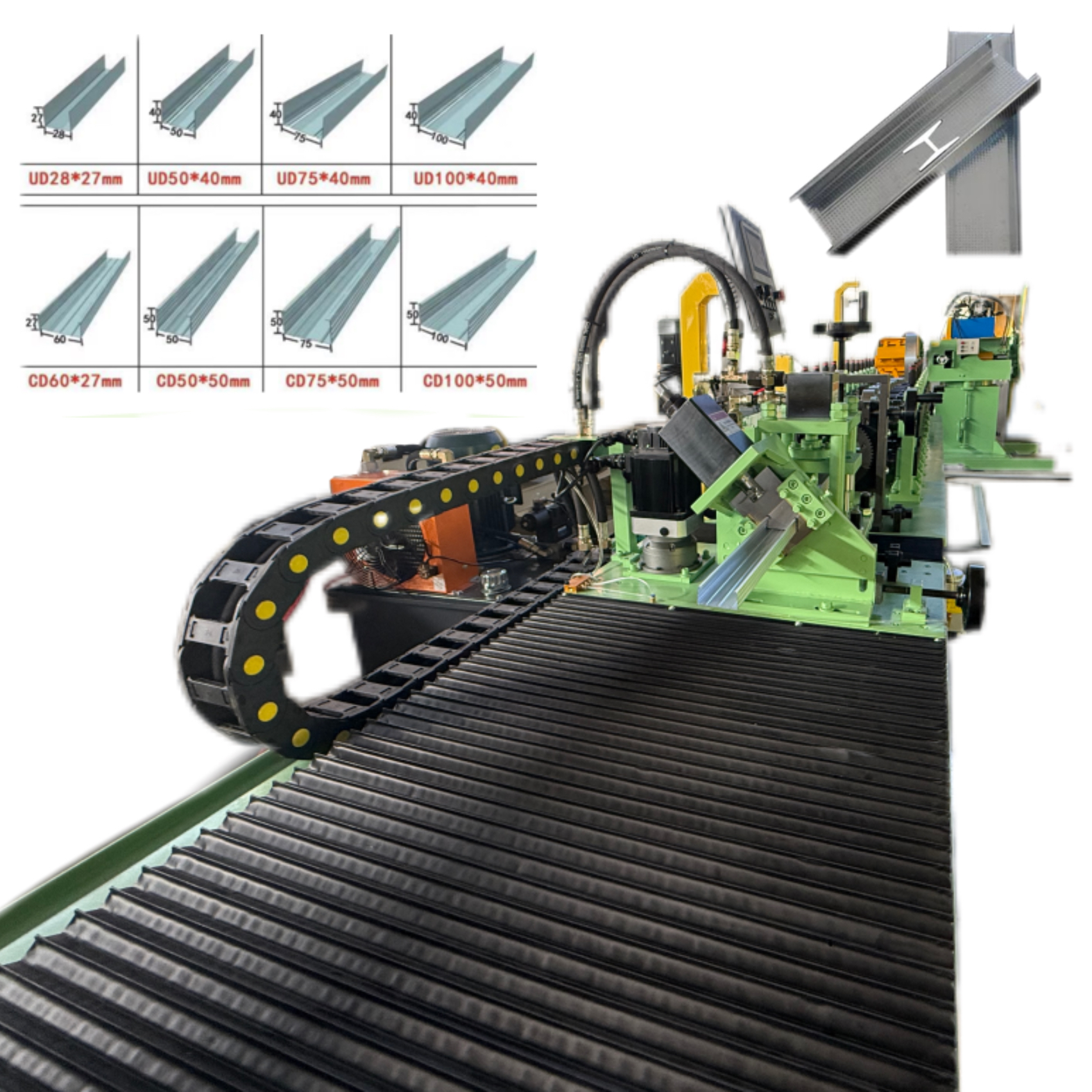

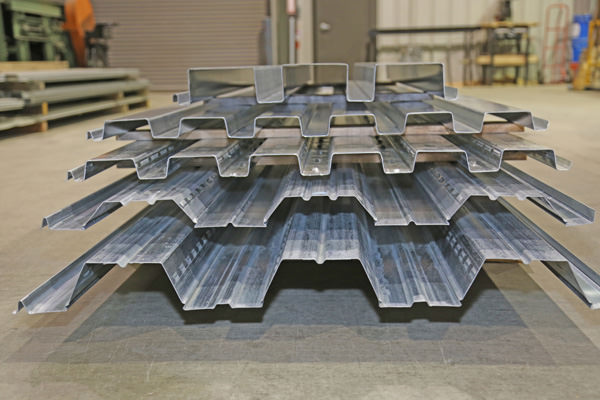

Pattern diagram:

Choosing us is not just a machine, but a complete solution

✔️ Lifetime technical support+regular on-site maintenance and upkeep

✔️ 24-hour nationwide after-sales service response, fast delivery of accessories

✔️ Support customized production to meet the processing needs of special specification floor slabs