Product Introduction:

In today’s continuous pursuit of efficiency, quality, and innovation in the construction industry, floor bearing slab machines have become the best choice for many construction projects with their excellent performance and significant advantages. It not only changes the traditional building construction model, but also brings new development opportunities to the construction industry.

Floor slab machines have a highly automated production process. From the input of raw materials to the output of finished floor slabs, the whole process is completed in one go, which greatly reduces manual intervention and improves production efficiency. For example, advanced CNC systems can accurately control each process to ensure the dimensional accuracy and quality stability of floor bearing panels. Whether it is a large-scale commercial building or a small residential project, the floor slab machine can quickly produce various specifications of floor slabs according to different needs. The floor slab produced by the floor slab machine has excellent structural properties. Its unique design allows the floor bearing slab to remain stable even when subjected to large loads, providing reliable support for the building. Moreover, the surface of the floor bearing slab has been specially treated, which has good fireproof, moisture-proof and anti-corrosion properties, effectively extending the service life of the building. In some high-rise buildings and industrial plants, the floor plates produced by floor plate machines have been widely used due to their strong bearing capacity and excellent durability.

The use of floor slab machines also significantly reduces the construction cycle of buildings. Traditional building floor slab construction requires multiple complex steps such as building formwork, tying steel bars, and pouring concrete, while the floor slab produced by the floor slab machine only needs to be installed and connected at the construction site to carry out concrete pouring. This significantly reduces construction time, speeds up project schedules, and saves investors significant time and costs. In some engineering projects where time is of the essence, this advantage of floor slab machines is particularly obvious. Floor slab machines also excel in environmental protection. Due to its automated production process, manual operations are reduced, reducing energy consumption and waste generation. At the same time, the floor bearing plate produced by the floor bearing plate machine can be reused, which meets the requirements of the modern construction industry for energy conservation and environmental protection. In today’s advocacy of green buildings, floor bearing plate machines have undoubtedly made positive contributions to the sustainable development of the construction industry.

With its many advantages such as high efficiency, high quality, and environmental protection, floor bearing machine has become an indispensable and important equipment in the construction industry. Whether it’s improving building quality, shortening construction cycles, or achieving energy conservation and environmental protection, floor slab machines can provide you with the perfect solution. Choosing a floor bearing board machine is choosing the future of the construction industry!

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.7-1.2mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

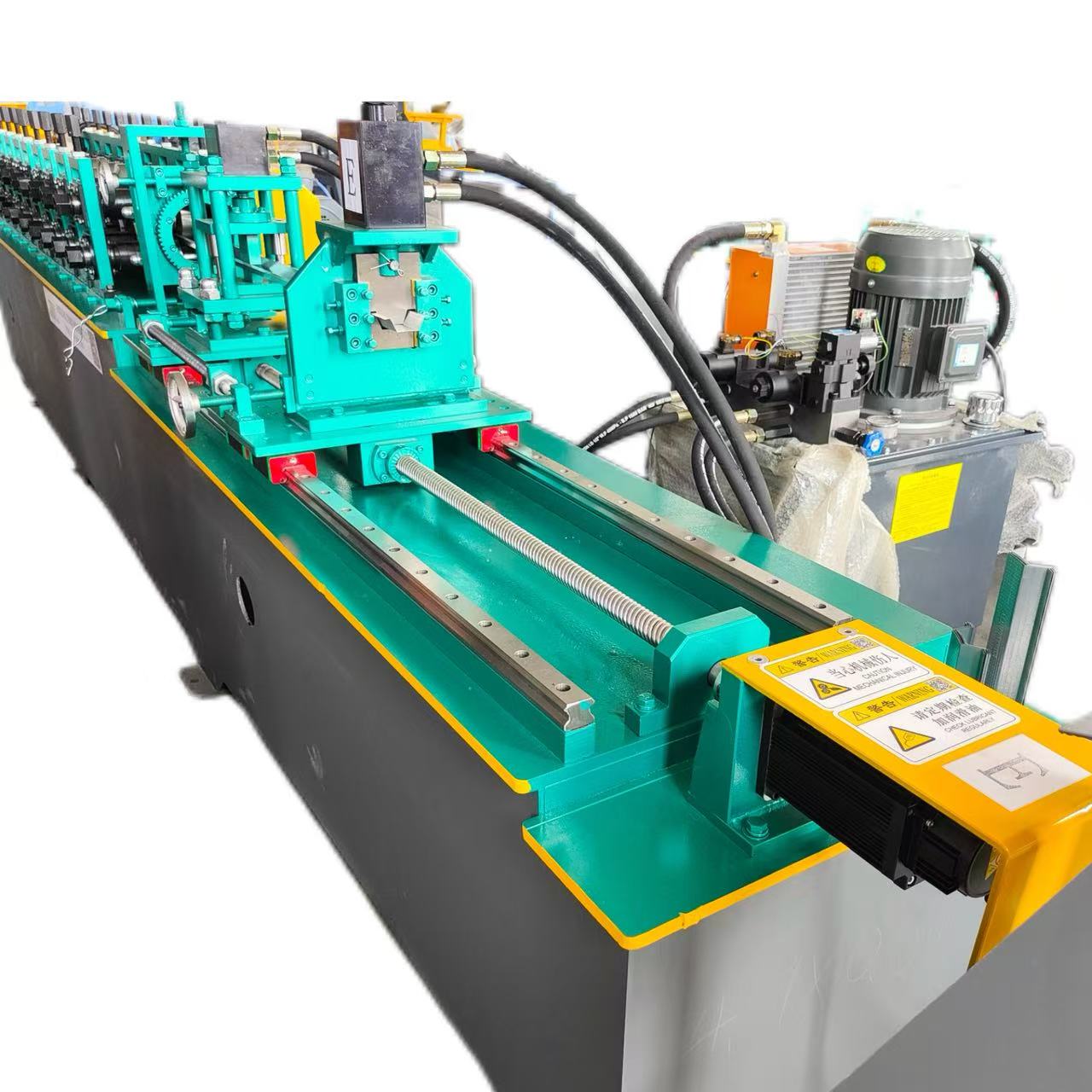

3.Main body

|

Roller station

|

33 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

The core advantage of floor bearing plate machines: a comprehensive breakthrough from efficiency to quality:

The core of the reason why floor bearing plate machines can occupy an important position in the field of construction equipment is that they have achieved multi-dimensional breakthroughs in production efficiency, product accuracy and cost control through technological innovation, providing better floor bearing solutions for the construction industry.

1. Efficient Production: Break time constraints with automation

The efficiency of the floor slab machine is reflected in the automatic design of the whole process. While traditional manual or semi-mechanical production requires multiple people to collaborate on feeding, forming, cutting, and other steps, and the output per day is often limited, high-quality floor slab machines achieve efficiency leaps by:

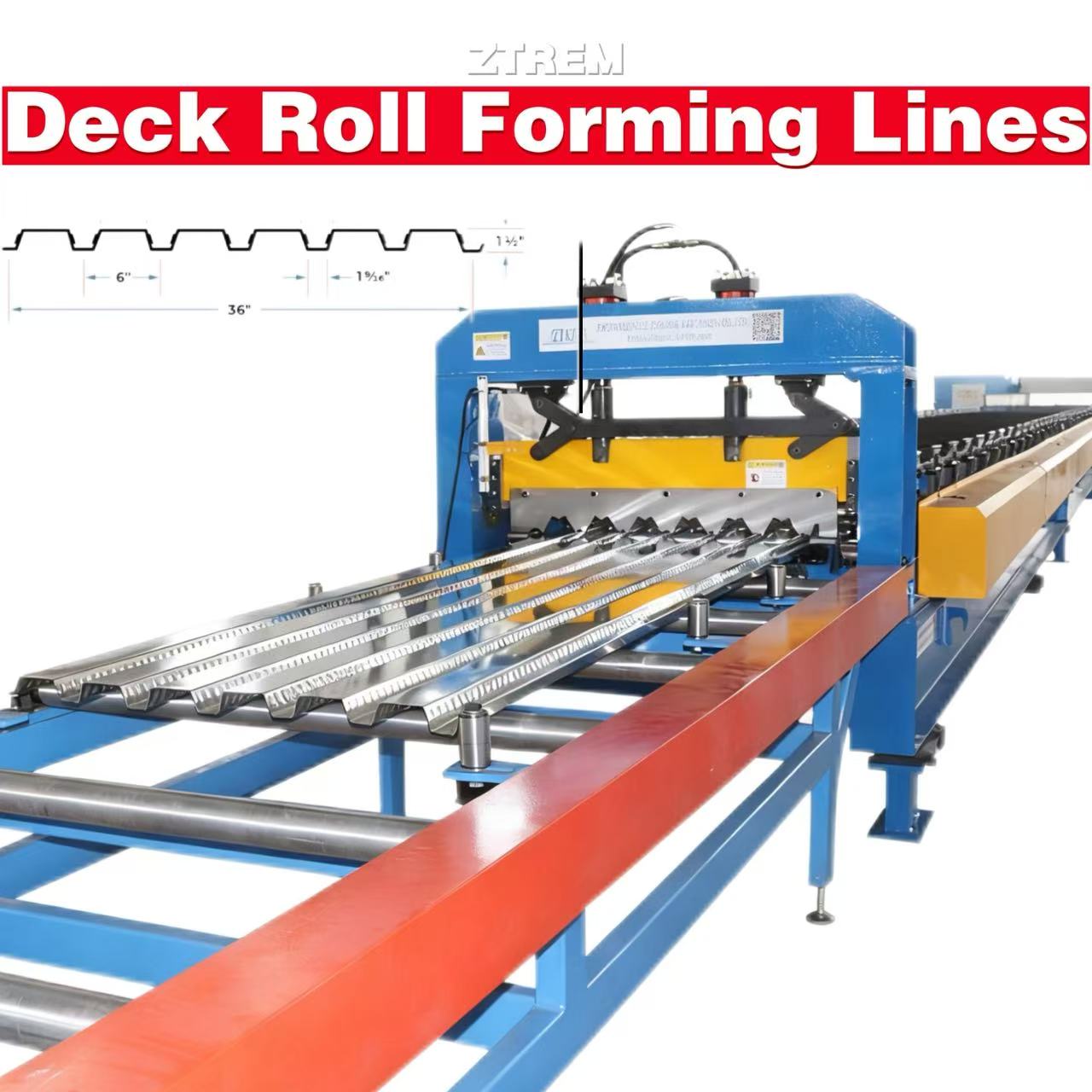

Continuous and uninterrupted production: Using the servo feeding system, raw materials can be continuously input, with multiple sets of rolls synchronously operating, a single production line can produce 50-150 meters of floor bearing plates per hour (depending on the model), and the daily output can reach 5-8 times that of the traditional method.

Seamless process connection: From raw material feeding to finished product output, feeding, forming, cutting, counting and other processes are completed by the PLC control system linkage, without manual intervention and conversion, reducing the time waste caused by process gaps.

This efficient performance directly helps construction projects shorten the construction period of floor slabs, especially suitable for large industrial plants, high-rise buildings and other scenarios with strict construction periods.

2. Precise and controllable: make the product quality consistent and consistent

2. Precise and controllable: make the product quality consistent and consistent

As a key component of the load-bearing structure of the building, the accuracy and consistency of the floor bearing plate directly affect the safety of the building. The floor bearing machine realizes the precise control of product quality through technical means:

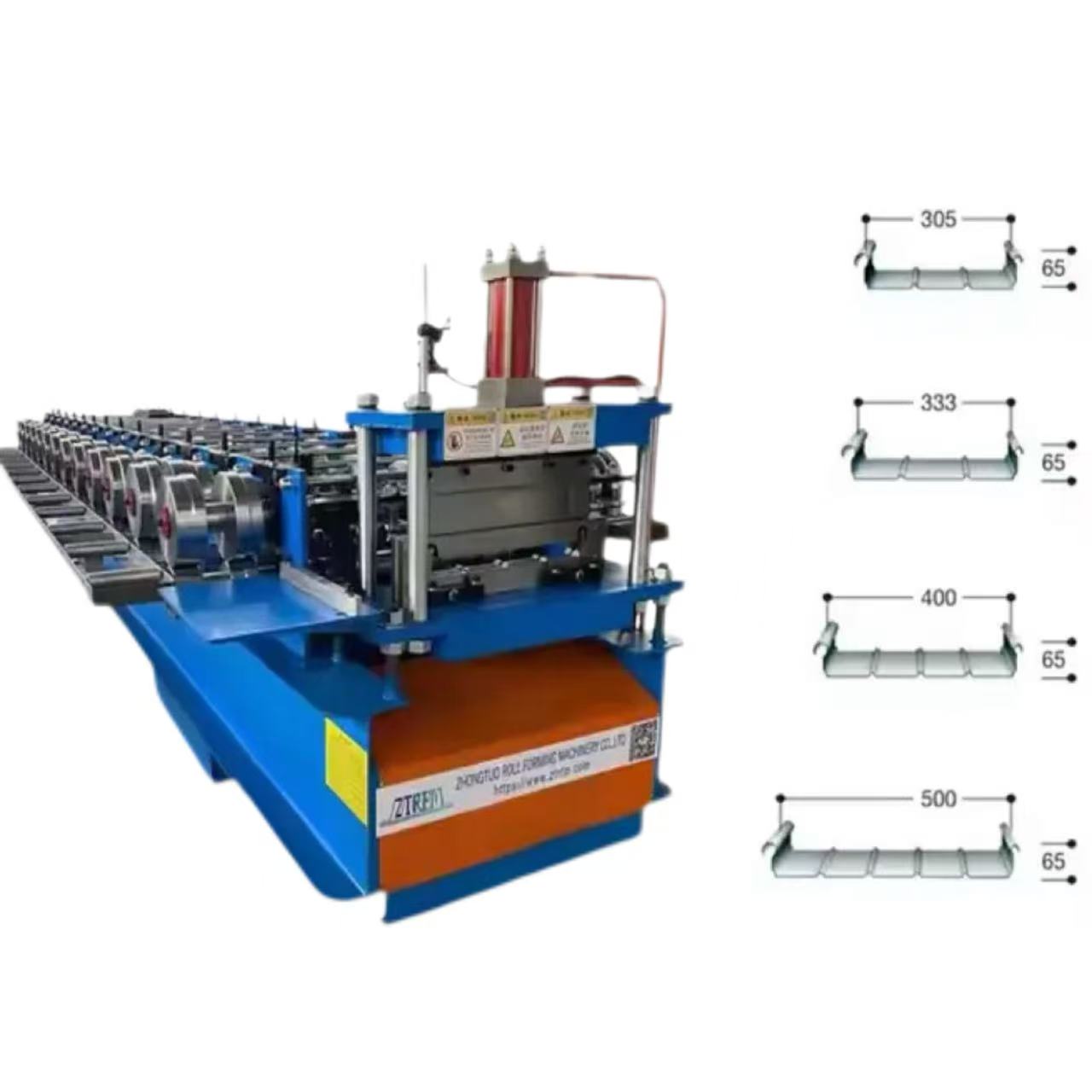

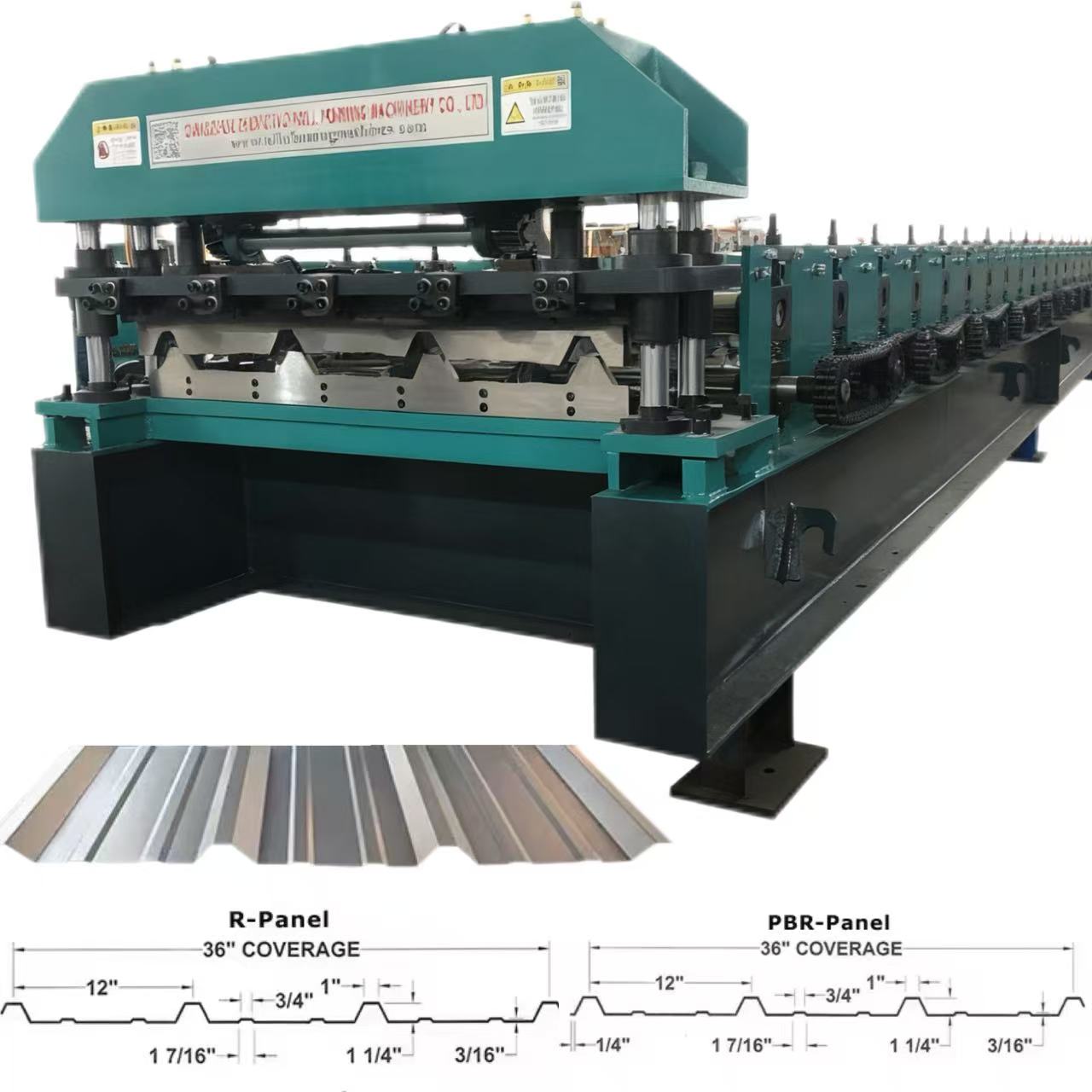

Multi-specification compatibility: By changing different roll dies, the same machine can produce multiple types of floor bearing plates (such as YXB series, TD series, etc.) to adapt to the architectural design needs of different spans and loads.

Customized production: Support customized floor bearing plates with special sections according to project drawings, and can quickly switch production modes by adjusting mold and program parameters, without the need for large-scale modification of equipment.

Efficient production in small batches: For non-standard orders for small and medium-sized projects, the machine can quickly complete parameter switching, avoiding the problem of low production efficiency in small batches in traditional processes.

3. Reduce costs and increase efficiency: Create value from long-term operations

The advantages of floor bearing machine are not only reflected in the production process, but also can bring long-term cost optimization to enterprises:

Reduced labor costs: 1-2 operators can complete the monitoring and maintenance of the entire production line, reducing labor expenses by 5-8 workers compared to traditional processes.

Reduced Material Waste: Precise cutting and forming control increases material utilization to over 95%, avoiding scrap waste caused by manual cutting.

Extended equipment life: The use of high-strength alloy rolls and wear-resistant components, combined with the automatic lubrication system, can reach more than 8000 hours of trouble-free operation of the equipment, reducing maintenance and replacement costs.