Product Introduction:

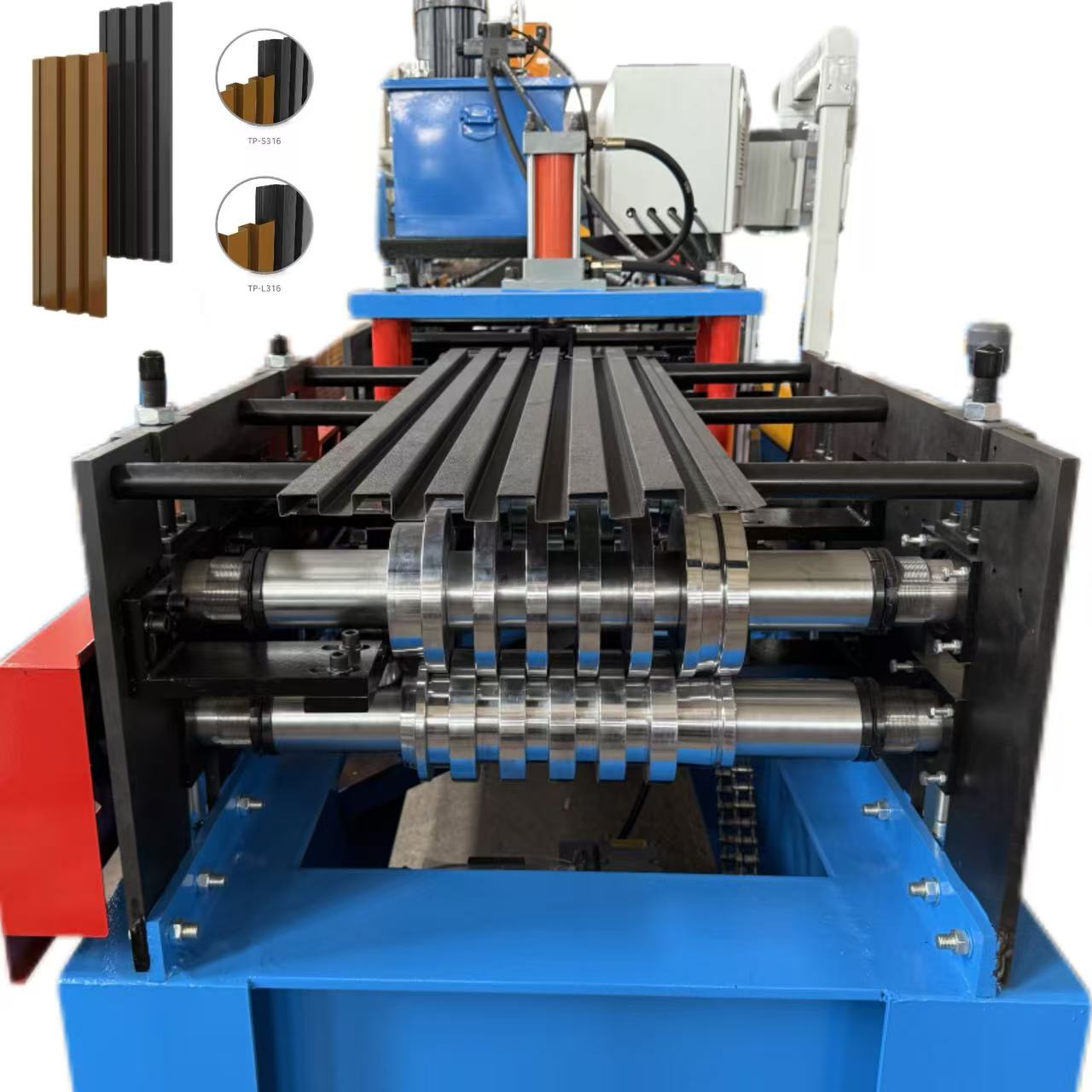

Roof ridge tile equipment, like the ingenuity creator of architectural aesthetics and practical function, is a precision molding equipment specially designed for carving the roof backbone of buildings. He is active in the roof field of various buildings such as modern buildings with steel structures and traditional buildings cast in concrete, and reshapes the contours of buildings with exquisite craftsmanship. When working, it transforms metal color steel plates, aluminum plates, or non-metallic cement and resin into unique tiles with both sealing and decorative functions through mechanized artistic creation, and puts gorgeous and practical armor on the backbone of the building.

The operation of the equipment is like a wonderful variation on materials. Raw materials such as smart dancers step into the art palace of rolling and stamping in turn in the form of coils or plates. Under the carving of precise processes, they fade away from their original form and transform into ridge tile shapes that conform to the ingenuity of design, or elegant arcs like crescent moons, or triangles as stable as mountains, or regular trapezoids like steps. These ingenious tiles can fit the ridge structure tightly, build a strong barrier of waterproof and windproof in silent places, become loyal guardians of the roof, and give the building enduring vitality.

Product Attributes :

|

Formed Material

|

PPGI, GI, AI

|

Thickness:0.3-0.8mm

|

|

Decoiler

|

Hydraulic automatic decoiler

|

manual decoiler (will give you as free)

|

|

Main body

|

roller station

|

13 rows (as your requirement)

|

|

diameter of shaft

|

70mm solid shaft

|

|

|

material of rollers

|

45# steel, hard chrome plated on the surface

|

|

|

machine body frame

|

350 H steel

|

|

|

drive

|

chain transmission

|

|

|

dimension(L*W*H)

|

5500mm*1600mm*1600mm (customized)

|

|

|

weight

|

2.5T

|

|

|

Cutter

|

automatic

|

Cr12mov material, no scratches, no deformation

|

|

Power

|

motor power

|

4kW

|

|

hydraulic system power

|

3KW

|

|

|

Voltage

|

380V 50HZ 3PH

|

as your requirement

|

|

Control system

|

electric box

|

customized (famous brand)

|

|

language

|

English (support multiple languages)

|

|

|

PLC

|

automatic production of the whole machine. can set batch, length, quantity, etc

|

|

|

3-5m/min

|

The speed depends on the final cutting length

|

Significant advantages:

1.Efficient production:

The production efficiency of ridge tile equipment is remarkable. Taking metal ridge tile equipment as an example, its production speed can reach several meters per minute, which greatly shortens the production cycle compared with traditional production methods and can meet the urgent needs of large-scale building construction. For example, in the construction projects of some large industrial parks, the roofing projects of many factories require a large number of ridge tiles, and the ridge tile equipment can quickly supply the required products and ensure the project progress with its efficient production capacity.

2.Precise molding:

With precision molds and advanced parameter control technology, the equipment ensures that the dimensional accuracy and shape consistency of each ridge tile meet extremely high standards. Whether it’s regular standard-sized ridge tiles or special-shaped ridge tiles tailored to special architectural design requirements, they can be precisely built. This high-precision production capacity makes the installation of ridge tiles smoother and the splicing tighter during the roof construction process, effectively improving the overall quality and aesthetics of the roof.

3.Stable operation:

Many ridge tile equipment adopts a mid-plate structure design. This design method is to select high-strength steel plates of moderate thickness from the fuselage frame and molding mechanism support parts of the equipment and build them by integral welding or assembly. The middle plate structure greatly enhances the rigidity and deformation resistance of the main body of the equipment, and can effectively offset the vibration and stress generated by material conveying, roll pressing or die stamping during the production process. This avoids the occurrence of body shaking or component displacement, thereby ensuring that the raw materials are always accurately positioned during the molding process, and reducing quality problems such as tile size deviation and surface scratches caused by unstable equipment operation. Even in a long-term continuous production state, the equipment can maintain smooth operation, providing a solid guarantee for the production of high-quality ridge tiles.

Unique characteristics:

1.Flexible customization:

Different construction projects have very different roof slopes, ridge types and design styles, and the specifications and style requirements for ridge tiles are also different. The ridge tile equipment has strong customization capabilities, and the production parameters can be flexibly adjusted according to specific project needs. Whether it is the standard-size ridge tiles commonly found in conventional buildings or the special-shaped special-designed ridge tiles required in some characteristic buildings and landmark buildings, the equipment can easily cope with them and produce products that perfectly fit various building structures. This high degree of flexibility provides architectural designers with a wide creative space, allowing them to unleash their imagination and create unique and personalized architectural roofs.

2.Diverse material adaptation:

The equipment can not only process metal sheets, but also mold non-metallic materials such as cement and resin. Ridge tiles of different materials have their own unique performance advantages. Metal ridge tiles, such as color steel ridge tiles, have excellent strength, wind resistance, and compressive performance, and are widely used in industrial plants, warehouses and other buildings with high roof structural strength. Ridge tiles made of cement and resin have excellent performance in waterproofing, heat insulation, sound insulation, etc., and are often used in villas, resorts, large public buildings and other projects that focus on living comfort and architectural aesthetics. The adaptability of the equipment to various materials meets the diverse needs of different building scenarios for the performance of ridge tiles.

3.Intelligent control:

Modern ridge tile equipment is equipped with advanced intelligent control systems, achieving a high degree of automation and precision in the production process. Operators only need to enter relevant parameters on the control interface, and the equipment can automatically complete a series of complex processes such as raw material transportation, processing, molding and shearing. The intelligent control system also has powerful fault diagnosis and early warning functions, which can monitor the operating status of equipment in real time. Once a potential problem is found, the system will issue an alarm in time and provide detailed fault information, which is convenient for maintenance personnel to quickly locate and solve the problem, greatly improving the reliability and maintenance efficiency of the equipment, reducing equipment downtime, and ensuring the continuity of production.

4. Wide application:

1.Industrial construction:

In industrial plants, warehouses and other industrial buildings, the products produced by metal ridge tile equipment have become the first choice for roofing projects due to their outstanding advantages such as high strength and convenient installation. Industrial buildings are usually large and have high requirements for the bearing capacity and stability of the roof, and metal ridge tiles can meet these needs well. At the same time, its rapid installation characteristics can effectively shorten the construction period, reduce construction costs, and create conditions for the early commissioning of industrial projects.

2.Civil construction field:

In civil buildings such as villas and residential communities, ridge tiles of various materials and styles produced by roof tile equipment play an important role in improving the aesthetics and living comfort of buildings. For example, some European-style villas often use antique ridge tiles made of cement or resin, which not only have good waterproof and thermal insulation properties, but also create an elegant and solemn architectural atmosphere, which complements the overall style of the villa. In residential communities, ridge tiles with rich colors and diverse shapes can add unique charm to the building complex and enhance the overall quality of the community.

3.In the field of public buildings:

In large-scale public buildings, such as stadiums, exhibition halls, airport terminals and other projects, ridge tile equipment also plays an important role. These buildings usually have extremely high requirements for waterproof, windproof, sealing performance and aesthetics of the roof. The high-quality ridge tiles produced by the roof shingle equipment ensure that the roof always maintains good performance under various adverse weather conditions. At the same time, through customized production, according to the unique design of the building, the ridge tile shape that integrates with the overall style of the building can be created, so that the public building can show its unique artistic charm while meeting the functional needs.