In today’s rapidly developing building materials industry, ridge tiles, as the “finishing touch” of house roofs, not only carry practical functions of waterproofing and wind resistance, but also become a key element in showcasing architectural style. However, in the traditional production process of roof tiles, pain points such as low efficiency, poor accuracy, high energy consumption, and high labor costs have always constrained the development of enterprises. How to break through production bottlenecks and achieve large-scale and high-quality production of roof tiles? The emergence of Zhongtuo Intelligent Roof Tile Equipment has brought a new solution to the industry!

Product Attributes :

|

Formed Material

|

PPGI, GI, AI

|

Thickness:0.3-0.8mm

|

|

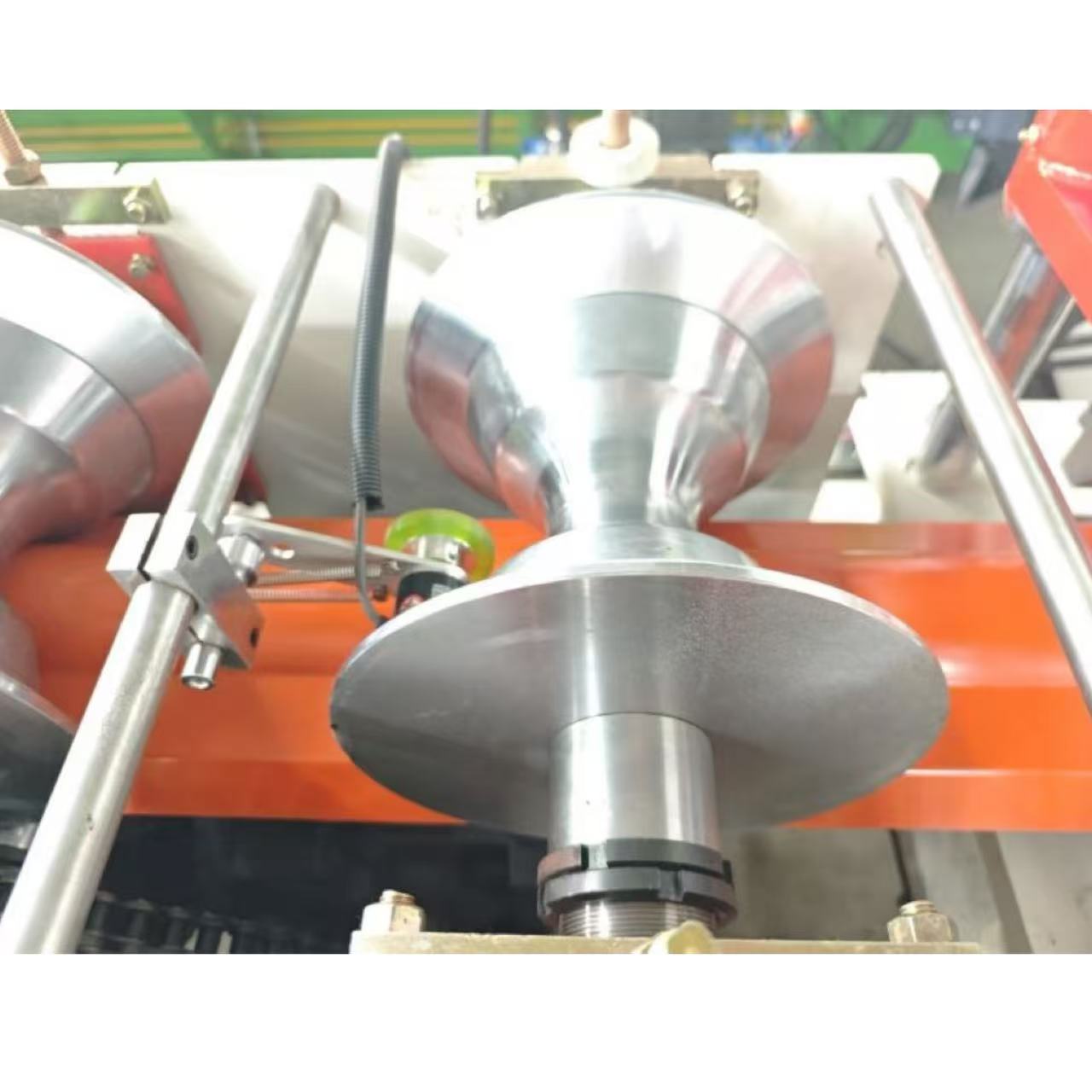

Decoiler

|

Hydraulic automatic decoiler

|

manual decoiler (will give you as free)

|

|

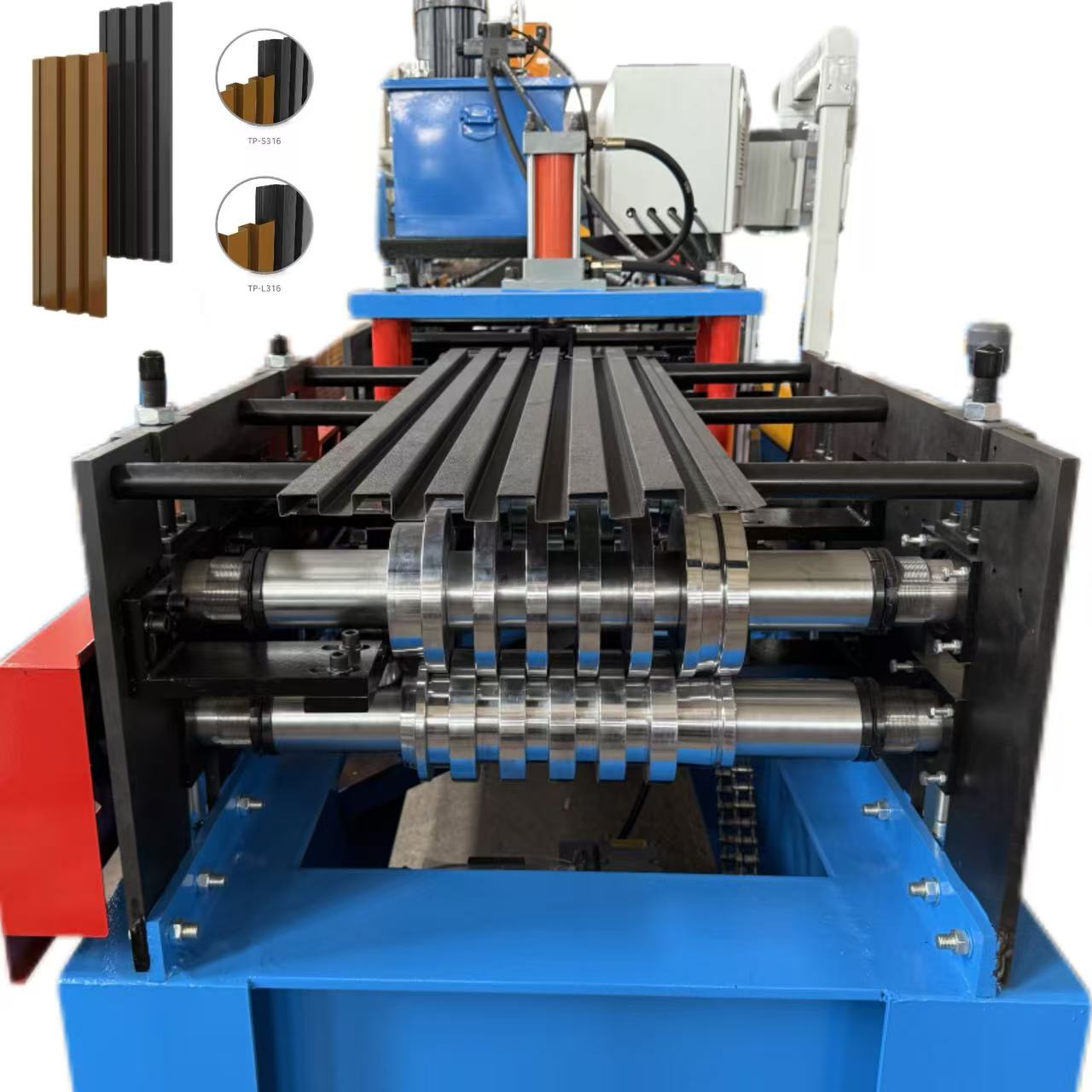

Main body

|

roller station

|

13 rows (as your requirement)

|

|

diameter of shaft

|

70mm solid shaft

|

|

|

material of rollers

|

45# steel, hard chrome plated on the surface

|

|

|

machine body frame

|

350 H steel

|

|

|

drive

|

chain transmission

|

|

|

dimension(L*W*H)

|

5500mm*1600mm*1600mm (customized)

|

|

|

weight

|

2.5T

|

|

|

Cutter

|

automatic

|

Cr12mov material, no scratches, no deformation

|

|

Power

|

motor power

|

4kW

|

|

hydraulic system power

|

3KW

|

|

|

Voltage

|

380V 50HZ 3PH

|

as your requirement

|

|

Control system

|

electric box

|

customized (famous brand)

|

|

language

|

English (support multiple languages)

|

|

|

PLC

|

automatic production of the whole machine. can set batch, length, quantity, etc

|

|

|

3-5m/min

|

The speed depends on the final cutting length

|

Accurately tackling industry pain points and redefining production standards:

Traditional roof tile production relies heavily on semi-automatic equipment, requiring a large amount of manual participation in raw material proportioning, mold adjustment, finished product cutting, and other processes. This not only easily leads to low product qualification rates due to human operation errors (some enterprises even have a qualification rate of less than 85%), but also has problems such as low production efficiency (single shift output of only 300-500 pieces) and high energy consumption. And Zhongtuo Intelligent Roof Tile Equipment has solved these problems from the root through the full process intelligent design:

1.High precision molding with zero quality deviation:

Equipped with imported servo control system and high-precision sensors, the molding error can be controlled within ± 0.5mm. The tile curvature, size, and thickness fully comply with national standards, and the product qualification rate remains stable at over 99%. Whether it’s Chinese classical blue grey tiles, European style colored stone metal tiles, or modern minimalist cement tiles, they can accurately replicate design details to meet diverse architectural needs.

2.Fully automated operation, reducing costs and increasing efficiency:

realizing unmanned operation of the entire process of “automatic feeding of raw materials – proportioning and mixing – pressing and forming – automatic cutting – finished product stacking”, the single shift output has been increased to 1500-2000 pieces, which is more than three times more efficient than traditional equipment. At the same time, reducing labor input by 80% can save enterprises over 200000 yuan in labor costs annually, making production more efficient and worry free.

3.Low consumption and energy-saving design, green and sustainable:

adopting a new type of variable frequency motor and thermal energy circulation system, energy consumption is reduced by 30% compared to traditional equipment, and producing 1000 roof tiles can save about 80 yuan in electricity bills. The noise level during equipment operation is below 65 decibels, which meets environmental protection requirements and helps enterprises achieve green production, responding to the national “dual carbon” call.

Hardcore configuration+flexible adaptation to meet diverse production needs:

Zhongtuo Intelligent Roof Tile Equipment not only has outstanding performance, but also has strong adaptability, which can be flexibly adjusted according to the production needs of enterprises, truly achieving “one machine for multiple uses, customized according to needs”:

1.Multi material compatibility:

It can easily handle various roof tile materials such as cement, colored sand, metal, resin, etc. Whether producing traditional thick cement roof tiles or lightweight and durable metal roof tiles, the equipment can operate stably without frequent mold replacement.

2.Customized molds:

We provide exclusive mold design services and can customize ridge tile molds of different specifications and shapes (such as circular, square, curved, carved, etc.) according to customer needs, to meet the roof decoration needs of different scenarios such as villas, villas, ancient buildings, and new rural residences.

3.Intelligent control system:

equipped with a 7-inch touch screen, easy to operate, and workers only need simple training to get started. The system can monitor production data in real-time (such as output, temperature, pressure, etc.) and automatically warn of equipment failures, reducing downtime and ensuring production continuity.

Strength escorts, making cooperation more reassuring:

Choosing Zhongtuo Intelligent Roof Tile Equipment is not only about choosing an efficient production tool, but also about choosing a comprehensive service guarantee. We always prioritize customer satisfaction and provide one-stop thoughtful services from equipment selection to after-sales maintenance

1.Free on-site planning:

A professional team provides free on-site inspections of production sites. Based on factors such as enterprise production capacity, raw material types, and site area, we tailor equipment placement plans and production process planning to ensure rapid equipment production.

2.Full process technical training:

After the equipment is delivered, professional technical personnel will be arranged to provide on-site operation and maintenance training to ensure that enterprise employees are proficient in equipment operation skills and daily maintenance methods.

3.24-hour after-sales response:

Establish a comprehensive after-sales service system, answer customer questions online 24 hours a day, and if equipment malfunctions, nearby service outlets can come to repair within 48 hours to minimize business losses.

4.Lifetime technical upgrade:

Provide lifelong technical support to cooperative customers, and enjoy priority services for subsequent equipment upgrades and process optimization, ensuring that the enterprise always stays at the forefront of ridge tile production technology.

From traditional manual labor to intelligent production, from low efficiency to excellent quality, Zhongtuo Intelligent Roof Tile Equipment is driving the transformation and upgrading of the roof tile industry. Whether you are a small processing plant just starting out or a large building materials enterprise seeking to expand production, we can provide you with the most suitable production solutions to help you seize the opportunity in the fierce market competition and win more business opportunities!