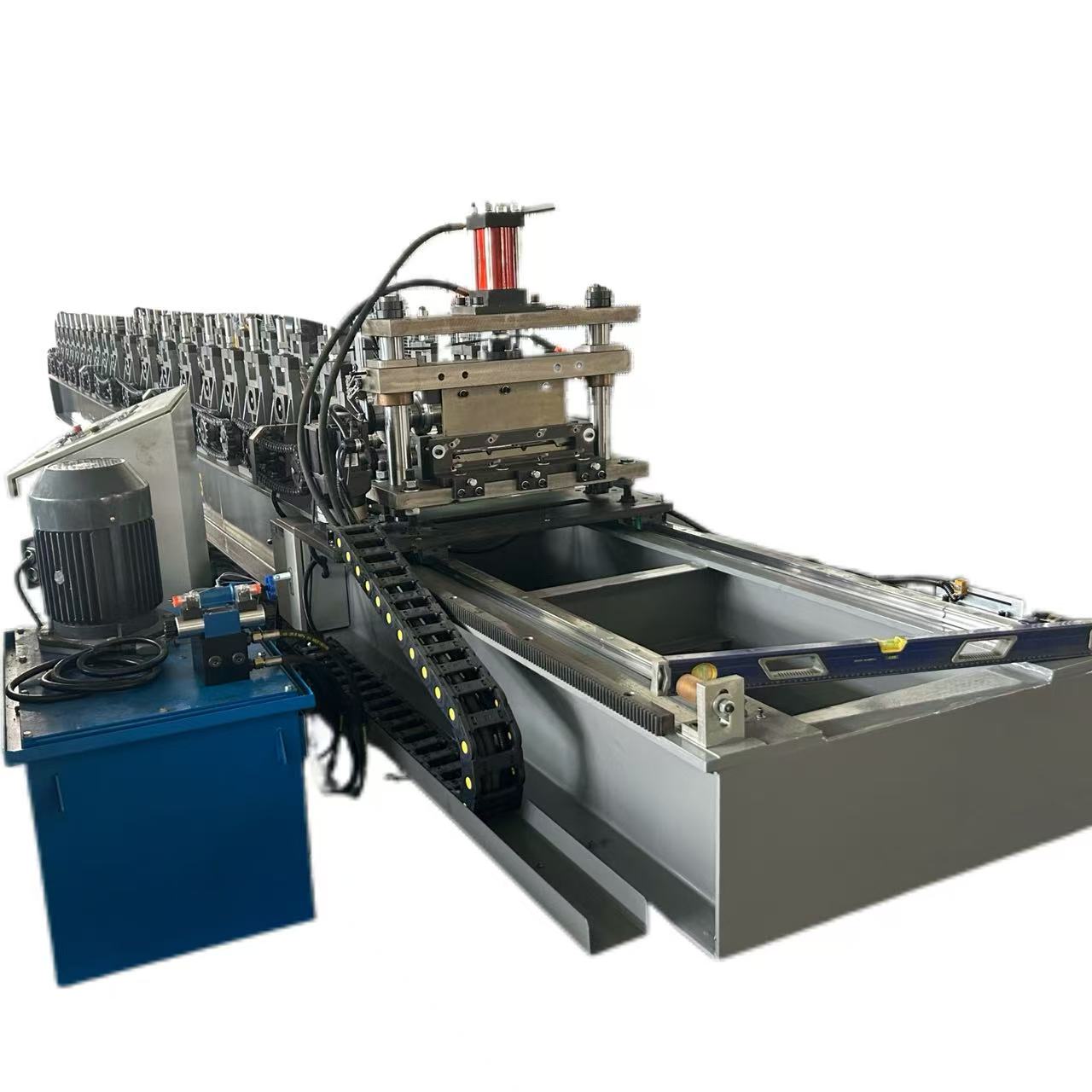

Ridge cap roll forming machine, also known as roll cold bending equipment, is mainly used to process metal plates and metal strips into the required cross-sectional shape, such as roof tiles. This machine bends metal materials into shape by connecting them in a series of forming mills. The working principle is to place the raw materials on the feeding device, adjust the position and tension through the adjustment sleeve, and then the materials enter the forming roll system. Driven by the transmission system, the forming rollers roll and bend the material to form the shape of the roof tile. Then, the formed ridge cap enters the cutting device and is cut according to the preset length to obtain the finished ridge cap. The ridge cap roll forming machine is widely used in the production of ridge tiles for various industrial plants, residential buildings, warehouses, and simple steel shed roofs. Its advantages include high production efficiency, high yield, easy operation, saving human resources, and reducing labor costs.

The main features of the machine are:

- Efficient production:

The ridge cap roll forming machine adopts computer motherboards, relays, and frequency converters, with high production efficiency, which can reach 5-8 meters per minute. For example, when pressing flat tiles, about 1500 pieces can be produced per hour. - High degree of automation:

The entire production process, from feeding raw materials to sending out formed tiles, is automatically controlled by a program, without the need for manual operation. Only the tiles automatically sent to the picking table need to be taken away. This not only reduces manual operation, but also solves the problem of the ridge cap roll forming machine potentially injuring the operator’s fingers, improving safety. - Energy saving and fuel-efficient:

The machine is designed to save energy and automatically apply release oil, reducing the amount of oil used. In addition, the tile blanks do not require manual trimming and can be directly shelved without the need for tile pallets, further saving costs. - Multifunctionality:

By replacing the corresponding molds, the ridge cap roll forming machine can produce different varieties and specifications of bricks and tiles, such as square tiles, face tiles, antique tiles, flat tiles, hanging tiles, Bo tiles, board tiles, tube tiles, three curved tiles, ridge tiles, ditch tiles, etc. - High quality products:

The brick and tile products produced are smooth, shiny, beautiful and generous, and are welcomed by customers. In addition, the product has a smooth and beautiful appearance, uniform paint patterns, high strength, and durability, and is widely used in industrial and civil buildings.

Pattern diagram:

Application scenarios:

1.Temple architecture:

Due to the use of ancient architectural styles in temples, ridge cap roll forming machines have been widely used in the production of antique roof tiles. This type of tile not only meets the style requirements of temple architecture, but also provides strong protection.2.High end residential buildings:

Modern high-end residential buildings often adopt ancient architectural styles to showcase luxury and elegance. The ridge cap roll forming machine can produce roof tiles that conform to this style, meeting the decoration needs of high-end residential buildings.3.Exhibition Hall:

The exhibition hall often receives foreign tourists, and the classical architectural style roof tiles can better showcase the Chinese style, enhance the overall beauty and cultural atmosphere of the exhibition hall.4.Rural self built housing:

In rural areas, self built housing requires a beautiful and durable roof solution. The ridge cap roll forming machine can produce tiles in various colors and styles to meet the needs of self built houses in rural areas, providing sturdy protection and good appearance.5.Farmhouse and homestay:

For rural families who operate farmhouses or homestays, the ridge caps produced by machine can not only enhance the beauty of the building, but also ensure the safety and comfort of the house, providing tourists with a good accommodation experience.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness: 0.4-0.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler (will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows (As your requirement)

|

||

|

Diameter of shaft

|

65mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

about 5500*1600*1600(customize)

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW, servo motor

|

||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

10-15m/min

|

The speed can be adjusted as customer’s request

|

||