Basic introduction of floor bearing machine

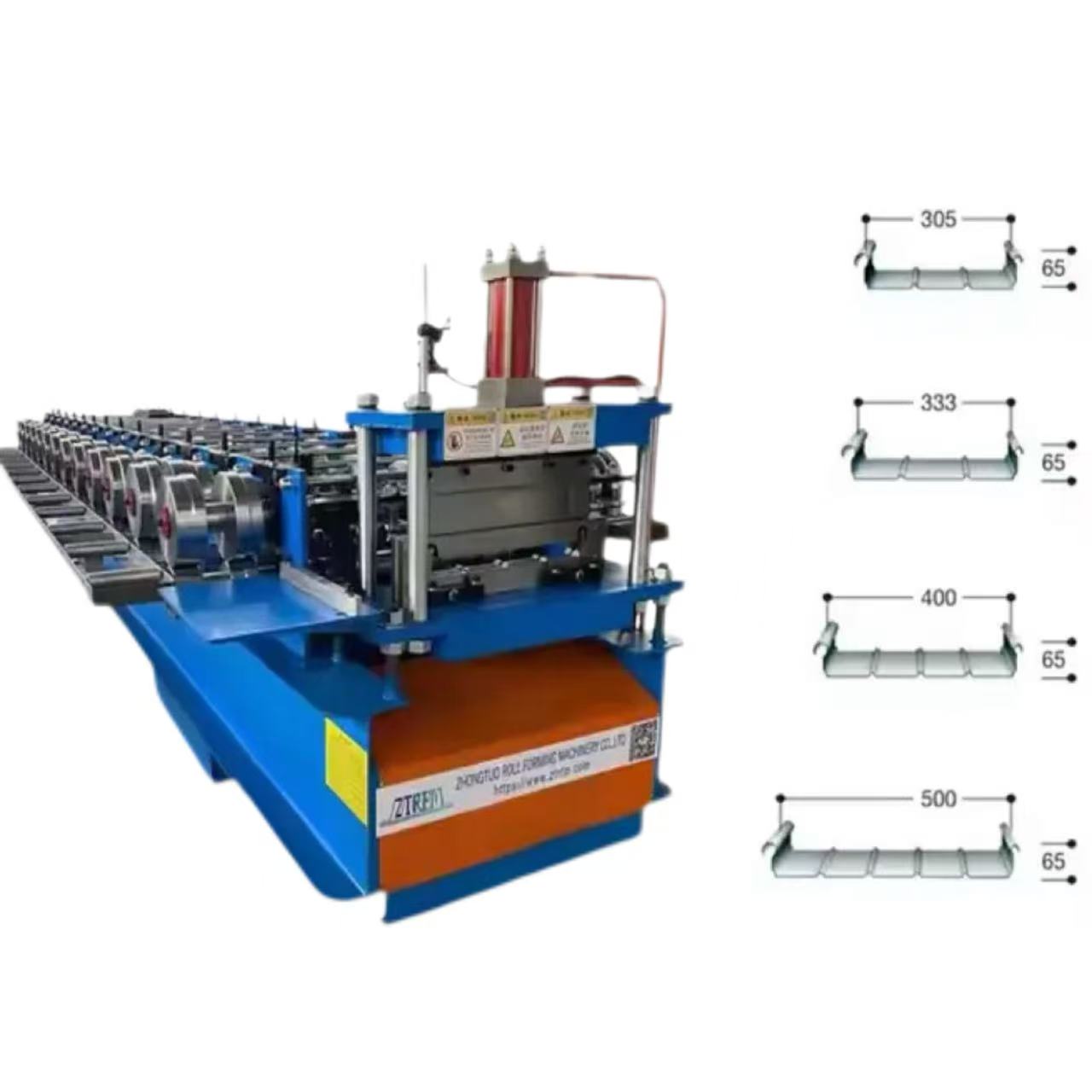

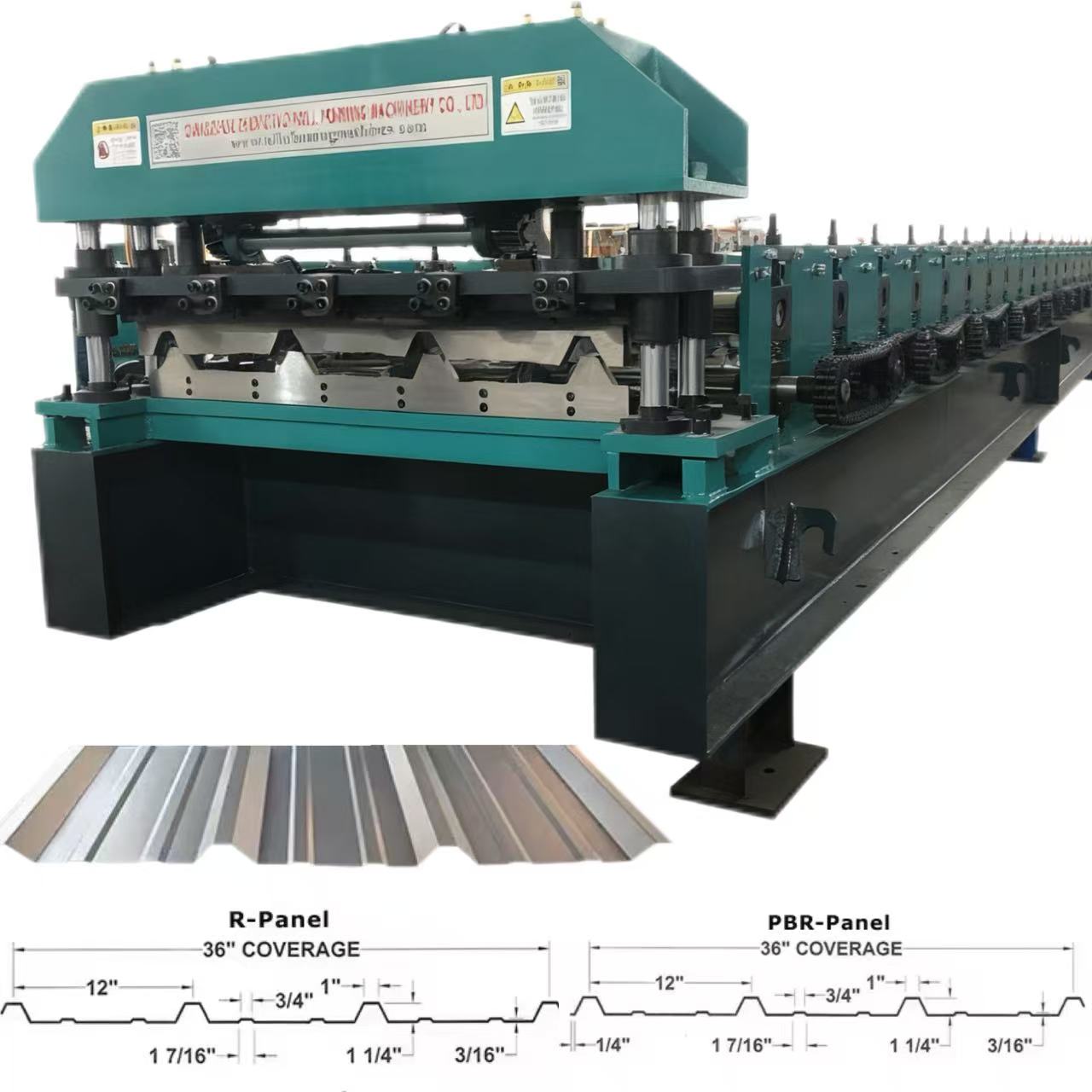

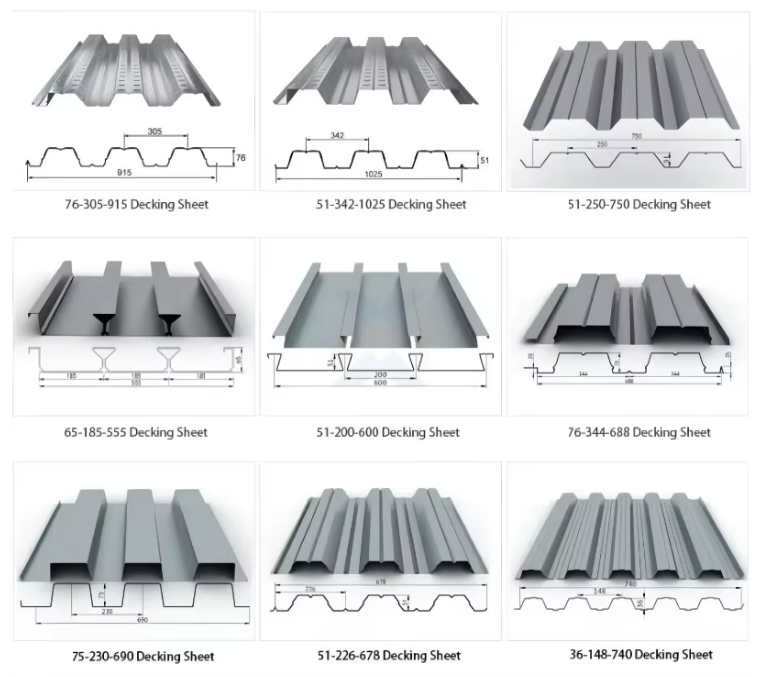

The floor plate machine is a type of metal processing equipment specially used for the production of floor plates. There are various types, including open floor plate bearing machine, closed floor plate bearing machine and dovetail floor plate bearing machine. Different types of floor plate bearing machines have slight differences in construction and functionality to meet different building needs. For example, the floor bearing plate produced by the open floor plate bearing machine has good bearing capacity and construction convenience, and is often used in industrial plants, warehouses and other buildings; The floor bearing plate produced by the closed floor plate bearing machine has good sealing, superior fire resistance and waterproof performance, and is mostly used in commercial buildings and high-rise buildings; The floor plates produced by dovetail floor plate bearing machines have a unique connection method, which can enhance the integrity between floor bearing plates.

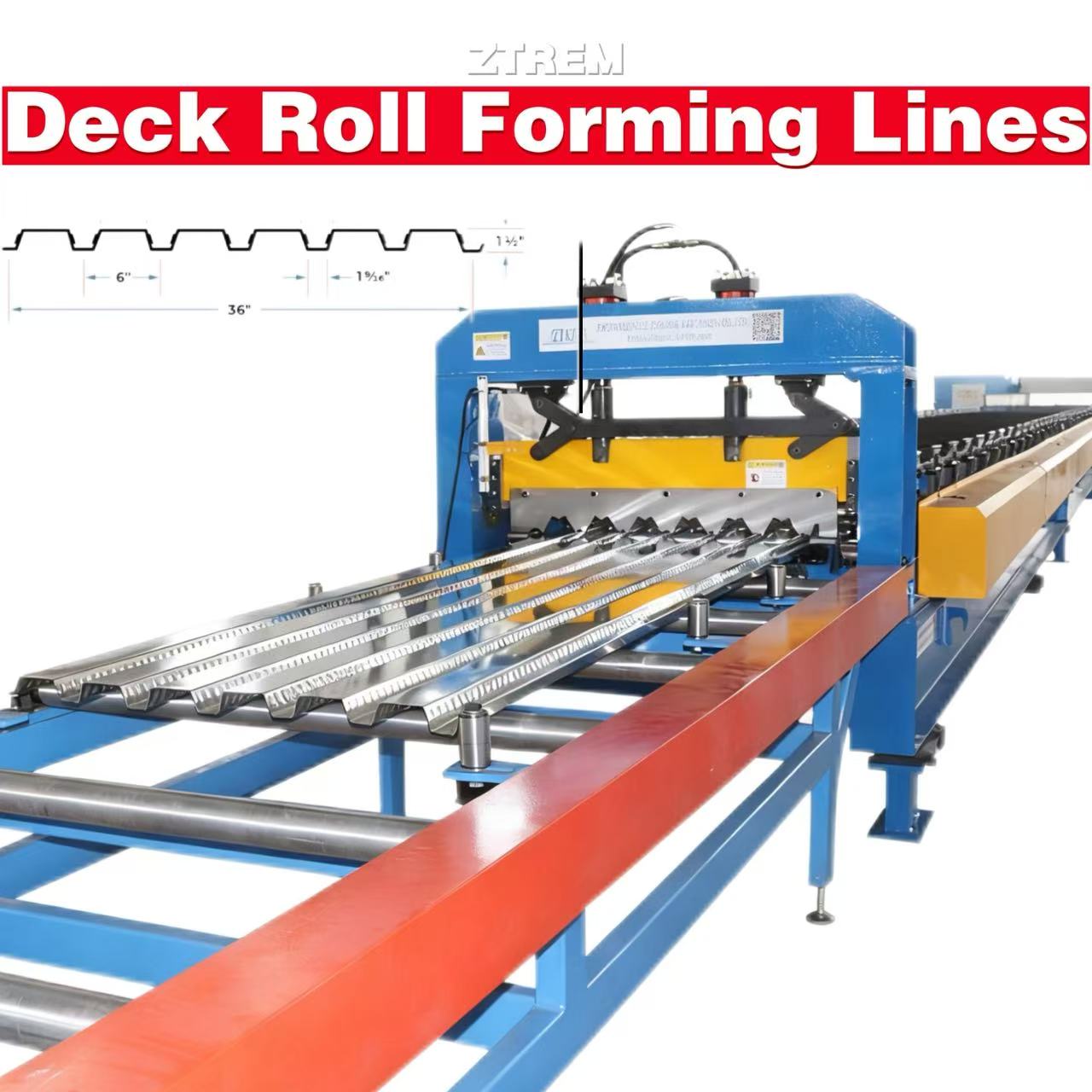

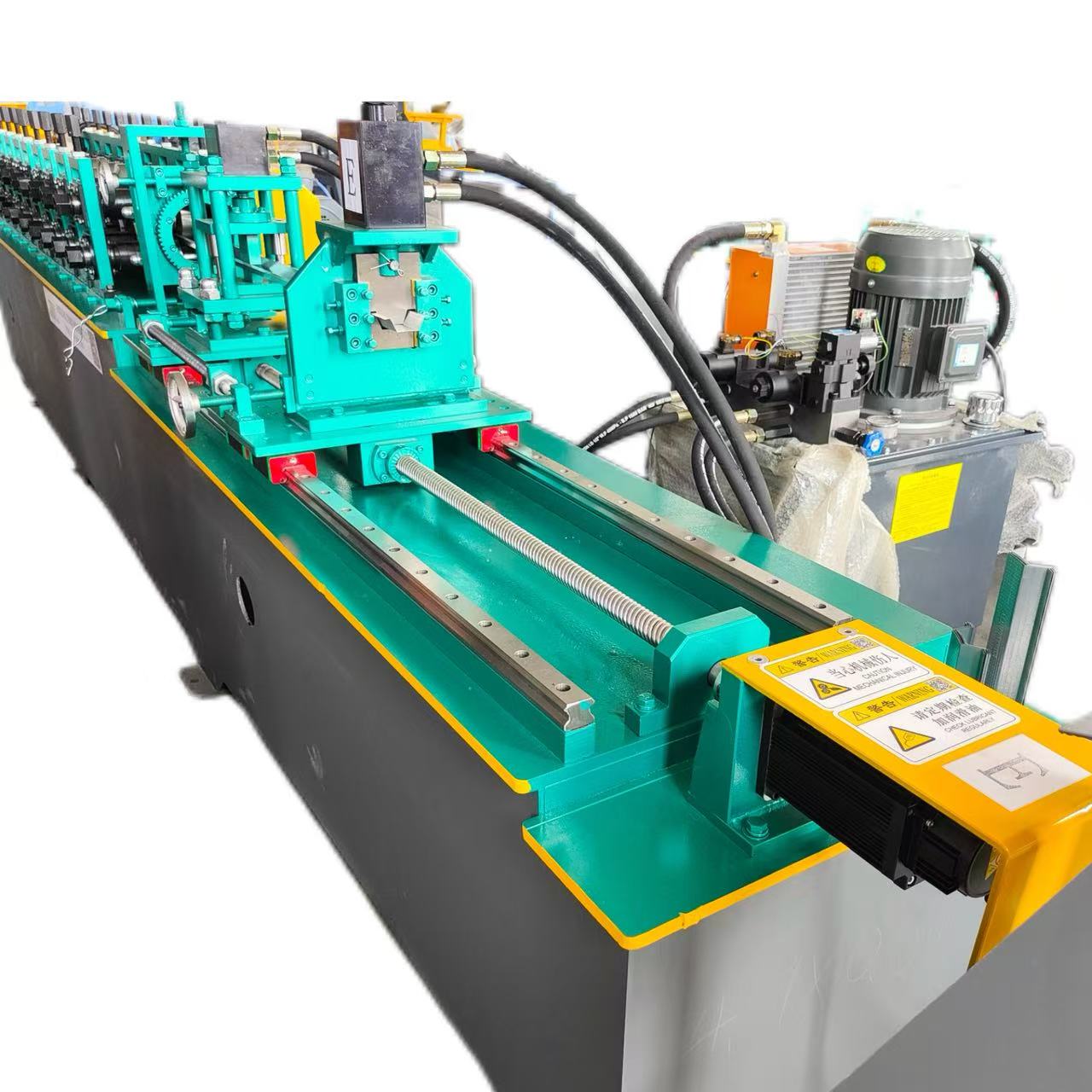

The main components of the floor plate bearing machine include the discharge system, forming system, cutting system and control system. The discharge system is responsible for smoothly unfolding and transporting the metal coil to the forming system; The forming system is the core part of the floor plate bearing machine, which continuously cold-forming the sheet metal through a series of high-precision rollers to achieve the desired shape and size; The cutting system accurately cuts off the formed floor bearing plate according to the set length; The control system is used to monitor and adjust the entire production process, ensuring the stable operation of equipment and the consistency of product quality.

Advantages of floor plate bearing machine

1.Efficient production capacity

The floor bearing plate machine adopts advanced automation technology, has a fast production speed, and can complete the production of a large number of floor bearing plates in a short period of time. Compared with traditional manual or semi-automated production methods, the production efficiency of floor plate bearing machines can be increased by several times or even dozens of times. For example, some advanced floor bearing machines can produce several meters of floor bearing plates per minute, which greatly shortens the construction period of construction projects and improves the project schedule.

2.Stable product quality

During the production process, the floor bearing machine can strictly control the dimensional accuracy and shape accuracy of the floor bearing plate through high-precision rollers and advanced control systems, ensuring that the quality of each floor bearing plate is stable and reliable. The size deviation of the floor bearing plate produced by it is extremely small, the surface flatness is high, and the waveform is uniform and consistent, so as to ensure the bearing capacity and stability of the floor bearing plate in the building structure. Compared with the manually made floor slab, the quality of the floor bearing slab produced by the machine is more stable, which can effectively reduce the engineering hidden dangers caused by quality problems.

3.Wide material adaptability

The floor plate bearing machine can process a variety of metal materials, such as galvanized steel plate, cold-rolled steel plate, color-coated steel plate, etc., and can also choose the appropriate material thickness and strength grade according to different building needs and design requirements. This wide range of material adaptability allows floor plate machines to meet the needs of various types of construction projects, whether it is industrial, commercial, or civil buildings, to find suitable floor panel solutions.

4.Significant energy-saving and environmental protection characteristics

In the production process, the floor plate bearing machine can effectively save energy consumption due to the cold forming process, which does not require heat treatment of the metal sheet. Compared with the hot processing process, the cold forming process not only consumes less energy, but also reduces the emission of pollutants such as exhaust gas and waste residue generated by the heating process, which is in line with the development concept of modern energy conservation and environmental protection. At the same time, the floor bearing plate produced by the floor bearing machine can also play a certain role in energy conservation and environmental protection in building use, such as galvanized floor bearing plate has good anti-corrosion performance, which can extend the service life of the building structure, reduce the cost of building maintenance and replacement, and indirectly achieve energy conservation and environmental protection.

Application fields of floor plate bearing machine

1.Industrial construction sector

In industrial buildings such as industrial plants, warehouses, workshops, etc., the floor bearing plates produced by floor bearing plate machines have been widely used. As the load-bearing structure of the floor, the floor bearing plate has the characteristics of high strength and large bearing capacity, which can meet the requirements of large span and heavy load in industrial buildings. At the same time, the rapid installation and construction convenience of floor bearing slabs can also effectively shorten the construction cycle of industrial buildings, reduce construction costs, and enable enterprises to put into production and operation faster.

2.In the field of commercial construction

In commercial buildings such as commercial complexes, shopping malls, and office buildings, the floor plates produced by the floor plate bearing machine also play an important role. The floor bearing plate not only provides reliable structural support for commercial buildings, but also can be combined with the decoration and decoration of the building to create a beautiful and comfortable commercial space. For example, the sealing of the closed floor bearing plate is good, which can effectively prevent dust, noise and other pollution, and provide a good indoor environment for commercial buildings. The color-coated floor bearing panels have rich colors and beautiful appearances, which can add a unique visual effect to commercial buildings.

3.Civil construction field

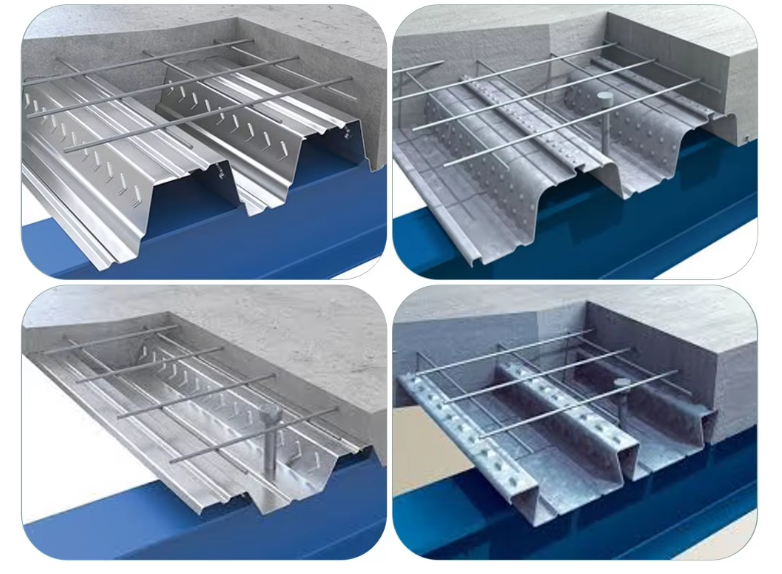

In residential buildings, apartments, villas and other civil buildings, the floor plates produced by floor plate machines are also gradually applied. The floor bearing slab has the characteristics of light weight and high strength, which can reduce the weight of the building and reduce the cost of infrastructure construction. At the same time, the construction speed of the floor bearing slab is fast, which can reduce the wet operation on the construction site, reduce the impact of construction on the surrounding environment, and improve the quality of life of residents. In addition, the floor bearing slab can also be combined with cast-in-place concrete to form a composite floor slab, which improves the seismic performance and sound insulation performance of the floor slab and provides residents with a safer and more comfortable living environment.

4.In the field of public buildings

In public buildings such as gymnasiums, exhibition halls, airport terminals, and railway stations, the floor plates produced by floor plate bearing machines are widely used due to their unique advantages. Public buildings usually have the characteristics of large space and large span, and the floor bearing panel can well meet the requirements of these building structures and provide reliable bearing capacity. At the same time, the rapid installation and construction convenience of floor bearing slabs can also ensure that public building projects are successfully completed within the specified time to meet the society’s demand for public facilities.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.5-1.0mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

24 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

22000*2500*1800(customize)

|

|||

|

Weight

|

13T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

Speed is adjustable

|

||