The Metal Sheet Punching Production Line is a cutting-edge solution designed for efficient and precise punching of metal sheets. This state-of-the-art production line combines advanced technology and robust construction to deliver exceptional performance and productivity. With its high-speed punching capabilities and accurate positioning, it ensures consistent and flawless results. The production line is versatile, accommodating various sheet sizes and thicknesses, making it suitable for a wide range of industrial applications. Experience enhanced productivity and quality with the Metal Sheet Punching Production Line, the perfect choice for your metal fabrication needs.

Metal sheet punching production line is designed to make the metal sheet, ALUMINIUM sheet punching and other material punching either from decoiler to recoiler or from decoiler to cut to length or only sheet punching machine.

Metal sheet punching production line is designed to make the metal sheet, ALUMINIUM sheet punching and other material punching either from decoiler to recoiler or from decoiler to cut to length or only sheet punching machine. Meanwhile it also could be worked with the rolling forming machine. For example, some kind of profile needed to be punched and then do the rolling forming. So as to the punching line, it has many types combination. Here I will show you some types by some drawing profile for your reference:

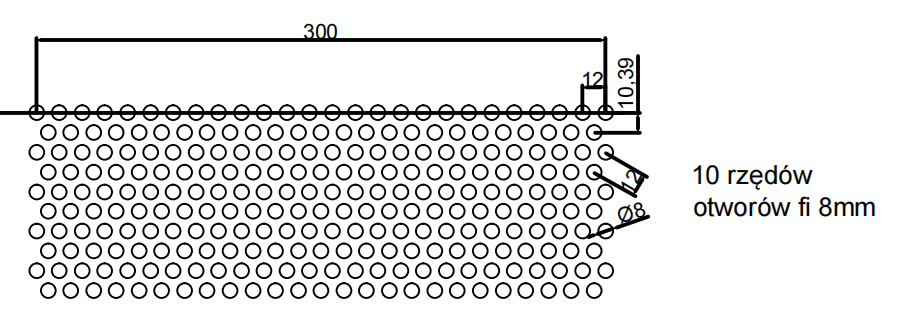

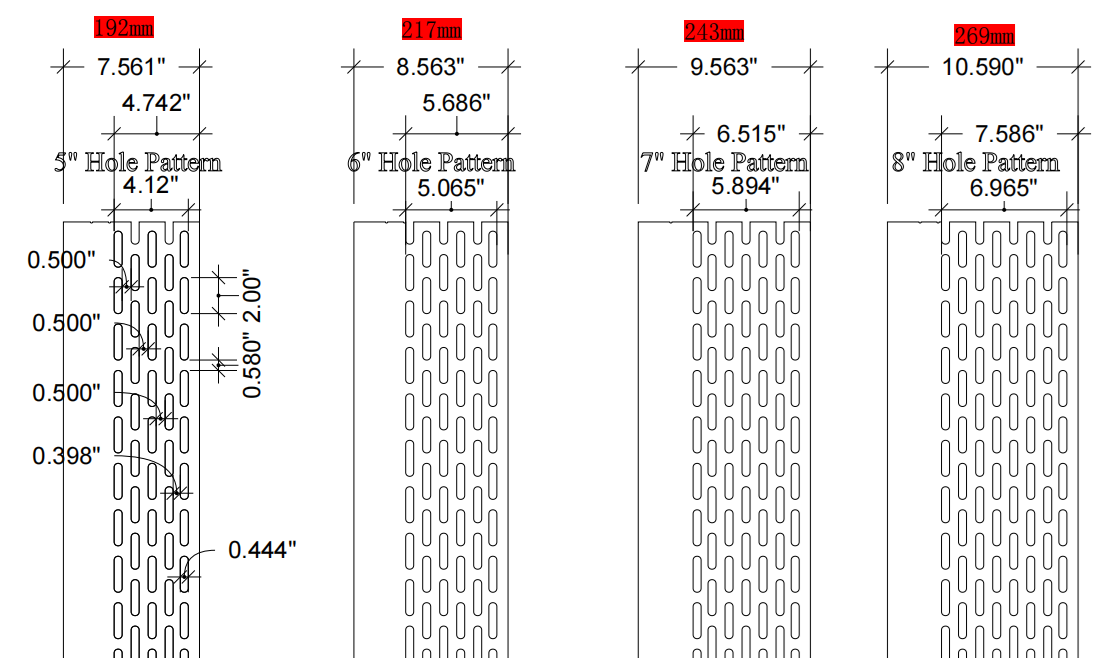

For example, the punching could be like this:

Or punching could be like this:

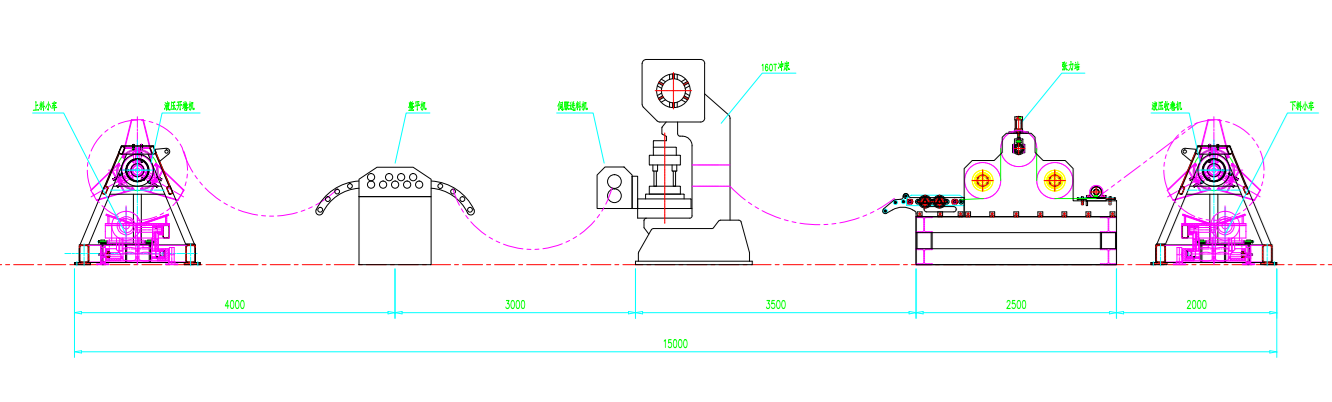

Metal sheet punching production line working flow:

Hydraulic decoiler — Servo feeder — Punching — Damping device S rollers — Recoiler (or could be cut to length)–> or main rolling forming machines

Actually all elements are optional, like you can choose manual decoiler or electrical decoiler or hydraulic decoiler. As to the punching machine, you can choose to use the high speed punching or the normal speed punching machine and then the cost will be totally different.

More details of each elements:

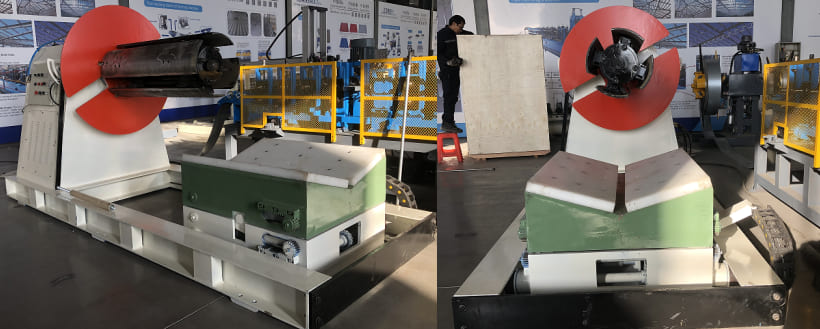

Hydraulic decoiler with loading car

Support the coils and doing uncoiling.

◆The decoiler expands and shrinks by hydraulic and fit to the inner diameter of coils.

◆Motor drives the coils running and can do forward and do the decoiling with tension.

◆The core can ensure the expand range

◆Structure: welding by the steel plates and profiled bar

And loading car can help you load the coils more easily.

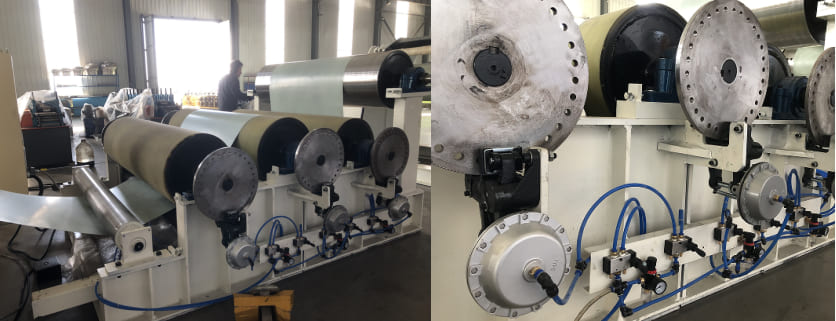

Punching machine with the servo coil feeder:

Punching four rows for higher speed. The punching machine can punch 120 times Max per minute.

All presses are designed, manufactured and tested in accordance with the ISO9001 standards and requirements. According to the customers’ feedback and our service experience, the most important factor to maintain the initial precision of machine is to use it properly and maintain it timely to

achieve its best effectiveness

As to cut to length or recoil the punched sheet, it depends on the customer requirements.

The following I showed is the recoiler type:

In order to make sure the recoiler tight, neat and clean, we add the S roller tension system like the following.

Metal sheet punching production line working videos for your reference: