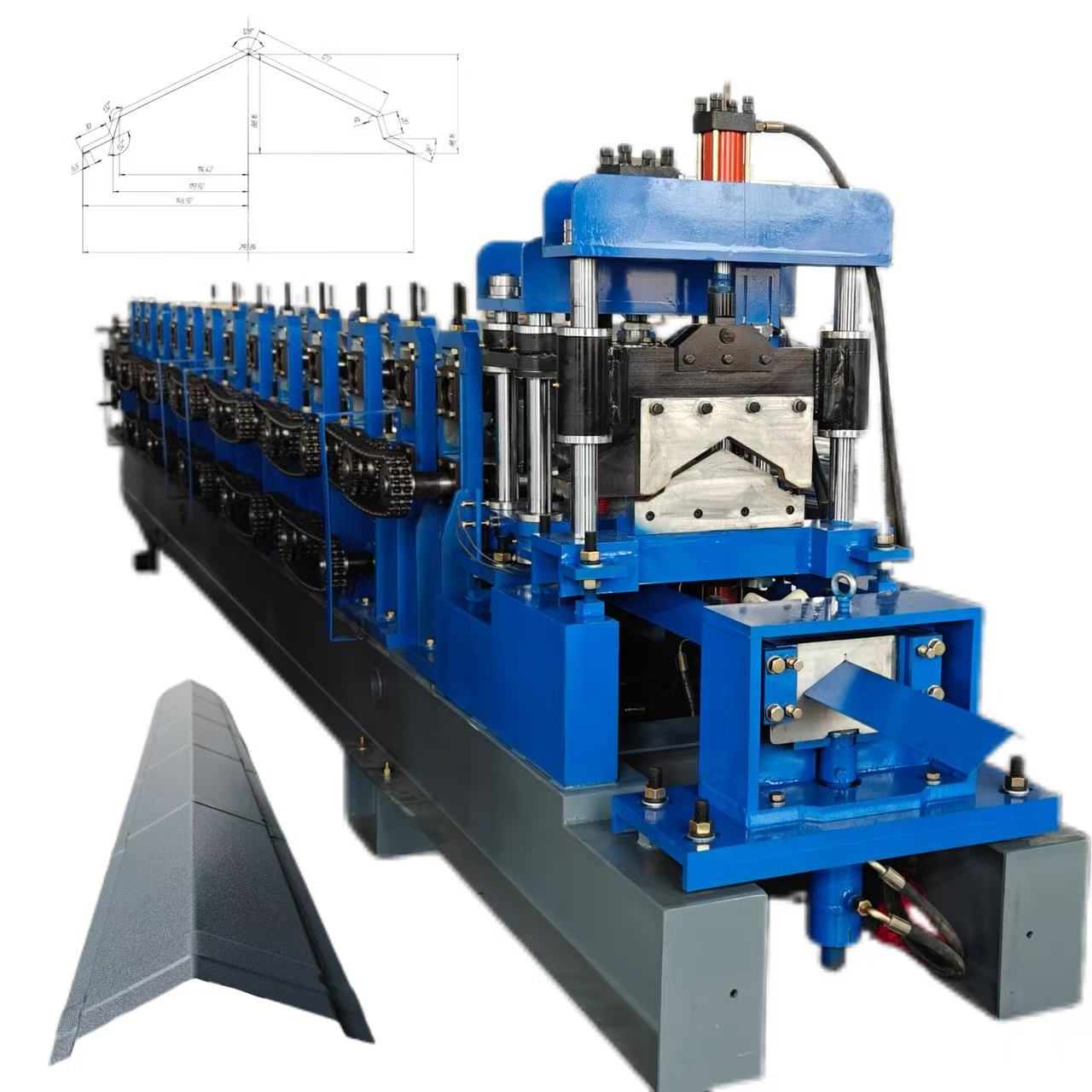

Punching and forming of angle steel have always been key factors affecting production efficiency and product quality in fields such as steel structure processing, power support production, and shelf construction. The traditional processing method relies on multiple equipment for step-by-step operation, which not only requires frequent handling of workpieces and repeated adjustment of positioning, but also often leads to hole displacement and insufficient forming accuracy due to manual operation errors, wasting raw materials and delaying project schedules. Nowadays, the emergence of Metal Wall Angle High Speed Rotary Punching Roll Forming Machines has completely broken the pain point of this industry, and with the core advantage of “one-time forming, precision and efficiency”, it has become the core equipment for modern metal processing enterprises to upgrade and transform.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.2-0.3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Punching device

|

Punching type

|

High speed rotary punching

|

||

|

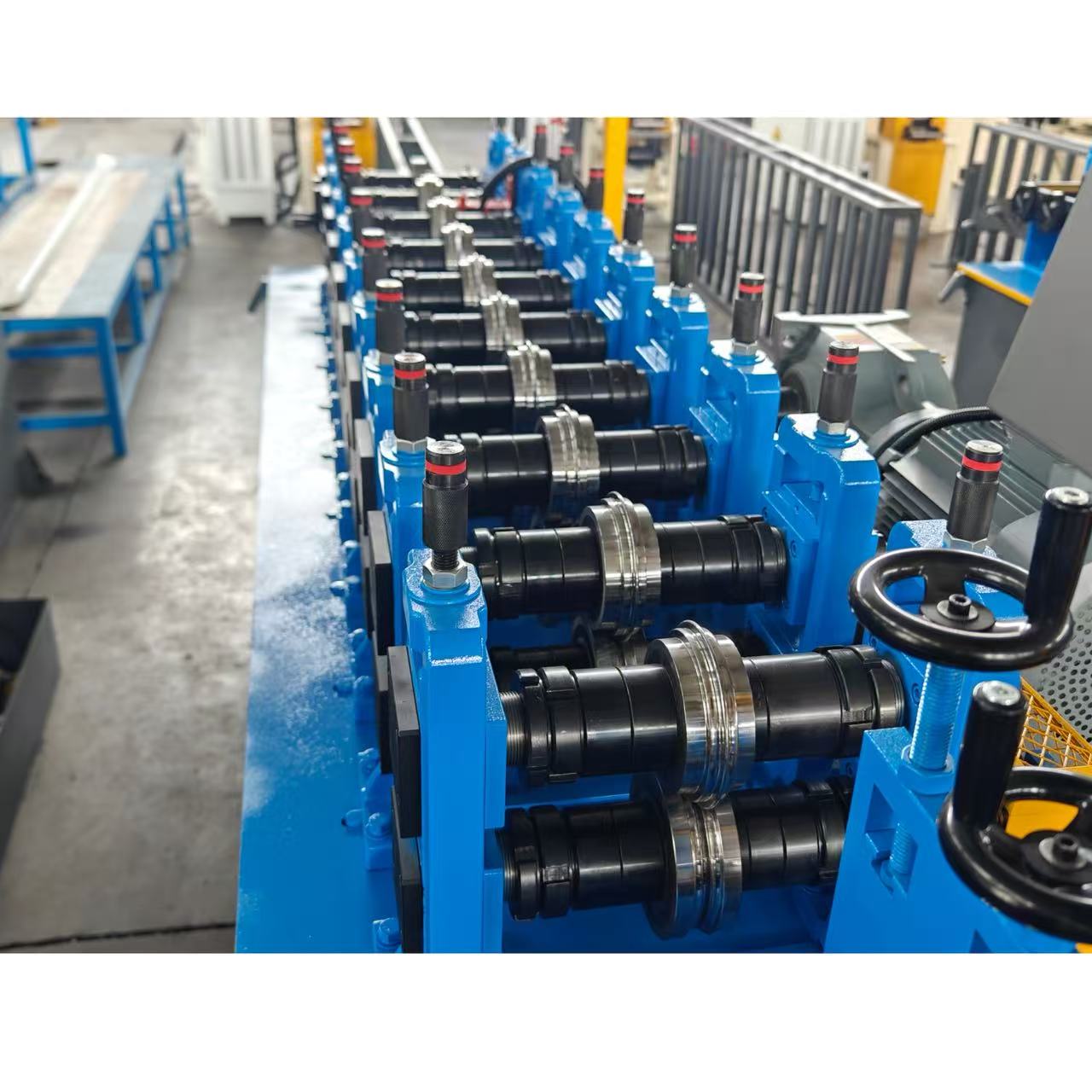

4.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

5.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

6.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

7.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

8.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

9.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Widely adaptable to multiple scenarios, injecting new momentum into industry upgrading

The Metal Wall Angle High Speed Rotary Punching Roll Forming Machine, with its flexible processing capability, can be widely used in multiple fields: in the power industry, it can accurately process power brackets and cross arm angle steel, meeting the high-precision requirements of high-voltage transmission line construction; In the warehousing and logistics industry, efficient production of shelf columns, crossbeam angle steel can help to quickly build intelligent warehousing systems; In the construction steel structure industry, curtain wall supports and steel structure connectors can be processed to enhance the stability and safety of building structures; In the photovoltaic new energy industry, customized photovoltaic bracket angle steel can be used to meet the construction needs of photovoltaic power stations in different terrains.

Choose Zhongtuo professional equipment and enjoy comprehensive service guarantee

High quality equipment cannot do without comprehensive service support. We not only provide customers with high-performance punching angle steel forming machines, but also establish a full process service system from “demand research – solution customization – equipment installation – operation training – after-sales maintenance”. Engineers will conduct on-site inspections and customize exclusive production line layout plans based on the production scale and processing needs of different customers; After the equipment is delivered, on-site installation, debugging, and operator training will be provided to ensure the rapid production of the equipment; The after-sales team is available 24 hours a day online to provide customers with worry free production.

In today’s manufacturing industry, which is transforming towards “efficiency, precision, and intelligence”, punching angle steel forming machines are no longer simple processing tools, but a “weapon” for enterprises to enhance their core competitiveness. Choosing it can not only significantly reduce production costs and improve production efficiency, but also safeguard product quality, help enterprises seize the opportunity in fierce market competition, and open a new chapter in metal processing!

If you want to learn more about equipment parameters, customize exclusive processing solutions, or make an appointment for on-site inspection of equipment operation, please feel free to contact us at any time. We will provide you with professional consulting services and technical support!

Product images: