As the construction industry accelerates its transition toward industrialization and green development, the demand for efficient, standardized, and environmentally friendly wall material production has become increasingly urgent. Traditional wall panel production relies on manual operations, which not only limits production capacity and results in unstable quality but also involves high energy consumption and significant pollution, making it difficult to meet the fast-paced requirements of modern construction projects. To address these industry pain points, ZTRFM Metal Wall Cladding Panel Roll Forming Machine have emerged, integrating advanced technology with practical design to provide a one-stop solution for wall material production for building material manufacturers, redefining new standards in wall panel production!

Product Attributes:

|

1.Formed Material

|

PPGI

|

Thickness:0.3-0.6mm

|

||

|

2.Decoiler

|

Hydraulic decoiler

|

3 tons

|

||

|

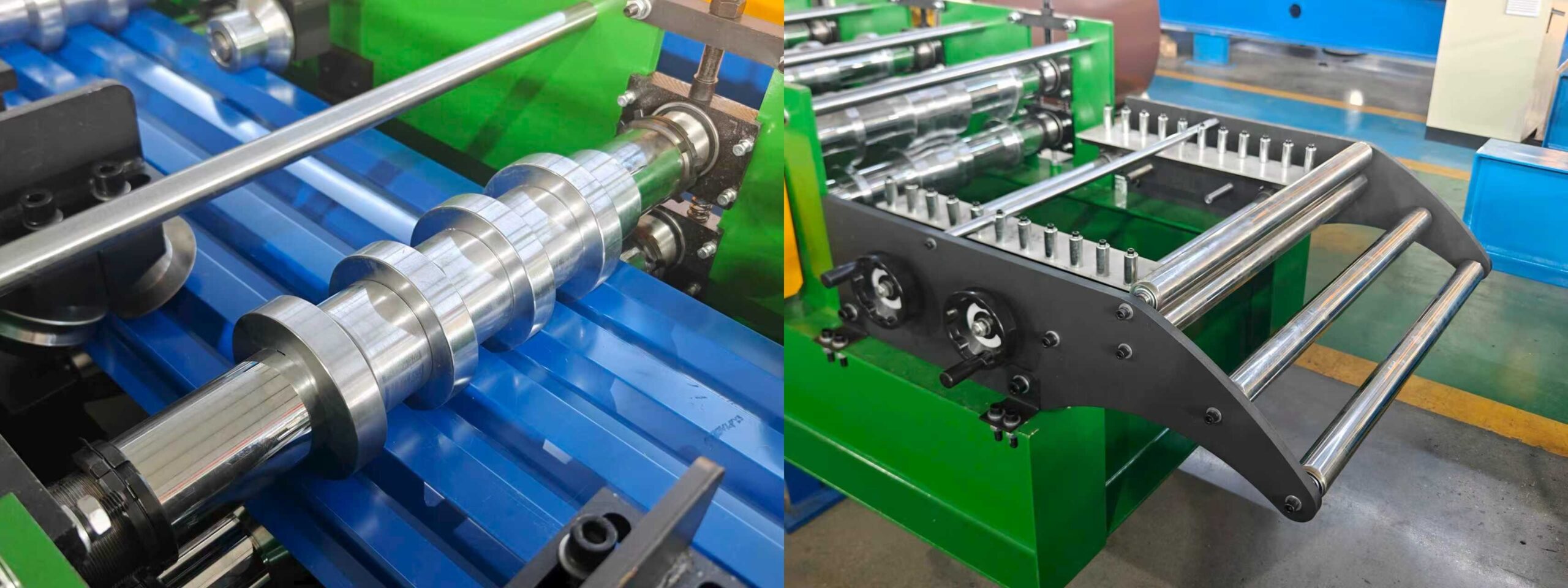

3.Main body

|

Roller station

|

26 rows(As your requirement)

|

||

|

Diameter of shaft

|

65mm solid shaft

|

|||

|

Material of rollers

|

45# steel,with heat treatment

|

|||

|

Machine frame

|

350mm H beam structure,18mm middle plate

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600mm

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

Gcr12 steel

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Core features of the product

1. Efficient automation, doubling production capacity

2. Green and energy-saving, in line with environmental trends

3. Intelligent control, stable and controllable quality

4. Flexible adaptation and wide applicability

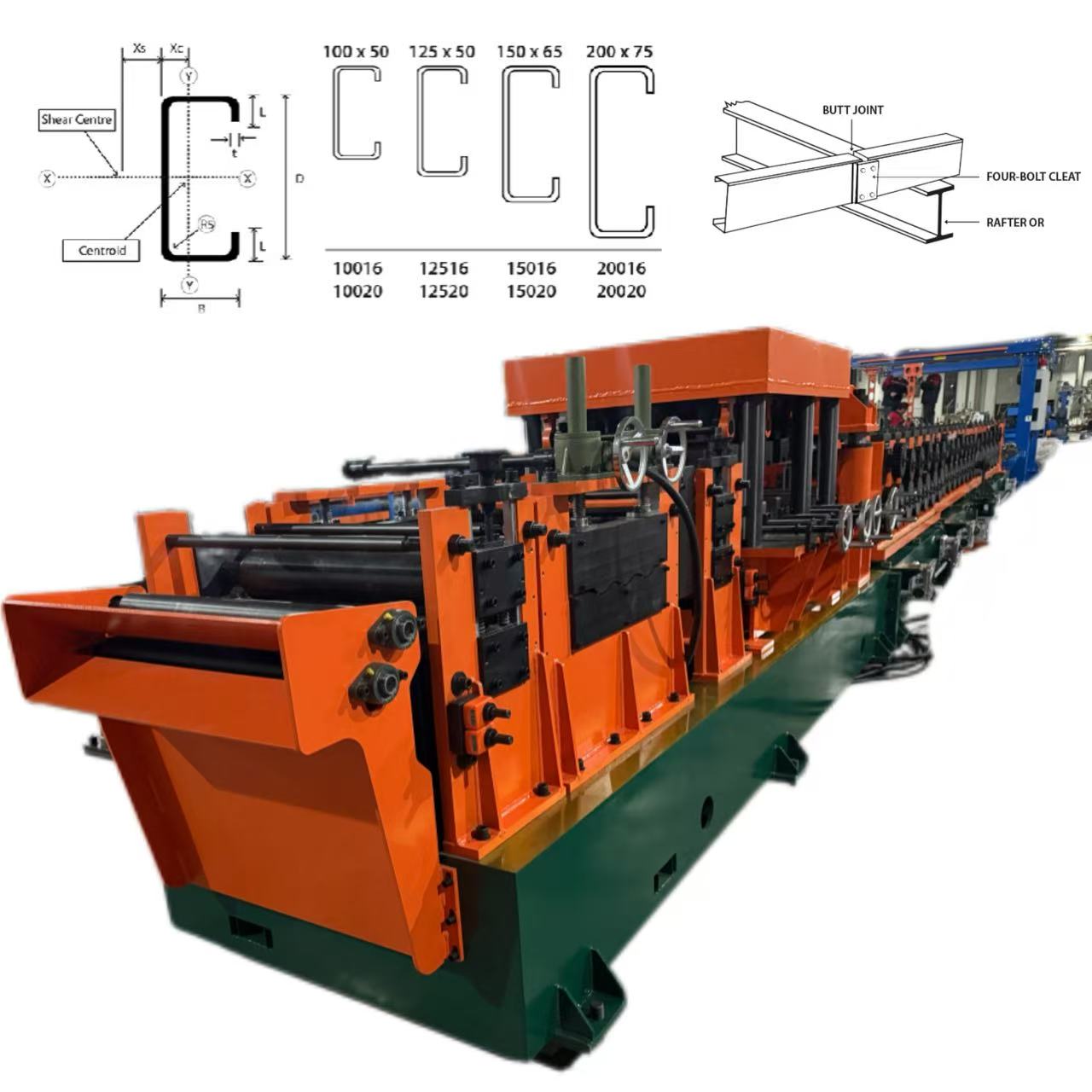

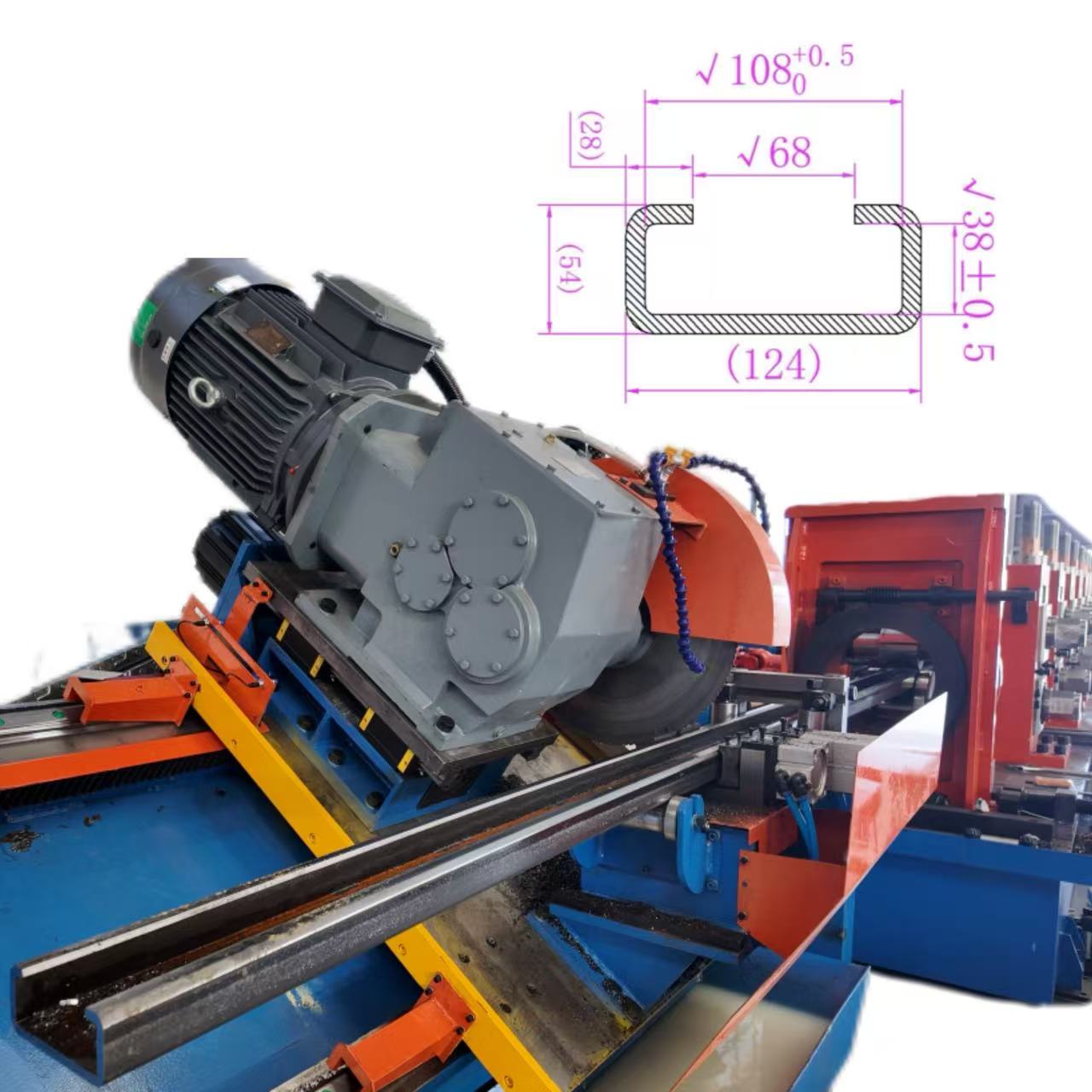

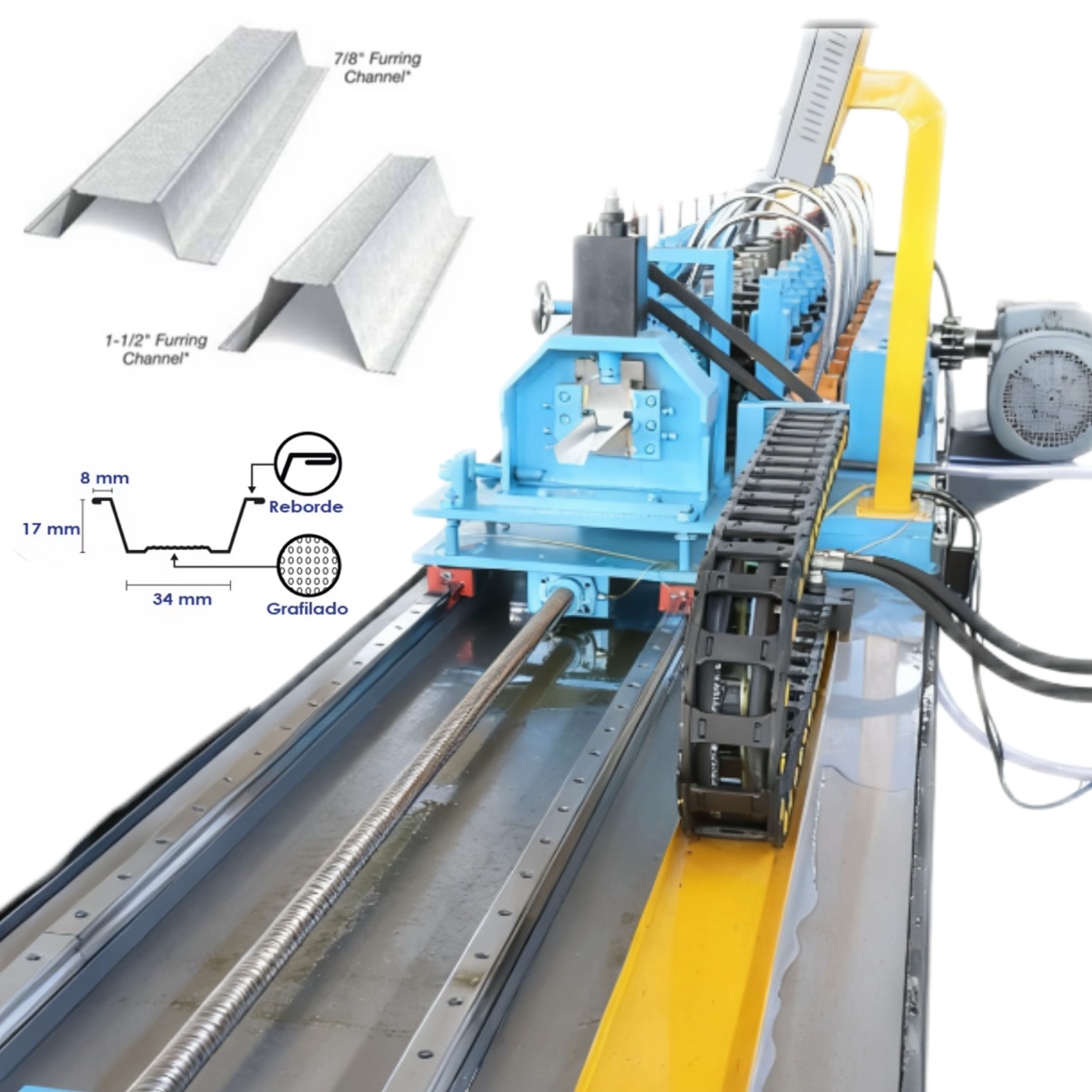

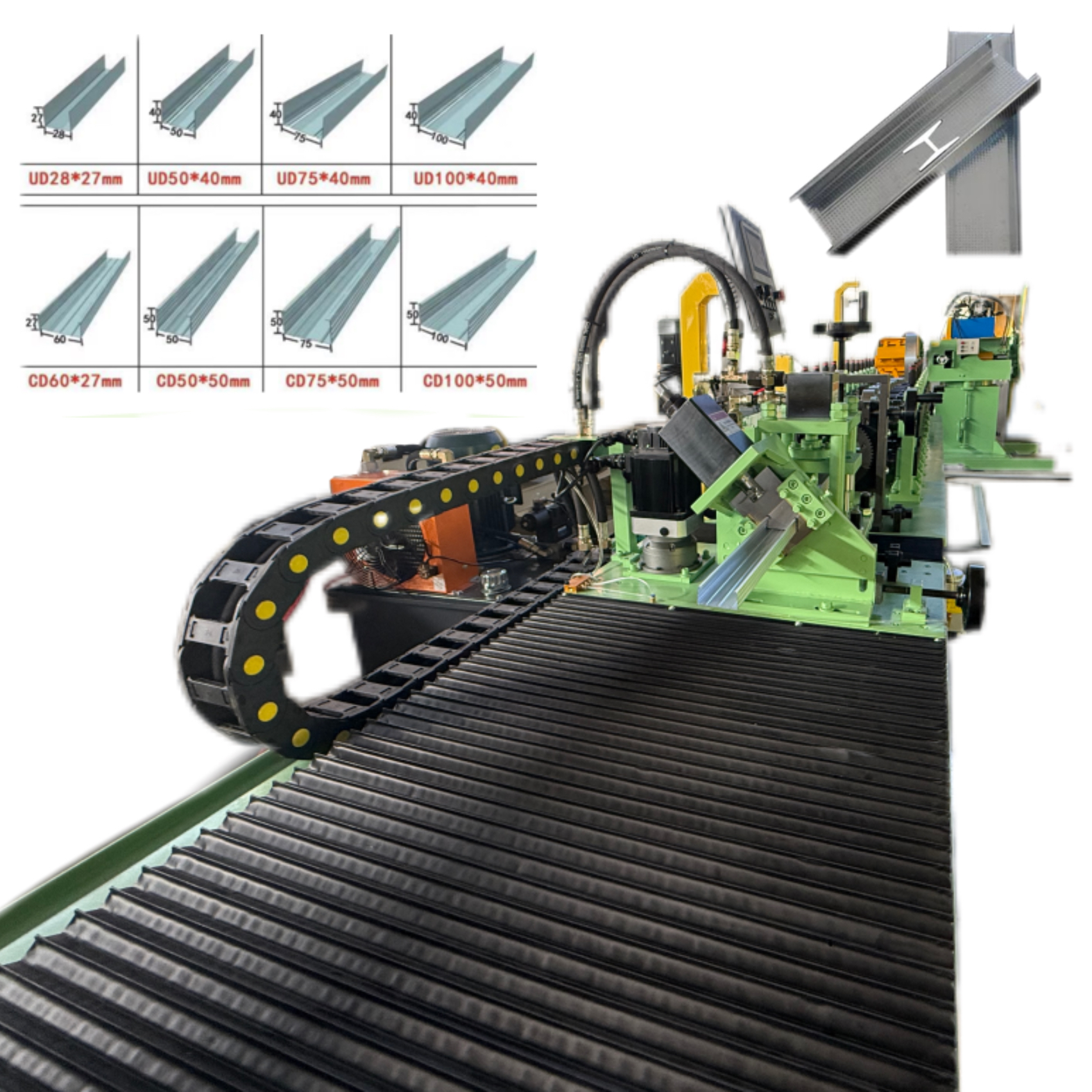

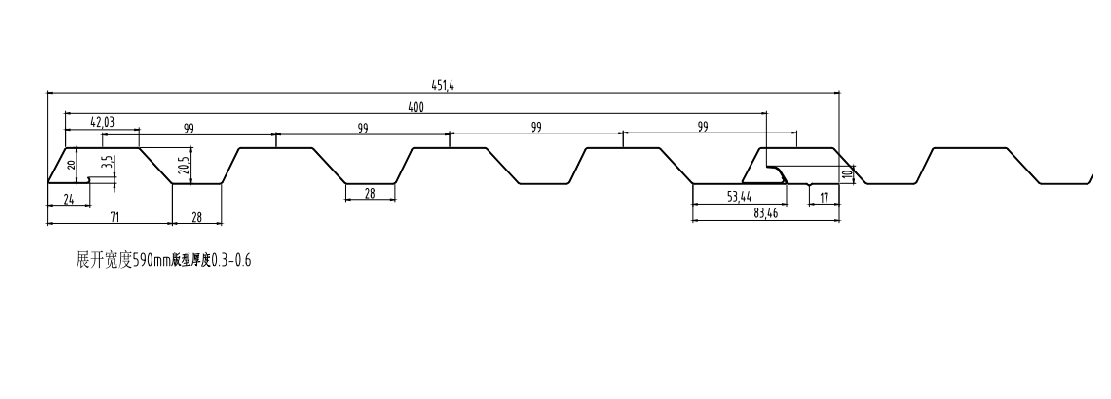

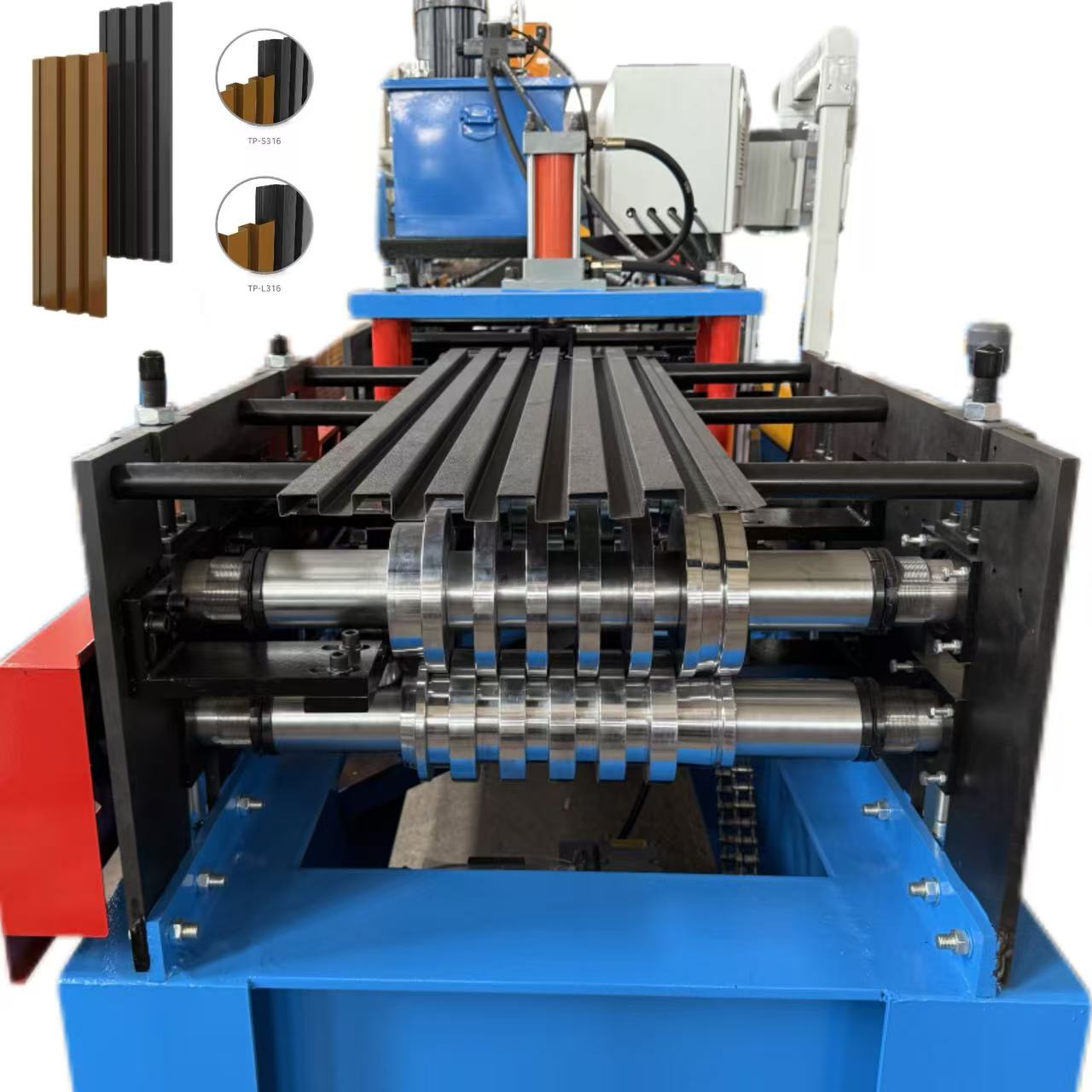

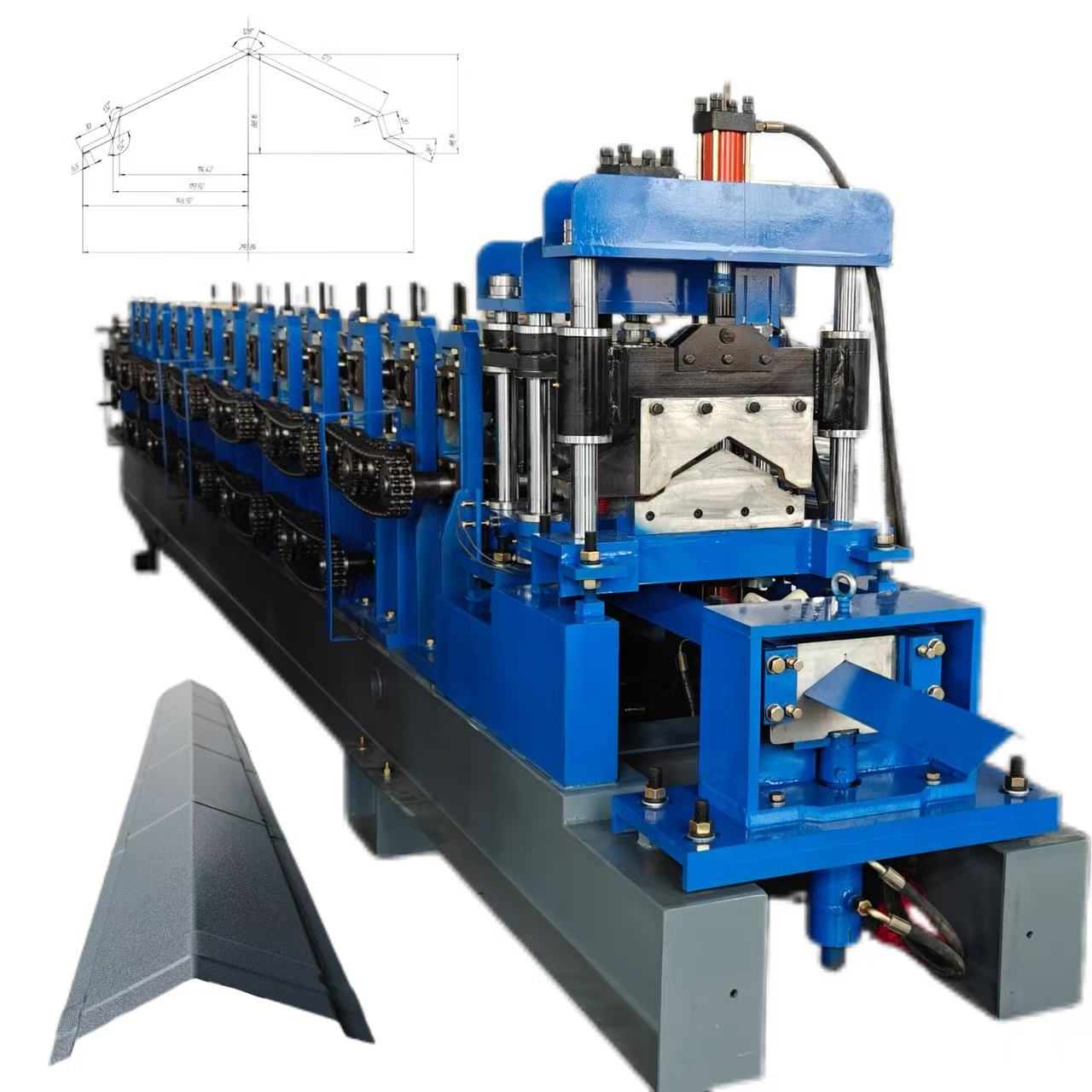

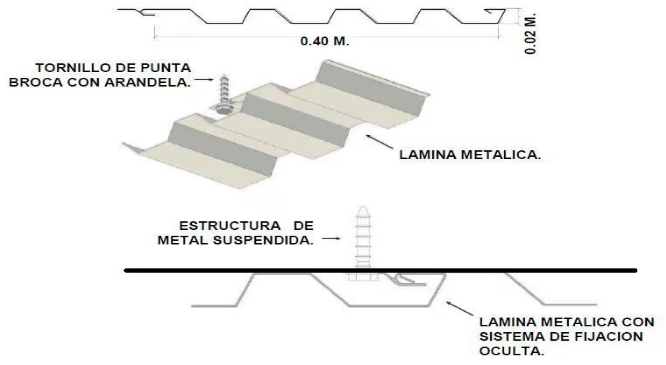

Pattern diagram:

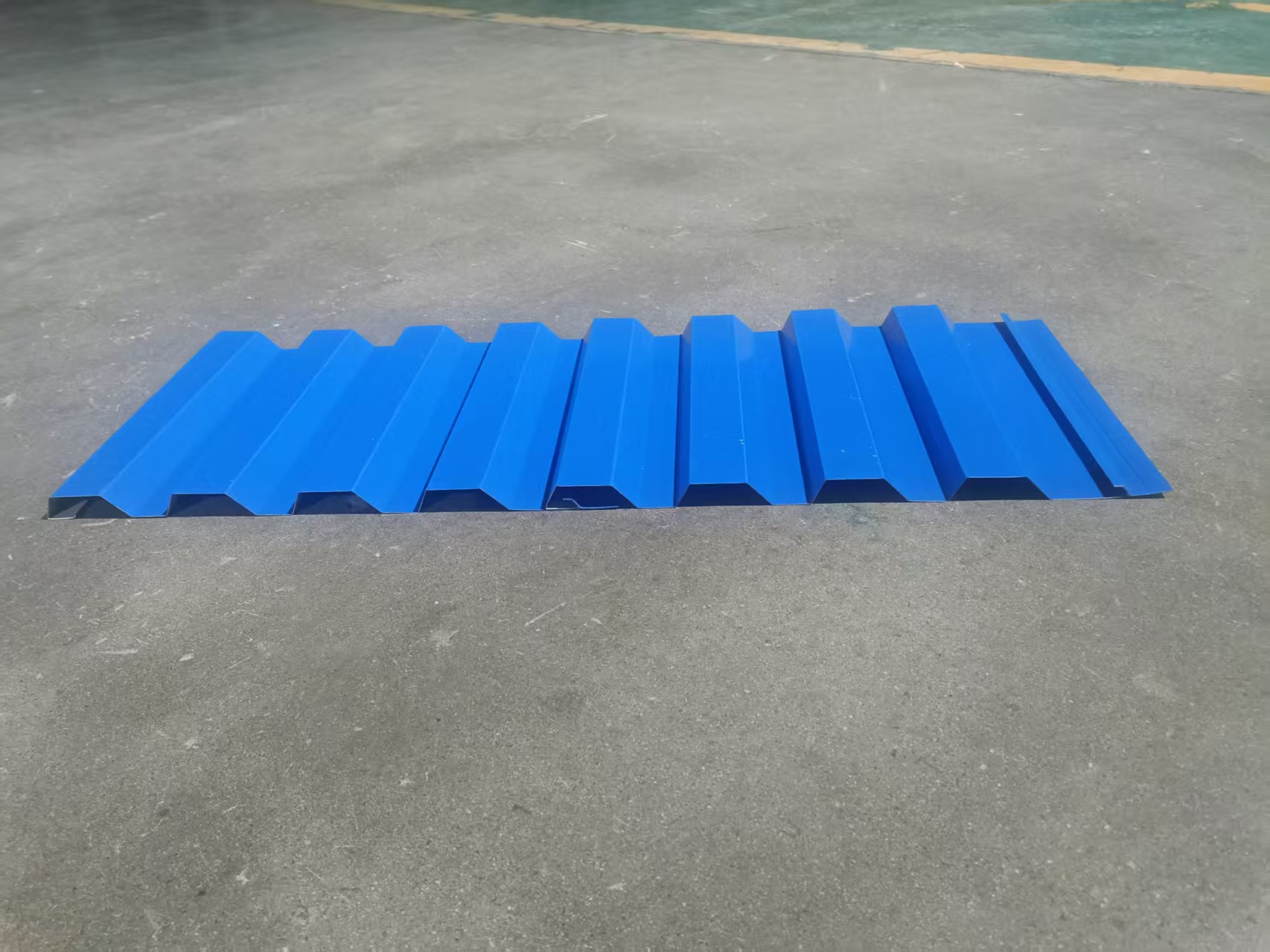

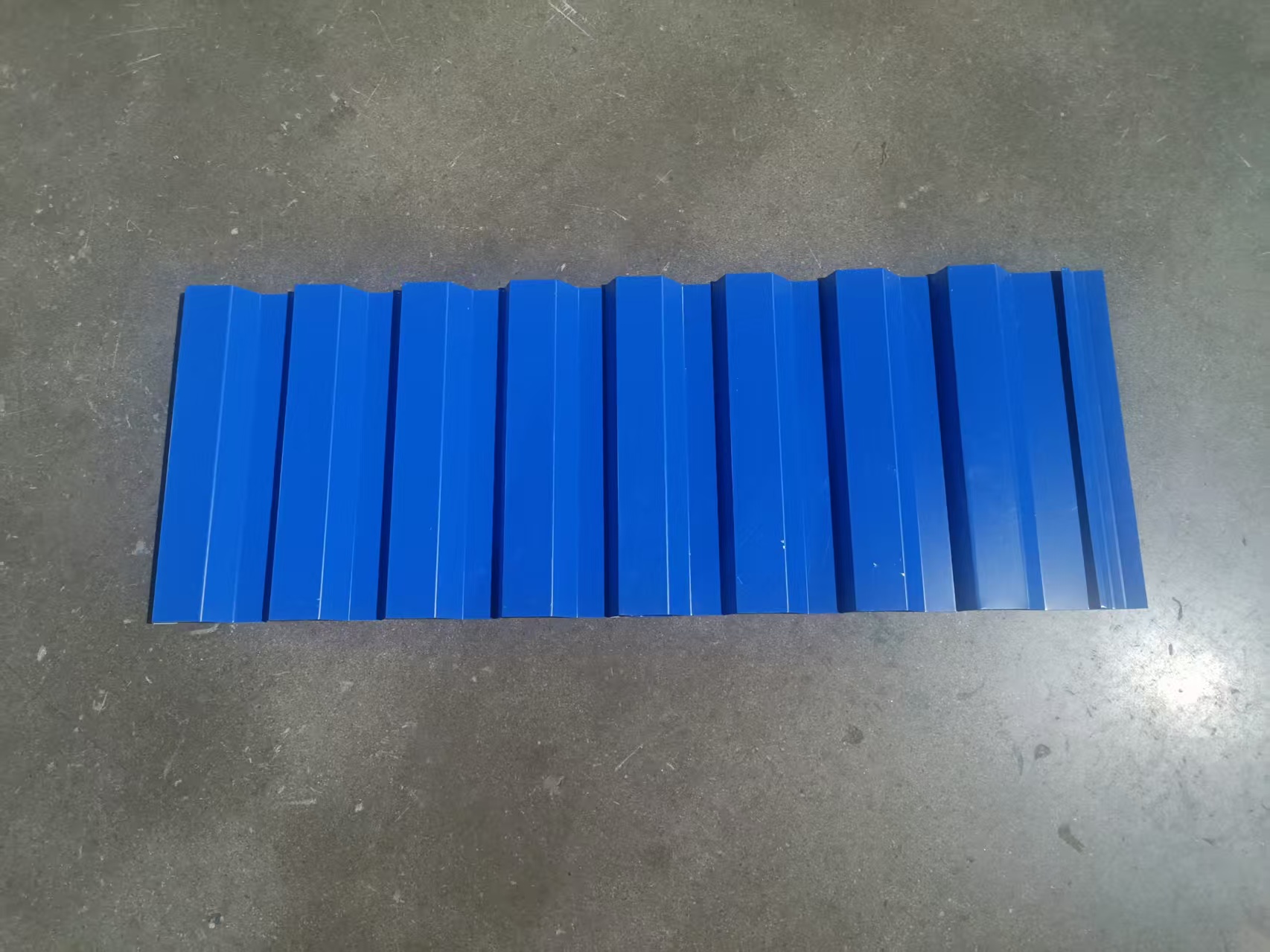

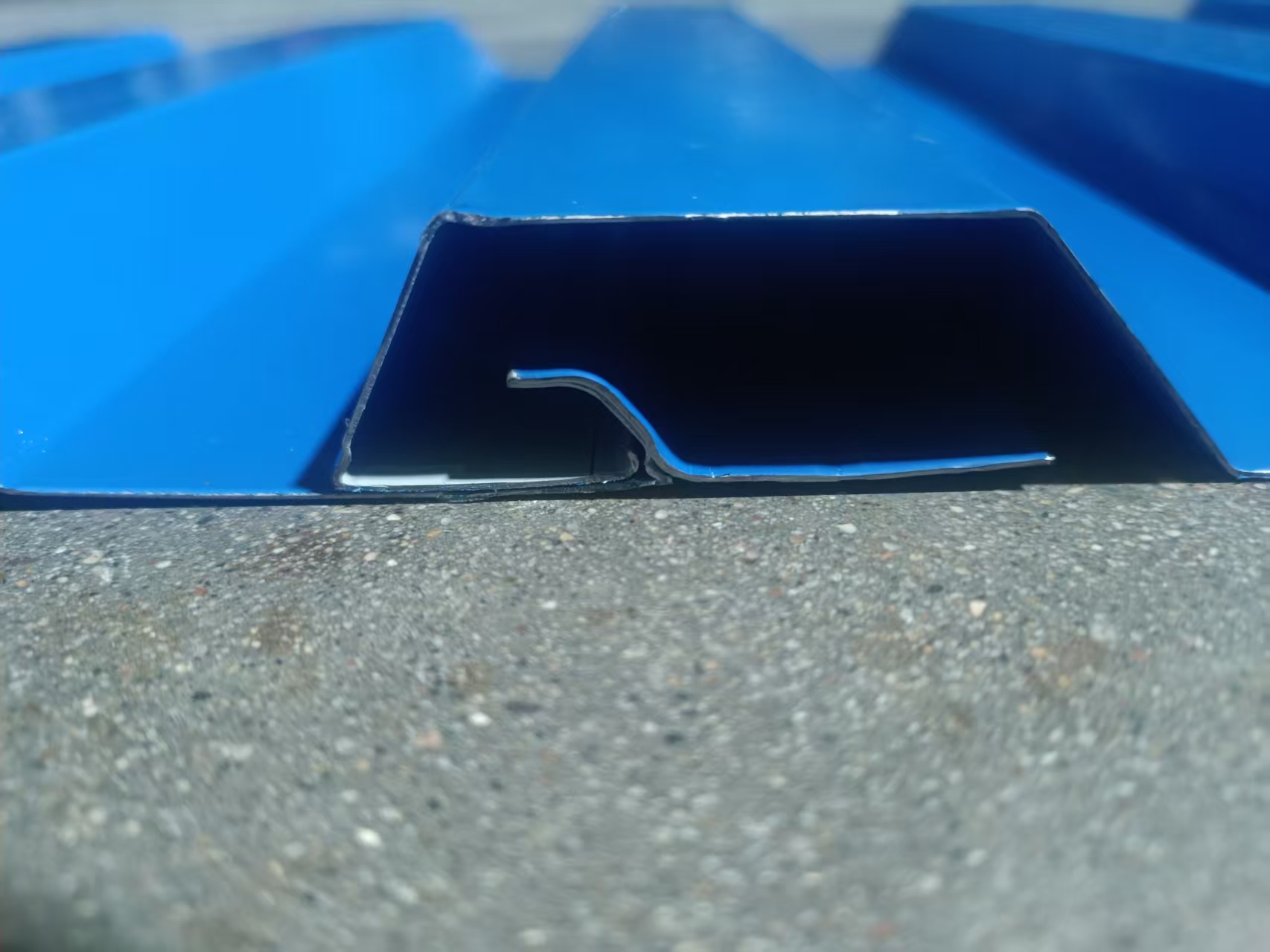

Finished product image:

Application Scenario:

1. Residential buildings:

The lightweight partition boards, insulation wall panels and other products produced can be widely used in indoor partition walls, external wall insulation projects of residential projects such as commercial housing, affordable housing, and rural self built houses. They have the advantages of lightweight, sound insulation, environmental protection and safety, and can improve the comfort of residential living.

2. Commercial buildings:

Suitable for the wall decoration needs of commercial projects such as office buildings, shopping malls, hotels, etc., the produced fireproof and explosion-proof wall panels and soundproof wall panels can meet the strict requirements of commercial buildings for fire safety and sound insulation effects. At the same time, the standardized production of wall panels is easy to install and can shorten the construction period.

3. Public buildings:

Suitable for the construction of public facilities such as hospitals, schools, sports centers, libraries, etc., the produced environmentally friendly wall panels and antibacterial wall panels meet the high requirements of public buildings for health and environmental protection. The thermal insulation, fire and sound insulation performance can ensure the safety and comfort of public space use.

4. Industrial buildings:

The load-bearing wall panels and firewall panels produced can be applied to the wall construction of industrial buildings such as factories and warehouses. They have the characteristics of high strength, fire and moisture resistance, corrosion resistance, etc., and can adapt to the special needs of industrial production environments, ensuring the structural safety of industrial buildings.