The metal glazed roof panel cold roll forming machine is an efficient and environmentally friendly production equipment, mainly used for producing imitation resin glazed tiles, with characteristics of high efficiency, precision, safety, and reliability. The machine mainly consists of three parts: roller forming, pressing, and cutting blades. The roller forming part is driven by a motor and driven by a chain to rotate each roller; The molding part is driven up and down by a hydraulic cylinder to press the raw material into a multi section shape; The cutting part uses a hydraulic cylinder to move the cutting tool up and down, achieving fixed length cutting of tiles. This design makes the production process orderly. The raw materials are first formed by the roller conveyor, then pressed into equidistant sections by the pressing part, and finally cut to a fixed length by the cutting blade part.

Application scenarios:

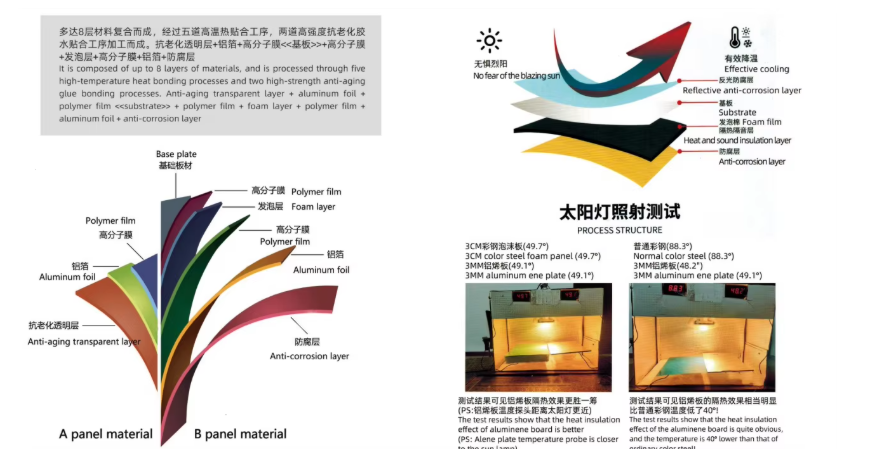

The tiles produced by the metal glazed roof panel cold roll forming machine have various advantages, such as diverse colors, good surface gloss, corrosion resistance, acid and alkali resistance, aging resistance, good impact resistance, thermal insulation, sound insulation, etc. At the same time, it is easy to install, environmentally friendly and clean, and can be recycled and reused. These tiles are widely used in various building scenarios, including roofs, high-rise steel structures, etc.

Product features:

- Appearance:

Adopting antique glass craftsmanship, the appearance is beautiful and traditional. - Performance:

waterproof, fireproof, weather resistant, corrosion resistant, anti-aging, heat insulation, sound insulation and other characteristics. - Environmental Protection:

Easy to install, environmentally friendly and clean, and recyclable.

Product Attributes :

1.Formed MaterialPPGI,GI,AIThickness:0.3-1.0mm2.Main bodyRaw material coilPPGI,GI,SSCoil width200-2000mm customized as requestCapacity5-30THydraulic power4 kwMotor power7.5 kwPress armTo keep the coil from loosingBraking systemPnuematic3.Voltage380V 50Hz 3PhaseAs your requirement4.Forming Speed0-40m/minMatch with the mail machineProducts Display:

Here is the working video of this machine for everyone to watch: