In the field of contemporary architecture, as the concept of sustainable development gains deeper understanding and green building standards become increasingly stringent, traditional roofing materials can no longer meet the demands of high energy efficiency, environmental protection, and durability. The emergence of Metal Roofing Double Layer Trapezoidal Sheets Roll Forming Machine has become one of the key technologies driving the transformation and upgrading of the construction industry. Through innovative design, this type of equipment achieves a perfect integration of high production efficiency, lightweight products, and structural optimization, offering revolutionary solutions for industrial plants, sports venues, commercial complexes, and residential projects.

Product Attributes:

| 1.Formed Material | PPGI,GI | Thickness:0.4-0.7mm | ||

| 2.Decoiler | Hydraulic decoiler | 3 tons | ||

| 3.Main body | Roller station | 17+18rows(As your requirement) | ||

| Diameter of shaft | 80mm solid shaft | |||

| Material of rollers | 45# steel,with quenched and tempering | |||

| Machine frame | 350mm H | |||

| Drive | Chain transmission | |||

| Dimension(L*W*H) | 9500*1600*1600mm | |||

| Weight | 7.5T | |||

| 4.Cutter | Automatic | Gcr12 steel | ||

| 5.Power | Motor Power | 7.5KW | ||

| Hydraulic system power | 5.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | Support multiple languages | |||

| PLC | Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 15-20m/min | The speed is adjustable | ||

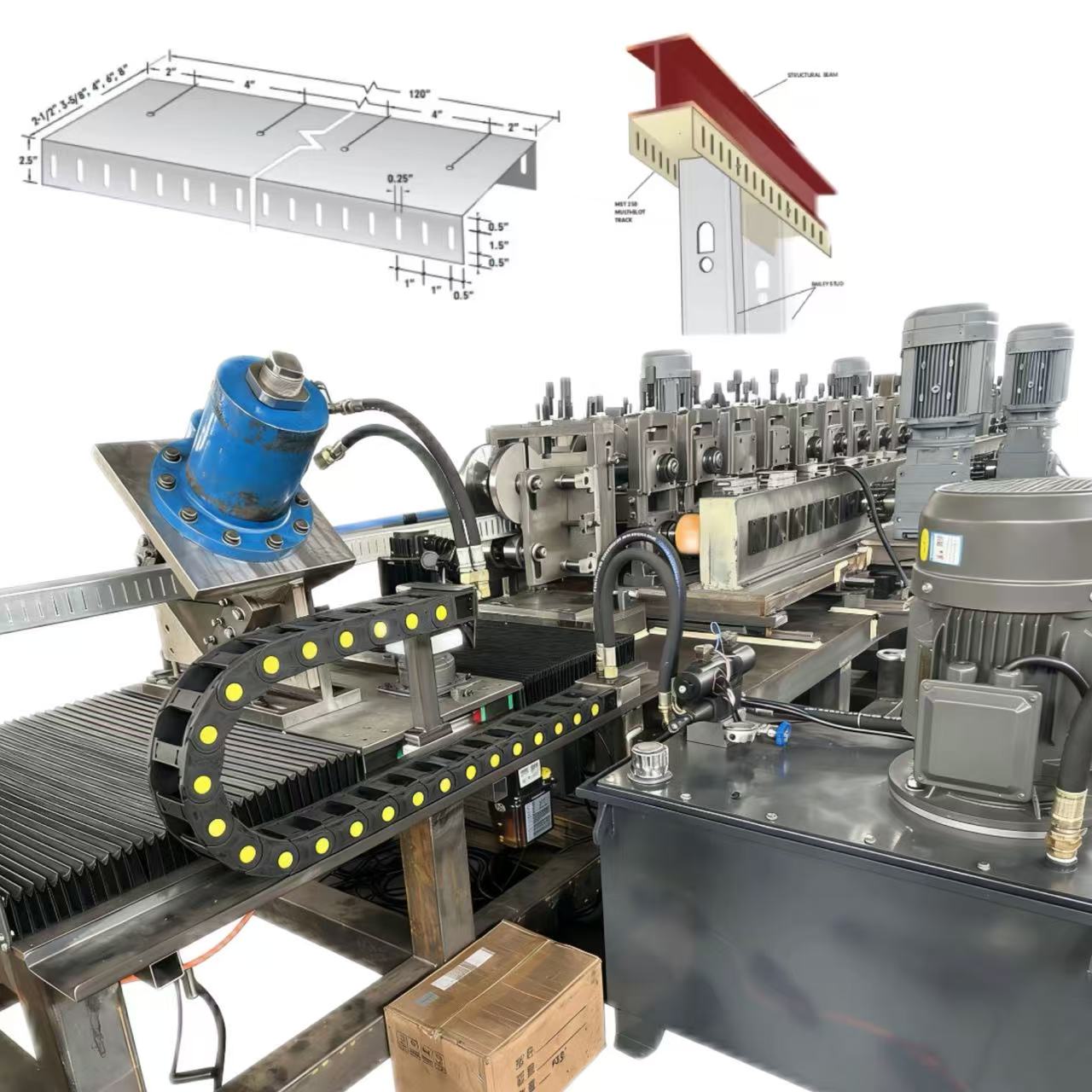

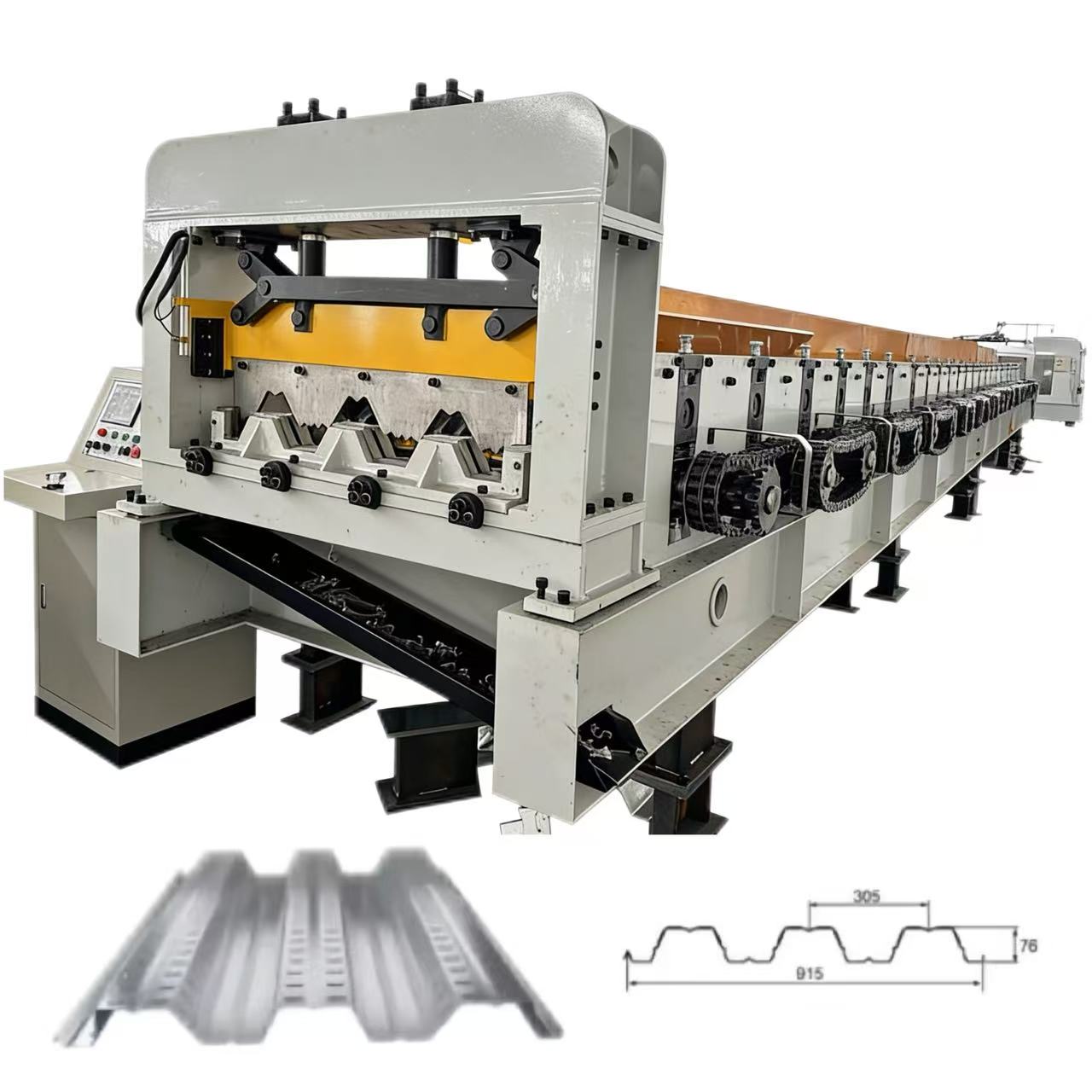

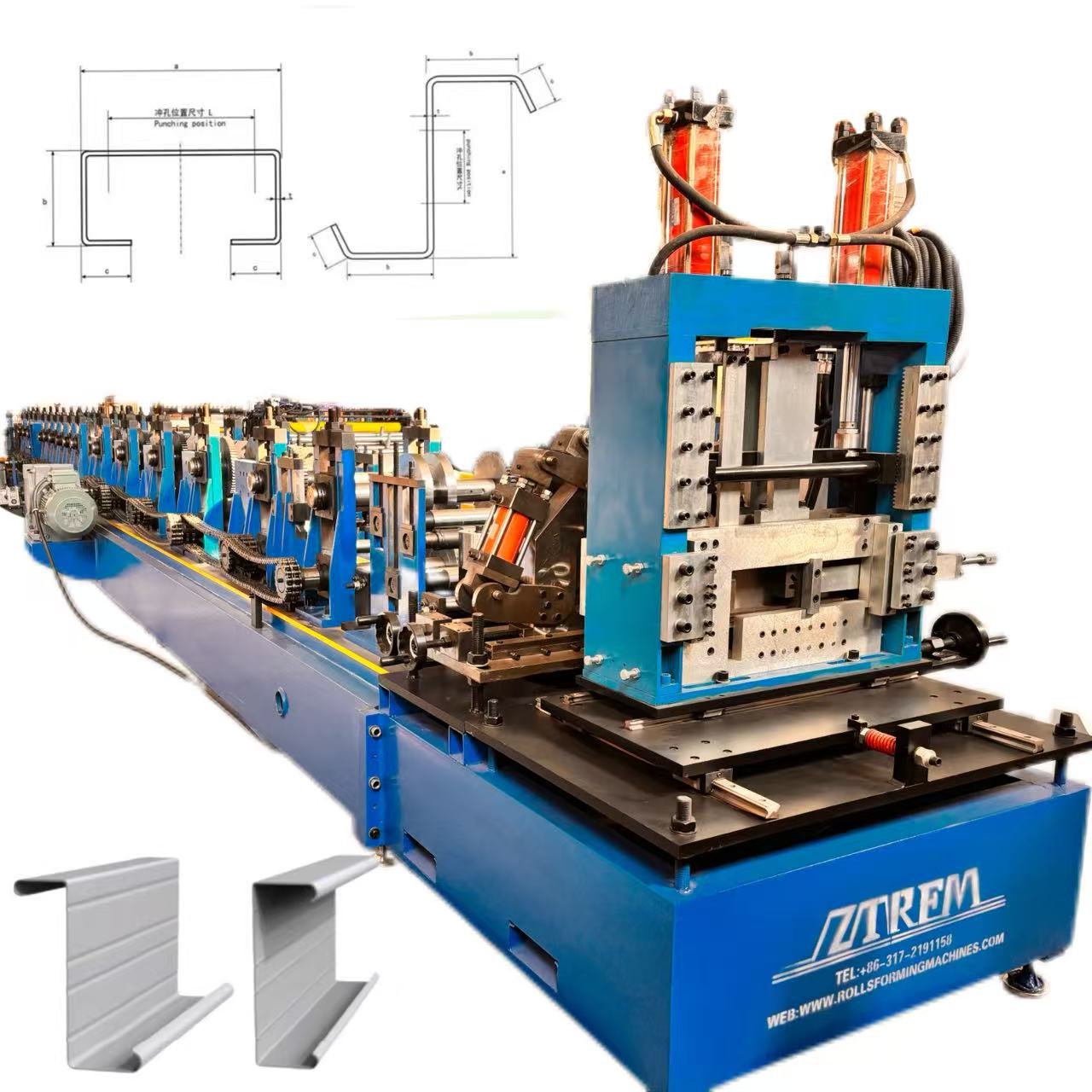

Pattern diagram:

Application scenario: Practice in multiple fields

• Industrial plant

In scenarios such as automobile manufacturing and logistics warehousing, the panels produced by double-layer roof panel equipment are an ideal choice due to their large span and strong load-bearing capacity.

• Commercial and public buildings

Large span buildings such as sports venues and convention centers have extremely high requirements for the aesthetic and functional properties of their roofs. The double-layer metal roof system improves indoor air circulation and reduces air conditioning energy consumption through ventilation duct design.

• Residential and villa

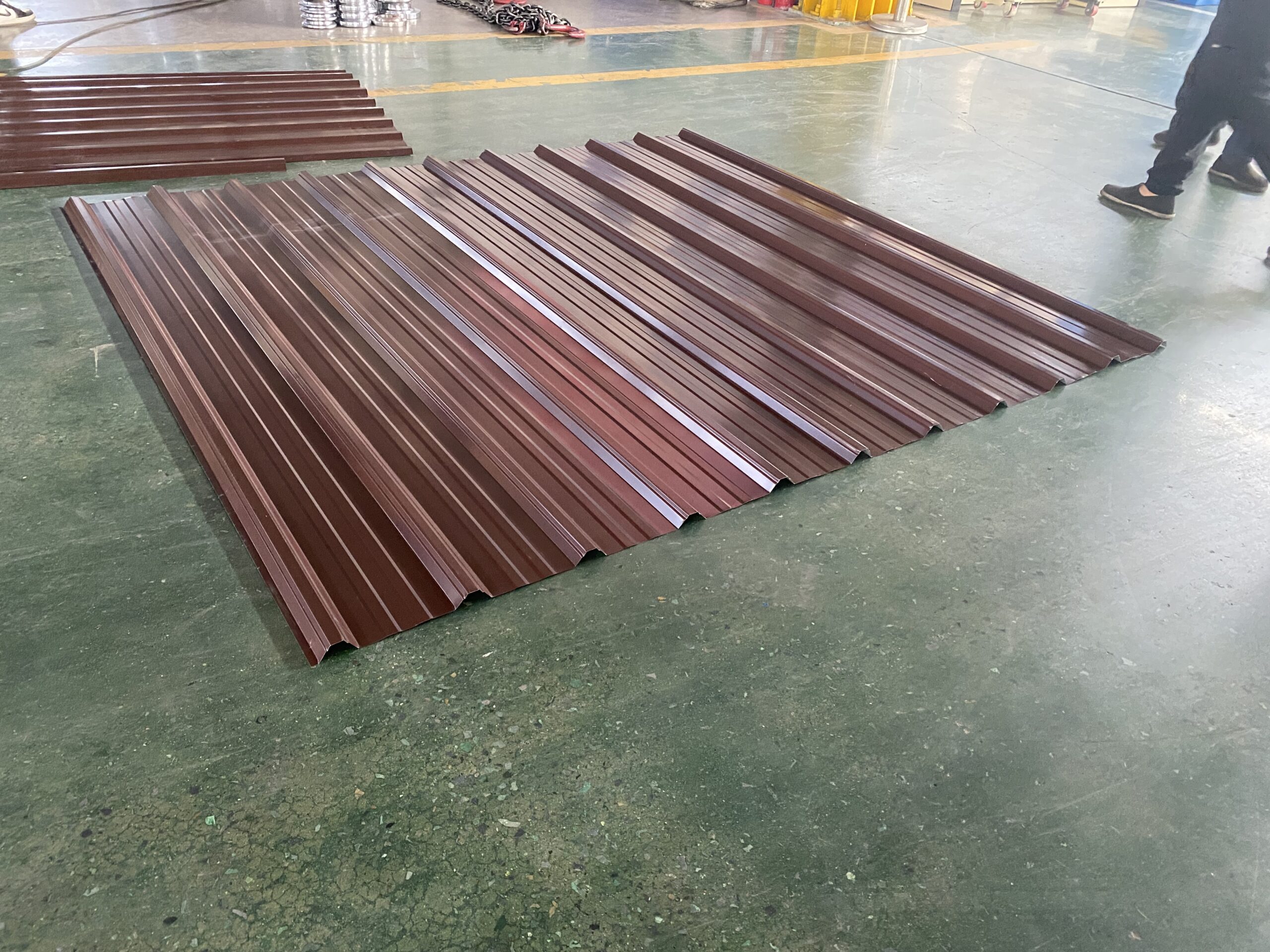

In the high-end residential field, the rich color selection of color steel plates can match modern minimalist or classical styles.

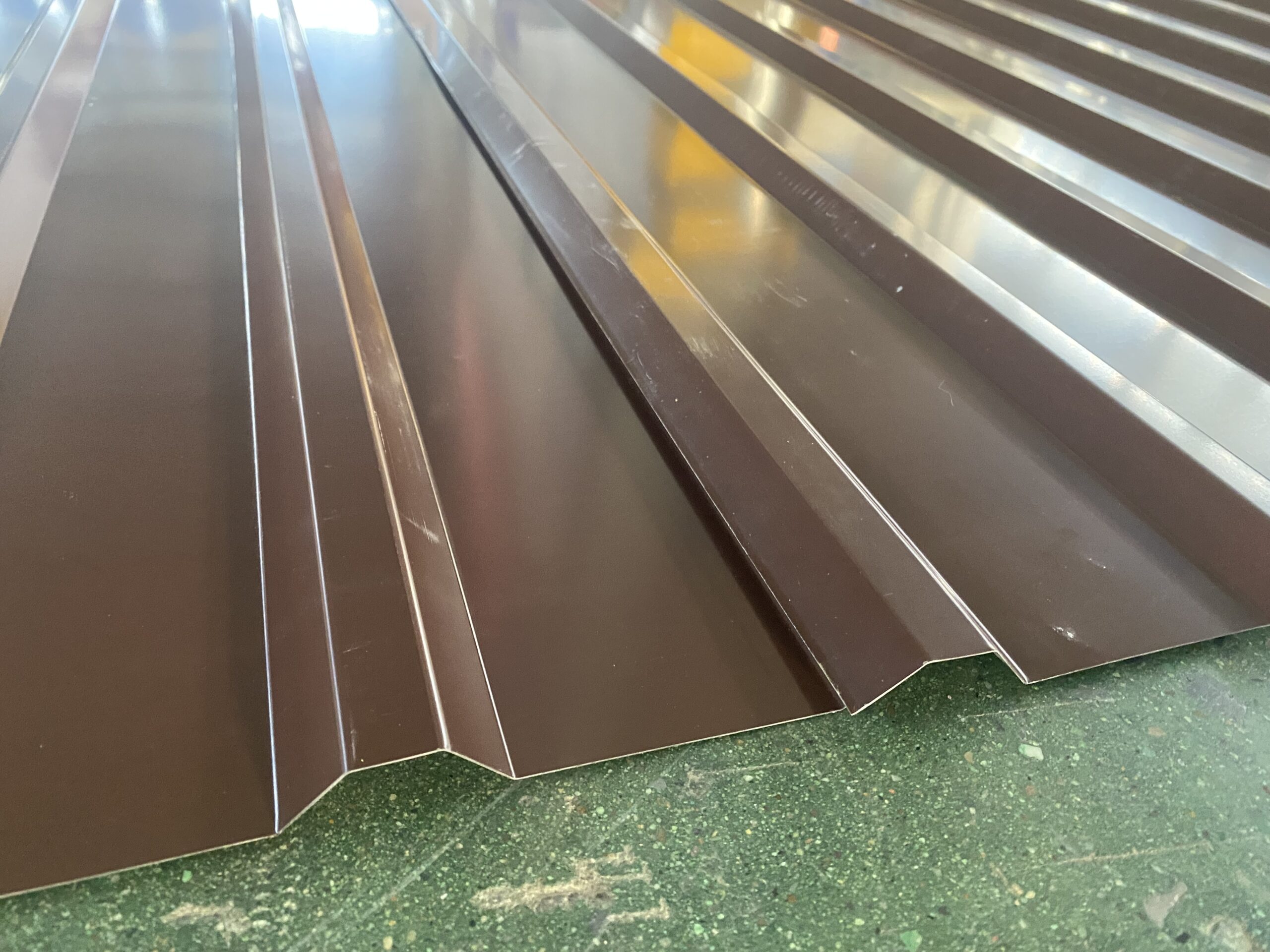

Finished product image:

Core advantage: Beyond traditional competitiveness

1. Efficient and energy-saving, cost optimization

The double-layer structure design enables the equipment to produce higher output per unit time while reducing raw material waste.

2. Coexistence of lightweight and high strength

Using galvanized steel plates with a thickness of 0.4-0.7mm, the equipment produces plates with light weight, but through waveform structure design, the bending strength is increased by 40% -60%. This enables the roof system to withstand extreme weather conditions such as strong winds and snow while reducing building loads.

3. Environmental Protection and Sustainability

The surface coating of color coated steel plate has excellent anti-corrosion and weather resistance, which can resist UV and acid rain erosion and extend the service life to more than 25 years. In addition, the device supports the recycling of materials for reuse, reducing construction waste. seven.

Machine image: